Viscoelastic Behavior of Glass-Fiber-Reinforced Silicone Composites Exposed to Cyclic Loading

Abstract

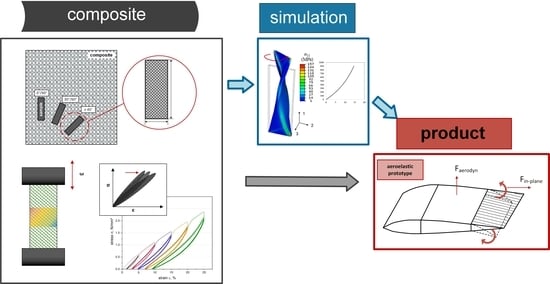

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Specimens

2.3. Dynamic Mechanical Analysis

2.4. Step Cycle Test

3. Results and Discussion

3.1. Dynamic Mechanical Analysis

3.2. Step Cycle Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Neitzel, M.; Mitschang, P.; Breuer, U. Handbuch Verbundwerkstoffe. In Werkstoffe, Verarbeitung, Anwendung, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2014; ISBN 978-3-446-43696-1. [Google Scholar]

- Smitthipong, W.; Suethao, S.; Shah, D.U.; Vollrath, F. Interesting green elastomeric composites: Silk textile reinforced natural rubber. Polym. Test. 2016, 55, 17–24. [Google Scholar] [CrossRef] [Green Version]

- Chou, T.-W. Flexible composites. J. Mater. Sci. 1989, 24, 761–783. [Google Scholar] [CrossRef]

- Kang, G.J.; Kang, B.-S. Dynamic analysis of fiber-reinforced elastomeric isolation structures. J. Mech. Sci. Technol. 2009, 23, 1132–1141. [Google Scholar] [CrossRef]

- Kishi, H.; Kuwata, M.; Matsuda, S.; Asami, T.; Murakami, A. Damping properties of thermoplastic-elastomer interleaved carbon fiber-reinforced epoxy composites. Compos. Sci. Technol. 2004, 64, 2517–2523. [Google Scholar] [CrossRef]

- Drenkelford, S. Energy-Saving Potential of Aramid-Based Conveyor Belts. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Moon, B.-Y.; Kang, G.-J.; Kang, B.-S.; Kelly, J.M. Design and manufacturing of fiber reinforced elastomeric isolator for seismic isolation. J. Mater. Process. Technol. 2002, 130–131, 145–150. [Google Scholar] [CrossRef]

- Geethamma, V.; Kalaprasad, G.; Groeninckx, G.; Thomas, S. Dynamic mechanical behavior of short coir fiber reinforced natural rubber composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1499–1506. [Google Scholar] [CrossRef]

- Gerhaher, U. Faserverstärkte Elastomerlager—Konzeption und Bemessung. Ph.D. Thesis, Universität für Bodenkultur, Wien, Austria, 2010. [Google Scholar]

- Peel, L. Fabrication and Mechanics of Fiber-Reinforced Elastomers. Ph.D. Thesis, Brigham Young University, Brigham, MA, USA, 1998. [Google Scholar]

- Jin, H.; Dong, E.; Xu, M.; Liu, C.; Alici, G.; Jie, Y. Soft and smart modular structures actuated by shape memory alloy (SMA) wires as tentacles of soft robots. Smart Mater. Struct. 2016, 25, 85026. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Chillara, V.S.C.; Dapino, M.J. Review of Morphing Laminated Composites. Appl. Mech. Rev. 2019, 72, 10801. [Google Scholar] [CrossRef]

- Peel, L.D.; Mejia, J.; Narvaez, B.; Thompson, K.; Lingala, M. Development of a Simple Morphing Wing Using Elastomeric Composites as Skins and Actuators. J. Mech. Des. 2009, 131, 091003. [Google Scholar] [CrossRef]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2017, 114, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Connolly, F.; Polygerinos, P.; Walsh, C.J.; Bertoldi, K. Mechanical Programming of Soft Actuators by Varying Fiber Angle. Soft Robot. 2015, 2, 26–32. [Google Scholar] [CrossRef] [Green Version]

