Comparison of Mechanical Properties of PMMA Disks for Digitally Designed Dentures

Abstract

:1. Introduction

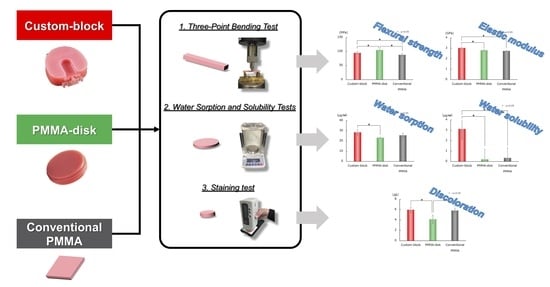

2. Materials and Methods

2.1. Preparation of Various Blocks

2.2. Manufacturing the Specimens

2.3. Three-Point Bending Test

2.4. Water Sorption and Solubility Tests

2.5. Staining Test

2.6. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

- Significant differences in flexural strength were observed among the materials (p < 0.001). The flexural modulus and water solubility were significantly higher in the Custom-block. Furthermore, the water sorption of the Custom-block was significantly higher than that of the PMMA-disk, but it did not significantly differ from that of the Conventional PMMA. The discoloration of all the materials tended to increase initially, and till 7 days after the immersion.

- With the exception of the staining test, the three materials met the ISO standard requirements for all tests, but the mechanical properties of the three materials differed depending on the manufacturing method used, which considerably affected the flexural strength, flexural modulus, water sorption, water solubility, and discoloration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Becerra, J.; Mainjot, A.; Hüe, O.; Sadoun, M.; Nguyen, J.F. Influence of High-Pressure Polymerization on Mechanical Properties of Denture Base Resins. J. Prosthodont. 2021, 30, 128–134. [Google Scholar] [CrossRef] [PubMed]

- Nejatian, T.; Pezeshki, S.; Syed, A.U.Y. 5-Acrylic denture base materials. In Advanced Dental Biomaterials; Woodhead Publishing: Cambridge, UK, 2019; pp. 79–104. [Google Scholar]

- Rickman, L.J.; Padipatvuthikul, P.; Satterthwaite, J.D. Contemporary denture base resins: Part 1. Dent. Update 2012, 39, 25–28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anusavice, K.J.; Shen, C.; Rawls, H.R. Phillips’ Science of Dental Materials; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Darbar, U.R.; Huggett, R.; Harrison, A. Denture fracture—A survey. Br. Dent. J. 1994, 176, 342–345. [Google Scholar] [CrossRef] [PubMed]

- Gautam, R.; Singh, R.D.; Sharma, V.P.; Siddhartha, R.; Chand, P.; Kumar, R. Biocompatibility of polymethylmethacrylate resins used in dentistry. J. Biomed. Mater. Res. B Appl. Biomater. 2012, 100, 1444–1450. [Google Scholar] [CrossRef]

- Gad, M.M.; Abualsaud, R.; Al-Thobity, A.M.; Baba, N.Z.; Al-Harbi, F.A. Influence of Addition of Different Nanoparticles on the Surface Properties of Poly(methylmethacrylate) Denture Base Material. J. Prosthodont. 2020, 29, 422–428. [Google Scholar] [CrossRef]

- Abushowmi, T.H.; AlZaher, Z.A.; Almaskin, D.F.; Qaw, M.S.; Abualsaud, R.; Akhtar, S.; Al-Thobity, A.M.; Al-Harbi, F.A.; Gad, M.M.; Baba, N.Z. Comparative Effect of Glass Fiber and Nano-Filler Addition on Denture Repair Strength. J. Prosthodont. 2020, 29, 261–268. [Google Scholar] [CrossRef]

- Nejatian, T.; Almassi, S.; Shamsabadi, A.F.; Vasudeva, G.; Hancox, Z.; Dhillon, A.S.; Sefat, F. 19-Digital Dentistry. In Advanced Dental Biomaterials; Woodhead Publishing: Cambridge, UK, 2019; pp. 507–540. [Google Scholar]

