Attapulgite–MXene Hybrids with Ti3C2Tx Lamellae Surface Modified by Attapulgite as a Mechanical Reinforcement for Epoxy Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis of Composites

2.3. Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, S.-Y.; Lin, W.-N.; Huang, Y.-L.; Tien, H.-W.; Wang, J.-Y.; Ma, C.-C.M.; Li, S.-M.; Wang, Y.-S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Chen, L.; Chai, S.; Liu, K.; Ning, N.; Gao, J.; Liu, Q.; Chen, F.; Fu, Q. Enhanced Epoxy/Silica Composites Mechanical Properties by Introducing Graphene Oxide to the Interface. ACS Appl. Mater. Interfaces 2012, 4, 4398–4404. [Google Scholar] [CrossRef]

- Yousefi, N.; Lin, X.; Zheng, Q.; Shen, X.; Pothnis, J.R.; Jia, J.; Zussman, E.; Kim, J.-K. Simultaneous in situ reduction, self-alignment and covalent bonding in graphene oxide/epoxy composites. Carbon 2013, 59, 406–417. [Google Scholar] [CrossRef]

- Lyu, Q.; Yan, H.; Li, L.; Chen, Z.; Yao, H.; Nie, Y. Imidazolium Ionic Liquid Modified Graphene Oxide: As a Reinforcing Filler and Catalyst in Epoxy Resin. Polymers 2017, 9, 447. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhang, H.; Wu, W.; Li, M.; Xu, Y.; Chen, G.; Dai, L. A Novel POSS-Based Copolymer Functionalized Graphene: An Effective Flame Retardant for Reducing the Flammability of Epoxy Resin. Polymers 2019, 11, 241. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gogotsi, Y.; Anasori, B. The Rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef] [Green Version]

- Anasori, B.; Lukatskaya, M.R.; Gogotsi, Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat. Rev. Mater. 2017, 2, 16098. [Google Scholar] [CrossRef]

- Ying, G.; Dillon, A.D.; Fafarman, A.T.; Barsoum, M.W. Transparent, conductive solution processed spincast 2D Ti2CTx (MXene) films. Mater. Res. Lett. 2017, 5, 391–398. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Ying, G.; Hu, C.; Zhang, K.; Ma, F.; Su, L.; Zhang, C.; Wang, C. Functionalization with MXene (Ti3C2) Enhances the Wettability and Shear Strength of Carbon Fiber-Epoxy Composites. ACS Appl. Nano Mater. 2019, 2, 5553–5562. [Google Scholar] [CrossRef]

- Chen, W.Y.; Jiang, X.; Lai, S.-N.; Peroulis, D.; Stanciu, L. Nanohybrids of a MXene and transition metal dichalcogenide for selective detection of volatile organic compounds. Nat. Commun. 2020, 11, 1302. [Google Scholar] [CrossRef] [Green Version]

- Mirkhani, S.A.; Zeraati, A.S.; Aliabadian, E.; Naguib, M.; Sundararaj, U. High Dielectric Constant and Low Dielectric Loss via Poly(vinyl alcohol)/Ti3C2Tx MXene Nanocomposites. ACS Appl. Mater. Interfaces 2019, 11, 18599–18608. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, L.; Chen, Q.; Li, P.; Zhou, A.; Cao, X.; Hu, Q. Preparation, mechanical and anti-friction performance of MXene/polymer composites. Mater. Des. 2016, 92, 682–689. [Google Scholar] [CrossRef]

