Acrylic Bone Cements Modified with Graphene Oxide: Mechanical, Physical, and Antibacterial Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis and Characterization of GO

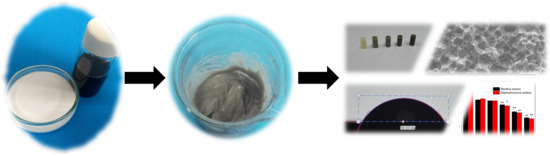

2.3. Preparation of ABCs

2.4. Characterization of ABCs

2.4.1. Fourier Transform Infrared (FTIR)

2.4.2. Thermogravimetric Analysis (TGA)

2.4.3. Scanning Electron Microscope (SEM)

2.4.4. Water Contact Angle (WCA)

2.4.5. Handling Properties

2.4.6. Mechanical Properties

2.4.7. Dynamic Mechanical Analysis (DMA)

2.4.8. Residual Monomer Content (RMC)

2.4.9. Antimicrobial Activity

2.5. Statistical Analysis

3. Results and Discussion

3.1. GO Characterization

3.2. Characterization of ABCs

3.2.1. FTIR

3.2.2. TGA

3.2.3. SEM

3.2.4. Water Contact Angle (WCA)

3.2.5. Handling Properties

3.2.6. Mechanical Properties

3.2.7. DMA and RMC

3.2.8. Antibacterial Activity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Eil Bakhtiari, S.S.; Bakhsheshi-Rad, H.R.; Karbasi, S.; Tavakoli, M.; Razzaghi, M.; Fauzi Ismail, A.; Ramakrishna, S.; Berto, F. Polymethyl Methacrylate-Based Bone Cements Containing Carbon Nanotubes and Graphene Oxide: An Overview of Physical, Mechanical, and Biological Properties. Polymers 2020, 12, 1469. [Google Scholar] [CrossRef] [PubMed]

- Tavakoli, M.; Bakhtiari, S.S.E.; Karbasi, S. Incorporation of chitosan/graphene oxide nanocomposite in to the PMMA bone cement: Physical, mechanical and biological evaluation. Int. J. Biol. Macromol. 2020, 149, 783–793. [Google Scholar] [CrossRef] [PubMed]

- Vazquez-Lasa, B. Poly(methylmethacrylate) Bone Cement: Chemical Composition and Chemistry. In Orthopaedic Bone Cements; Deb, S., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2008. [Google Scholar]

- Dunne, N.J.; Orr, J.F.; Road, S.; Ireland, N. Curing characteristics of acrylic bone cement. J. Mater. Sci. Mater. Med. 2002, 13, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Shen, S.-C.; Ng, W.K.; Dong, Y.-C.; Ng, J.; Tan, R.B.H. Nanostructured material formulated acrylic bone cements with enhanced drug release. Mater. Sci. Eng. C 2016, 58, 233–241. [Google Scholar] [CrossRef]

- Magnan, B.; Bondi, M.; Maluta, T.; Samaila, E.; Schirru, L.; Dall’Oca, C. Acrylic bone cement: Current concept review. Musculoskelet. Surg. 2013, 97, 93–100. [Google Scholar] [CrossRef]

- Maleki Dizaj, S.; Mennati, A.; Jafari, S.; Khezri, K.; Adibkia, K. Antimicrobial activity of carbon-based nanoparticles. Adv. Pharm. Bull. 2015, 5, 19–23. [Google Scholar]

- Lu, N.; Li, Z. Chapter 5. Graphene Oxide: Theoretical Perspectives. In Quantum Simulations of Materials and Biological Systems; Springer: Dordrecht, The Netherlands, 2012; pp. 69–84. [Google Scholar]

- Hu, W.; Peng, C.; Luo, W.; Lv, M.; Li, X.; Li, D.; Huang, Q.; Fan, C. Graphene-based antibacterial paper. ACS Nano 2010, 4, 4317–4323. [Google Scholar] [CrossRef]

