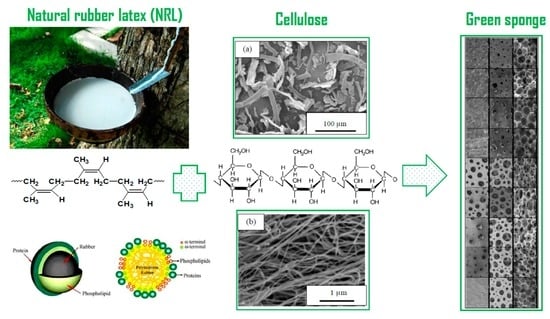

Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Cellulose Powder

2.3. Characterization of Cellulose

2.4. Preparation of NRLF and Reinforced NRLF

2.5. Characterization of NRLF, NRLF-MC and NRLF-NC

3. Results and Discussion

3.1. Characterization of Cellulose Fibers/Powders

3.2. Morphology of NRLF, NRLF-MC, and NRLF-NC

3.3. Foam Density

3.4. Crosslinking Density

3.5. Mechanical Properties

3.6. Compression Properties

3.7. Surface Wettability

3.8. Water Uptake

3.9. Thermal Degradation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bashir, A.S.; Munusamy, Y.; Chew, T.L.; Ismail, H.; Ramasamy, S. Mechanical, thermal, and morphological properties of (eggshell powder)-filled natural rubber latex foam. J. Vinyl Addit. Technol. 2015, 23, 3–12. [Google Scholar] [CrossRef]

- Zou, L.; Phule, A.D.; Sun, Y.; Zhu, T.Y.; Wen, S.; Zhang, Z. Superhydrophobic and superoleophilic polyethylene aerogel coated natural rubber latex foam for oil-water separation application. Polym. Test. 2020, 85, 106451. [Google Scholar] [CrossRef]

- Rathnayake, W.G.I.U.; Ismail, H.; Baharin, A.; Bandara, C.D.; Rajapakse, S. Enhancement of the antibacterial activity of natural rubber latex foam by the incorporation of zinc oxide nanoparticles. J. Appl. Polym. Sci. 2013, 131, 131. [Google Scholar] [CrossRef]

- Karim, A.F.A.; Ismail, H.; Ariff, Z.M. Properties and characterization of Kenaf-Filled natural rubber latex foam. Bioresources 2016, 11, 1080–1091. [Google Scholar]

- Ramasamy, S.; Ismail, H.; Munusamy, Y. Tensile and morphological properties of rice husk powder filled natural rubber latex foam. Polym. Technol. Eng. 2012, 51, 1524–1529. [Google Scholar] [CrossRef]

- Phomrak, S.; Phisalaphong, M. Reinforcement of natural rubber with bacterial cellulose via a latex aqueous Microdispersion process. J. Nanomater. 2017, 2017, 1–9. [Google Scholar] [CrossRef]

- Ciechanska, D. Multifunctional bacterial cellulose/chitosan composite materials for medical applications. Fibres Text. East. Eur. 2004, 12, 69–72. [Google Scholar]

- Czaja, W.; Krystynowicz, A.; Bielecki, S.; Brown, R.M., Jr. Microbial cellulose—The natural power to heal wounds. Biomaterials 2006, 27, 145–151. [Google Scholar] [CrossRef]

- Deng, C.-M.; He, L.-Z.; Zhao, M.; Yang, D.; Liu, Y. Biological properties of the chitosan-gelatin sponge wound dressing. Carbohydr. Polym. 2007, 69, 583–589. [Google Scholar] [CrossRef]

- Bodhibukkana, C.; Srichana, T.; Kaewnopparat, S.; Tangthong, N.; Bouking, P.; Martin, G.P.; Suedee, R. Composite membrane of bacterially-derived cellulose and molecularly imprinted polymer for use as a transdermal enantioselective controlled-release system of racemic propranolol. J. Control. Release 2006, 113, 43–56. [Google Scholar] [CrossRef]