- Carey, M.S.; Sokol, M.; Palmese, G.R.; Barsoum, M.W. Water Transport and Thermomechanical Properties of Ti3C2Tz MXene Epoxy Nanocomposites. ACS Appl. Mater. Interfaces 2019, 11, 39143–39149. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Chen, L.; Song, P.; Liang, C.; Lu, Y.; Qiu, H.; Zhang, Y.; Kong, J.; Gu, J. Fabrication on the annealed Ti3C2Tx MXene/Epoxy nanocomposites for electromagnetic interference shielding application. Compos. Part B Eng. 2019, 171, 111–118. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Zhou, A.; Shen, C.; Dai, Y.; Liu, F.; Chen, J.; Li, P.; Hu, Q. Effects of 2-D transition metal carbide Ti2CTx on properties of epoxy composites. RSC Adv. 2016, 6, 87341–87352. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; He, Y.; Wu, M.; Zhou, A. The effect of two-dimensional d-Ti3C2 on the mechanical and thermal conduc-tivity properties of thermoplastic polyurethane composites. Polym. Compos. 2019, 41, 350–359. [Google Scholar] [CrossRef]

- Liu, R.; Li, W. High-Thermal-Stability and High-Thermal-Conductivity Ti3C2Tx MXene/Poly(vinyl alcohol) (PVA) Composites. ACS Omega 2018, 3, 2609–2617. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [Green Version]

- Naguib, M.; Mochalin, V.; Barsoum, M.W.; Gogotsi, Y. 25th Anniversary Article: MXenes: A New Family of Two-Dimensional Materials. Adv. Mater. 2014, 26, 992–1005. [Google Scholar] [CrossRef]

- Ran, J.; Gao, G.; Li, F.; Ma, T.; Du, A.; Qiao, S. Ti3C2 MXene co-catalyst on metal sulfide photo-absorbers for enhanced visi-ble-light photocatalytic hydrogen production. Nat. Commun. 2017, 8, 13907. [Google Scholar] [CrossRef] [Green Version]

- Deysher, G.; Shuck, C.E.; Hantanasirisakul, K.; Frey, N.C.; Foucher, A.C.; Maleski, K.; Sarycheva, A.; Shenoy, V.B.; Stach, E.A.; Anasori, B.; et al. Synthesis of Mo4VAlC4 MAX Phase and Two-Dimensional Mo4VC4 MXene with Five Atomic Layers of Transition Metals. ACS Nano 2020, 14, 204–217. [Google Scholar] [CrossRef] [PubMed]

- Anasori, B.; Xie, Y.; Beidaghi, M.; Lu, J.; Hosler, B.C.; Hultman, L.; Kent, P.R.C.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional, Ordered, Double Transition Metals Carbides (MXenes). ACS Nano 2015, 9, 9507–9516. [Google Scholar] [CrossRef] [PubMed]

- Naguib, M.; Mashtalir, O.; Carle, J.; Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Transition Metal Carbides. ACS Nano 2012, 6, 1322–1331. [Google Scholar] [CrossRef]

- Bao, H.; Qiu, Y.; Peng, X.; Wang, J.-A.; Mi, Y.; Zhao, S.; Liu, X.; Liu, Y.; Cao, R.; Zhuo, L.; et al. Isolated copper single sites for high-performance electroreduction of carbon monoxide to multicarbon products. Nat. Commun. 2021, 12, 238. [Google Scholar] [CrossRef] [PubMed]

- Hart, J.L.; Hantanasirisakul, K.; Lang, A.C.; Anasori, B.; Pinto, D.; Pivak, Y.; Van Omme, J.T.; May, S.J.; Gogotsi, Y.; Taheri, M.L. Control of MXenes’ electronic properties through termination and intercalation. Nat. Commun. 2019, 10, 522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, R.; Li, Z.; Liu, W.; Jiao, W.; Hao, L.; Yang, F. Attapulgite-graphene oxide hybrids as thermal and mechanical reinforcements for epoxy composites. Compos. Sci. Technol. 2013, 87, 29–35. [Google Scholar] [CrossRef]

- Barsoum, M.W. The MN+1AXN phases: A new class of solids: Thermodynamically stable nanolaminates. Prog. Solid State Chem. 2000, 28, 201–281. [Google Scholar] [CrossRef]

- Ghidiu, M.; Lukatskaya, M.R.; Zhao, M.-Q.; Gogotsi, Y.; Barsoum, M.W. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nat. Cell Biol. 2014, 516, 78–81. [Google Scholar] [CrossRef]

