Tribological Performance and Thermal Stability of Nanorubber-Modified Polybenzoxazine Composites for Non-Asbestos Friction Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparations

2.3. Research Methods

3. Results and Discussion

3.1. Effect of UFNBRPs Content on Processing Behaviors of BA-a/UFNBRPs Molding Compounds

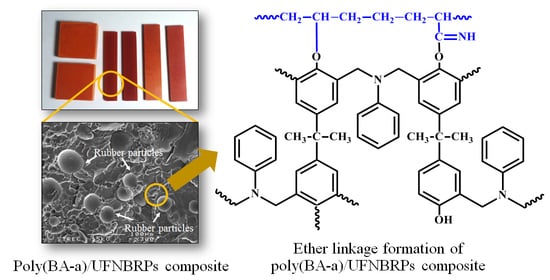

3.2. Chemical Bonding Formation between UFNBRPs and Poly(BA-a)

3.3. Thermomechanical Property, Thermal Stability, and Flammability Poly(BA-a)/UFNBRPs Composites

3.4. Tribological Properties of UFNBRPs-Modified Poly(BA-a) Composite at 25 °C

3.5. Tribological Property of UFNBRPs-Modified Poly(BA-a) Composite at High Temperatures

3.6. Properties of Poly(BA-a)/UFNBRPs Composite for Non-Asbestos Friction Material

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pilipović, A.; Ilinčić, P.; Petruša, J.; Domitran, Z. Influence of polymer composites and memory foam on energy absorption in vehicle application. Polymers 2020, 12, 1222. [Google Scholar] [CrossRef] [PubMed]

- Wongpayakyotin, A.; Jubsilp, C.; Tiptipakorn, S.; Mora, P.; Bielawski, C.W.; Rimdusit, S. Effects of alkyl-substituted polybenzoxazines on tribological properties of non-asbestos composite friction materials. Polymers 2021, 13, 567. [Google Scholar] [CrossRef] [PubMed]

- Zhang, E.; Gao, F.; Fu, R.; Lu, Y.; Han, X.; Su, L. Tribological behavior of phenolic resin-based friction composites filled with graphite. Materials 2021, 14, 742. [Google Scholar] [CrossRef]

- Chan, D.; Stachowiak, G.W. Review of automotive brake friction materials. Proc. Instn. Mech. Engrs. Part D 2004, 218, 953–966. [Google Scholar] [CrossRef]

- Kurihara, S.; Idei, H.; Aoyagi, Y.; Kuroe, M. Binder Resin for Friction Material, Binder Resin Composition for Friction Material, Composite Material for Friction Material Containing the Same, Friction Material and Production Method Thereof. U.S. Patent 8227390 B2, 2012. [Google Scholar]

- Singh, T.; Patnaik, A.; Satapathy, B.K.; Kumar, M.; Tomar, B.S. Effect of nanoclay reinforcement on the friction braking performance of hybrid phenolic friction composites. J. Mater. Eng. Perform. 2013, 22, 796–805. [Google Scholar] [CrossRef]

- Kim, Y.C.; Cho, M.H.; Kim, S.J.; Jang, H. The effect of phenolic resin, potassium titanate, and CNSL on the tribological properties of brake friction materials. Wear 2008, 264, 204–210. [Google Scholar] [CrossRef]

- Patnaik, A.; Kumar, M.; Satapathy, B.K.; Tomar, B.S. Performance sensitivity of hybrid phenolic composites in friction braking: Effect of ceramic and aramid fibre combination. Wear 2010, 269, 891–899. [Google Scholar] [CrossRef]

- Morshed, M.M.; Haseeb, A.S.M.A. Physical and chemical characteristics of commercially available brake shoe lining materials: A comparative study. J. Mater. Process. Technol. 2004, 155–156, 1422–1427. [Google Scholar] [CrossRef]

- Lu, Y. A combinatorial approach for automotive friction materials: Effects of ingredients on friction performance. Compos. Sci. Technol. 2006, 66, 591–598. [Google Scholar] [CrossRef]

- Jubsilp, C.; Taewattana, R.; Takeichi, T.; Rimdusit, S. Investigation on rubber-modified polybenzoxazine composites for lubricating material applications. J. Mater. Eng. Perform. 2015, 24, 3958–3968. [Google Scholar] [CrossRef]

- Jubsilp, C.; Rimdusit, S. Polybenzoxazine-based self-lubricating and friction materials. In Advanced and Emerging Polybenzoxazine Science and Technology, 1st ed.; Ishida, H., Froimowicz, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 945–974. [Google Scholar]

