Natural Fiber Reinforced Composite Material for Product Design: A Short Review

Abstract

:1. Introduction

2. Natural Fiber Reinforced Composite Material

Natural Fiber

3. Composites

4. Product Design for Natural Fiber Composite (NFC)

4.1. Selection Material in Product Design

4.2. Evaluation Concept for Product Design

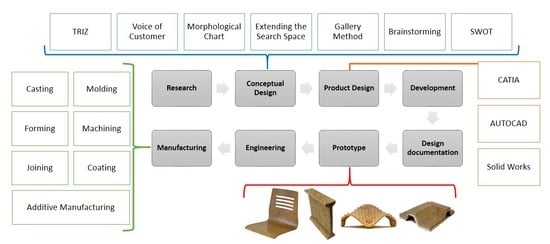

4.3. Development of Product Design by Integrating Design for Sustainability with Other Concurrent Engineering Techniques

4.3.1. Theory of Inventive Problem Solving (TRIZ)

4.3.2. Voice of Customer

4.3.3. Morphological Chart

4.3.4. Extending the Search Space

4.3.5. Gallery Method

4.3.6. Brainstorming

5. Natural Fibers Composite Applications

5.1. Natural Fibers Composites’ Applications in Electrical and Electronic Components

5.2. Natural Fibers Composites’ Applications in Packaging

5.3. Natural Fibers Composites’ Applications in Sports Equipment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Milton, A.; Rodgers, P. Product Design Process and Methods. In Research Methods for Product Design; Laurence King Publishing: London, UK, 2013; ISBN 9781780673028. [Google Scholar]

- Bocci, E.; Prosperi, E.; Mair, V.; Bocci, M. Ageing and Cooling of Hot-Mix-Asphalt During Hauling and Paving—A Laboratory and Site Study. Sustainabilty 2020, 12, 8612. [Google Scholar] [CrossRef]

- Corrado, A.; Polini, W. Measurement of high flexibility components in composite material by touch probe and force sensing resistors. J. Manuf. Process. 2019, 45, 520–531. [Google Scholar] [CrossRef]

- Hanan, F.; Jawaid, M.; Tahir, P.M. Mechanical performance of oil palm/kenaf fiber-reinforced epoxy-based bilayer hybrid composites. J. Nat. Fibers 2018, 17, 155–167. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Potential Application of Green Composites for Cross Arm Component in Transmission Tower: A Brief Review. Int. J. Polym. Sci. 2020, 2020, 1–15. [Google Scholar] [CrossRef]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of Natural Fiber Reinforced Polymer Composites in Sandwich Structures: A Review on Its Mechanical Properties. Polymers 2021, 13, 423. [Google Scholar] [CrossRef]

- Sapuan, S.; Hemapriya, G.; Ilyas, R.; Atikah, M.; Asyraf, M.; Mansor, M.R. Implementation of design for sustainability in developing trophy plaque using green kenaf polymer composites. In Design for Sustainability; Elsevier: Amsterdam, The Netherlands, 2021; pp. 85–103. [Google Scholar]

- Amir, A.; Ishak, M.; Yidris, N.; Zuhri, M.; Asyraf, M. Potential of Honeycomb-Filled Composite Structure in Composite Cross-Arm Component: A Review on Recent Progress and Its Mechanical Properties. Polymers 2021, 13, 1341. [Google Scholar] [CrossRef] [PubMed]

- Elanchezhian, C.; Ramnath, B.; Ramakrishnan, G.; Rajendrakumar, M.; Naveenkumar, V.; Saravanakumar, M. Review on mechanical properties of natural fiber composites. Mater. Today Proc. 2018, 5, 1785–1790. [Google Scholar] [CrossRef]

- Bakar, N.H.; Hyie, K.M.; Ramlan, A.S.; Hassan, M.K.; Jumahat, A. Mechanical Properties of Kevlar Reinforcement in Kenaf Composites. Appl. Mech. Mater. 2013, 465-466, 847–851. [Google Scholar] [CrossRef]

- Nordin, N.A.; Yussof, F.M.; Kasolang, S.; Salleh, Z.; Ahmad, M.A. Wear Rate of Natural Fibre: Long Kenaf Composite. Procedia Eng. 2013, 68, 145–151. [Google Scholar] [CrossRef] [Green Version]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 28, 2675–2695. [Google Scholar] [CrossRef]

- Johari, A.; Ishak, M.; Leman, Z.; Yusoff, M.; Asyraf, M.R.M. Influence of CaCO3 in pultruded glass fiber/unsaturated polyester resin composite on flexural creep behavior using conventional and time-temperature superposition principle methods. Polimery 2020, 65, 792–800. [Google Scholar] [CrossRef]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N. Utilization of Bracing Arms as Additional Reinforcement in Pultruded Glass Fiber-Reinforced Polymer Composite Cross-Arms: Creep Experimental and Numerical Analyses. Polymers 2021, 13, 620. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.; Kamarudin, S.; Ahmad, S.; Mahat, A.; Lee, C.; Aisyah, H.; et al. Fabrication, Functionalization, and Application of Carbon Nanotube-Reinforced Polymer Composite: An Overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.; Sapuan, S.; Asyraf, M.; Dayana, D.; Amelia, J.; Rani, M.; Norrrahim, M.; Nurazzi, N.; Aisyah, H.; Sharma, S.; et al. Polymer Composites Filled with Metal Derivatives: A Review of Flame Retardants. Polymery 2021, 13, 1701. [Google Scholar] [CrossRef]

- Rognoli, V.; Karana, E.; Pedgley, O. Natural fibre composites in product design: An investigation into material perception and acceptance. In Proceedings of the 2011 Conference on Designing Pleasurable Products and Interfaces, Milan, Italy, 22–25 June 2011; pp. 1–4. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Atikah, M.S.N.; Ibrahim, R.; Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Megashah, L.N. Mechanical and Dynamic Mechanical Analysis of Bio-based Composites. In Mechanical and Dynamic Properties of Biocomposites; Krishnasamy, S., Nagarajan, R., Thiagamani, S.M.K., Siengchin, S., Eds.; WILEY-VCH GmbH: Weinheim, Germany, 2021. [Google Scholar]