- Vocke, R.D.; Kothera, C.S.; Woods, B.K.; Wereley, N.M. Development and Testing of a Span-Extending Morphing Wing. J. Intell. Mater. Syst. Struct. 2011, 22, 879–890. [Google Scholar] [CrossRef]

- Peel, L.D.; Baur, J.; Phillips, D.; McClung, A. The effect of scaling on the performance of elastomer composite actuators. Proc. SPIE Int. Soc. Opt. Eng. 2010, 7644, 76441W. [Google Scholar] [CrossRef]

- Toopchi-Nezhad, H.; Tait, M.; Drysdale, R.G. Bonded versus unbonded strip fiber reinforced elastomeric isolators: Finite element analysis. Compos. Struct. 2011, 93, 850–859. [Google Scholar] [CrossRef]

- Vassilopoulos, A.P. Fatigue Life Prediction of Composites and Composite Structures, 2nd ed.; Woodhead Publishing: Oxford, UK, 2019; ISBN 978-1845695255. [Google Scholar]

- Hanif, A.; Usman, M.; Lu, Z.; Cheng, Y.; Li, Z. Flexural fatigue behavior of thin laminated cementitious composites incorporating cenosphere fillers. Mater. Des. 2018, 140, 267–277. [Google Scholar] [CrossRef]

- Castillo, E.; Fernández-Canteli, A. A Unified Statistical Methodology for Modeling Fatigue Damage; Springer: Dordrecht, The Netherlands, 2009; ISBN 978-1-4020-9182-7. [Google Scholar]

- Mansouri, M.; Fuchs, P.; Criscione, J.; Schrittesser, B.; Beter, J. The contribution of mechanical interactions to the constitutive modeling of fiber-reinforced elastomers. Eur. J. Mech. A Solids 2020, 85, 104081. [Google Scholar] [CrossRef]

- Mansouri, M.; Fuchs, P.F.; Schuecker, C. Hyperelastic modeling of woven structures undergoing large deformations. In Proceedings of the 18th European Conference on Composite Materials (ECCM18), Athen, Greece, 25–28 June 2018. [Google Scholar]

- Ehrenstein, G.W.; Riedel, G.; Trawiel, P. Praxis der Thermischen Analyse Von Kunststoffen, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2003; ISBN 978-3-446-22340-0. [Google Scholar]

- Gent, A.N. Engineering with Rubber. In How to Design Rubber Components, 3rd ed.; Carl Hanser Verlag: Munich, Germany, 2012; ISBN 978-3-446-42871-3. [Google Scholar]

- Fleischmann, D.D.; Arbeiter, F.; Schaller, R.; Holzner, A.; Kern, W.; Schlögl, S. Influence of crosslinker and water on cyclic properties of carboxylated nitrile butadiene rubber (XNBR). Polym. Test. 2018, 67, 309–321. [Google Scholar] [CrossRef]

- Diani, J.; Fayolle, B.; Gilormini, P. A review on the Mullins effect. Eur. Polym. J. 2009, 45, 601–612. [Google Scholar] [CrossRef] [Green Version]

- Almeida, J.H.S., Jr.; Ornaghi, H.L., Jr.; Amico, S.C.; Amado, F.D.R. Study of hybrid intralaminate curaua/glass composites. Mater. Des. 2012, 42, 111–117. [Google Scholar] [CrossRef]

- Guo, C.; Song, Y.-M.; Wang, Q.-W.; Shen, C.-S. Dynamic-mechanical analysis and SEM morphology of wood flour/polypropylene composites. J. For. Res. 2006, 17, 315–318. [Google Scholar] [CrossRef]

- Hassan, A.; Rahman, N.A.; Yahya, R. Extrusion and injection-molding of glass fiber/MAPP/polypropylene: Effect of coupling agent on DSC, DMA, and mechanical properties. J. Reinf. Plast. Compos. 2011, 30, 1223–1232. [Google Scholar] [CrossRef]