- Mukherjee, S.P.; Gliga, A.R.; Lazzaretto, B.; Brandner, B.; Fielden, M.; Vogt, C.; Newman, L.; Rodrigues, A.F.; Shao, W.; Fournier, P.M.; et al. Graphene oxide is degraded by neutrophils and the degradation products are non-genotoxic. Nanoscale 2018, 10, 1180–1188. [Google Scholar] [CrossRef] [Green Version]

- Girish, C.M.; Sasidharan, A.; Gowd, G.S.; Nair, S.; Koyakutty, M. Confocal raman imaging study showing macrophage mediated biodegradation of graphene in vivo. Adv. Healthc. Mater. 2013, 2, 1489–1500. [Google Scholar] [CrossRef]

- Palmieri, V.; Papi, M.; Conti, C.; Ciasca, G.; Maulucci, G.; De Spirito, M.; Palmieri, V.; Papi, M.; Conti, C.; Ciasca, G.; et al. The future development of bacteria fighting medical devices: The role of graphene oxide The future development of bacteria fighting medical devices: The role of graphene oxide. Expert Rev. Med. Devices 2016, 13, 1013–1019. [Google Scholar] [CrossRef]

- Khan, A.A.; Mirza, E.H.; Mohamed, B.A.; El-Sharawy, M.A.; Hasil Al-Asmari, M.; Abdullah Al-Khureif, A.; Ahmad Dar, M.; Vallittu, P.K. Static and dynamic mechanical properties of graphene oxide-based bone cementing agents. J. Compos. Mater. 2019, 53, 2297–2304. [Google Scholar] [CrossRef]

- Khan, A.A.; Mirza, E.H.; Mohamed, B.A.; Alharthi, N.H.; Abdo, H.S.; Javed, R.; Alhur, R.S.; Vallittu, P.K. Physical, mechanical, chemical and thermal properties of nanoscale graphene oxide-poly methylmethacrylate composites. J. Compos. Mater. 2018, 52, 2803–2813. [Google Scholar] [CrossRef]

- Paz, E.; Forriol, F.; del Real, J.C.; Dunne, N. Graphene oxide versus graphene for optimisation of PMMA bone cement for orthopaedic applications. Mater. Sci. Eng. C 2017, 77, 1003–1011. [Google Scholar] [CrossRef] [PubMed]

- Valencia Zapata, M.E.; Mina Hernandez, J.H.; Grande Tovar, C.D.; Valencia Llano, C.H.; Diaz Escobar, J.A.; Vazquez-Lasa, B.; San Roman, J.; Rojo, L. Novel Bioactive and Antibacterial Acrylic Bone Cement Nanocomposites Modified with Graphene Oxide and Chitosan. Int. J. Mol. Sci. 2019, 20, 2938. [Google Scholar] [CrossRef] [Green Version]

- Paz, E.; Ballesteros, Y.; Abenojar, J.; Del Real, J.C.; Dunne, N.J. Graphene Oxide and Graphene Reinforced PMMA Bone Cements: Evaluation of Thermal Properties and Biocompatibility. Mol. Divers. Preserv. Int. 2019, 12, 3146. [Google Scholar] [CrossRef] [Green Version]

- Mirza, E.H.; Khan, A.A.; Al-Khureif, A.A.; Saadaldin, S.A.; Mohamed, B.A.; Fareedi, F.; Khan, M.M.; Alfayez, M.; Al-Fotawi, R.; Vallittu, P.K.; et al. Characterization of osteogenic cells grown over modified grapheneoxide-biostable polymers. Biomed. Mater. 2019, 14, 065004. [Google Scholar] [CrossRef]