- Mashtalir, O.; Cook, K.M.; Mochalin, V.; Crowe, M.; Barsoum, M.W.; Gogotsi, Y. Dye adsorption and decomposition on two-dimensional titanium carbide in aqueous media. J. Mater. Chem. A 2014, 2, 14334–14338. [Google Scholar] [CrossRef]

- Ying, Y.; Liu, Y.; Wang, X.; Mao, Y.; Cao, W.; Hu, P.; Peng, X. Two-Dimensional Titanium Carbide for Efficiently Reductive Removal of Highly Toxic Chromium(VI) from Water. ACS Appl. Mater. Interfaces 2015, 7, 1795–1803. [Google Scholar] [CrossRef]

- Lee, G.-W.; Park, M.; Kim, J.; Lee, J.I.; Yoon, H.G. Enhanced thermal conductivity of polymer composites filled with hybrid filler. Compos. Part A Appl. Sci. Manuf. 2006, 37, 727–734. [Google Scholar] [CrossRef]

- Yu, A.; Ramesh, P.; Sun, X.; Bekyarova, E.; Itkis, M.E.; Haddon, R.C. Enhanced Thermal Conductivity in a Hybrid Graphite Nanoplatelet—Carbon Nanotube Filler for Epoxy Composites. Adv. Mater. 2008, 20, 4740–4744. [Google Scholar] [CrossRef]

- Huang, Z.; Wu, W.; Drummer, D.; Liu, C.; Wang, Y.; Wang, Z. Enhanced the Thermal Conductivity of Polydimethylsiloxane via a Three-Dimensional Hybrid Boron Nitride@Silver Nanowires Thermal Network Filler. Polymers 2021, 13, 248. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Sheng, J. Preparation and properties of polypropylene/org-attapulgite nanocomposites. Polymers 2005, 46, 6243–6249. [Google Scholar] [CrossRef]

- Dong, L.; Wang, H.; Huang, Y.; Chen, H.; Cheng, H.; Liu, L.; Xu, L.; Zha, J.; Yu, M.; Wang, S.; et al. Elemental mercury removal from coal-fired flue gas using recyclable magnetic Mn-Fe based attapulgite sorbent. Chem. Eng. J. 2021, 407, 127182. [Google Scholar] [CrossRef]

- Xu, L.; Liu, Y.; Wang, J.; Tang, Y.; Zhang, Z. Selective adsorption of Pb2+ and Cu2+ on amino-modified attapulgite: Kinetic, thermal dynamic and DFT studies. J. Hazard. Mater. 2021, 404, 124140. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Ying, G.; Wen, D.; Zhang, K.; Hu, C.; Zheng, Y.; Zhang, C.; Wang, X.; Wang, C. Aqueous solution-processed MXene (Ti3C2Tx) for non-hydrophilic epoxy resin-based composites with enhanced mechanical and physical properties. Mater. Des. 2021, 197, 109276. [Google Scholar] [CrossRef]

- Zhang, K.; Ying, G.; Liu, L.; Wu, D.; Wang, X.; Zhou, Y. Three-Dimensional Porous Ti3C2Tx-NiO Composite Electrodes with Enhanced Electrochemical Performance for Supercapacitors. Materials 2019, 12, 188. [Google Scholar] [CrossRef] [Green Version]

- Su, L.; Ying, G.; Liu, L.; Ma, F.; Zhang, K.; Zhang, C.; Wang, X.; Wang, C. Ti3C2Tx on copper and nickel foams with improved electrochemical performance produced via solution processing for supercapacitor. Process. Appl. Ceram. 2018, 12, 366–373. [Google Scholar] [CrossRef]

- Yu, Q.; Liang, Y.; Cheng, J.; Chen, S.; Zhang, A.; Miao, M.; Zhang, D. Synthesis of a Degradable High-Performance Epoxy-Ended Hyperbranched Polyester. ACS Omega 2017, 2, 1350–1359. [Google Scholar] [CrossRef] [Green Version]