- Klemm, D.; Schumann, D.; Udhardt, U.; Marsch, S. Bacterial synthesized cellulose—Artificial blood vessels for microsurgery. Prog. Polym. Sci. 2001, 26, 1561–1603. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.; Martin, A., Jr.; Conrad, C. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Treloar, L.R.G. The Physics of Rubber Elasticity; Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Najib, N.; Ariff, Z.M.; Bakar, A.; Sipaut, C. Correlation between the acoustic and dynamic mechanical properties of natural rubber foam: Effect of foaming temperature. Mater. Des. 2011, 32, 505–511. [Google Scholar] [CrossRef]

- Ariff, Z.; Zakaria, Z.; Tay, L.; Lee, S. Effect of foaming temperature and rubber grades on properties of natural rubber foams. J. Appl. Polym. Sci. 2008, 107, 2531–2538. [Google Scholar] [CrossRef]

- Abd-El-Messieh, S.; El-Nashar, D.; Khafagi, M. Compatibility investigation of microwave irradiated acrylonitrile butadiene/ethylene propylene diene rubber blends. Polym. Technol. Eng. 2004, 43, 135–158. [Google Scholar] [CrossRef]

- Zheng, Y.; Fu, Z.; Li, D.; Wu, M. Effects of ball milling processes on the microstructure and rheological properties of microcrystalline cellulose as a sustainable polymer additive. Materials 2018, 11, 1057. [Google Scholar] [CrossRef] [Green Version]

- Gao, C.; Xiao, W.; Ji, G.; Zhang, Y.; Cao, Y.; Han, L. Regularity and mechanism of wheat straw properties change in ball milling process at cellular scale. Bioresour. Technol. 2017, 241, 214–219. [Google Scholar] [CrossRef]

- Zhou, L.; He, H.; Li, M.-C.; Song, K.; Cheng, H.; Wu, Q. Morphological influence of cellulose nanoparticles (CNs) from cottonseed hulls on rheological properties of polyvinyl alcohol/CN suspensions. Carbohydr. Polym. 2016, 153, 445–454. [Google Scholar] [CrossRef] [Green Version]

- Ling, Z.; Edwards, J.V.; Guo, Z.; Prevost, N.T.; Nam, S.; Wu, Q.; French, A.D.; Xu, F. Structural variations of cotton cellulose nanocrystals from deep eutectic solvent treatment: Micro and nano scale. Cellulose 2019, 26, 861–876. [Google Scholar] [CrossRef]

- Phisalaphong, M.; Suwanmajo, T.; Sangtherapitikul, P. Novel nanoporous membranes from regenerated bacterial cellulose. J. Appl. Polym. Sci. 2008, 107, 292–299. [Google Scholar] [CrossRef]

- Liu, M.; Wang, H.; Han, J.; Niu, Y. Enhanced hydrogenolysis conversion of cellulose to C2–C3 polyols via alkaline pretreatment. Carbohydr. Polym. 2012, 89, 607–612. [Google Scholar] [CrossRef]

- Nomura, S.; Kugo, Y.; Erata, T. 13C NMR and XRD studies on the enhancement of cellulose II crystallinity with low concentration NaOH post-treatments. Cellulose 2020, 27, 3553–3563. [Google Scholar] [CrossRef]

- Keshk, S.M.A.S.; Hamdy, M.S. Preparation and physicochemical characterization of zinc oxide/sodium cellulose composite for food packaging. Turk. J. Chem. 2019, 43, 94–105. [Google Scholar] [CrossRef]

- Williams, T.; Hosur, M.; Theodore, M.; Netravali, A.; Rangari, V.; Jeelani, S. Time effects on morphology and bonding ability in mercerized natural fibers for composite reinforcement. Int. J. Polym. Sci. 2011, 2011, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Yu, H.-y.; Zhang, Z.-t.; Zhang, M.; Guo, M. Selective phase transformation behavior of titanium-bearing electric furnace molten slag during the molten NaOH treatment process. ISIJ Int. 2015, 55, 134–141. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.-S.; Kim, E. A novel system for measurement of types and densities of sulfur crosslinks of a filled rubber vulcanizate. Polym. Test. 2015, 42, 62–68. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P. Effect of various surface treatments on the performance of jute fibers filled natural rubber (NR) composites. Polymers 2020, 12, 369. [Google Scholar] [CrossRef] [Green Version]