- Dicker, M.P.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Nurazzi, N.; Asyraf, M.; Khalina, A.; Abdullah, N.; Aisyah, H.; Rafiqah, S.; Sabaruddin, F.; Kamarudin, S.; Norrrahim, M.; Ilyas, R.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N.; Ilyas, R. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Nukman, Y. The Relationship Between Manufacturing and Design for Manufacturing in Product Development of Natural Fibre Composites. In Manufacturing of Coir Fiber Reinforced Polymer Composites Using Hot Compression Technique; Springer: Berlin/Heidelberg, Germany, 2014; p. 2. [Google Scholar]

- Mansor, M.; Sapuan, S.; Zainudin, E.S.; Nuraini, A.; Hambali, A. Conceptual design of kenaf fiber polymer composite automotive parking brake lever using integrated TRIZ–Morphological Chart–Analytic Hierarchy Process method. Mater. Des. 2014, 54, 473–482. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Comparison of Static and Long-term Creep Behaviors between Balau Wood and Glass Fiber Reinforced Polymer Composite for Cross-arm Application. Fibers Polym. 2021, 22, 793–803. [Google Scholar] [CrossRef]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 2061. [Google Scholar] [CrossRef]

- Marzuki, I. Jurureka Perindustrian. In Reka Bentuk Produk; Dewan Bahasa dan Pustaka: Kuala Lumpur, Malaysia, 2013; pp. 4–5. ISBN 978-983-46-1439-3. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Evaluation of design and simulation of creep test rig for full-scale cross arm structure. Adv. Civ. Eng. 2020, 6980918. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Harussani, M.; Hakimi, M.; Haziq, M.; Atikah, M.; Asyraf, M.; Ishak, M.; Razman, M.; Nurazzi, N.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef] [PubMed]

- Suriani, M.; Rapi, H.; Ilyas, R.; Petrů, M.; Sapuan, S. Delamination and Manufacturing Defects in Natural Fiber-Reinforced Hybrid Composite: A Review. Polymers 2021, 13, 1323. [Google Scholar] [CrossRef] [PubMed]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef] [Green Version]

- Sanjay, M.; Arpitha, G.; Yogesha, B. Study on Mechanical Properties of Natural—Glass Fibre Reinforced Polymer Hybrid Composites: A Review. Mater. Today Proc. 2015, 2, 2959–2967. [Google Scholar] [CrossRef]

- Bharath, K.N.; Basavarajappa, S. Applications of biocomposite materials based on natural fibers from renewable resources: A review. Sci. Eng. Compos. Mater. 2016, 23, 123–133. [Google Scholar] [CrossRef]

- Aditya, P.H.; Kishore, K.S.; Prasad, D.V.V.K. Characterization of Natural Fiber Reinforced Composites. Int. J. Eng. Appl. Sci. 2017, 4, 1–10. [Google Scholar]

- Corona, A.; Madsen, B.; Hauschild, M.Z.; Birkved, M. Natural fibre selection for composite eco-design. CIRP Ann. 2016, 65, 13–16. [Google Scholar] [CrossRef] [Green Version]

- Padmavathi, T.; Naidu, S.V.; Rao, R. Studies on Mechanical Behavior of Surface Modified Sisal Fibre–Epoxy Composites. J. Reinf. Plast. Compos. 2012, 31, 519–532. [Google Scholar] [CrossRef]

- Amir, N.; Abidin, K.A.Z.; Shiri, F.B.M. Effects of Fibre Configuration on Mechanical Properties of Banana Fibre/PP/MAPP Natural Fibre Reinforced Polymer Composite. Procedia Eng. 2017, 184, 573–580. [Google Scholar] [CrossRef]

- Maleque, M.A.; Belal, F.Y.; Sapuan, S.M. Mechanical properties study of pseudo-stem banana fiber reinforced epoxy composite. Arab. J. Sci. Eng. 2007, 32, 359–364. [Google Scholar]

- Taekema, J.; Karana, E. Creating awareness on natural fibre composites in design. In Proceedings of the DS 70: Proceedings of DESIGN 2012, the 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012; pp. 1141–1150. [Google Scholar]

- Sapuan, S.; Maleque, A. Design and fabrication of natural woven fabric reinforced epoxy composite for household telephone stand. Mater. Des. 2005, 26, 65–71. [Google Scholar] [CrossRef]

- Shekar, H.S.; Ramachandra, M. Green Composites: A Review. Mater. Today: Proc. 2018, 5, 2518–2526. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Norizan, M.N.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; Ishak, M.R.; Zainudin, E.S.; Izwan, S.; Azammi, A.M.N.; et al. Potential of natural fibre composites for transport industry: A review. In Prosiding Seminar Enau Kebangsaan 2019; Institute of Tropical Forest and Forest Products (INTROP); Universiti Putra Malaysia: Bahau, Malaysia, 2019; pp. 2–11. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Atiqah, A.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Nurazzi, N.M.; Atikah, M.S.N.; Ansari, M.N.M.; et al. Sugar palm (Arenga pinnata [Wurmb.] Merr) starch films containing sugar palm nanofibrillated cellulose as reinforcement: Water barrier properties. Polym. Compos. 2019, 41, 459–467. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Atikah, M.; Asyraf, M.; Rafiqah, S.A.; Aisyah, H.; Nurazzi, N.M.; Norrrahim, M. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text. Res. J. 2021, 91, 152–167. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Ray, D.; Mohanty, A.K.; Mishra, M. Natural-fiber composites in the automotive sector. In Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008; pp. 221–268. [Google Scholar]

- Girijappa, Y.G.T.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 1–14. [Google Scholar] [CrossRef]

- Arpitha, G.; Sanjay, M.; Senthamaraikannan, P.; Barile, C.; Yogesha, B. Hybridization Effect of Sisal/Glass/Epoxy/Filler Based Woven Fabric Reinforced Composites. Exp. Tech. 2017, 41, 577–584. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Senthamaraikannan, P.; Pradeep, S.; Saravanakumar, S.S.; Yogesha, B. A review on synthesis and characterization of commercially available natural fibers: Part-I. J. Nat. Fibers 2018, 11, 25–36. [Google Scholar]

- Chandra, C.S.J.; George, N.; Narayanankutty, S.K. Isolation and characterization of cellulose nanofibrils from arecanut husk fibre. Carbohydr. Polym. 2016, 142, 158–166. [Google Scholar]

