Interface Controlled Micro- and Macro-Mechanical Properties of Vibration Processed Carbon Fiber/Epoxy Composites

Abstract

:1. Introduction

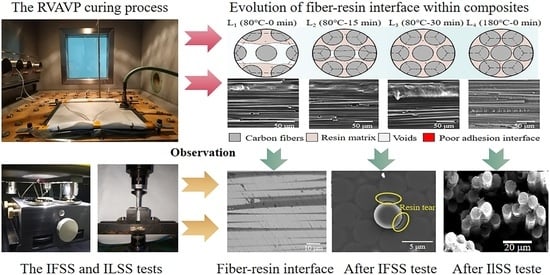

2. Experimental and Modeling Procedures

2.1. Laminate Fabrication Process

2.2. Micro-Mechanical Property Testing Method

2.3. Macro-Mechanical Property Testing Method

2.4. Composite Fiber Volume Fraction Measurement

3. Results and Discussion

3.1. Micro Interfacial Shear Property Analysis

3.1.1. Interfacial Shear Strength

3.1.2. Composite Microstructure

3.1.3. Fiber-Resin Interface Development

3.2. Macro Interfacial Shear Property Analysis

3.2.1. Interlaminar Shear Strength

3.2.2. Rupture Surface of Composites

3.3. Correlation of Micro- and Macro-Mechanics

4. Conclusions

- (1)

- Applying random vibration into the curing process of composite laminates production can improve the impregnation of the resin matrix into fiber bundles and impede the growth of micro-defects around the fiber-resin interface, which helps to form a better interface adhesion between the fiber and matrix under low curing pressures. Compared with the 0 MPa autoclave process, the IFSS increased from 52.62 MPa to higher than 78.02 MPa, together with an increase of the interface fracture toughness from 27.1 J/m2 to higher than 51.7 J/m2.

- (2)

- Due to the strong fiber-resin interfacial interactions, the introduction of random vibration significantly enhanced the composite ILSS to higher than 93.91 MPa, which obtained a slight reduction of 5.07% compared with the one cured by the 0.6 MPa autoclave process. Meanwhile, the flat fracture surfaces with the limited pull-out fibers and significant successive cusps indicated increases in the capability to transfer loads from the matrix to reinforcements through interfaces.

- (3)

- Regardless of whether they were static or vibrated, the sufficient impregnation of the resin matrix into fiber bundles was accompanied by the enhanced flow-compaction behavior during the formation process of the fiber-resin interface. The micro and macro-mechanical properties showed a positive correlation to the fiber volume fraction and tended to be stable when the fiber volume fraction reached 65.5%

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, L.; Jia, C.; He, J.; Zhao, F.; Fan, D.; Xing, L.X.; Wang, M.Q.; Wang, F.; Jiang, Z.X.; Huang, Y.D. Interfacial characterization control and modification of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2015, 121, 56–72. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, J.; Zhao, Y.; Wei, X.; Ju, L.; Chen, Y. A new vacuum pressure infiltration CFRP method and preparation experimental study of composite. Polymers 2020, 12, 419. [Google Scholar] [CrossRef] [Green Version]

- Uthaman, A.; Xian, G.; Thomas, S.; Wang, Y.; Zheng, Q.; Liu, X. Durability of an epoxy resin and its carbon fiber-reinforced polymer composite upon immersion in water, acidic, and alkaline solutions. Polymers 2020, 12, 614. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Medina, M.C.; Molina-Aldareguía, J.M.; Gonzále, C.; Melendrez, M.F.; Flores, P.; LLorca, J. Comparison of push-in and push-out tests for measuring interfacial shear strength in nano-reinforced composite materials. J. Compos. Mater. 2015, 50, 1651–1659. [Google Scholar] [CrossRef] [Green Version]

