1. Introduction

Growing concerns for the environment have accelerated the replacement of synthetic composites and plastics with natural fibre composites (NFC), which potentially have lower carbon footprint. Natural fibre-based composites have also been found in structural applications. For example, the use of jute-based natural fibre composites in structural applications is recommended due to the improved strain behaviour and fatigue strength [

1]. More specifically, composites can be used to store cryogenic liquids in space shuttles or satellites (liquefied oxygen and hydrogen) [

2]. Structural composites are also used in extremely cold weather. In these circumstances, the temperature variation causes high thermal stress in materials, which lead to failure [

3]. The hydrophilic nature (presence of free and bound water in the organic biomass) of natural fibre composites is a critical factor that limits the use of natural fibre composites in the cryogenic conditions. Natural fibres’ hydrophilic nature (i.e., higher volume of ice than that of water) causes poor load transfer and unexpected failure in cold environments. To avoid such a failure, the composite strength must be increased to withstand thermal stress under cryogenic conditions [

4]. Hybridisation and chemical treatment of natural fibres are the notable methods that are in practice to increase the strength of such composites.

India is the top jute-producing nation in the world, contributing over 50% of the global jute production [

5]. Such an abundant availability of jute fibre could be used for manufacturing bio-based composite materials. Jute possesses greater stiffness and strength compared to other natural fibres [

6]. Stable compounds could be obtained owing to the bidirectional nature of jute fibres that could offer resistance to cracking. Apart from being renewable and easily available, the motivation for employing jute fibre instead of conventional glass fibres arises from the fact that it has lower specific gravity (1.45 GPa) and workable specific modulus (19 GPa) when compared to that of glass fibres (2.56 GPa and 29 GPa, respectively) [

7]. Gowda et al. [

8] conducted an experimental study on untreated woven-jute reinforced polyester composites and demonstrated its potential use in numerous consumer products. Vinod et al. [

9] investigated the thermo-mechanical characterisation of

Calotropis gigantea stem powder-filled jute fibre-reinforced epoxy composites and showed that the higher weight percentage

Calotropis gigantea filled jute fibre composites showed superior results in tensile, flexural, compression, hardness, and impact properties than the ones with partially filled and no filler materials. Tavassolli et al. [

10] showed that hydrothermally treated wood fibres showed improvement in mechanical properties. Hence, a renewable filler material like saw-dust could be dispersed in resin and improvement in properties could be achieved. Pinto et al.’s [

11] investigation demonstrated the efficacy of jute epoxy composites for structural applications. The treated-jute/epoxy composites showed enhanced toughness and interlaminar shear strength. According to the findings of the Assis et al. [

12] investigation, the use of jute fibre in the multilayer armour system (MAS) can reduce the weight of the MAS by 5.4% and the cost by 474%. The jute/kenaf-based hybrid composites showed enhanced performance in the low velocity impact test. The hybrid jute/kenaf composites withstood the 30 J impact energy without being penetrated. Elsewhere, Park et al. [

13] evaluated the mechanical properties of single jute fibres after alkaline, silane and thermal treatments using uni- and bi-modal Weibull distribution. They showed that alkaline- and silane-treated jute fibres showed an increase in the mechanical properties of single jute fibres, while thermal treatment resulted in deterioration of mechanical properties. Rafiquzzaman et al. [

14] asserted that jute fibre could serve as a partial replacement for glass-fibres for light load structural applications. Based on the aforementioned findings from literature, this study used jute-fibre with saw-dust as a filler material dispersed in polyester matrix. Saw-dust could be used a filler material because of its renewable nature, and its availability as waste material from sawmills at a cheap cost [

2]. The fibres were chemically treated, and the final fabricated Fibre-Reinforced Composites (FRC) were then subjected to cryogenic treatment to improve the mechanical properties.