- Tibolla, H.; Pelissari, F.M.; Menegalli, F.C. Cellulose nanofibers produced from banana peel by chemical and enzymatic treatment. LWT 2014, 59, 1311–1318. [Google Scholar] [CrossRef]

- Corrêa, A.C.; Teixeira, E.D.M.; Pessan, L.; Mattoso, L.H.C. Cellulose nanofibers from curaua fibers. Cellulose 2010, 17, 1183–1192. [Google Scholar] [CrossRef]

- Chirayil, C.J.; Joy, J.; Mathew, L.; Mozetic, M.; Koetz, J.; Thomas, S. Isolation and characterization of cellulose nanofibrils from Helicteres isora plant. Ind. Crop. Prod. 2014, 59, 27–34. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Shakeri, A.; Misra, M.; Oksmand, K. Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofibers. BioResources 2009, 4, 626–639. [Google Scholar] [CrossRef]

- Chan, H.C.; Chia, C.H.; Zakaria, S.; Ahmad, I.; Dufresne, A. Production and Characterisation of Cellulose and Nano-Crystalline Cellulose from Kenaf Core Wood. Bioresources 2012, 8, 785–794. [Google Scholar] [CrossRef] [Green Version]

- Sheltami, R.M.; Abdullah, I.; Ahmad, I.; Dufresne, A.; Kargarzadeh, H. Extraction of cellulose nanocrystals from mengkuang leaves (Pandanus tectorius). Carbohydr. Polym. 2012, 88, 772–779. [Google Scholar] [CrossRef]

- Megashah, L.N.; Ariffin, H.; Zakaria, M.R.; Hassan, M.A. Properties of Cellulose Extract from Different Types of Oil Palm Biomass. IOP Conf. Series: Mater. Sci. Eng. 2018, 368, 012049. [Google Scholar] [CrossRef]

- Jonoobi, M.; Khazaeian, A.; Tahir, P.M.; Azry, S.S.; Oksman, K. Characteristics of cellulose nanofibers isolated from rubberwood and empty fruit bunches of oil palm using chemo-mechanical process. Cellulose 2011, 18, 1085–1095. [Google Scholar] [CrossRef]

- Bendahou, A.; Habibi, Y.; Kaddami, H.; Dufresne, A. Physico-Chemical Characterization of Palm from Phoenix Dactylifera–L, Preparation of Cellulose Whiskers and Natural Rubber–Based Nanocomposites. J. Biobased Mater. Bioenergy 2009, 3, 81–90. [Google Scholar] [CrossRef]

- Cherian, B.M.; Leão, A.L.; de Souza, S.F.; Thomas, S.; Pothan, L.A.; Kottaisamy, M. Isolation of nanocellulose from pineapple leaf fibres by steam explosion. Carbohydr. Polym. 2010, 81, 720–725. [Google Scholar] [CrossRef]

- Syafri, E.; Kasim, A.; Abral, H.; Asben, A. Cellulose nanofibers isolation and characterization from ramie using a chemical-ultrasonic treatment. J. Nat. Fibers 2018, 16, 1145–1155. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Isolation and characterization of nanofibers from agricultural residues—Wheat straw and soy hulls. Bioresour. Technol. 2008, 99, 1664–1671. [Google Scholar] [CrossRef]

- Li, M.; Wang, L.-J.; Li, D.; Cheng, Y.-L.; Adhikari, B. Preparation and characterization of cellulose nanofibers from de-pectinated sugar beet pulp. Carbohydr. Polym. 2014, 102, 136–143. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Ishak, M. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, E.D.M.; Bondancia, T.; Teodoro, K.B.R.; Corrêa, A.C.; Marconcini, J.M.; Mattoso, L.H.C. Sugarcane bagasse whiskers: Extraction and characterizations. Ind. Crop. Prod. 2011, 33, 63–66. [Google Scholar] [CrossRef]

- Abral, H.; Dalimunthe, M.H.; Hartono, J.; Efendi, R.P.; Asrofi, M.; Sugiarti, E.; Sapuan, S.M.; Park, J.-W.; Kim, H.-J. Characterization of Tapioca Starch Biopolymer Composites Reinforced with Micro Scale Water Hyacinth Fibers. Starch Stärke 2018, 70, 1–8. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Biocomposites from wheat straw nanofibers: Morphology, thermal and mechanical properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- Wang, F.; Xie, Z.; Liang, J.; Fang, B.; Piao, Y.; Hao, M.; Wang, Z. Tourmaline-Modified FeMnTiOx Catalysts for Improved Low-Temperature NH3-SCR Performance. Environ. Sci. Technol. 2019, 53, 6989–6996. [Google Scholar] [CrossRef]

- Piao, Y.; Jiang, Q.; Li, H.; Matsumoto, H.; Liang, J.; Liu, W.; Pham-Huu, C.; Liu, Y.; Wang, F. Identify Zr Promotion Effects in Atomic Scale for Co-Based Catalysts in Fischer–Tropsch Synthesis. ACS Catal. 2020, 10, 7894–7906. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial Activities of Starch-Based Biopolymers and Biocomposites Incorporated with Plant Essential Oils: A Review. Polymers 2020, 12, 2403. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syafiq, R.; Sherwani, S.F.K. Nanocellulose Reinforced Thermoplastic Starch (TPS), Polylactic Acid (PLA), and Polybutylene Succinate (PBS) for Food Packaging Applications. Front. Chem. 2020, 8, 1–12. [Google Scholar] [CrossRef]

- Diyana, Z.; Jumaidin, R.; Selamat, M.; Ghazali, I.; Julmohammad, N.; Huda, N.; Ilyas, R. Physical Properties of Thermoplastic Starch Derived from Natural Resources and Its Blends: A Review. Polymers 2021, 13, 1396. [Google Scholar] [CrossRef]

- Sapuan, S.; Aulia, H.; Ilyas, R.; Atiqah, A.; Dele-Afolabi, T.; Nurazzi, M.; Supian, A.; Atikah, M. Mechanical Properties of Longitudinal Basalt/Woven-Glass-Fiber-reinforced Unsaturated Polyester-Resin Hybrid Composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef]

- Abdul, R.A.H.; Roslan, A.F.; Jaafar, M.; Roslan, M.N.; Ariffin, S. Mechanical Properties Evaluation of Woven Coir and Kevlar Reinforced Epoxy Composites. Adv. Mater. Res. 2011, 277, 36–42. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A.; Bhat, A.; Abu Baker, A. Impact Properties of Natural Fiber Hybrid Reinforced Epoxy Composites. Adv. Mater. Res. 2011, 264-265, 688–693. [Google Scholar] [CrossRef]

- Masoodi, R.; Pillai, K.M. A study on moisture absorption and swelling in bio-based jute-epoxy composites. J. Reinf. Plast. Compos. 2012, 31, 285–294. [Google Scholar] [CrossRef]

- What Is Industrial Design? Available online: https://www.idsa.org/what-industrial-design (accessed on 18 March 2021).