- Gonçalves, G.; Portolés, M.-T.; Ramírez-Santillán, C.; Vallet-Regí, M.; Serro, A.P.; Grácio, J.; Marques, P.A.A.P. Evaluation of the in vitro biocompatibility of PMMA/high-load HA/carbon nanostructures bone cement formulations. J. Mater. Sci. Mater. Med. 2013, 24, 2787–2796. [Google Scholar] [CrossRef]

- Paz, E.; Ballesteros, Y.; Forriol, F.; Dunne, N.J.; del Real, J.C. Graphene and graphene oxide functionalisation with silanes for advanced dispersion and reinforcement of PMMA-based bone cements. Mater. Sci. Eng. C 2019, 104, 109946. [Google Scholar] [CrossRef]

- International Standard ISO 5833: Implants for Surgery-Acrylic Resin Cements; ISO: Geneva, Switzerland, 2002; pp. 1–22.

- Muniyalakshmi, M.; Sethuraman, K.; Silambarasan, D. Materials Today: Proceedings Synthesis and characterization of graphene oxide nanosheets. Mater. Today Proc. 2020, 21, 408–410. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, M.; Kumar, A.; Singh, R. Surface modification of Graphene Oxide using Esterification. Mater. Today Proc. 2019, 18, 1556–1561. [Google Scholar] [CrossRef]

- Torrisi, L.; Cutroneo, M.; Havranek, V.; Silipigni, L.; Fazio, B.; Fazio, M.; Marco, G.D.; Stassi, A.; Torrisi, A. Self-supporting graphene oxide films preparation and characterization methods. Vacuum 2019, 160, 1–11. [Google Scholar] [CrossRef]

- Sharma, R.; Kapusetti, G.; Bhong, S.Y.; Roy, P.; Singh, S.K.; Singh, S.; Balavigneswaran, C.K.; Mahato, K.K.; Ray, B.; Maiti, P.; et al. Osteoconductive Amine-Functionalized Graphene-Poly(methyl methacrylate) Bone Cement Composite with Controlled Exothermic Polymerization. Bioconjug. Chem. 2017, 28, 2254–2265. [Google Scholar] [CrossRef]

- Gonçalves, G.; Cruz, S.M.A.; Ramalho, A.; Grácio, J.; Marques, P.A.A.P. Graphene oxide versus functionalized carbon nanotubes as a reinforcing agent in a PMMA/HA bone cement. Nanoscale 2012, 4, 2937–2945. [Google Scholar] [CrossRef] [PubMed]

- Akhavan, O.; Ghaderi, E. Toxicity of graphene and graphene oxide nanowalls against bacteria. ACS Nano 2010, 4, 5731–5736. [Google Scholar] [CrossRef] [PubMed]

- Perreault, F.; Fonseca de Faria, A.; Nejati, S.; Elimelech, M. Antimicrobial Properties of Graphene Oxide Nanosheets: Why Size Matters. ACS Nano 2015, 9, 7226–7236. [Google Scholar] [CrossRef]

- Gurunathan, S.; Han, J.W.; Abdal Dayem, A.; Eppakayala, V.; Kim, J.H. Oxidative stress-mediated antibacterial activity of graphene oxide and reduced graphene oxide in Pseudomonas aeruginosa. Int. J. Nanomed. 2012, 7, 5901–5914. [Google Scholar] [CrossRef] [Green Version]

- Velasco-Soto, M.A.; Pérez-García, S.A.; Alvarez-Quintana, J.; Cao, Y.; Nyborg, L.; Licea-Jiménez, L. Selective band gap manipulation of graphene oxide by its reduction with mild reagents. Carbon N. Y. 2015, 93, 967–973. [Google Scholar] [CrossRef] [Green Version]

- Gamze, Z.; Doğan, M. Characterization and thermal kinetic analysis of PMMA/modified-MWCNT nanocomposites. Diam. Relat. Mater. 2020, 108, 107950. [Google Scholar]

