Binderless Thermal Insulation Panels Made of Spruce Bark Fibres

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Formaldehyde Content

3.2. Physical Properties

3.3. Thickness Swelling and Water Absorption after 24 h

3.4. Internal Bond

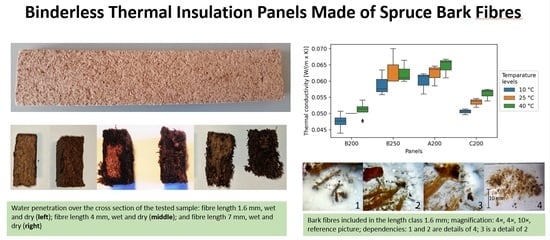

3.5. Thermal Conductivity (TC)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pásztory, Z.; Mohácsiné, I.R.; Gorbacheva, G.; Börcsök, Z. The utilization of tree bark. Bioresources 2016, 11, 7859–7888. [Google Scholar] [CrossRef]

- Chow, P.; Nakayama, F.S.; Blahnik, B.; Youngquist, J.A.; Coffelt, T.A. Chemical constituents and physical properties of guayule wood and bark. Ind. Crop. Prod. 2008, 28, 303–308. [Google Scholar] [CrossRef]

- Jablonsky, M.; Nosalova, J.; Sladkova, A.; Haz, A.; Kreps, F.; Valka, J.; Miertus, S.; Frecer, V.; Ondrejovic, M.; Sima, J.; et al. Valorisation of softwood bark through extraction of utilizable chemicals. A review. Biotechnol. Adv. 2017, 35, 726–750. [Google Scholar] [CrossRef]

- Borysiuk, P.; Boruszewski, P.; Auriga, R.; Danecki, L.; Auriga, A.; Rybak, K.; Nowacka, M. Influence of a bark-filler on the properties of PLA biocomposites. J. Mater. Sci. 2021, 56, 9196–9208. [Google Scholar] [CrossRef]

- Aydin, I.; Demirkir, C.; Colak, S.; Colakoglu, G. Utilization of bark flours as additive in plywood manufacturing. Eur. J. Wood Prod. 2017, 75, 63–69. [Google Scholar] [CrossRef]

- Barbu, M.C.; Lohninger, Y.; Hofmann, S.; Kain, G.; Petutschnigg, A.; Tudor, E.M. Larch bark as a formaldehyde scavenger in thermal insulation panels. Polymers 2020, 12, 2632. [Google Scholar] [CrossRef]

- Sutrisno Alamsyah, E.M.; Syamsudin, T.S.; Purwasasmita, B.S.; Suzuki, S.; Kobori, H. The potential using of organic nanoparticles synthesized from Gmelina (Gmelina arborea Roxb.) wood bark as nanofiller of wood adhesive: Physical, chemical and thermal properties. J. Indian Acad. Wood Sci. 2020, 17, 165–175. [Google Scholar] [CrossRef]

- Réh, R.; Krišťák, Ľ.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Vozárová, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of birch bark as an eco-friendly filler in urea-formaldehyde adhesives for plywood manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef]

- Feng, S.; Cheng, S.; Yuan, Z.; Leitch, M.; Xu, C. Valorization of bark for chemicals and materials: A review. Renew. Sustain. Energy Rev. 2013, 26, 560–578. [Google Scholar] [CrossRef]

- Bortenschlager, S.; Oeggl, K. The Iceman and His Natural Environment: Palaeobotanical Results; Springer: Vienna, Austria, 2000. [Google Scholar]

- Pásztory, Z.; Ronyecz Mohácsiné, I.; Börcsök, Z. Investigation of thermal insulation panels made of black locust tree bark. Constr. Build. Mater. 2017, 147, 733–735. [Google Scholar] [CrossRef]

- Pásztory, Z.; Ronyecz, I. The thermal insulation capacity of tree bark. Acta Silv. Lignaria Hung. 2013, 9, 111–117. [Google Scholar] [CrossRef] [Green Version]

- Paulitsch, M.; Barbu, M.C. Holzwerkstoffe der Moderne, 1. Aufl.; DRW-Verlag: Leinfelden-Echterdingen, Germany, 2015. [Google Scholar]

- Busquets-Ferrer, M.; Czabany, I.; Vay, O.; Gindl-Altmutter, W.; Hansmann, C. Alkali-extracted tree bark for efficient bio-based thermal insulation. Constr. Build. Mater. 2021, 271, 121577. [Google Scholar] [CrossRef]

- Blanchet, P.; Cloutier, A.; Riedl, B. Particleboard made from hammer milled black spruce bark residues. Wood Sci. Technol. 2000, 34, 11–19. [Google Scholar] [CrossRef]

- Pedieu, R.; Riedl, B.; Pichette, A. Properties of mixed particleboards based on white birch (Betula papyrifera) inner bark particles and reinforced with wood fibres. Eur. J. Wood Prod. 2009, 67, 95–101. [Google Scholar] [CrossRef]