- Abidin, S.Z.; Abdullah, M.H.; Yusoff, Z. Seni reka perindustrian: Daripada Idea Kepada Lakaran Dewan Bahasa dan Pustaka; Seni Reka Perindustrian: Kuala Lumpur, Malaysia, 2013; ISBN 9834615337. [Google Scholar]

- Ramani, K.; Ramanujan, D.; Bernstein, W.Z.; Zhao, F.; Sutherland, J.; Handwerker, C.; Choi, J.-K.; Kim, H.; Thurston, D. Integrated sustainable life cycle design: A review. J. Mech. Des. 2010, 132, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Yung, W.K.; Chan, H.K.; So, J.H.; Wong, D.W.; Choi, A.C.; Yue, T.M. A life-cycle assessment for eco-redesign of a consumer electronic product. J. Eng. Des. 2011, 22, 69–85. [Google Scholar] [CrossRef]

- Karana, E. Materials selection in design: From research to education. In Proceedings of the the 1st International Symposium for Design Education Researchers, Paris, France, 18–19 May 2011. [Google Scholar]

- Marzuki, I. Proses Reka Bentuk Produk. In Reka Bentuk Produk; Dewan Bahasa dan Pustaka: Kuala Lumpur, Malaysia, 2013; p. 16. ISBN 978-983-46-1439-3. [Google Scholar]

- Karana, E.; Hekkert, P.; Kandachar, P. A tool for meaning driven materials selection. Mater. Des. 2010, 31, 2932–2941. [Google Scholar] [CrossRef]

- Mahmud, J.; Khor, S.; Ismail, M.M.; Taib, J.M.; Ramlan, N.; Ling, K. Design for paraplegia: Preparing product design specifications for a wheelchair. Technol. Disabil. 2015, 27, 79–89. [Google Scholar] [CrossRef]

- Azman, M.A.; Yusof, S.A.M.; Abdullah, I.; Mohamad, I.; Mohammed, J.S. Factors influencing face mask selection and design specifications: Results from pilot study amongst malaysian umrah pilgrims. J. Teknol. 2017, 79, 79. [Google Scholar] [CrossRef] [Green Version]

- Spangenberg, J.H.; Fuad-Luke, A.; Blincoe, K. Design for Sustainability (DfS): The interface of sustainable production and consumption. J. Clean. Prod. 2010, 18, 1485–1493. [Google Scholar] [CrossRef]

- Ali, S.; Razman, M.; Awang, A.; Asyraf, M.; Ishak, M.; Ilyas, R.; Lawrence, R. Critical Determinants of Household Electricity Consumption in a Rapidly Growing City. Sustainabilty 2021, 13, 4441. [Google Scholar] [CrossRef]

- Spangenberg, J.H. Sustainable development indicators: Towards integrated systems as a tool for managing and monitoring a complex transition. Int. J. Glob. Environ. Issues 2009, 9, 318. [Google Scholar] [CrossRef]

- Von Keyserlingk, M.A.G.; Martin, N.P.; Kebreab, E.; Knowlton, K.F.; Grant, R.J.; Stephenson, M.; Sniffen, C.J.; Harner, J.R., III; Wright, A.D.; Smith, S.I. Invited review: Sustainability of the US dairy industry. J. Dairy Sci. 2013, 96, 5405–5425. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jawahir, I.S.; Rouch, K.E.; Dillon, O.W.; Holloway, L.; Hall, A.; Knuf, J. Design for sustainability (DFS): New challenges in developing and implementing a curriculum for next generation design and manufacturing engineers. Int. J. Eng. Educ. 2007, 23, 1053–1064. [Google Scholar]

- Hambali, A.; Sapuan, S.M.; Ismail, N.; Nukman, Y. Application of analytical hierarchy process in the design concept selection of automotive composite bumper beam during the conceptual design stage. Sci. Res. Essays 2009, 4, 198–211. [Google Scholar]

- Mazani, N.; Sapuan, S.; Sanyang, M.; Atiqah, A.; Ilyas, R. Design and Fabrication of a Shoe Shelf from Kenaf Fiber Reinforced Unsaturated Polyester Composites. In Lignocellulose for Future Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 315–332. [Google Scholar]

- Pahl, G.; Beitz, W. Engineering design: A Systematic Approach; Springer: London, UK, 1996; ISBN 1846283183. [Google Scholar]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N. Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. J. Mater. Res. Technol. 2020, 9, 2357–2368. [Google Scholar] [CrossRef]

- Rosli, M.U.; Ariffin, M.K.A.; Sapuan, S.M.; Sulaiman, S. Integrated AHP-TRIZ innovation method for automotive door panel design. Int. J. Eng. Technol. 2013, 5, 3158–3167. [Google Scholar]

- Li, M.; Ming, X.; He, L.; Zheng, M.; Xu, Z. A TRIZ-based Trimming method for Patent design around. Comput. Des. 2015, 62, 20–30. [Google Scholar] [CrossRef]

- Ahmad, S.A.; Ang, M.C.; Ng, K.W.; Abdul Wahab, A.N. Reducing home energy usage based on TRIZ concept. Adv. Environ. Biol. 2015, 9, 6–11. [Google Scholar]

- San, Y.T.; Jin, Y.T.; Li, S.C. TRIZ: Systematic Innovation in Manufacturing; Firstfruit Sdn. Bhd.: Selangor, Malaysia, 2011; ISBN 9838040266. [Google Scholar]

- Li, T. Retracted article: Applying TRIZ and AHP to develop innovative design for automated assembly systems. Int. J. Adv. Manuf. Technol. 2009, 46, 301–313. [Google Scholar] [CrossRef]