- Angelopoulou, A.; Efthimiadou, E.K.; Boukos, N.; Kordas, G. A new approach for the one-step synthesis of bioactive PS vs. PMMA silica hybrid microspheres as potential drug delivery systems. Colloid Surf. B 2014, 117, 322–329. [Google Scholar] [CrossRef]

- Alves, F.; Brena, S.; Fontele, C.; Karine, L.; Santos, B.; Alves, L.; Marcelo, J.; Castro, D.; Carlos, J.; Gonçalves, R.; et al. Synthesis, characterization of α -terpineol-loaded PMMA nanoparticles as proposed of therapy for melanoma. Mater. Today Commun. 2020, 22, 100762. [Google Scholar] [CrossRef]

- Valencia Zapata, M.E.; Mina Hernandez, J.H.; Grande Tovar, C.D. Acrylic Bone Cement Incorporated with Low Chitosan Loadings. Polymers (Basel) 2020, 12, 1617. [Google Scholar] [CrossRef] [PubMed]

- Tadano, T.; Zhu, R.; Suzuki, S.; Hoshi, T.; Sasaki, D.; Hagiwara, T.; Sawaguchi, T. Thermal degradation of transparent poly (methyl methacrylate)/silica nanoparticle hybrid fi lms. Polym. Degrad. Stab. 2014, 109, 7–12. [Google Scholar] [CrossRef]

- Xiong, S.Y.; Xu, Y.M.; Jiao, Y.H.; Wang, L.; Li, M.Z. Effects of Gamma Irradiation on the Structure and Mechanical Properties of Wild Silkworms and Bombyx Mori Silk Fibroin Films. Adv. Mater. Res. 2011, 197–198, 27–31. [Google Scholar] [CrossRef]

- Kieswetter, K.; Schwartz, Z.; Hummert, T.W.; Cochran, D.L.; Simpson, J.; Dean, D.D.; Boyan, B.D. Surface roughness modulates the local production of growth factors and cytokines by osteoblast-like MG-63 cells. J. Biomed. Mater. Res. 1996, 32, 55–63. [Google Scholar] [CrossRef]

- Lampin, M.; Legris, C.; Degrange, M.; Sigot-Luizard, M.F.; Warocquier-Clerout, R.; Legris, C.; Degrange, M.; Sigot-Luizard, M.F. Correlation between substratum roughness and wettability, cell adhesion, and cell migration. J. Biomed. Mater. Res. 1997, 36, 99–108. [Google Scholar] [CrossRef]

- Shen, J.; Shi, M.; Ma, H.; Yan, B.; Li, N.; Hu, Y.; Ye, M. Synthesis of hydrophilic and organophilic chemically modified graphene oxide sheets. J. Colloid Interface Sci. 2010, 351, 366–370. [Google Scholar] [CrossRef] [PubMed]

- Sugita, Y.; Okubo, T.; Saita, M.; Ishijima, M.; Rezaei, N.M.; Taniyama, T.; Sato, N.; Saruta, J.; Maeda, H.; Ogawa, T. Novel Osteogenic Behaviors around Hydrophilic and Radical-Free 4-META/MMA-TBB: Implications of an Osseointegrating Bone Cement. Int. J. Mol. Sci. 2020, 21, 2405. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoshinari, M.; Wei, J.; Matsuzaka, K.; Inoue, T. Effect of cold plasma-surface modification on surface wettability and initial cell attachment. World Acad. Sci. Eng. Technol. 2009, 58, 171–175. [Google Scholar]

- Chen, S.; Li, L.; Zhao, C.; Zheng, J. Surface hydration: Principles and applications toward low-fouling/non-fouling biomaterials. Polymer (Guildf) 2010, 51, 5283–5293. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.-H.; Jo, J.-K.; Kim, D.-A.; Dev, K.; Kim, H.-W.; Lee, H. Nano-graphene oxide incorporated into PMMA resin to prevent microbial adhesion. Dent. Mater. 2018, 34, 63–72. [Google Scholar] [CrossRef]