Alkaline treatment, also known as mercerisation, disrupts the hydrogen bonding in the molecular structure of the fibre and increases the surface roughness. This improves the interfacial adhesion between the matrix and the fibre. This treatment also eliminates lignin, waxy and oily materials that cover the external wall of the fibre [

15]. Ray et al. [

16] achieved an improvement in crystallinity of jute fibres by treating it to 5% alkali solution for up to 8 h. Enhancement in modulus, tenacity, flexural strength and laminar shear strength was reported after alkali treatment. Rajesh and Prasad [

17] showed that jute fibres treated with 10% NaOH improved the tensile strength of the composites. They demonstrated that the alkali-treated (5%, 10%, and 15%) fibre had considerably increased the tensile strength of the composites compared to its untreated counterpart.

The mechanical properties of the fibre-reinforced composites could be modified on the basis of requirements by altering the fibre–resin–filler combination [

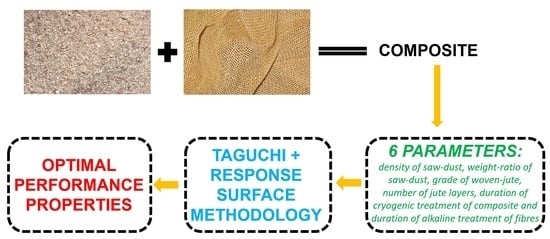

18]. The renewable, cheap, non-abrasive nature of jute-fibre makes it an attractive option for use as reinforcement in composites. However, its hydrophilic nature can create binding issues with commercial synthetic resins resulting in poor strength and stiffness. Furthermore, composites can have a wide range of applications in aerospace industry and as structural components in colder climates where extreme temperature variations are possible. Therefore, an attempt was made to overcome these limitations by chemical treatment and hybridisation. The present study employed a modelling and optimisation approach, which can be used to study the interactive effects of the considered parameters and to quantify the individual influences of these parameters on different mechanical properties of the composite. This study used six parameters, viz., density of saw-dust, weight ratio of saw-dust, grade of woven-jute, number of jute layers, duration of cryogenic treatment of composite and duration of alkaline treatment of jute-fibre for optimization with an objective to maximise tensile strength, impact strength, flexural strength and hardness. These six parameters were considered, since these are the major influencing factors that greatly affect natural fibre composites’ properties [

19]. The novel aspect of the current study can be highlighted by the fact that this is one of the first studies to investigate composites with woven jute as reinforcement and teak saw-dust as filler material in polyester resin under cryogenic conditions. It is envisaged that the results of this investigation could open up new application routes for natural fibre-based composites in extreme cold environments. Moreover, the effects of cryogenic treatment on the composite and alkaline treatment of jute-fibre on mechanical properties were investigated together for the first time. The main objective of this study is to identify the most significant parameters that have the highest effect on the mechanical properties of natural fibre composites under cryogenic conditions. The specific aims of the study can be sub-divided as follows: (i) to identify the statistically significant parameters that affect the mechanical properties of the fabricated composite, (ii) to develop regression models for the mechanical properties using RSM, (iii) to predict the mechanical properties, e.g., tensile strength, impact strength, flexural strength and hardness of the composite, and (iii) to determine an optimum combination of the considered factors to achieve the best possible performance properties.

3. Results

3.1. Cryogenic Treatment

It was observed that mechanical properties were better at 60 min of cryogenic treatment.

Figure 3a–d show the fractured surface of composites with cryogenic treatment. The cryogenic treatment showed adverse effects in the composites leading to reduced strength. The composites experienced high internal stresses during the cryogenic treatment. The internal stress at the interface region affected the fibre and matrix bonding [

24]. Further expanding the treatment length was found to diminish the mechanical properties as a result of the developments of break on the material because of the high internal stresses [

25]. However, with the continued increase of the cryogenic treatment time, cracks developed at secluded regions because the fibres, saw-dust and the matrix constricted at different rates [

26],

Figure 4c. However, the composite with the alkaline-treated fibre showed good bonding (

Figure 3b). The increased internal stress at the increased cryogenic treatment time, burst the fibres into fibrils (

Figure 3d), and this negatively affected the stress distribution during loading and reduced the strength. The investigation by Liu et al. [

27] demonstrated that the fibre under cryogenic conditions caused variations in the hemicellulose and lignin content, but not in the cellulose content. In comparison, it can be stated that the physical and chemical properties of the jute fibre in the composites may have changed after the cryogenic treatment, which may have influenced the composites’ strength.