- Cascini, G.; Rissone, P.; Rotini, F.; Russo, D. Systematic design through the integration of TRIZ and optimization tools. Procedia Eng. 2011, 9, 674–679. [Google Scholar] [CrossRef] [Green Version]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N. Conceptual design of creep testing rig for full-scale cross arm using TRIZ-Morphological chart-analytic network process technique. J. Mater. Res. Technol. 2019, 8, 5647–5658. [Google Scholar] [CrossRef]

- Yeh, C.H.; Huang, J.C.Y.; Yu, C.K. Integration of four-phase QFD and TRIZ in product R&D: A notebook case study. Res. Eng. Des. 2010, 22, 125–141. [Google Scholar] [CrossRef]

- Ullman, D.G. The Mechanical Design Process; McGraw-Hill: Maidenhead, UK, 1992; ISBN 0-07-065739-4. [Google Scholar] [CrossRef]

- Ulrich, K.; Eppinger, S. Product Design and Development; McGraw Hill: New York, NY, USA, 1995. [Google Scholar]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, morphological chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 41, 2917–2932. [Google Scholar] [CrossRef]

- Eder, W. Engineering design methods. Des. Stud. 1990, 11, 54. [Google Scholar] [CrossRef]

- McKoy, F.L.; Vargas-Hernández, N.; Summers, J.D.; Shah, J.J. Influence of Design Representation on Effectiveness of Idea Generation. In Proceedings of the Volume 4: 13th International Conference on Design Theory and Methodology; ASME International, 2001, Pittsburgh, PA, USA, 9–12 September 2001; Volume 4, pp. 39–48. [Google Scholar]

- Pahl, G.; Beitz, W. Engineering Design; Design Council: London, UK, 1984; ISBN 9781405146012. [Google Scholar]

- Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Suhrisman, A.; Afiq, T.M.N.; Atikah, M.S.N.; Ibrahim, R. Application of Design for Sustainability to Develop Smartphone Holder using Roselle Fiber-Reinforced Polymer Composites. In Roselle: Production, Processing, Products and Biocomposites; Sapuan, S.M., Razali, N., Radzi, A.M., Ilyas, R.A., Eds.; Elsevier Academic Press: Cambridge, MA, USA, 2021; pp. 1–300. ISBN 978-0323852135. [Google Scholar]

- Sapuan, S. Concurrent Engineering in Natural Fibre Composite Product Development. Appl. Mech. Mater. 2015, 761, 59–62. [Google Scholar] [CrossRef]

- Sapuan, S.M. A Conceptual Design of the Concurrent Engineering Design System for Polymeric-Based Composite Automotive Pedals. Am. J. Appl. Sci. 2005, 2, 514–525. [Google Scholar] [CrossRef] [Green Version]

- Ilyas, R.A.; Asyraf, M.R.M.; Sapuan, S.M.; Afiq, T.M.N.; Suhrisman, A.; Atikah, M.S.N.; Ibrahim, R. Development of Roselle Fiber Reinforced Polymer Biocomposites Mug Pad using Hybrid Design for Sustainability and Pugh Method. In Roselle: Production, Processing, Products and Biocomposites; Sapuan, S.M., Razali, N., Radzi, A.M., Ilyas, R.A., Eds.; Elsevier Academic Press: Cambridge, MA, USA, 2021; pp. 1–300. ISBN 978-0323852135. [Google Scholar]

- Sari, N.H.; Pruncu, C.I.; Sapuan, S.M.; Ilyas, R.A.; Catur, A.D.; Suteja, S.; Sutaryono, Y.A.; Pullen, G. The effect of water immersion and fibre content on properties of corn husk fibres reinforced thermoset polyester composite. Polym. Test. 2020, 91, 106751. [Google Scholar] [CrossRef]

- Syafri, E.; Sudirman; Mashadi; Yulianti, E.; Deswita; Asrofi, M.; Abral, H.; Sapuan, S.; Ilyas, R.; Fudholi, A. Effect of sonication time on the thermal stability, moisture absorption, and biodegradation of water hyacinth (Eichhornia crassipes) nanocellulose-filled bengkuang (Pachyrhizus erosus) starch biocomposites. J. Mater. Res. Technol. 2019, 8, 6223–6231. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.R.; Siengchin, S.; Fouad, H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. Polym. Lett. 2020, 14, 717–730. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Sapuan, S.; Ilyas, R. Highly transparent and antimicrobial PVA based bionanocomposites reinforced by ginger nanofiber. Polym. Test. 2020, 81, 106186. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Pratama, A.B.; Fajri, N.; Sapuan, S.; Ilyas, R. Transparent and antimicrobial cellulose film from ginger nanofiber. Food Hydrocoll. 2020, 98, 105266. [Google Scholar] [CrossRef]

- Prachayawarakorn, J.; Limsiriwong, N.; Kongjindamunee, R.; Surakit, S. Effect of Agar and Cotton Fiber on Properties of Thermoplastic Waxy Rice Starch Composites. J. Polym. Environ. 2011, 20, 88–95. [Google Scholar] [CrossRef]

- Kumar, T.S.M.; Chandrasekar, M.; Senthilkumar, K.; Ilyas, R.A.; Sapuan, S.M.; Hariram, N.; Rajulu, A.V.; Rajini, N.; Siengchin, S. Characterization, Thermal and Antimicrobial Properties of Hybrid Cellulose Nanocomposite Films with in-Situ Generated Copper Nanoparticles in Tamarindus indica Nut Powder. J. Polym. Environ. 2021, 29, 1134–1142. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Berkalp, O.B.; Lee, S.H.; Lee, C.H.; Nurazzi, N.M.; Ramli, N.; Wahab, M.S.; et al. Thermal Properties of Woven Kenaf/Carbon Fibre-Reinforced Epoxy Hybrid Composite Panels. Int. J. Polym. Sci. 2019, 2019, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Jaafar, C.A.; Zainol, I.; Ishak, N.; Ilyas, R.; Sapuan, S. Effects of the liquid natural rubber (LNR) on mechanical properties and microstructure of epoxy/silica/kenaf hybrid composite for potential automotive applications. J. Mater. Res. Technol. 2021, 12, 1026–1038. [Google Scholar] [CrossRef]