- Liu, Y.; He, M.; Qin, S.-H.; Yu, J. Effect of fiber length and dispersion on properties of long glass fiber reinforced thermoplastic composites based on poly(butylene terephthalate). RSC Adv. 2017, 7, 15439–15454. [Google Scholar] [CrossRef] [Green Version]

- Vleugels, N. Short Fibre-Reinforced Elastomeric Composites: Fundamental Routes towards Improvement of the Interfacial Interaction of Short-Cut Aramid Fibres in a SBR Compound, to Improve Friction and Wear Properties. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2017. [Google Scholar]

- Song, Y.S.; Lee, J.T.; Ji, D.S.; Kim, M.W.; Lee, S.H.; Youn, J.R. Viscoelastic and thermal behavior of woven hemp fiber reinforced poly(lactic acid) composites. Compos. Part B Eng. 2012, 43, 856–860. [Google Scholar] [CrossRef]

- Liu, M.H.; Li, R.; Wang, G.; Hou, Z.Y.; Huang, B. Morphology and dynamic mechanical properties of long glass fiber-reinforced polyamide 6 composites. J. Therm. Anal. Calorim. 2016, 126, 1281–1288. [Google Scholar] [CrossRef]

- Cordin, M.; Bechtold, T.; Pham, T. Effect of fibre orientation on the mechanical properties of polypropylene–lyocell composites. Cellulose 2018, 25, 7197–7210. [Google Scholar] [CrossRef] [Green Version]

- Jawaid, M.; Khalil, H.A.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. Part B Eng. 2013, 45, 619–624. [Google Scholar] [CrossRef]

- Saha, A.K.; Das, S.; Bhatta, D.; Mitra, B.C. Study of jute fiber reinforced polyester composites by dynamic mechanical analysis. J. Appl. Polym. Sci. 1999, 71, 1505–1513. [Google Scholar] [CrossRef]

- Prioglio, G.; Agnelli, S.; Conzatti, L.; Balasooriya, W.; Schrittesser, B.; Galimberti, M. Graphene Layers Functionalized with a Janus Pyrrole-Based Compound in Natural Rubber Nanocomposites with Improved Ultimate and Fracture Properties. Polymers 2020, 12, 944. [Google Scholar] [CrossRef] [Green Version]

- Göktepe, S. Micro-Macro Approaches to Rubbery and Glassy Polymers: Predictive Micromechanically-Based Models and Simulations. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2007. [Google Scholar]

- Sedlan, K. Viskoelastisches Materialverhalten von Elastomerwerkstoffen: Experimentelle Untersuchung und Modellbildung. Ph.D. Thesis, Universität Gesamthochschule Kassel, Kassel, Germany, 2000. [Google Scholar]

- Gao, J.; Yang, X.; Huang, L.; Suo, Y. Experimental study on mechanical properties of aramid fibres reinforced natural rubber/SBR composite for large deformation—Quasi-static mechanical properties. Plast. Rubber Compos. 2018, 47, 381–390. [Google Scholar] [CrossRef]

- Jiménez, F.L.; Pellegrino, S. Folding of fiber composites with a hyperelastic matrix. Int. J. Solids Struct. 2012, 49, 395–407. [Google Scholar] [CrossRef] [Green Version]

- Cherif, C. Textile Werkstoffe für den Leichtbau. In Techniken—Verfahren—Materialien—Eigenschaften, 1st ed.; Springer: Berlin, Germany, 2011; ISBN 978-3-642-17992-1. [Google Scholar]

- Beter, J.; Schrittesser, B.; Meier, G.; Fuchs, P.F.; Pinter, G. Influence of Fiber Orientation and Adhesion Properties On Tailored Fiber-reinforced Elastomers. Appl. Compos. Mater. 2020, 27, 149–164. [Google Scholar] [CrossRef]

