Development and Validation of a Test Mold for Thermoplastic Resin Transfer Molding of Reactive PA-6

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

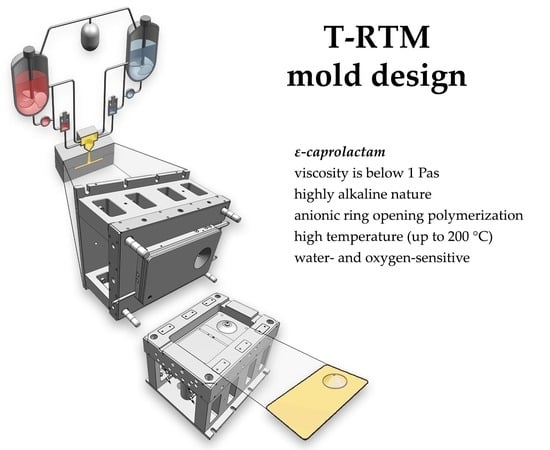

2.2. T-RTM Equipment

2.3. The Concept of Designing a T-RTM Mold

3. Results and Discussion

3.1. Details of the Design Process of the T-RTM Mold

3.1.1. Product Design

3.1.2. Process Requirements

3.1.3. Determining the Geometry and Structure of the Mold

3.1.4. Mold Materials Selection

3.2. Testing of the T-RTM Mold

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AROP | anionic ring opening polymerization |

| HP | high pressure |

| LCM | liquid composite molding |

| LP | low pressure |

| PA | polyamide |

| RIM | reactive injection molding |

| T-RTM | thermoplastic resin transfer molding |

| ε-CL | ε-caprolactam |

References

- Van Rijswijk, K.; Bersee, H.E.N. Reactive processing of textile fiber-reinforced thermoplastic composites—An overview. Compos. Part A Appl. Sci. Manuf. 2007, 38, 666–681. [Google Scholar] [CrossRef]

- Ageyeva, T.; Sibikin, I.; Karger-Kocsis, J. Polymers and related composites via anionic ring-opening polymerization of lactams: Recent developments and future trends. Polymers 2018, 10, 357. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sibikin, I.; Karger-Kocsis, J. Toward industrial use of anionically activated lactam polymers: Past, present and future. Adv. Ind. Eng. Polym. Res. 2018, 1, 48–60. [Google Scholar] [CrossRef]

- Kim, B.-J.; Cha, S.-H.; Park, Y.-B. Ultra-high-speed processing of nanomaterial-reinforced woven carbonfiber/polyamide 6 composites using reactive thermoplastic resin transfer molding. Compos. Part B Eng. 2018, 143, 36–46. [Google Scholar] [CrossRef]

- Gilbert, M. Aliphatic polyamides. In Brydson’s Plastics Materials; Gilbert, M., Ed.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 487–511. [Google Scholar] [CrossRef]

- Chen, K.; Jia, M.; Hua, S.; Xue, P. Optimization of initiator and activator for reactive thermoplastic pultrusion. J. Polym. Res. 2019, 26, 40. [Google Scholar] [CrossRef]

- Schmidhuber, S.; Fries, E.; Zimmermann, P. It couldn’t be more hybrid. Thermoplastic matrix rtm on the roof frame of the roading roadster. Kunst. Int. 2017, 1–2, 36–38. [Google Scholar]

- Bitterlich, M.; Ehleben, M.; Wollny, A.; Desbois, P.; Renkl, J.; Schmidhuber, S. Tailored to reactive polyamide 6. Kunst. Int. 2014, 3, 47–51. [Google Scholar]

- Sealy, C. Molding the future: Engel takes composite approach to composites. Reinf. Plast. 2016, 60, 138–141. [Google Scholar] [CrossRef]

- Ageyeva, T.; Horváth, S.; Kovács, J.G. In-mold sensors for injection molding: On the way to industry 4.0. Sensors 2019, 19, 3551. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Puffr, R.; Kubanek, V. Equipment for the rim process. In Lactam-Based Polyamides; CRC Press: Boca Raton, FL, USA, 1991; pp. 161–164. [Google Scholar]

- Thomassey, M.; Revol, B.P.; Ruch, F.; Schell, J.; Bouquey, M. Interest of a Rheokinetic Study for the Development of Thermoplastic Composites by T-RTM. Univ. J. Mater. Sci. 2017, 5, 15–27. [Google Scholar] [CrossRef] [Green Version]

- Van Rijswijk, K. Thermoplastic Composite Wind Turbine Blades. Vacuum Infusion Technology for Anionic Polyamide-6 Composites. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 2007. [Google Scholar]

- Kazmer, D.O. Injection Mold Design Engineering; Hanser: Munich, Germany, 2007; p. 423. [Google Scholar]

- Mennig, G.; Stoeckhert, K. Mold-Making Handbook, 3rd ed.; Hanser: Munich, Germany, 2013; p. 701. [Google Scholar]

- Potter, K. RTM mould tool design. In Resin Transfer Moulding; Springer Netherlands: Dordrecht, The Netherlands, 1997; pp. 74–145. [Google Scholar] [CrossRef]

- Boros, R.; Kannan Rajamani, P.; Kovacs, J.G. Combination of 3D printing and injection molding: Overmolding and overprinting. Express Polym. Lett. 2019, 13, 889–897. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boros, R.; Sibikin, I.; Ageyeva, T.; Kovács, J.G. Development and Validation of a Test Mold for Thermoplastic Resin Transfer Molding of Reactive PA-6. Polymers 2020, 12, 976. https://doi.org/10.3390/polym12040976

Boros R, Sibikin I, Ageyeva T, Kovács JG. Development and Validation of a Test Mold for Thermoplastic Resin Transfer Molding of Reactive PA-6. Polymers. 2020; 12(4):976. https://doi.org/10.3390/polym12040976

Chicago/Turabian StyleBoros, Róbert, Ilya Sibikin, Tatyana Ageyeva, and József Gábor Kovács. 2020. "Development and Validation of a Test Mold for Thermoplastic Resin Transfer Molding of Reactive PA-6" Polymers 12, no. 4: 976. https://doi.org/10.3390/polym12040976

APA StyleBoros, R., Sibikin, I., Ageyeva, T., & Kovács, J. G. (2020). Development and Validation of a Test Mold for Thermoplastic Resin Transfer Molding of Reactive PA-6. Polymers, 12(4), 976. https://doi.org/10.3390/polym12040976