3.2. Model Analysis and Evaluation

Cubic models (third order polynomial functions) were developed using Equation (3) for mechanical properties (tensile strength, flexural strength, impact strength and hardness) from the data recorded as per the experimental matrix designed based on Taguchi L

27 orthogonal array as shown in

Table 2. The developed models were then analysed for normality using normal probability plots. These plots were found to follow normal distribution as could be evidenced from

Figure 4. Normal plot also serves as a diagnostic plot for the validity of analysis of variance (ANOVA).

The predicted vs. actual plots for the properties in

Figure 5 reveal the homogenous nature of the variance. The models were then evaluated (

Table 3) for goodness of fit with actual values using coefficient of determination (R

2). All the values were very close to 1, which indicate that the models have a good fit [

23]. High values of Adjusted R

2 closer to 1 also imply good accuracy of the developed models. Values of adequate precision for all property models were greater than 4, which indicate that they can be used to navigate the design space. Low values of coefficient of variation (CoV%) indicate that the reliability of the performed experiments was very high.

3.3. Flexural Strength

Only the factors and their two-way interactions that have a “significant effect” on mechanical properties (

p-values < 0.05) were included in the ANOVA. For flexural strength in

Table 4, the F-value (15.51) implies that the cubic model is significant, and there is only 0.82% possibility for this large F-value to occur due to errors. Other insignificant model terms were neglected. The number of jute layers and the duration of cryogenic treatment have a significant effect (

p-values < 0.05) on the flexural strength of the fabricated composite material. Since flexural failures are dictated by the rupture of the cell walls in fibre bundles, the increase in number of jute layers has worked favourably in increasing the flexural strength of the composite [

28]. The duration of cryogenic treatment also affected flexural strength significantly because of development of cracks in isolated regions as shown in SEM images in

Figure 3c.

The final model equation for flexural strength in terms of coded factors is given below. This equation could be used to make predictions about flexural strength for the given levels of the factors. Their relative impact could be identified by comparing the coefficients of the factors.

Flexural Strength = +37.36 − 2.84 × A − 3.12 × B + 2.5 × C − 3.97 × D − 4.18 × E + 0.57 × A × B − 7.09 × A × C − 1.49 × A × E − 6.87 × B × C − 0.4825 × B × E + 1.91 × C × E + 0.5543 × D × E − 4.81 × E × F.

From the interactive response-surface plots in

Figure 6, it can be seen that the flexural strength is maximum in the region where the duration of cryogenic treatment is lower, and the duration of alkaline treatment is higher. Flexural strength was found to increase gradually with increase in duration of alkaline treatment of jute-fibre due to enhanced bonding between the matrix and fibre as seen from SEM images in

Figure 3b.

3.4. Tensile Strength

The F-value (24.65) from

Table 5 of ANOVA implies that the cubic model for tensile strength is significant and there is only 0.34% possibility for this large F-value to occur due to errors. The weight ratio of the saw-dust, number of jute layers and the duration of cryogenic treatment have significant effect on tensile strength of the composite (

p-values < 0.05). From the interactive response-surface plots in

Figure 7, it could be seen that the tensile strength is maximum in the region where the duration of cryogenic treatment is lower, and the duration of alkaline treatment is higher. Tensile strength was found to increase with increase in duration of alkaline treatment of jute-fibre when the duration of cryogenic treatment is kept lower. When the duration of cryogenic treatment was high, the tensile strength of the composite suffered due crack formation as witnessed in SEM image in

Figure 3c. The external damage induced in the fibres during treatment was the main reason for the crack development. The externally damaged areas acted as the crack nucleating points in the matrix. This is supported by the investigation of Zhang et al. [

29]. The final model equation for tensile strength in terms of coded factors is given below. This equation could be used to make predictions about flexural strength for the given levels of the factors.

Tensile Strength = +26.92 − 1.20 × A − 2.77 × B + 0.4014 × C − 2.45 × D − 2.19 × E - 0.21 × A × B − 5.64 × A × C + 0.1642 × A × E − 3.00 × B × C − 0.0900 × B × E − 0.0933 × C × E − 0.2967 × D × E − 1.64 × E × F.