- Yemele, M.; Koubaa, A.; Diouf, P.N.; Blanchet, P.; Cloutier, A.; Stevanovic, T. Effects of hot-water treatment of black spruce bark and trembling aspenbark rawmaterialon the physical and mechanical properties of bark particleboards. Wood Fiber Sci. 2008, 40, 339–351. [Google Scholar]

- Xing, C.; Zhang, S.Y.; Deng, J.; Wang, S. Investigation of the effects of bark fiber as core material and its resin content on three-layer MDF performance by response surface methodology. Wood Sci. Technol. 2007, 41, 585–595. [Google Scholar] [CrossRef]

- Xing, C.; Deng, J.; Zhang, S.Y. Effect of thermo-mechanical refining on properties of MDF made from black spruce bark. Wood Sci. Technol. 2007, 41, 329–338. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, X.M.; Wan, H.; Brunette, G. Binderless panels made with black spruce bark. Bioresources 2011, 6, 3960–3972. [Google Scholar]

- Kain, G.; Tudor, E.M.; Barbu, M.-C. Bark thermal insulation panels: An explorative study on the effects of bark species. Polymers 2020, 12, 2140. [Google Scholar] [CrossRef]

- Rosell, J.A.; Gleason, S.; Méndez-Alonzo, R.; Chang, Y.; Westoby, M. Bark functional ecology: Evidence for tradeoffs, functional coordination, and environment producing bark diversity. New Phytol. 2014, 201, 486–497. [Google Scholar] [CrossRef] [PubMed]

- Tudor, E.M.; Scheriau, C.; Barbu, M.C.; Réh, R.; Krišťák, Ľ.; Schnabel, T. Enhanced resistance to fire of the bark-based panels bonded with clay. Appl. Sci. 2020, 10, 5594. [Google Scholar] [CrossRef]

- Kain, G.; Güttler, V.; Barbu, M.-C.; Petutschnigg, A.; Richter, K.; Tondi, G. Density related properties of bark insulation boards bonded with tannin hexamine resin. Eur. J. Wood Prod. 2014, 72, 417–424. [Google Scholar] [CrossRef]

- Kain, G.; Lienbacher, B.; Barbu, M.-C.; Richter, K.; Petutschnigg, A. Larch (Larix decidua) bark insulation board: Interactions of particle orientation, physical–mechanical and thermal properties. Eur. J. Wood Prod. 2018, 76, 489–498. [Google Scholar] [CrossRef] [Green Version]

- Tudor, E.M.; Zwickl, C.; Eichinger, C.; Petutschnigg, A.; Barbu, M.C. Performance of softwood bark comminution technologies for determination of targeted particle size in further upcycling applications. J. Clean. Prod. 2020, 269, 122412. [Google Scholar] [CrossRef]

- Tsalagkas, D.; Börcsök, Z.; Pásztory, Z. Thermal, physical and mechanical properties of surface overlaid bark-based insulation panels. Eur. J. Wood Prod. 2019, 77, 721–730. [Google Scholar] [CrossRef] [Green Version]

- Tudor, E.M.; Dettendorfer, A.; Kain, G.; Barbu, M.C.; Réh, R.; Krišťák, L. Sound-Absorption coefficient of bark-based insulation panels. Polymers 2020, 12, 1012. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; van Renterghem, T.; Kang, J.; Verheyen, K.; Botteldooren, D. Sound absorption by tree bark. Appl. Acoust. 2020, 165, 107328. [Google Scholar] [CrossRef] [Green Version]

- Yemele, M.C.; Blanchet, P.; Cloutier, A.; Koubaa, A. Effect of bark content and particle geometry on the physical and mechanical properties of particleboard made from black spruce and trembling aspen bark. For. Prod. J. 2008, 58, 48–56. [Google Scholar]

- Burrows, C.H. Particleboard from Douglas-fir bark without additives. In Forest Products Research Laboratories, Report, No.15 pp.40 Ref.15.; United States Department of Agriculture: Madison, WI, USA, 1960. [Google Scholar]

- Almusawi, A.; Lachat, R.; Atcholi, K.E.; Gomes, S. Proposal of manufacturing and characterization test of binderless hemp shive composite. Int. Biodeterior. Biodegrad. 2016, 115, 302–307. [Google Scholar] [CrossRef]

- Krilov, A. Debarking of fibrous-barked hardwoods by ultra-high pressure water jets. Wood Sci.Technol. 1983, 17, 145–158. [Google Scholar] [CrossRef]

- EN 12667:2001-Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance; CEN, European Committee for Standardization: Brüssel, Belgium, 2001.

- EN 1607:2013-Plattenebene Thermal Insulating Products for Building Applications—Determination of Tensile Strength Perpendicular to Faces; CEN, European Committee for Standardization: Brüssel, Belgium, 2013.

- EN 317:2005-Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water; CEN, European Committee for Standardization: Brüssel, Belgium, 2005.