- Komiya, G.; Imai, T.; Happoya, A.; Fukumoto, T.; Sagae, H.; Sone, N.; Takahashi, A. Effects of Lignin Derivatives on Cross-Link Density and Dielectric Properties in the Epoxy-Based Insulating Materials for Printed Circuit Boards. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 1057–1062. [Google Scholar] [CrossRef]

- Pellice, S.A.; Fasce, D.P.; Williams, R.J.J. Properties of epoxy networks derived from the reaction of diglycidyl ether of bisphenol A with polyhedral oligomeric silsesquioxanes bearing OH-functionalized organic substituents. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 1451–1461. [Google Scholar] [CrossRef]

- ISO. ISO 527-1:1993 Plastics—Determination of Tensile Properties—Part 1: General Principles; International Organization for Standardization: Geneva, Switzerland, 1993. [Google Scholar]

- ISO. ISO 178:2010 Plastics—Determination of Flexural Properties; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- ISO. ISO 13586: 2000 Plastics—Determination of Fracture Toughness (GIC and KIC)—Linear Elastic Fracture Mechanics (LEFM) Approach; International Organization for Standardization: Geneva, Switzerland, 2000. [Google Scholar]

- Li, Z.; Wang, R.; Young, R.J.; Deng, L.; Yang, F.; Hao, L.; Jiao, W.; Liu, W. Control of the functionality of graphene oxide for its application in epoxy nanocomposites. Polymers 2013, 54, 6437–6446. [Google Scholar] [CrossRef]

- Fu, K.; Xie, Q.; Lü, F.; Duan, Q.; Wang, X.; Zhu, Q.; Huang, Z. Molecular Dynamics Simulation and Experimental Studies on the Thermomechanical Properties of Epoxy Resin with Different Anhydride Curing Agents. Polymers 2019, 11, 975. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pan, L.; Ban, J.; Lu, S.; Chen, G.; Yang, J.; Luo, Q.; Wu, L.; Yu, J. Improving thermal and mechanical properties of epoxy composites by using functionalized graphene. RSC Adv. 2015, 5, 60596–60607. [Google Scholar] [CrossRef]

- Qi, B.; Yuan, Z.; Lu, S.; Liu, K.; Li, S.; Yang, L.; Yu, J. Mechanical and thermal properties of epoxy composites containing graphene oxide and liquid crystalline epoxy. Fibers Polym. 2014, 15, 326–333. [Google Scholar] [CrossRef]

- Naebe, M.; Wang, J.; Amini, A.; Khayyam, H.; Hameed, N.; Li, L.H.; Chen, Y.; Fox, B. Mechanical Property and Structure of Covalent Functionalised Graphene/Epoxy Nanocomposites. Sci. Rep. 2015, 4, 4375. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Koh, K.L.; Lu, J.; Yang, L.; Phua, S.; Kong, J.; Chen, Z.; Lu, X. Simultaneous catalyzing and reinforcing effects of im-idazole-functionalized graphene in anhydride-cured epoxies. J. Mater. Chem. 2012, 22, 18395–18402. [Google Scholar] [CrossRef]

- Kim, K.-S.; Jeon, I.-Y.; Ahn, S.-N.; Kwon, Y.-D.; Baek, J.-B. Edge-functionalized graphene-like platelets as a co-curing agent and a nanoscale additive to epoxy resin. J. Mater. Chem. 2011, 21, 7337–7342. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Hu, X.; Jiang, Q.; Sun, Z.; Wang, P.; Qiu, Y.; Liu, W. Influence of graphene oxide with different oxidation levels on the properties of epoxy composites. Compos. Sci. Technol. 2018, 161, 74–84. [Google Scholar] [CrossRef]

- González Domínguez, J.M.; Díez Pascual, A.M.; Ansón Casaos, A.; Gómez Fatou, M.A. Epoxy composites with covalently anchored amino-functionalized SWNTs: Towards the tailoring of physical properties through targeted functionalization. J. Mater. Chem. 2011, 21, 14948–14958. [Google Scholar] [CrossRef] [Green Version]