- Sabaruddin, F.A.; Tahir, P.M.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Hps, A.K. The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites. Polymers 2020, 13, 116. [Google Scholar] [CrossRef]

- Suriani, M.; Zainudin, H.; Ilyas, R.; Petrů, M.; Sapuan, S.; Ruzaidi, C.; Mustapha, R. Kenaf Fiber/Pet Yarn Reinforced Epoxy Hybrid Polymer Composites: Morphological, Tensile, and Flammability Properties. Polymers 2021, 13, 1532. [Google Scholar] [CrossRef]

- Jumaidin, R.; Ilyas, R.A.; Saiful, M.; Hussin, F.; Mastura, M.T. Water Transport and Physical Properties of Sugarcane Bagasse Fibre Reinforced Thermoplastic Potato Starch Biocomposite. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 61, 273–281. [Google Scholar]

- Asrofi, M.; Sujito, S.; Syafri, E.; Sapuan, S.; Ilyas, R. Improvement of Biocomposite Properties Based Tapioca Starch and Sugarcane Bagasse Cellulose Nanofibers. Key Eng. Mater. 2020, 849, 96–101. [Google Scholar] [CrossRef]

- Asrofi, M.; Sapuan, S.; Ilyas, R.; Ramesh, M. Characteristic of composite bioplastics from tapioca starch and sugarcane bagasse fiber: Effect of time duration of ultrasonication (Bath-Type). Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Nassiopoulos, E.; Njuguna, J. Thermo-mechanical performance of poly(lactic acid)/flax fibre-reinforced biocomposites. Mater. Des. 2015, 66, 473–485. [Google Scholar] [CrossRef]

- Battegazzore, D.; Noori, A.; Frache, A. Hemp hurd and alfalfa as particle filler to improve the thermo-mechanical and fire retardant properties of poly (3-hydroxybutyrate-co-3-hydroxyhexanoate). Polym. Compos. 2019, 40, 3429–3437. [Google Scholar] [CrossRef]

- Prachayawarakorn, J.; Chaiwatyothin, S.; Mueangta, S.; Hanchana, A. Effect of jute and kapok fibers on properties of thermoplastic cassava starch composites. Mater. Des. 2013, 47, 309–315. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, R. PLA-coated sisal fibre-reinforced polyester composite: Water absorption, static and dynamic mechanical properties. J. Compos. Mater. 2019, 53, 65–72. [Google Scholar] [CrossRef]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Ilyas, R.A.; Lee, C.H. Characterization Study of Empty Fruit Bunch (EFB) Fibers Reinforcement in Poly(Butylene) Succinate (PBS)/Starch/Glycerol Composite Sheet. Polymers 2020, 12, 1571. [Google Scholar] [CrossRef]

- Suriani, M.; Radzi, F.; Ilyas, R.; Petrů, M.; Sapuan, S.; Ruzaidi, C. Flammability, Tensile, and Morphological Properties of Oil Palm Empty Fruit Bunches Fiber/Pet Yarn-Reinforced Epoxy Fire Retardant Hybrid Polymer Composites. Polymers 2021, 13, 1282. [Google Scholar] [CrossRef] [PubMed]

- Jumaidin, R.; Diah, N.; Ilyas, R.; Alamjuri, R.; Yusof, F. Processing and Characterisation of Banana Leaf Fibre Reinforced Thermoplastic Cassava Starch Composites. Polymers 2021, 13, 1420. [Google Scholar] [CrossRef]

- Rozilah, A.; Jaafar, C.N.A.; Sapuan, S.M.; Zainol, I.; Ilyas, R.A. The Effects of Silver Nanoparticles Compositions on the Mechanical, Physiochemical, Antibacterial, and Morphology Properties of Sugar Palm Starch Biocomposites for Antibacterial Coating. Polymers 2020, 12, 2605. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.; Ishak, M.; Ansari, M.; Ilyas, R. Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 3726–3732. [Google Scholar] [CrossRef]

- Atikah, M.; Ilyas, R.; Sapuan, S.; Ishak, M.; Zainudin, E.; Ibrahim, R.; Atiqah, A.; Ansari, M.; Jumaidin, R. Degradation and physical properties of sugar palm starch/sugar palm nanofibrillated cellulose bionanocomposite. Polimery 2019, 64, 680–689. [Google Scholar] [CrossRef] [Green Version]

- Ilyas, R.; Sapuan, S.; Ibrahim, R.; Abral, H.; Ishak, M.; Zainudin, E.; Atikah, M.; Nurazzi, N.M.; Atiqah, A.; Ansari, M.; et al. Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata (Wurmb.) Merr) starch. J. Mater. Res. Technol. 2019, 8, 4819–4830. [Google Scholar] [CrossRef]

- Kedzierski, M.; Wiejak, A.; Janiszewska, J.; Wiśniewska, A.; Grzywa-Niksinska, I.; Kurzepa, K. Efficiency of selected biocide compounds in the protection of building coatings against colonization by mold fungi, cyanobacteria and algae. Polimery 2020, 65, 371–379. [Google Scholar] [CrossRef]

- Suriani, M.; Sapuan, S.; Ruzaidi, C.; Nair, D.; Ilyas, R. Flammability, morphological and mechanical properties of sugar palm fiber/polyester yarn-reinforced epoxy hybrid biocomposites with magnesium hydroxide flame retardant filler. Text. Res. J. 2021, 1–12. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Ishak, M.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atiqah, A.; Atikah, M.S.N.; Syafri, E.; Asrofi, M.; et al. Thermal, Biodegradability and Water Barrier Properties of Bio-Nanocomposites Based on Plasticised Sugar Palm Starch and Nanofibrillated Celluloses from Sugar Palm Fibres. J. Biobased Mater. Bioenergy 2020, 14, 234–248. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Sanyang, M.L.; Ishak, M.R.; Zainudin, E.S. Nanocrystalline Cellulose as Reinforcement for Polymeric Matrix Nanocomposites and its Potential Applications: A Review. Curr. Anal. Chem. 2018, 14, 203–225. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Majeed, K.; Jawaid, M.; Hassan, A.; Abu Bakar, A.; Khalil, H.A.; Salema, A.; Inuwa, I. Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites. Mater. Des. 2013, 46, 391–410. [Google Scholar] [CrossRef]