- ISO 12460-5:2015-Wood-Based Panels—Determination of Formaldehyde Release—Part 5: Extraction Method (Called the Perforator Method); CEN, European Committee for Standardization: Brüssel, Belgium, 2015.

- EN 326-1:2005-Wood-Based Panels—Sampling, Cutting and Inspection—Part 1: Sampling and Cutting of Test Pieces and Expression of Test Results; CEN, European Committee for Standardization: Brüssel, Belgium, 2005.

- Tudor, E.M.; Barbu, M.C.; Petutschnigg, A.; Réh, R.; Krišťák, Ľ. Analysis of larch-bark capacity for formaldehyde removal in wood adhesives. Int. J. Environ. Res. Public Health 2020, 17, 764. [Google Scholar] [CrossRef] [Green Version]

- Medved, S.; Gajšek, U.; Tudor, E.M.; Barbu, M.C.; Antonović, A. Efficiency of bark for reduction of formaldehyde emission from particleboards. Wood Res. 2019, 64, 307–316. [Google Scholar]

- Burhenne, L.; Messmer, J.; Aicher, T.; Laborie, M.-P. The effect of the biomass components lignin, cellulose and hemicellulose on TGA and fixed bed pyrolysis. J. Anal. Appl. Pyrolysis 2013, 101, 177–184. [Google Scholar] [CrossRef]

- Kemppainen, K.; Siika-aho, M.; Pattathil, S.; Giovando, S.; Kruus, K. Spruce bark as an industrial source of condensed tannins and non-cellulosic sugars. Ind. Crop. Prod. 2014, 52, 158–168. [Google Scholar] [CrossRef]

- Li, J.; Li, C.; Wang, W.; Zhang, W. Reactivity of larch and valonia tannins in synthesis of tannin-formaldehyde resins. Bioresources 2016, 11, 2256–2268. [Google Scholar] [CrossRef] [Green Version]

- Blechschmidt, J. (Ed.) Taschenbuch der Papiertechnik; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2010. [Google Scholar]

- Medved, S.; Lesar, B.; Tudor, E.M.; Humar, M. Thermal insulation panels from cellulosic fibres. For. Prod. J. 2015, 65, 554–558. [Google Scholar]

- Sprengard, C.; Treml, S.; Holm, H.A. Technologien und Techniken zur Verbesserung der Energieeffizienz von Gebäuden durch Wärmedämmstoffe: Metastudie Wärmedämmstoffe—Produkte—Anwendungen—Innovationen. 2013. Available online: http://www.fiw-muenchen.de/media/pdf/metastudie_waermedaemmstoffe.pdf (accessed on 9 January 2020).

| Insulation Panel (Target Density) | Density (kg/m3) | Fibre Length (mm) | Boards Number |

|---|---|---|---|

| A200 | 277 | 1.6 | 3 |

| B250 | 245 | 4 | 3 |

| B200 | 185 | 4 | 4 |

| C200 | 204 | 7 | 3 |

| Sample | TS % | WA % | TC 10 °C mW/(m*K) | TC 25 °C mW/(m*K) | TC 40 °C mW/(m*K) | IB N/mm² | Density kg/m3 |

|---|---|---|---|---|---|---|---|

| A200 | 10.0 b (5.4) | 207 b (108) | 59.9 c (3.4) | 62.2 c (3.3) | 64.5 c (3.1) | 0.129 c (0.035) | 277 d (19) |

| B250 | 18.6 d (3.8) | 301 c (32) | 58.9 c (3.9) | 60.8 c (3.7) | 62.4 c (3.5) | 0.069 b (0.011) | 245 c (27) |

| B200 | 14.4 c (3.0) | 305 c (57) | 47.5 a (2.8) | 49.3 a (2.7) | 51.1 a (2.6) | 0.034 b (0.006) | 185 a (21) |

| C200 | 8.0 a (3.8) | 172 a (45) | 50.6 b (0.9) | 53.4 b (1.4) | 56.1 b (1.9) | 0.009 a (0.013) | 204 b (4) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gößwald, J.; Barbu, M.-C.; Petutschnigg, A.; Tudor, E.M. Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers 2021, 13, 1799. https://doi.org/10.3390/polym13111799

Gößwald J, Barbu M-C, Petutschnigg A, Tudor EM. Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers. 2021; 13(11):1799. https://doi.org/10.3390/polym13111799

Chicago/Turabian StyleGößwald, Jakob, Marius-Cătălin Barbu, Alexander Petutschnigg, and Eugenia Mariana Tudor. 2021. "Binderless Thermal Insulation Panels Made of Spruce Bark Fibres" Polymers 13, no. 11: 1799. https://doi.org/10.3390/polym13111799

APA StyleGößwald, J., Barbu, M. -C., Petutschnigg, A., & Tudor, E. M. (2021). Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers, 13(11), 1799. https://doi.org/10.3390/polym13111799