- Feng, A.; Hou, T.; Jia, Z.; Zhang, Y.; Zhang, F.; Wu, G. Preparation and characterization of epoxy resin filled with Ti3C2Tx MXene nanosheets with excellent electric conductivity. Nanomaterials 2020, 10, 162. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, L.-C.; Wan, Y.-J.; Yan, D.; Pei, Y.-B.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 2013, 60, 16–27. [Google Scholar] [CrossRef]

- Bortz, D.R.; Heras, E.G.; Martingullon, I. Impressive Fatigue Life and Fracture Toughness Improvements in Graphene Ox-ide/Epoxy Composites. Macromolecules 2012, 45, 238–245. [Google Scholar] [CrossRef]

- Jiang, T.; Kuila, T.; Kim, N.H.; Ku, B.-C.; Lee, J.H. Enhanced mechanical properties of silanized silica nanoparticle attached graphene oxide/epoxy composites. Compos. Sci. Technol. 2013, 79, 115–125. [Google Scholar] [CrossRef]

- Chen, B.; Tang, J.; Zhang, G.; Chen, S.; Zhang, J. Properties and Morphologies of Epoxy Resin Based Composites Reinforced by Polyurethane and Graphene Oxide. Mater. Trans. 2017, 58, 842–844. [Google Scholar] [CrossRef] [Green Version]

- Wan, Y.-J.; Tang, L.-C.; Gong, L.-X.; Yan, D.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. Grafting of epoxy chains onto graphene oxide for epoxy composites with improved mechanical and thermal properties. Carbon 2014, 69, 467–480. [Google Scholar] [CrossRef]

- Madeshwaran, S.R.; Jayaganthan, R.; Velmurugan, R.; Gupta, N.K.; Manzhirov, A. Mechanical and thermal properties of MoS2 reinforced epoxy nanocomposites. J. Phys. Conf. Ser. 2018, 991, 012054. [Google Scholar] [CrossRef]

- Nieto, A.; Bisht, A.; Lahiri, D.; Zhang, C.; Agarwal, A. Graphene reinforced metal and ceramic matrix composites: A review. Int. Mater. Rev. 2017, 62, 241–302. [Google Scholar] [CrossRef]

| Sample Abbreviation | Formulation |

|---|---|

| Neat epoxy | (DGEBA (16.216 g) and MTHPA (13.784 g) at mass ratio of 100:85) + 0.3 wt % DMP-30 (0.090 g) |

| M02/epoxy | 0.2 wt % Ti3C2Tx (0.060 g) + (DGEBA (16.216 g) and MTHPA (13.784 g) at mass ratio of 100:85) + 0.3 wt % DMP-30 (0.090 g) |

| M02A01/epoxy | 0.2 wt % Ti3C2Tx (0.060 g) + 0.1 wt % ATP (0.030 g) + (DGEBA (16.216 g) and MTHPA (13.784 g) at mass ratio of 100:85) + 0.3 wt % DMP-30 (0.090 g) |

| M02A025/epoxy | 0.2 wt % Ti3C2Tx (0.060 g) + 0.25 wt % ATP (0.075 g) +(DGEBA (16.216 g) and MTHPA (13.784 g) at mass ratio of 100:85) + 0.3 wt % DMP-30 (0.090 g) |

| M02A05/epoxy | 0.2 wt % Ti3C2Tx (0.060 g) + 0.5 wt % ATP (0.151 g) + (DGEBA (16.216 g) and MTHPA (13.784 g) at mass ratio of 100:85) + 0.3 wt % DMP-30 (0.090 g) |

| M02A10/epoxy | 0.2 wt % Ti3C2Tx (0.060 g) + 1.0 wt %. ATP (0.304 g) + (DGEBA (16.216 g) and MTHPA (13.784 g) at mass ratio of 100:85) + 0.3 wt % DMP-30 (0.090 g) |