3.5. Impact Strength

The F-value (132.16) from ANOVA in

Table 6 implies that the cubic model for impact strength is significant and there is only 0.01% possibility for this large F-value to occur due to errors. The weight ratio of saw-dust, and the number of jute layers have a significant effect on the impact strength of the fabricated composite material (

p-values < 0.05).

From the response-surface plots in

Figure 8, it is clear that the impact strength of the composite will be optimum when there is a balance between the grade of woven-jute fibre and the density of saw-dust. Impact strength is higher either at regions of higher grades of jute-fibre and lower density of saw-dust or at regions of lower grades of jute-fibre and higher density of saw-dust filler. The final model equation for impact strength in terms of coded factors is given below. This equation could be used to make predictions about impact strength for the given levels of the factors.

Impact Strength = +1.52 − 0.0541 × A − 0.2204 × B - 0.0307 × C − 0.7059 × D − 0.0556 × E − 0.0917 × A × B − 1.23 × A × C − 0.0997 × A × E − 0.4367 × B × C − 0.0750 × B × E + 0.1019 × C × E − 0.294 × D × E − 0.0017 × E × F.

3.6. Hardness

The F-value (7.19) from

Table 7 implies that the cubic model for hardness is significant and there is only 3.41% possibility for this large F-value to occur due to errors. The weight ratio of saw-dust and the duration of cryogenic treatment have a significant effect (

p-values < 0.05) on the hardness of the fabricated composite material. From the interactive response-surface plots in

Figure 9, it could be observed that higher hardness of the composite could be achieved by increasing the duration of alkaline treatment of jute fibres and by keeping duration of cryogenic treatment lower.

The final model equation for hardness in terms of coded factors is given below. This equation could be used to make predictions about hardness for the given levels of the factors.

Hardness = +32.91 − 0.7455 × A − 7.72 × B − 1.05 × C − 6.51 × D − 4.20 × E − 0.4467 × A × B − 15.23 × A × C + 2.53 × A × E − 7.15 × B × C − 1.78 × B × E − 4.79 × C × E − 3.64 × D × E − 3.52 × E × F

3.7. Optimisation

The criteria for optimisation with an objective to maximise the mechanical properties is shown in

Table 8.

Table 9 lists the two topmost solutions obtained by employing desirability approach using Equation (5). These solutions have higher desirability, which implies that they are closer to the set objective. From this approach, saw-dust of density 300 kg/m

3 used as a filler with a weight ratio of 13% and a reinforcement of a single layer of woven-jute-fibre mat of grade 250 gsm subjected to alkaline treatment for 4 h in a composite that has undergone 45 min of cryogenic treatment delivers an impact strength of 3.3375 kJ/m

2, flexural strength of 44.9604 MPa, tensile strength of 33.4353 MPa and hardness of 51.4875 BHN. During cryogenic treatment, fibre undergoes variation in its diameter and also in its chemical composition. This affects the interfacial bonding leading to lowering of the strength. This observation can be corroborated by the results of the investigation of Ma et al. [

24].

3.8. Validation

The solutions from

Table 9 generated using the desirability approach were validated by confirmatory trials. Three trials were taken for each combination and the readings were averaged. The final experimental values were compared with the solutions suggested by desirability approach.

Table 10 presents the results of the confirmatory trials in conjunction with the solutions from

Table 9. It was found that the experimental values were closer in agreement with the predicted values with error in prediction below 5%. This suggests that the models developed using RSM were able to describe the effect of the six parameters on the mechanical properties adequately.

Table 11 shows the response values at optimum factor levels obtained using the desirability approach when compared to untreated woven-jute/saw-dust polyester composite with similar density of saw-dust, weight ratio of saw-dust, grade of woven-jute and number of jute layers.

It can be seen that composite with saw-dust of density 300 kg/m3 used as a filler with a weight ratio of 13% and a reinforcement of a single layer of woven-jute-fibre mat of grade 250 gsm subjected to alkaline treatment for 4 h in a composite that has undergone 45 min of cryogenic treatment presented an improvement of 64% in impact strength, 20.75% in flexural strength, 14.8% in tensile strength and 27.7% in hardness when compared to the composite reinforced with untreated fibres.