- Ormsby, R.W.; Modreanu, M.; Mitchell, C.A.; Dunne, N.J. Carboxyl functionalised MWCNT/polymethyl methacrylate bone cement for orthopaedic applications. J. Biomater. Appl. 2014, 29, 209–221. [Google Scholar] [CrossRef] [PubMed]

- Boner, V.; Kuhn, P.; Mendel, T.; Gisep, A. Temperature Evaluation During PMMA Screw Augmentation in Osteoporotic Bone-An In Vitro Study About the Risk of Thermal Necrosis in Human Femoral Heads. J. Biomed. Mater. Res. Part B 2009, 90B, 842–848. [Google Scholar] [CrossRef] [PubMed]

- Verlaan, J.; Oner, F.C.; Verbout, A.J.; Dhert, W.J.A. Temperature Elevation after Vertebroplasty with Polymethyl- Methacrylate in the Goat Spine. J. Biomed. Mater. Res. Part B Appl. Biomater. 2003, 67B, 581–585. [Google Scholar] [CrossRef] [PubMed]

- Golz, T.; Graham, C.R.; Busch, L.C.; Wulf, J.; Winder, R.J. Temperature elevation during simulated polymethylmethacrylate (PMMA) cranioplasty in a cadaver model. J. Clin. Neurosci. 2010, 17, 617–622. [Google Scholar] [CrossRef]

- Pina, S.; Ferreira, J.M.F. Brushite-Forming Mg-, Zn-and Sr-Substituted Bone Cements for Clinical Applications. Materials (Basel) 2010, 3, 519–535. [Google Scholar] [CrossRef] [Green Version]

- Baroud, G.; Samara, M.; Steffen, T. Influence of Mixing Method on the Cement Temperature-Mixing Time History and Doughing Time of Three Acrylic Cements for Vertebroplasty. J. Biomed. Mater. Res. Part B Appl. Biomater. 2003, 68B, 112–116. [Google Scholar] [CrossRef]

- Yeon, S.; Hyun, S. Setting properties, mechanical strength and in vivo evaluation of calcium phosphate-based bone cements. J. Ind. Eng. Chem. 2012, 18, 128–136. [Google Scholar]

- Schröder, C.; Nguyen, M.; Kraxenberger, M.; Chevalier, Y.; Melcher, C.; Wegener, B.; Birkenmaier, C. Modification of PMMA vertebroplasty cement for reduced stiffness by addition of normal saline: A material properties evaluation. Eur. Spine J. 2017, 26, 3209–3215. [Google Scholar] [CrossRef]

- Ormsby, R.; McNally, T.; O’Hare, P.; Burke, G.; Mitchell, C.; Dunne, N. Fatigue and biocompatibility properties of a poly(methyl methacrylate) bone cement with multi-walled carbon nanotubes. Acta Biomater. 2012, 8, 1201–1212. [Google Scholar] [CrossRef]

- Ruiz, S.; Tamayo, J.A.; Ospina, J.D.; Navia Porras, D.P.; Valencia Zapata, M.E.; Mina Hernandez, J.H.; Valencia, C.H.; Zuluaga, F.; Grande Tovar, C.D. Antimicrobial Films Based on Nanocomposites of Chitosan /Poly (vinyl alcohol) /Graphene Oxide for Biomedical Applications. Biomolecules 2019, 9, 109. [Google Scholar] [CrossRef] [Green Version]

- Du, J.; Wang, S.; You, H.; Zhao, X. Understanding the toxicity of carbon nanotubes in the environment is crucial to the control of nanomaterials in producing and processing and the assessment of health risk for human: A review. Environ. Toxicol. Pharmacol. 2013, 36, 451–462. [Google Scholar] [CrossRef] [PubMed]