- Goodacre, C.J.; Garbacea, A.; Naylor, W.P.; Daher, T.; Marchack, C.B.; Lowry, J. CAD/CAM fabricated complete dentures: Concepts and clinical methods of obtaining required morphological data. J. Prosthet. Dent. 2012, 107, 34–46. [Google Scholar] [CrossRef]

- Inokoshi, M.; Kanazawa, M.; Minakuchi, S. Evaluation of a complete denture trial method applying rapid prototyping. Dent. Mater. J. 2012, 31, 40–46. [Google Scholar] [CrossRef] [Green Version]

- Kanazawa, M.; Inokoshi, M.; Minakuchi, S.; Ohbayashi, N. Trial of a CAD/CAM system for fabricating complete dentures. Dent. Mater. J. 2011, 30, 93–96. [Google Scholar] [CrossRef] [Green Version]

- AvaDent Digital Dental Solutions. Avadent Support—AvaDent Materials, Global Dental Science 2021. Available online: https://www.avadent.com/avadent/materials/ (accessed on 14 February 2020).

- Iwaki, M.; Kanazawa, M.; Arakida, T.; Minakuchi, S. Mechanical properties of a polymethyl methacrylate block for CAD/CAM dentures. J. Oral Sci. 2020, 62, 420–422. [Google Scholar] [CrossRef]

- Alp, G.; Murat, S.; Yilmaz, B. Comparison of Flexural Strength of Different CAD/CAM PMMA-Based Polymers. J. Prosthodont. 2019, 28, e491–e495. [Google Scholar] [CrossRef]

- Arslan, M.; Murat, S.; Alp, G.; Zaimoglu, A. Evaluation of flexural strength and surface properties of prepolymerized CAD/CAM PMMA-based polymers used for digital 3D complete dentures. Int. J. Comput. Dent. 2018, 21, 31–40. [Google Scholar]

- Al-Dwairi, Z.N.; Tahboub, K.Y.; Baba, N.Z.; Goodacre, C.J. A Comparison of the Flexural and Impact Strengths and Flexural Modulus of CAD/CAM and Conventional Heat-Cured Polymethyl Methacrylate (PMMA). J. Prosthodont. 2020, 29, 341–349. [Google Scholar] [CrossRef]

- Steinmassl, P.A.; Wiedemair, V.; Huck, C.; Klaunzer, F.; Steinmassl, O.; Grunert, I.; Dumfahrt, H. Do CAD/CAM dentures really release less monomer than conventional dentures? Clin. Oral Investig. 2017, 21, 1697–1705. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.J.E.; Uy, C.E.; Plaksina, P.; Ramani, R.S.; Ganjigatti, R.; Waddell, J.N. Bond strength of denture teeth to heat-cured, CAD/CAM and 3D printed denture acrylics. J. Prosthodont. 2020, 29, 415–421. [Google Scholar] [CrossRef]

- Soeda, Y.; Kanazawa, M.; Arakida, T.; Iwaki, M.; Minakuchi, S. CAD-CAM milled complete dentures with custom disks and prefabricated artificial teeth: A dental technique. J. Prosthet. Dent. 2020, in press. [Google Scholar] [CrossRef]

- DGSHAPE Support. Manual Library—Roland DG Corporation, Hamamatsu. 2021. Available online: https://webmanual.rolanddg.com/CA-DK1 (accessed on 4 March 2021).

- International Organization for Standardization (ISO). Dentistry—Base Polymers—Part 1: Denture Base Polymers; ISO 20795-1:2013(en); International Organization of Standardization (ISO): Geneva, Switzerland, 2013; Available online: https://www.iso.org/obp/ui/#iso:std:iso:20795:-1:ed-2:v1:en (accessed on 3 December 2019).