- Mora, P.; Jubsilp, C.; Liawthanyarat, N.; Okhawilai, M.; Rimdusit, S. Friction and mechanical properties of highly filled polybenzoxazine composites: Nanosilica particle size and surface treatment. Macro. Chem. Phys. 2019, 220, 1800328. [Google Scholar] [CrossRef]

- Jubsilp, C.; Singto, J.; Yamo, W.; Rimdusit, S. Effect of graphite particles size on tribological and mechanical properties of polybenzoxazine composites. Chem. Eng. Transac. 2017, 57, 1351–1356. [Google Scholar]

- Lertwassana, W.; Parnklang, T.; Mora, P.; Jubsilp, C.; Rimdusit, S. High performance aramid pulp/carbon fiber-reinforced polybenzoxazine composites as friction materials. Compos. Part B 2019, 177, 107280. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, M.; Xu, Q.; Hou, S.; Jin, H.; Fan, L. Effects of glass-to rubber transition of thermosetting resin matrix on the friction and wear properties of friction materials. Tribol. Int. 2012, 54, 51–57. [Google Scholar] [CrossRef]

- Ishida, H. Process for Preparation of Benzoxazine Compounds in Solventless System. U.S. Patent 5543516, 6 August 1996. [Google Scholar]

- Ishida, H.; Agag, T. Handbook of Benzoxazine Resins, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Tanpitaksit, T.; Jubsilp, C.; Rimdusit, S. Effects of benzoxazine resin on property enhancement of shape memory epoxy: A dual function of benzoxazine resin as a curing agent and a stable network segment. Express Polym. Lett. 2015, 9, 824–837. [Google Scholar] [CrossRef]

- Rimdusit, S.; Ramsiri, B.; Jubsilp, C.; Dueramae, I. Characterizations of polybenzoxazine modified with isomeric biphenyltetracarboxylic dianhydrides. Express Polym. Lett. 2012, 6, 773–782. [Google Scholar] [CrossRef]

- Jubsilp, C.; Panyawanitchakun, C.; Rimdusit, S. Flammability and thermo-mechanical properties of dianhydride-modified polybenzoxazine composites reinforced with carbon fiber. Polym. Compos. 2013, 34, 2067–2075. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, C.; Pilla, S.; Gong, S. Polybenzoxazine-core shell rubber–carbon nanotube nanocomposites. Compos. Part A 2008, 39, 1653–1659. [Google Scholar] [CrossRef]

- Ishida, H.; Froimowicz, P. Advanced and Emerging Polybenzoxazine Science and Technology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Saffar, A.; Shojaei, A.; Arimand, M. Theoretical and experimental analysis of the thermal, fade and wear characteristics of rubber-based composite friction materials. Wear 2010, 269, 145–151. [Google Scholar] [CrossRef]

- Zhang, S.W. Tribology of Elastomers, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Liu, Y.; Fan, Z.; Ma, H.; Tan, Y.; Qiao, J. Application of nano powdered rubber in friction materials. Wear 2006, 261, 225–229. [Google Scholar] [CrossRef]

- Agag, T.; Takeichi, T. Effect of hydroxyphenylmaleimide on the curing behaviour and thermomechanical properties of rubber modified polybenzoxazine. High Perform. Polym. 2001, 13, S327–S342. [Google Scholar] [CrossRef]

- Jubsilp, C.; Takeichi, T.; Rimdusit, S. Property enhancement of polybenzoxazine modified with dianhydride. Polym. Degrad. Stabil. 2011, 96, 1047–1053. [Google Scholar] [CrossRef]

- Abadchi, M.R.; Jalali-Arani, A. The Use of gamma irradiation in preparation of polybutadiene rubber nanopowder; its effect on particle size, morphology and crosslink structure of the powder. Nucl. Instrum. Methods Phys. Res. B 2014, 320, 1–5. [Google Scholar]

- Vijayabaskar, V.; Stephan, M.; Kalaivani, S.; Volke, S.; Heinrich, G.; Dorschner, H.; Bhowmickb, A.K.; Wagenknecht, U. Influence of radiation temperature on the crosslinking of nitrile rubber by electron beam irradiation. Radiat. Phys. Chem. 2008, 77, 511–521. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.; Hoftyzer, P.J. Properties of Polymer; Elsevier: New York, NY, USA, 1976. [Google Scholar]

- Manoharan, S.; Suresha, B.; Bharath, P.B.; Ramadoss, G. Investigations on three-body abrasive wear behaviour of composite brake pad material. Plast. Polym. Technol. 2014, 3, 10–18. [Google Scholar]

- Brake Linings Vehicles; TIS.97-2557; Thailand Industrial Standards Institute: Bangkok, Thailand, 2014.

- Brake Linings and Pads for Automobiles; JIS D 4411; Japanese Standards Association (JSA): Tokyo, Japan, 2020.