- Liao, M.; Yang, Y.; Hamada, H. Mechanical performance of glass woven fabric composite: Effect of different surface treatment agents. Compos. Part B Eng. 2016, 86, 17–26. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Maroh, B.; Sarlin, E.; Fuchs, P.F.; Pinter, G. Comparison and Impact of Different Fiber Debond Techniques on Fiber Reinforced Flexible Composites. Polymers 2020, 12, 472. [Google Scholar] [CrossRef] [Green Version]

- Beter, J.; Schrittesser, B.; Grassegger, F. Klemmvorrichtung und Verfahren zur Prüfung Einer Zugfestigkeit Eines Objektes; A50009/2020; Austrian Patent Office: Vienna, Austria, 20 January 2020. [Google Scholar]

- Muliana, A.H.; Rajagopal, K.R.; Tscharnuter, D.; Schrittesser, B.; Saccomandi, G. Determining Material Properties of Natural Rubber Using Fewer Material Moduli in Virtue of a Novel Constitutive Approach for Elastic Bodies. Rubber Chem. Technol. 2018, 91, 375–389. [Google Scholar] [CrossRef]

- Hanif, A.; Kim, Y.; Park, C. Numerical Validation of Two-Parameter Weibull Model for Assessing Failure Fatigue Lives of Laminated Cementitious Composites—Comparative Assessment of Modeling Approaches. Materials 2018, 12, 110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beter, J.; Schrittesser, B.; Fuchs, P.F. Investigation of adhesion properties in load coupling applications for flexible composites. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM D2256-02:2015: Test Method for Tensile Properties of Yarns by the Single-Strand Method; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- International Organization for Standardization. ISO 37:2011-12: Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- International Organization for Standardization. ISO 527-4:1997: Plastics. Determination of Tensile Properties; International Organization for Standardization: London, UK, 1997. [Google Scholar]

- Hoffmann, J. Characterization of Fibre Reinforced Elastomers for Shape Morphing Structural Surfaces. Ph.D. Thesis, Technical University of Munich, München, Germany, 2012. [Google Scholar]

- International Organization for Standardization. ISO 6721-1:2019-04: Plastics—Determination of Dynamic Mechanical Properties; International Organization for Standardization: Berlin, Germany, 2019. [Google Scholar]

- International Organization for Standardization. ISO 4664:2011-11: Rubber, Vulcanized or Thermoplastic—Determination of Dynamic Properties; International Organization for Standardization: Berlin, Germany, 2011. [Google Scholar]

- International Organization for Standardization. ISO 291:2008-08: Plastics—Standard Atmospheres for Conditioning and Testing; International Organization for Standardization: Berlin, Germany, 2008. [Google Scholar]

- Röthemeyer, F.; Sommer, F. Kautschuk—Technologie. Werkstoffe—Verarbeitung—Produkte, 3rd ed.; Carl Hanser Verlag: Munich, Germany, 2013; ISBN 978-3-446-43776-0. [Google Scholar]

- Calabrò, R. Mechanical Characterization of Elastomers under Quasi-Static and Dynamic Biaxial Loading Conditions. Ph.D. Thesis, Politecnico di Milano, Milan, Italy, 2013. [Google Scholar]

- Domininghaus, H.; Elsner, P.; Eyerer, P.; Hirth, T. Kunststoffe. Eigenschaften und Anwendungen, 8th ed.; Springer: Berlin, Germany, 2012; ISBN 978-3-642-16173-5. [Google Scholar]

- Ehrenstein, G. Polymer-Werkstoffe. Struktur; Eigenschaften; Anwendung, 3rd ed.; Carl Hanser Verlag: Munich, Germany, 2011; ISBN 978-3-446-42283-4. [Google Scholar]

- Abts, G. Einführung in die Kautschuktechnologie; Carl Hanser Fachbuchverlag: Munich, Germany, 2019; ISBN 978-3-446-45461-3. [Google Scholar]