- Dominic CD, M.; Joseph, R.; Begum, P.; Joseph, M.; Padmanabhan, D.; Morris, L.A.; Kumar, A.S.; Formela, K. Cellulose nanofibers isolated from the cuscuta reflexa plant as a green reinforcement of natural rubber. Polymers 2020, 12, 814. [Google Scholar] [CrossRef] [Green Version]

- Khimi, S.; Syamsinar, S.; Najwa, T. Effect of carbon black on self-healing efficiency of natural rubber. Mater. Today Proc. 2019, 17, 1064–1071. [Google Scholar] [CrossRef]

- Zheng, L.; Li, C.; Zhang, D.; Guan, G.; Xiao, Y.; Wang, D. Multiblock copolymers composed of poly (butylene succinate) and poly (1, 2-propylene succinate): Effect of molar ratio of diisocyanate to polyester-diols on crosslink densities, thermal properties, mechanical properties and biodegradability. Polym. Degrad. Stab. 2010, 95, 1743–1750. [Google Scholar] [CrossRef]

- Abdul Azam, F.A.; Rajendran Royan, N.R.; Yuhana, N.Y.; Mohd Radzuan, N.A.; Ahmad, S.; Sulong, A.B. Fabrication of porous recycled HDPE biocomposites foam: Effect of rice husk filler contents and surface treatments on the mechanical properties. Polymers 2020, 12, 475. [Google Scholar] [CrossRef] [Green Version]

- Tangpasuthadol, V.; Intasiri, A.; Nuntivanich, D.; Niyompanich, N.; Kiatkamjornwong, S. Silica-reinforced natural rubber prepared by the sol–gel process of ethoxysilanes in rubber latex. J. Appl. Polym. Sci. 2008, 109, 424–433. [Google Scholar] [CrossRef]

- Kemaloglu, S.; Ozkoc, G.; Aytac, A. Properties of thermally conductive micro and nano size boron nitride reinforced silicon rubber composites. Thermochim. Acta 2010, 499, 40–47. [Google Scholar] [CrossRef]

- Mohan, T.; Kuriakose, J.; Kanny, K. Effect of nanoclay reinforcement on structure, thermal and mechanical properties of natural rubber–styrene butadine rubber (NR–SBR). J. Ind. Eng. Chem. 2011, 17, 264–270. [Google Scholar] [CrossRef]

- Chong, E.; Ahmad, I.; Dahlan, H.; Abdullah, I. Reinforcement of natural rubber/high density polyethylene blends with electron beam irradiated liquid natural rubber-coated rice husk. Radiat. Phys. Chem. 2010, 79, 906–911. [Google Scholar] [CrossRef]

- Phomrak, S.; Phisalaphong, M. Lactic acid modified natural rubber–bacterial cellulose composites. Appl. Sci. 2020, 10, 3583. [Google Scholar] [CrossRef]

- Samaržija-Jovanović, S.; Jovanovic, V.; Markovic, G.; Zeković, I.; Marinović-Cincović, M. Properties of vulcanized polyisoprene rubber composites filled with opalized white tuff and precipitated silica. Sci. World J. 2014, 2014, 1–9. [Google Scholar]

- Ismail, H.; Edyham, M.; Wirjosentono, B. Bamboo fibre filled natural rubber composites: The effects of filler loading and bonding agent. Polym. Test. 2002, 21, 139–144. [Google Scholar] [CrossRef]

- Karmarkar, A.; Chauhan, S.; Modak, J.M.; Chanda, M. Mechanical properties of wood–fiber reinforced polypropylene composites: Effect of a novel compatibilizer with isocyanate functional group. Compos. Part A Appl. Sci. Manuf. 2007, 38, 227–233. [Google Scholar] [CrossRef]

- Thomas, M.G.; Abraham, E.; Jyotishkumar, P.; Maria, H.J.; Pothen, L.A.; Thomas, S. Nanocelluloses from jute fibers and their nanocomposites with natural rubber: Preparation and characterization. Int. J. Biol. Macromol. 2015, 81, 768–777. [Google Scholar] [CrossRef]