- Prpic, V.; Slacanin, I.; Schauperl, Z.; Catic, A.; Dulcic, N.; Cimic, S. A study of the flexural strength and surface hardness of different materials and technologies for occlusal device fabrication. J. Prosthet. Dent. 2019, 121, 955–959. [Google Scholar] [CrossRef]

- Imamura, S.; Takahashi, H.; Hayakawa, I.; Loyaga-Rendon, P.G.; Minakuchi, S. Effect of filler type and polishing on the discoloration of composite resin artificial teeth. Dent. Mater. J. 2008, 27, 802–808. [Google Scholar] [CrossRef] [Green Version]

- Munikamaiah, R.L.; Jain, S.K.; Pal, K.S.; Gaikwad, A. Evaluation of Flexural Strength of Polymethyl Methacrylate modified with Silver Colloidal Nanoparticles subjected to Two Different Curing Cycles: An in vitro Study. J. Contemp. Dent. Pract. 2018, 1, 262–268. [Google Scholar]

- Lee, H.H.; Lee, C.J.; Asaoka, K. Correlation in the mechanical properties of acrylic denture base resins. Dent. Mater. J. 2012, 31, 157–164. [Google Scholar] [CrossRef] [Green Version]

- Iwata, Y. Assessment of clasp design and flexural properties of acrylic denture base materials for use in non-metal clasp dentures. J. Prosthet. Dent. 2016, 60, 114–122. [Google Scholar] [CrossRef]

- Mumcu, E.; Cilingir, A.; Gencel, B.; Sülün, T. Flexural properties of a light-cure and a self-cure denture base materials compared to conventional alternatives. J. Adv. Prosthodont. 2011, 3, 136–139. [Google Scholar] [CrossRef]

- Pfeiffer, P.; Rosenbauer, E.U. Residual methyl methacrylate monomer, water sorption, and water solubility of hypoallergenic denture base materials. J. Prosthet. Dent. 2004, 92, 72–78. [Google Scholar] [CrossRef]

- Hargreaves, A.S. The effects of cyclic stress on dental polymethylmethacrylate I. Thermal and environmental fluctuation. J. Oral Rehabil. 1983, 10, 75–85. [Google Scholar] [CrossRef]

- Nair, R.G.; Samaranayake, L.P. The effect of oral commensal bacteria on candidal adhesion to denture acrylic surfaces: An in vitro study. APMIS 1996, 104, 339–349. [Google Scholar] [CrossRef]

- Takahashi, Y.; Chai, J.; Kawaguchi, M. Effect of water sorption on the resistance to plastic deformation of a denture base material relined with four different denture reline materials. Int. J. Prosthodont. 1998, 11, 49–54. [Google Scholar]

- Jagger, R.G. Effect of the curing cycle on some properties of a polymethylmethacrylate denture base material. J. Oral Rehabil. 1978, 5, 151–157. [Google Scholar] [CrossRef]

- Vallittu, P.K.; Ruyter, I.E.; Buykuilmaz, S. Effect of polymerization temperature and time on the residual monomer content of denture base polymers. Eur. J. Oral Sci. 1998, 106, 588–593. [Google Scholar] [CrossRef]

- Shofu Global. Product Information; Shofu Inc.: Kyoto, Japan, 2021; Available online: https://www.shofu.co.jp/product/contents/hp0493/index.php?No=315&CNo=493 (accessed on 8 March 2021).