- Cui, J.; Wang, S.; Wang, S.; Li, G.; Wang, P.; Liang, C. The Effects of Strain Rates on Mechanical Properties and Failure Behavior of Long Glass Fiber Reinforced Thermoplastic Composites. Polymers 2019, 11, 2019. [Google Scholar] [CrossRef] [Green Version]

- Tran, T.Q.; Lee, J.K.Y.; Chinnappan, A.; Loc, N.H.; Tran, L.T.; Ji, D.; Jayathilaka, W.A.D.M.; Kumar, V.V.; Ramakrishna, S. High-Performance Carbon Fiber/Gold/Copper Composite Wires for Lightweight Electrical Cables. J. Mater. Sci. Technol. 2020, 42, 46–53. [Google Scholar] [CrossRef]

- Tan, W.; Naya, F.; Yang, L.; Chang, T.; Falzon, B.G.; Zhan, L.; Molina-Aldareguía, J.M.; González, C.; Llorca, J. The role of interfacial properties on the intralaminar and interlaminar damage behaviour of unidirectional composite laminates: Experimental characterization and multiscale modelling. Compos. B Eng. 2018, 138, 206–221. [Google Scholar] [CrossRef] [Green Version]

- Chang, T.; Zhan, L.; Tan, W.; Wu, X. Cohesive zone modeling of the autoclave pressure effect on the delamination behavior of composite laminates. J. Reinf. Plast. Comp. 2018, 37, 1468–1480. [Google Scholar] [CrossRef]

- Chang, T.F.; Zhan, L.H.; Tan, W.; Li, S.J. Void content and interfacial properties of composite laminates under different autoclave cure pressure. Compos. Interfaces 2016, 24, 529–540. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, B.; Li, D.; Zhang, D.; Chen, Y. Influence of voids on the tensile performance of carbon/epoxy fabric laminates. J. Mater. Sci. Technol. 2011, 27, 69–73. [Google Scholar] [CrossRef]

- Loos, A.C.; Springer, G.S. Curing of epoxy matrix composites. J. Compos. Mater. 1983, 17, 135–169. [Google Scholar] [CrossRef] [Green Version]

- Kardos, J.L.; Dudukovic, M.P.; Dave, R. Void growth and resin transport during processing of thermosetting-matrix composites. Adv. Polym. Sci. 1986, 80, 101–123. [Google Scholar]

- Hou, Z.; Luo, R.; Yang, W.; Xu, H.; Han, T. Effect of interface type on the static and dynamic mechanical properties of 3D braided SiC f /SiC composites. Mater. Sci. Eng. A 2016, 669, 66–74. [Google Scholar] [CrossRef]

- Udayakumar, A.; Sri Ganesh, A.; Raja, S.; Balasubramanianc, M. Effect of intermediate heat treatment on mechanical properties of SiCf/SiC composites with BN interphase prepared by ICVI. J. Eur. Ceram. Soc. 2011, 31, 1145–1153. [Google Scholar] [CrossRef]

- Kavouras, P.; Dragatogiannis, D.A.; Batsouli, D.I.; Charitidis, C.A. Effect of local microstructure on the indentation induced damage of a fiber reinforced composite. Polym. Test. 2017, 61, 197–204. [Google Scholar] [CrossRef]

- Li, W.; Krehl, J.; Gillespie, J.W.; Heider, D. Process and Performance Evaluation of the Vacuum-Assisted Process. J. Compos. Mater. 2004, 38, 1803–1814. [Google Scholar] [CrossRef]

- Davies, L.W.; Day, R.J.; Bond, D.; Nesbitt, A.; Ellis, J.; Gardon, E. Effect of cure cycle heat transfer rates on the physical and mechanical properties of an epoxy matrix composite. Key Eng. Mater. 2007, 334, 545–548. [Google Scholar] [CrossRef]

- Chaowasakoo, T.; Sombatsompop, N. Mechanical and morphological properties of fly ash/epoxy composites using conventional thermal and microwave curing methods. Compos. Sci. Technol. 2007, 67, 2282–2291. [Google Scholar] [CrossRef]