- Yang, Y.; Fu, C.; Xu, F. A finite strain model predicts oblique wrinkles in stretched anisotropic films. Int. J. Eng. Sci. 2020, 155, 103354. [Google Scholar] [CrossRef]

| V, mm/min | ε, % | Δσ, N/mm2 | fσ,relax, % (30 s Relaxation) | ||||

|---|---|---|---|---|---|---|---|

| Cycles 1–2 | Cycles 2–3 | Cycles 5–6 | Cycle 1 | Cycle 2 | Cycle 6 | ||

| 10 | 5 | 0.07 ± 0.01 | 0.03 ± 0.00 * | 0.01 ± 0.00 * | 6.31 ± 0.15 | 3.24 ± 0.22 | 1.51 ± 0.04 |

| 15 | 0.10 ± 0.02 | 0.06 ± 0.01 | 0.03 ± 0.00 * | 7.23 ± 0.08 | 3.43 ± 0.25 | 2.35 ± 0.04 | |

| 25 | 0.53 ± 0.10 | 0.31 ± 0.08 | 0.06 ± 0.01 | 8.91 ± 0.11 | 4.11 ± 0.19 | 2.12 ± 0.03 | |

| 100 | 5 | 0.07 ± 0.01 | 0.05 ± 0.00 * | 0.02 ± 0.00 * | 9.35 ± 0.60 | 2.91 ± 0.10 | 2.23 ± 0.09 |

| 15 | 0.11 ± 0.05 | 0.06 ± 0.01 | 0.01 ± 0.00 * | 10.51 ± 0.31 | 3.85 ± 0.21 | 3.52 ± 0.10 | |

| 25 | 0.51 ± 0.11 | 0.18 ± 0.09 | 0.03 ± 0.00 * | 13.42 ± 0.48 | 5.31 ± 0.33 | 3.51 ± 0.12 | |

| 1000 | 5 | 0.05 ± 0.00 * | 0.02 ± 0.00 * | 0.01 ± 0.00 * | 8.93 ± 0.43 | 4.31 ± 0.15 | 2.12 ± 0.06 |

| 15 | 0.14 ± 0.03 | 0.09± 0.01 | 0.01 ± 0.00 * | 11.8 ± 0.52 | 4.20 ± 0.31 | 2.80 ± 0.13 | |

| 25 | 0.68 ± 0.10 | 0.27 ± 0.08 | 0.03 ± 0.00* | 16.26 ± 0.71 | 5.24 ± 0.19 | 3.31 ± 0.09 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beter, J.; Schrittesser, B.; Lechner, B.; Mansouri, M.R.; Marano, C.; Fuchs, P.F.; Pinter, G. Viscoelastic Behavior of Glass-Fiber-Reinforced Silicone Composites Exposed to Cyclic Loading. Polymers 2020, 12, 1862. https://doi.org/10.3390/polym12091862

Beter J, Schrittesser B, Lechner B, Mansouri MR, Marano C, Fuchs PF, Pinter G. Viscoelastic Behavior of Glass-Fiber-Reinforced Silicone Composites Exposed to Cyclic Loading. Polymers. 2020; 12(9):1862. https://doi.org/10.3390/polym12091862

Chicago/Turabian StyleBeter, Julia, Bernd Schrittesser, Bernhard Lechner, Mohammad Reza Mansouri, Claudia Marano, Peter Filipp Fuchs, and Gerald Pinter. 2020. "Viscoelastic Behavior of Glass-Fiber-Reinforced Silicone Composites Exposed to Cyclic Loading" Polymers 12, no. 9: 1862. https://doi.org/10.3390/polym12091862

APA StyleBeter, J., Schrittesser, B., Lechner, B., Mansouri, M. R., Marano, C., Fuchs, P. F., & Pinter, G. (2020). Viscoelastic Behavior of Glass-Fiber-Reinforced Silicone Composites Exposed to Cyclic Loading. Polymers, 12(9), 1862. https://doi.org/10.3390/polym12091862