- Ngo, T.-D. Natural Fibers for Sustainable Bio-Composites. In Natural and Artificial Fiber-Reinforced Composites as Renewable Sources; Günay, E., Ed.; InTech: London, UK, 2018; pp. 107–126. [Google Scholar]

- Zhang, L. The Application of Composite Fiber Materials in Sports Equipment. In Proceedings of the 2015 International Conference on Education, Management, Information and Medicine; Atlantis Press: Washington, DC, USA, 2015; pp. 450–453. [Google Scholar]

- Yusup, E.; Mahzan, S.; Kamaruddin, M. Natural Fiber Reinforced Polymer for the Application of Sports Equipment using Mold Casting Method. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 494, p. 012040. [Google Scholar]

- Floating on Flax—CAPiTA Snowboards with ampliTexTM Fusion Tape. Available online: https://www.bcomp.ch/news/capita-snowboards-with-amplitex-fusion-tape/ (accessed on 18 March 2021).

| Natural Fiber | Cellulose/Lignocellulose | Grass/Reed | Bamboo, corn |

| Stalk | Wheat, maize, oat, rice | ||

| Wood | Hardwood, softwood | ||

| Fruit | Coir | ||

| Seed | Cotton | ||

| Leaf | Abaca, banana, pineapple, sisal | ||

| Bast | Flax, hemp, jute, kenaf, ramie | ||

| Animal | Wool/hair | Cashmere, goat hair, horse hair, lamb wool | |

| silk | Mulberry | ||

| Mineral | - | Asbestos, ceramic, metal |

| Author (Year) | Advantages of Natural Fibers |

|---|---|

| Bakar et al. [10] | Low cost, low elongation, low density, non-conductivity, corrosion resistance, absorb significant amounts and able to solve environmental pollution. |

| Corona et al. [35] | Renewable, moderate energy consumption for production and disposal can reduce environmental problems. |

| Hanan et al. [4] | Has certain strength properties, non-rough surface, lightweight, renewable, has specific modulus properties, can reduce pollution, biodegradable, require less energy to produce, and inexpensive. |

| Aji et al. [36] | Low density, cost-saving during manufacturing, less rough surface, harmless biodegradation, renewable, comparable mechanical properties with inorganic fiber, recyclable in most countries, and the surface is easily modified. |

| Amir et al. [37] | Substitute for synthetic fibers and as a reinforcing material in composites. |

| Nordin et al. [11] | In terms of mechanical properties, natural fibers are a good substitute for polymer composites because of their renewable material source, light weight, inexpensiveness, low density, and the materials are readily available. |

| Maleque et al. [38] | Ease of use in chemical and mechanical modifications. |

| Rognoli et al. [17] | Environmentally friendly materials. |

| Taekema and Karana, [39] | Low density, high specific strength, renewable, recyclable according to the mixture of materials used, high thermal and acoustic insulation, energy consumption savings of up to 60% in the production process (average for automotive component manufacturing), can be produced with low technology and investment and highly recommended for developing countries. |

| Sapuan and Maleque [40] | Mechanical properties are comparable to existing conventional materials that include low production costs, renewability, and environmentally friendly materials. |

| Shekar and Ramachandra [41] | Good mechanical properties, renewable, non-abrasive to process equipment, and can be burned at the end of its life cycle for energy recovery, and also abundantly available. |

| Elanchezhian et al. [9] | Renewable, inexpensive, completely or partially recyclable material, and biodegradable. In addition, this material has low density, low cost, and has environmentally friendly mechanical properties. It is also an alternative material for fiberglass, carbon, and human-made fibers for composite manufacturing. |

| Ilyas et al. [42,43,44] | Cost-effective, biodegradable, and renewable materials. |

| Peças et al. [31] | Renewable, low production costs, low density, acceptable modulus–weight ratio, low manufacturing energy consumption, low carbon, and biodegradable. |

| Huda et al. [45] | Cheaper, less energy required in the production of fiber reinforcement compared to conventional fibers such as glass and carbon. |

| Thyavihalli Girijappa et al. [46] | Abundantly available and cost-effective production. |

| Arpitha et al. [47] | Good mechanical properties, light weight, low cost, high specific strength, less rough surface, environmentally friendly, and good biodegradation characteristics. |

| Madhu et al. [48] | Creates huge employment opportunities in the rural plantation sector, available in large quantities, biodegradable, recyclable, better energy recovery, low production costs, lightweight materials, high strength and specific modulus, lower health risks, low density, low cost, less skin irritation, less abrasion of equipment, reduced tool wear, improved energy recovery, and reduced skin irritation and respiration |

| Fibers | Holocellulose (wt. %) | Lignin (wt. %) | Ash (wt. %) | Extractives (wt. %) | Crystallinity (%) | Ref. | |

|---|---|---|---|---|---|---|---|

| Cellulose (wt. %) | Hemicellulose (wt. %) | ||||||

| Arecanut husk | 34.18 | 20.83 | 31.60 | 2.34 | - | 37 | [49] |

| Banana | 7.5 | 74.9 | 7.9 | 0.01 | 9.6 | 15.0 | [50] |

| Curauna | 70.2 ± 0.7 | 18.3 ± 0.8 | 9.3 ± 0.9 | - | - | 64 | [51] |

| Helicteres isora plant | 71 ± 2.6 | 3.1 ± 0.5 | 21 ± 0.9 | - | - | 38 | [52] |

| Kenaf bast | 63.5 ± 0.5 | 17.6 ±1.4 | 12.7 ± 1.5 | 2.2 ± 0.8 | 4.0 ± 1.0 | 48.2 | [53] |

| Kenaf core powder | 80.26 | 23.58 | - | - | 48.1 | [54] | |

| Mengkuang leaves | 37.3 ± 0.6 | 34.4 ± 0.2 | 24 ± 0.8 | 2.5 ± 0.02 | 55.1 | [55] | |

| Oil palm empty fruit bunch (OPEFB) | 37.1 ± 4.4 | 39.9 ± 0.75 | 18.6 ± 1.3 | - | 3.1 ± 3.4 | 45.0 | [56] |

| Oil palm empty fruit bunch (OPEFB) | 40 ±2 | 23 ±2 | 21 ± 1 | - | 2.0 ± 0.2 | 40 | [57] |