| Sample | Char Yield (%) | Onset Temperature (°C) | Step Inflection Point (°C) | End Temperature (°C) |

|---|---|---|---|---|

| Neat epoxy | 4.89 | 382.67 | 411.55 | 445.84 |

| M02/epoxy | 7.15 | 378.70 | 405.96 | 437.73 |

| M02A01/epoxy | 7.36 | 371.30 | 403.61 | 440.25 |

| M02A025/epoxy | 7.53 | 373.65 | 407.04 | 441.70 |

| M02A05/epoxy | 7.77 | 372.74 | 406.50 | 442.78 |

| M02A10/epoxy | 8.53 | 378.70 | 409.57 | 439.71 |

| Samples | Storage Modulus (MPa) (RT) | Tg (°C) | Storage Modulus (MPa) (Tg + 40 °C) | Crosslinking Density (mol/cm3) |

|---|---|---|---|---|

| Neat epoxy | 2209 | 131.3 | 15 | 1.35 × 10−3 |

| M02/epoxy | 2405 | 122.9 | 12 | 1.10 × 10−3 |

| M02A01/epoxy | 2460 | 119.3 | 10 | 0.93 × 10−3 |

| M02A025/epoxy | 2552 | 117.1 | 11 | 1.03 × 10−3 |

| M02A05/epoxy | 2649 | 115.1 | 10 | 0.94 × 10−3 |

| M02A10/epoxy | 2686 | 113.2 | 9 | 0.85 × 10−3 |

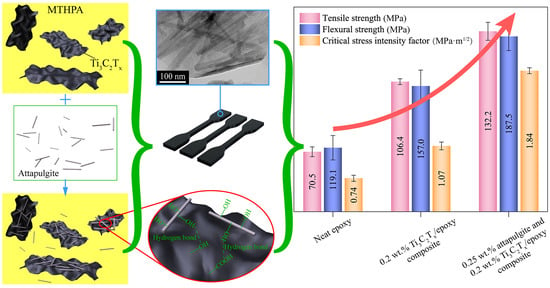

| Samples | Tensile Strength (MPa) | Elastic Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) | KIC (MPa·m1/2) |

|---|---|---|---|---|---|

| Neat epoxy | 70.5 ± 6.5 | 2.6 ± 0.3 | 119.1 ± 7.5 | 2.6 ± 0.2 | 0.74 ± 0.03 |

| M02/epoxy | 106.4 ± 1.5 | 3.5 ± 0.3 | 157.0 ± 8.7 | 2.6 ± 0.2 | 1.07 ± 0.04 |

| M02A01/epoxy | 122 ± 4.4 | 3.5 ± 0.2 | 169.6 ± 9.1 | 3.5 ± 0.3 | 1.73 ± 0.01 |

| M02A025/epoxy | 132.2 ± 4.6 | 3.6 ± 0.3 | 187.5 ± 8.9 | 3.6 ± 0.2 | 1.84 ± 0.03 |

| M02A05/epoxy | 120.2 ± 4.8 | 3.6 ± 0.1 | 161.6 ± 8.5 | 3.7 ± 0.3 | 2.04 ± 0.03 |

| M02A10/epoxy | 101.3 ± 1.8 | 3.5 ± 0.2 | 148.8 ± 8.9 | 3.6 ± 0.2 | 2.18 ± 0.04 |

| Reinforcement Filler Content (wt %) | σ, Gain in σ (%), (Matrix σ (MPa)) | σfM, Gain in σfM (%), (Matrix σfM (MPa)) | KIC, Gain in KIC (%), (Matrix KIC (MPa·m1/2)) | Reinforcement Filler and References |

|---|---|---|---|---|

| 0.2 MXene + 0.25 ATP | 132.2, 88, (70.5) | 187.5, 57, (119.1) | 1.84, 149, (0.74) | ATP–MXene hybrids, this work |