- Bates, J.F.; Stafford, G.D.; Huggett, R.; Handley, R.W. Current status of pour type denture base resins. J. Dent. 1977, 5, 177–189. [Google Scholar] [CrossRef]

- Winkler, S.; Vernon, H.M. Coloring acrylic denture base resins. J. Prosthet. Dent. 1978, 40, 4–7. [Google Scholar] [CrossRef]

- Ishikawa, N. Color fundamentals and practice. J. Imaging Soc. Jpn. 2005, 44, 489–498. [Google Scholar]

- Johnston, W.M.; Reisbick, M.H. Color and translucency changes during and after curing of esthetic restorative materials. Dent. Mater. 1997, 13, 89–97. [Google Scholar] [CrossRef]

- Nimeroff, I. Colorimetry. Natl. Bur. Stand. Monogr. 1986, 104, 4–32. [Google Scholar]

- Stober, T.; Gilde, H.; Lenz, P. Color stability of highly filled composite resin materials for facings. Dent. Mater. 2001, 17, 87–94. [Google Scholar] [CrossRef]

- Lee, H.H.; Lee, J.H.; Yang, T.H.; Kim, Y.J.; Kim, S.C.; Kim, G.R.; Kim, H.R.; Lee, C.J.; Okubo, C. Evaluation of the flexural mechanical properties of various thermoplastic denture base polymers. Dent. Mater. J. 2018, 37, 950–956. [Google Scholar] [CrossRef] [Green Version]

| Material Name | Code | Polymer Type | Composition | Manufacturer | Curing |

|---|---|---|---|---|---|

| Fit resin | Custom-block | Pour-type PMMA Self-polymerizing resin | Powder: Copolymer of methyl methacrylate and 2-ethylhexyl acrylate, reaction initiator, coloring material, others Liquid: methyl methacrylate, ethylene glycol dimethacrylate, reaction initiator, others | Shofu, Japan | Self-polymerization at 50 °C for 30 min |

| Lucitone 199 denture base disc | PMMA-disk | CAD/CAM PMMA-based polymer | N/A | Dentsply Sirona, USA | N/A |

| Acron | Conventional PMMA | Conventional PMMA Heat-polymerized resin | Powder: Methacrylic acid ester polymer, others Liquid: Methyl methacrylate, others | GC, Japan | Heat curing at 78 °C for 8 h |

| Custom-Block | PMMA-Disk | Conventional PMMA | |

|---|---|---|---|

| Mean (SD) | Mean (SD) | Mean (SD) | |

| Flexural strength (FS, MPa) | 95.1 (4.3) a | 105.1 (2.2) b | 87.9 (5.0) c |

| Flexural modulus (FM, GPa) | 3.0 (0.1) d | 2.8 (0.1) e | 2.8 (0.0) e |

| Water sorption (Wsp, µg/mm3) | 28.5 (2.6) fh | 23.2 (0.5) g | 25.6 (2.1) gh |

| Water solubility (Wsl, µg/mm3) | 3.1 (16) i | 0.2 (0.1) j | 0.3 (0.2) j |

| Discoloration (∆E*) | 6.0 (0.6) k | 4.1 (0.8) l | 5.8 (0.4) k |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hada, T.; Kanazawa, M.; Iwaki, M.; Katheng, A.; Minakuchi, S. Comparison of Mechanical Properties of PMMA Disks for Digitally Designed Dentures. Polymers 2021, 13, 1745. https://doi.org/10.3390/polym13111745

Hada T, Kanazawa M, Iwaki M, Katheng A, Minakuchi S. Comparison of Mechanical Properties of PMMA Disks for Digitally Designed Dentures. Polymers. 2021; 13(11):1745. https://doi.org/10.3390/polym13111745

Chicago/Turabian StyleHada, Tamaki, Manabu Kanazawa, Maiko Iwaki, Awutsadaporn Katheng, and Shunsuke Minakuchi. 2021. "Comparison of Mechanical Properties of PMMA Disks for Digitally Designed Dentures" Polymers 13, no. 11: 1745. https://doi.org/10.3390/polym13111745

APA StyleHada, T., Kanazawa, M., Iwaki, M., Katheng, A., & Minakuchi, S. (2021). Comparison of Mechanical Properties of PMMA Disks for Digitally Designed Dentures. Polymers, 13(11), 1745. https://doi.org/10.3390/polym13111745