- Mathur, R.B.; Thiyagarajan, P.; Dhami, T.L. Controlling the hardness and tribological behaviour of non-asbestos brake lining materials for automobiles. Carbon Sci. 2004, 5, 6–11. [Google Scholar]

- Goodman, S.H.; Dodiuk-Kenig, H. Handbook of Thermoset Plastics; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Phenolic. Available online: http://www.sdplastics.com/phenolic.html (accessed on 7 June 2021).

- EL-Tayeb, N.S.M.; Liew, K.W. On the dry and wet sliding performance of potentially new frictional brake pad materials for automotive industry. Wear 2009, 266, 275–287. [Google Scholar] [CrossRef]

| Ingredients (wt%) | Poly(BA-a)/UFNBRPs Friction Composite | Phenolic/UFNBRPs Friction Composite |

|---|---|---|

| Benzoxazine resin | 10 | - |

| Phenolic resin with curing agent | - | 10 |

| Aramid fiber | 5 | 5 |

| Inorganic fiber | 35 | 35 |

| Graphite | 10 | 10 |

| Zirconium silicate | 7 | 7 |

| Barium sulfate | 25 | 25 |

| UFNBRPs | 4 | 4 |

| Cashew dust | 4 | 4 |

| UFNBRP Content (wt%) | ΔH of BA-a/UFNBPs Compound (J/g) | ΔH of BA-a in Compound (J/g) | ΔH of Reacted UFNBRPs in Compound (J/g) |

|---|---|---|---|

| 0 | 277 | 277 | 0 |

| 2 | 285 | 271 | 14 |

| 5 | 291 | 263 | 28 |

| 10 | 288 | 249 | 39 |

| 15 | 290 | 235 | 55 |

| UFNBRP Content (wt%) | Tg (°C) | E′ at 30 °C (GPa) | Td5 (°C) | Td10 (°C) | Char yield at 800 °C (%) | LOI |

|---|---|---|---|---|---|---|

| 0 | 170 | 5.2 | 325 | 345 | 25.3 | 27.6 |

| 2 | 175 | 4.7 | 323 | 345 | 23.6 | 26.9 |

| 5 | 182 | 3.7 | 321 | 346 | 23.6 | 26.9 |

| 10 | 185 | 3.3 | 317 | 342 | 20.9 | 25.9 |

| 15 | 188 | 2.8 | 304 | 340 | 18.4 | 24.9 |

| 100 °C | 150 °C | 200 °C | 250 °C | 300 °C * | 350 °C * | |

|---|---|---|---|---|---|---|

| μavg. | 0.61 ± 0.02 | 0.58 ± 0.03 | 0.55 ± 0.01 | 0.50 ± 0.01 | na | na |

| Wear rate (mm3/Nm) | 3.98 × 10−4 | 4.23 × 10−4 | 11.13 × 10−4 | 28.81 × 10−4 | na | na |

| Samples | Ef (GPa) | σf (MPa) | Tg (°C) | Td5 (°C) | Char Yield at 800 °C (%) |

|---|---|---|---|---|---|

| Poly(BA-a)/UFNBRPs-based composite | 6.4 ± 0.3 | 61 ± 4 | 215 | 410 | 80 |

| Phenolic/UFNBRPs-based composite | 3.3 ± 0.2 | 33 ± 0.2 | 210 | 424 | 79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jubsilp, C.; Jantaramaha, J.; Mora, P.; Rimdusit, S. Tribological Performance and Thermal Stability of Nanorubber-Modified Polybenzoxazine Composites for Non-Asbestos Friction Materials. Polymers 2021, 13, 2435. https://doi.org/10.3390/polym13152435

Jubsilp C, Jantaramaha J, Mora P, Rimdusit S. Tribological Performance and Thermal Stability of Nanorubber-Modified Polybenzoxazine Composites for Non-Asbestos Friction Materials. Polymers. 2021; 13(15):2435. https://doi.org/10.3390/polym13152435

Chicago/Turabian StyleJubsilp, Chanchira, Jakkrit Jantaramaha, Phattarin Mora, and Sarawut Rimdusit. 2021. "Tribological Performance and Thermal Stability of Nanorubber-Modified Polybenzoxazine Composites for Non-Asbestos Friction Materials" Polymers 13, no. 15: 2435. https://doi.org/10.3390/polym13152435

APA StyleJubsilp, C., Jantaramaha, J., Mora, P., & Rimdusit, S. (2021). Tribological Performance and Thermal Stability of Nanorubber-Modified Polybenzoxazine Composites for Non-Asbestos Friction Materials. Polymers, 13(15), 2435. https://doi.org/10.3390/polym13152435