| Oil palm frond (OPF) | 45.0 ± 0.6 | 32.0 ± 1.4 | 16.9 ± 0.4 | - | 2.3 ± 1.0 | 54.5 | [56] |

| Oil palm mesocarp fiber (OPMF) | 28.2 ± 0.8 | 32.7 ± 4.8 | 32.4 ± 4.0 | - | 6.5 ± 0.1 | 34.3 | [56] |

| Phoenix dactylifera palm leaflet | 33.5 | 26.0 | 27.0 | 6.5 | - | 50 | [58] |

| Phoenix dactylifera palm rachis | 44.0 | 28.0 | 14.0 | 2.5 | - | 55 | [58] |

| Pineapple leaf | 81.27 ± 2.45 | 12.31 ± 1.35 | 3.46 ± 0.58 | - | - | 35.97 | [59] |

| Ramie | 69.83 | 9.63 | 3.98 | - | - | 55.48 | [60] |

| Rubber wood | 45 ±3 | 20 ± 2 | 29 ± 2 | - | 2.5 ± 0.5 | 46 | [57] |

| Soy hull | 56.4 ± 0.92 | 12.5 ± 0.72 | 18.0 ± 2.5 | - | - | 59.8 | [61] |

| Sugar beet | 44.95 ± 0.09 | 25.40 ± 2.06 | 11.23 ± 1.66 | 17.67 ± 1.54 | - | 35.67 | [62] |

| Sugar palm | 43.88 | 7.24 | 33.24 | 1.01 | 2.73 | 55.8 | [63] |

| Sugarcane bagasse | 43.6 | 27.7 | 27.7 | - | - | 76 | [64] |

| Water hyacinth | 42.8 | 20.6 | 4.1 | - | - | 59.56 | [65] |

| Wheat straw | 43.2 ± 0.15 | 34.1 ± 1.2 | 22.0 ± 3.1 | - | - | 57.5 | [66] |

| Design Specifications | Explanation |

|---|---|

| Universal design | Usable by both genders; availability of different sizes; usable by pilgrims with a beard, other facial hair, or other conditions that prevent a good seal between the face and the sealing surface of the face mask |

| Comfortable | Ergonomic; large breathing space (or dead space) for relaxed breathing; reduced facial covering without compromising the face mask’s efficiency |

| Effectiveness | Therapeutic effectiveness of the face masks against airborne infectious diseases is highly critical |

| Low cost | The low cost can allow face masks to be given for free by Tabung Haji, as preferred by the pilgrims |

| Conceptual Design | Description | |

|---|---|---|

| 1. |  |

|

| 2. |  |

|

| 3. |  |

|

| 4. |  |

|

| 5. |  |

|

| Conceptual Design | Description | |

|---|---|---|

| 1. |  |

|

| 2. |  |

|

| 3. |  |

|

| 4. |  |

|

| 5. |  |

|

| Natural Fiber Composite | Applications |

|---|---|

| Bamboo | Application in building, construction, and others |

| Roselle | Mug pad, smartphone holder, furniture, automotive applications |

| Hemp | Construction products, textile, cordage, geotextile, paper and packaging, furniture, electrical, banknote, and pipe |

| Oil palm | Building materials such as window, door frame, structural insulated panel building system, siding, fencing, roofing, decking, and others |

| Wood | Window frame, panel, door shutter, decking, railing system, and fencing |

| Flax | Window frame, panel, decking, railing system, fencing, tennis racket, bicycle frame, fork, seat post, snowboarding, and laptop case |

| Rice husk | Building materials such as building panel, brick, window frame, panel, decking, railing system, and fencing |

| Bagasse | Window frame, panel, decking, railing systems, and fencing |

| Sisal | Used in the construction industry such as in panels, doors, shutting plates, and roofing sheet; also, in the manufacturing of paper and pulp |

| Stalk | Building panel, furniture panel, brick, drain, and pipeline |

| Kenaf | Packing material, mobile case, bag, insulation, clothing-grade cloth, soilless potting mix, animal bedding, and material that absorbs oil and liquids |

| Cotton | Furniture industry, textile and yarn, food packaging, and cordage |

| Coir | Building panel, flush door shutter, roofing sheet, storage tank, packing material, helmet and postbox, mirror casing, paperweights, projector cover, voltage stabilizer cover, filling material for seat upholstery, brush and broom, rope and yarn for net, bag, and mat, as well as padding for mattress and seat cushion |

| Ramie | Industrial sewing thread, packing material, fishing net, and filter cloth. It is also made into fabrics for household furnishings (upholstery, canvas) and clothing, as well as paper manufacture |

| Jute | Building panel, roofing sheet, door frame, door shutter, transport, packaging, geotextiles, and chipboard |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azman, M.A.; Asyraf, M.R.M.; Khalina, A.; Petrů, M.; Ruzaidi, C.M.; Sapuan, S.M.; Wan Nik, W.B.; Ishak, M.R.; Ilyas, R.A.; Suriani, M.J. Natural Fiber Reinforced Composite Material for Product Design: A Short Review. Polymers 2021, 13, 1917. https://doi.org/10.3390/polym13121917

Azman MA, Asyraf MRM, Khalina A, Petrů M, Ruzaidi CM, Sapuan SM, Wan Nik WB, Ishak MR, Ilyas RA, Suriani MJ. Natural Fiber Reinforced Composite Material for Product Design: A Short Review. Polymers. 2021; 13(12):1917. https://doi.org/10.3390/polym13121917

Chicago/Turabian StyleAzman, M. A., M. R. M. Asyraf, A. Khalina, Michal Petrů, C. M. Ruzaidi, S. M. Sapuan, W. B. Wan Nik, M. R. Ishak, R. A. Ilyas, and M. J. Suriani. 2021. "Natural Fiber Reinforced Composite Material for Product Design: A Short Review" Polymers 13, no. 12: 1917. https://doi.org/10.3390/polym13121917

APA StyleAzman, M. A., Asyraf, M. R. M., Khalina, A., Petrů, M., Ruzaidi, C. M., Sapuan, S. M., Wan Nik, W. B., Ishak, M. R., Ilyas, R. A., & Suriani, M. J. (2021). Natural Fiber Reinforced Composite Material for Product Design: A Short Review. Polymers, 13(12), 1917. https://doi.org/10.3390/polym13121917