| 0.2 MXene + 1.0 ATP | 101.3, 44, (70.5) | 148.8, 25, (119.1) | 2.18, 195, (0.74) | |

| 0.2 | 106.4, 51, (70.5) | 157, 32, (119.1) | 1.07, 45, (0.74) | Ti3C2Tx [37] |

| 1 | 76.1, 8, (70.5) | 128.6, 8, (119.1) | 1.41, 91, (0.74) | |

| 1 | - | 98, 66, (59) | - | Ti2CTx [15] |

| 1.2 | ~66, 24.9, (~53) | - | - | Ti3C2Tx [55] |

| 0.1 | ~51, −2, (~52) | ~152, 8.6, (~140) | 0.611, 24, (0.493) | Graphene, thermally reduced GO [56] |

| 0.1 | ~71, 9, (~65) | ~150, 20 (~125) | ~96, 28 (~0.75) | Pristine GO sheet [57] |

| 0.5 | ~75, 15, (~65) | ~156, 25, (~125) | ~1.22, 63 (~0.75) | |

| 0.1 | ~75, 6, (~70) | - | ~1.9, 27, (~1.5) | Pristine GO sheet [58] |

| 0.5 | ~70.7, 1, (~70) | - | ~−1.2, 20, (~1.5) | |

| 0.1 | 78.9, 13.0, (69.7) | - | 1.14, 12, (1.02) | 3-aminopropyl trimethoxysilane functionalized GO sheet [46] |

| 0.2 | 81.2, 16.5, (69.7) | - | 1.22, 20, (1.02) | |

| 0.1 | 77.9, 11.7, (69.7) | - | 1.37, 34, (1.02) | 3-glycidoxypropyl trimethoxysilane functionalized GO sheet [46] |

| 0.2 | 79.2, 13.6, (69.7) | - | 1.46, 43, (1.02) | |

| 0.3 | 66.38, 22, (54.39) | 414.10, 87, (221.96) | - | Polyurethane, pristine GO sheet [59] |

| 0.1 | 94.79, 79, (52.98) | - | 0.684, 36, (0.503) | Functionalized GO sheet [60] |

| 0.5 | 85.51, 61, (52.98) | - | 0.669, 33, (0.503) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Ying, G.; Zhao, Y.; Li, Y.; Wu, Y.; Wen, D.; Wu, M.; Wang, M.; Zhou, Q.; Wang, X.; et al. Attapulgite–MXene Hybrids with Ti3C2Tx Lamellae Surface Modified by Attapulgite as a Mechanical Reinforcement for Epoxy Composites. Polymers 2021, 13, 1820. https://doi.org/10.3390/polym13111820

Liu L, Ying G, Zhao Y, Li Y, Wu Y, Wen D, Wu M, Wang M, Zhou Q, Wang X, et al. Attapulgite–MXene Hybrids with Ti3C2Tx Lamellae Surface Modified by Attapulgite as a Mechanical Reinforcement for Epoxy Composites. Polymers. 2021; 13(11):1820. https://doi.org/10.3390/polym13111820

Chicago/Turabian StyleLiu, Lu, Guobing Ying, Yinlong Zhao, Yuexia Li, Yiran Wu, Dong Wen, Meng Wu, Minghui Wang, Qingzhong Zhou, Xiang Wang, and et al. 2021. "Attapulgite–MXene Hybrids with Ti3C2Tx Lamellae Surface Modified by Attapulgite as a Mechanical Reinforcement for Epoxy Composites" Polymers 13, no. 11: 1820. https://doi.org/10.3390/polym13111820

APA StyleLiu, L., Ying, G., Zhao, Y., Li, Y., Wu, Y., Wen, D., Wu, M., Wang, M., Zhou, Q., Wang, X., & Wang, C. (2021). Attapulgite–MXene Hybrids with Ti3C2Tx Lamellae Surface Modified by Attapulgite as a Mechanical Reinforcement for Epoxy Composites. Polymers, 13(11), 1820. https://doi.org/10.3390/polym13111820