- Kassem, A.; Ayoub, G.M.; Malaeb, L. Antibacterial activity of chitosan nanocomposites and carbon nanotubes: A review. Sci. Total Environ. 2019, 668, 566–576. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zeng, T.H.; Hofmann, M.; Burcombe, E.; Wei, J.; Jiang, R.; Kong, J.; Chen, Y. Antibacterial activity of graphite, graphite oxide, graphene oxide, and reduced graphene oxide: Membrane and oxidative stress. ACS Nano 2011, 5, 6971–6980. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Grande, C.D.; Rodrigues, D.F. Biodegradation of graphene oxide-polymer nanocomposite films in wastewater. Environ. Sci. Nano 2017, 4, 1808–1816. [Google Scholar] [CrossRef]

| Formulation | MMA | DEAEA | DEAEM | DMPT | GO |

|---|---|---|---|---|---|

| ABC 0% GO | 88 | 1 | 1 | 2.5 | 0 |

| ABC 0.1% GO | 83 | 1 | 1 | 2.5 | 0.1 |

| ABC 0.2% GO | 78 | 1 | 1 | 2.5 | 0.2 |

| ABC 0.3% GO | 73 | 1 | 1 | 2.5 | 0.3 |

| ABC 0.5% GO | 68 | 1 | 1 | 2.5 | 0.5 |

| Binding Energy (eV) | Atomic Concentration (at.%) | |

|---|---|---|

| C=C | 285.2 | 27.21 |

| C–C and C–H | 286.0 | 4.95 |

| C–O–C and C–OH | 287.2 | 18.77 |

| C=O | 288.1 | 46.61 |

| O=C–OH | 291.7 | 2.46 |

| Formulation | Tg (°C) | RMC (%) |

|---|---|---|

| ABC 0% GO | 115 | 1.06 |

| ABC 0.1% GO | 118 | 1.06 |

| ABC 0.2% GO | 120 | 1.06 |

| ABC 0.3% GO | 120 | 1.32 |

| ABC 0.5% GO | 119 | 1.32 |

| Strain | Control | ABC 0% GO | ABC 0.1% GO | ABC 0.2% GO | ABC 0.3% GO | ABC 0.5% GO |

|---|---|---|---|---|---|---|

| Bacillus cereus ATCC 13061 | +++ | + | + | + | - | - |

| Staphylococcus aureus ATCC 55804 | +++ | + | + | + | - | - |

| Salmonella entérica ATCC 13311 | +++ | + | + | - | - | - |

| Escherichia coli ATCC 11775 | +++ | + | + | - | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zapata, M.E.V.; Ruiz Rojas, L.M.; Mina Hernández, J.H.; Delgado-Ospina, J.; Tovar, C.D.G. Acrylic Bone Cements Modified with Graphene Oxide: Mechanical, Physical, and Antibacterial Properties. Polymers 2020, 12, 1773. https://doi.org/10.3390/polym12081773

Zapata MEV, Ruiz Rojas LM, Mina Hernández JH, Delgado-Ospina J, Tovar CDG. Acrylic Bone Cements Modified with Graphene Oxide: Mechanical, Physical, and Antibacterial Properties. Polymers. 2020; 12(8):1773. https://doi.org/10.3390/polym12081773

Chicago/Turabian StyleZapata, Mayra Eliana Valencia, Lina Marcela Ruiz Rojas, José Herminsul Mina Hernández, Johannes Delgado-Ospina, and Carlos David Grande Tovar. 2020. "Acrylic Bone Cements Modified with Graphene Oxide: Mechanical, Physical, and Antibacterial Properties" Polymers 12, no. 8: 1773. https://doi.org/10.3390/polym12081773

APA StyleZapata, M. E. V., Ruiz Rojas, L. M., Mina Hernández, J. H., Delgado-Ospina, J., & Tovar, C. D. G. (2020). Acrylic Bone Cements Modified with Graphene Oxide: Mechanical, Physical, and Antibacterial Properties. Polymers, 12(8), 1773. https://doi.org/10.3390/polym12081773