- Timothy, J.J.; Meschke, G. A cascade continuum micromechanics model for the effective elastic properties of porous materials. Int. J. Solids Struct. 2016, 83, 1–12. [Google Scholar] [CrossRef]

- Nascimento, R.M.D.; Ramos, S.M.; Bechtold, I.H.; Hernandes, A.N.C. Wettability study on natural rubber surfaces for applications as biomembranes. ACS Biomater. Sci. Eng. 2018, 4, 2784–2793. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Kirdponpattara, S.; Phisalaphong, M.; Newby, B.-m.Z. Applicability of Washburn capillary rise for determining contact angles of powders/porous materials. J. Colloid Interface Sci. 2013, 397, 169–176. [Google Scholar] [CrossRef]

- Frone, A.N.; Panaitescu, D.M.; Chiulan, I.; Nicolae, C.A.; Casarica, A.; Gabor, A.R.; Trusca, R.; Damian, C.M.; Purcar, V.; Alexandrescu, E. Surface treatment of bacterial cellulose in mild, eco-friendly conditions. Coatings 2018, 8, 221. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Mani, T.; Murugan, P.; Abedi, J.; Mahinpey, N. Pyrolysis of wheat straw in a thermogravimetric analyzer: Effect of particle size and heating rate on devolatilization and estimation of global kinetics. Chem. Eng. Res. Des. 2010, 88, 952–958. [Google Scholar] [CrossRef]

- Wang, Z.; McDonald, A.G.; Westerhof, R.J.; Kersten, S.R.; Cuba-Torres, C.M.; Ha, S.; Pecha, B.; Garcia-Perez, M. Effect of cellulose crystallinity on the formation of a liquid intermediate and on product distribution during pyrolysis. J. Anal. Appl. Pyrolysis 2013, 100, 56–66. [Google Scholar] [CrossRef]

- Pichayakorn, W.; Suksaeree, J.; Boonme, P.; Taweepreda, W.; Ritthidej, G.C. Preparation of deproteinized natural rubber latex and properties of films formed by itself and several adhesive polymer blends. Ind. Eng. Chem. Res. 2012, 51, 13393–13404. [Google Scholar] [CrossRef]

- Farhadinejad, Z.; Ehsani, M.; Khosravian, B.; Ebrahimi, G. Study of thermal properties of wood plastic composite reinforced with cellulose micro fibril and nano inorganic fiber filler. Eur. J. Wood Wood Prod. 2012, 70, 823–828. [Google Scholar] [CrossRef]

| Ingredient | Amount (phr) |

|---|---|

| 60% DRC HA-NRL | 100 |

| MC or NC | 5, 10, 15, 20 |

| 10 wt % Potassium oleate soap | 1.5 |

| 50 wt % Sulfur | 2.0 |

| 50 wt % Phenolic Adhesive Antioxidant | 1.0 |

| 50 wt % ZMBT | 1.0 |

| 50 wt % ZDEC | 1.0 |

| 50 wt % ZnO | 5.0 |

| 33 wt % DPG | 1.0 |

| 12.5 wt % SSF | 1.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phomrak, S.; Nimpaiboon, A.; Newby, B.-m.Z.; Phisalaphong, M. Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method. Polymers 2020, 12, 1959. https://doi.org/10.3390/polym12091959

Phomrak S, Nimpaiboon A, Newby B-mZ, Phisalaphong M. Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method. Polymers. 2020; 12(9):1959. https://doi.org/10.3390/polym12091959

Chicago/Turabian StylePhomrak, Sirilak, Adun Nimpaiboon, Bi-min Zhang Newby, and Muenduen Phisalaphong. 2020. "Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method" Polymers 12, no. 9: 1959. https://doi.org/10.3390/polym12091959

APA StylePhomrak, S., Nimpaiboon, A., Newby, B. -m. Z., & Phisalaphong, M. (2020). Natural Rubber Latex Foam Reinforced with Micro- and Nanofibrillated Cellulose via Dunlop Method. Polymers, 12(9), 1959. https://doi.org/10.3390/polym12091959