- Bai, J.B.; Shenoi, R.A.; Yun, X.Y.; Xiong, J.J. Progressive damage modelling of hybrid RTM-made composite Π-joint under four-point flexure using mixed failure criteria. Compos. Struct. 2017, 159, 327–334. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y.; Li, N.; Hao, X.; Liu, C. Interfacial shear strength of microwave processed carbon fiber/epoxy composites characterized by an improved fiber-bundle pull-out test. Compos. Sci. Technol. 2016, 133, 173–183. [Google Scholar] [CrossRef]

- Yang, H.; Zhou, X.; Yu, J.; Wang, H.; Huang, Z. Microwave and conventional sintering of the SiC/SiC composites: The densification and pore distributions. J. Alloy. Compd. 2016, 662, 252–258. [Google Scholar] [CrossRef]

- Agius, S.L.; Fox, B.L. Rapidly cured out-of-autoclave laminates: Understanding and controlling the effect of voids on laminate fracture toughness. Compos. B Eng. 2015, 73, 186–194. [Google Scholar] [CrossRef]

- Agius, S.L.; Magniez, K.J.C.; Fox, B.L. Fracture behaviour of a rapidly cured polyethersulfone toughened carbon fibre/epoxy composite. Compos. Struct. 2010, 92, 2119–2127. [Google Scholar] [CrossRef]

- Agius, S.L.; Magniez, K.J.C.; Fox, B.L. Cure behaviour and void development within rapidly cured out-of-autoclave composites. Compos. Struct. 2009, 47, 230–237. [Google Scholar] [CrossRef]

- Ghiorse, S.R.; Jurta, R.M. Effects of low frequency vibration processing on carbon/epoxy laminates. Composites 1991, 22, 3–8. [Google Scholar] [CrossRef]

- Muric-Nesic, J.; Compston, P.; Noble, N.; Stachurski, Z.H. Effect of low frequency vibrations on void content in composite materials. Compos. Part A Appl. Sci. Manuf. 2009, 40, 548–551. [Google Scholar] [CrossRef]

- Muric-Nesic, J.; Compston, P.; Stachurski, Z.H. On the void reduction mechanisms in vibration assisted consolidation of fibre reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 320–327. [Google Scholar] [CrossRef]

- Meier, R.; Kahraman, I.; Seyhan, A.T. Evaluating vibration assisted vacuum infusion processing of hexagonal boron nitride sheet modified carbon fabric/epoxy composites in terms of interlaminar shear strength and void content. Compos. Sci. Technol. 2016, 128, 94–103. [Google Scholar] [CrossRef]

- Abdérafi, C.R.; Laronde, F.; Guérin, F.; Bigaud, D.; Coadou, F. Robustness evaluation using highly accelerated life testing. Int. J. Adv. Manuf. Technol. 2011, 56, 1253–1261. [Google Scholar]

- Chen, Y.S.; Chuong, L.H. Efficiency improvement of the highly accelerated life testing system by using multiple hammers. J. Mech. Sci. Technol. 2014, 28, 4815–4831. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.E.; Yuan, X.R.; Jian, X.Z. Curing process optimization with extra-thickness carbon fiber reinforced epoxy resin matrix. Polym. Mater. Sci. Eng. 2017, 33, 101–113. [Google Scholar]

- Liu, L.; Zhang, B.M.; Wang, D.F.; Wu, Z.J. Effects of cure cycles on void content and mechanical properties of composite laminates. Compos. Struct. 2006, 73, 303–309. [Google Scholar] [CrossRef]

- Xu, T.; Luo, H.; Xu, Z.; Hu, Z.; Minary-Jolandan, M.; Roy, S.; Liu, H. Evaluation of the Effect of Thermal Oxidation and Moisture on the Interfacial Shear Strength of Unidirectional IM7/BMI Composite by Fiber Push-in Nanoindentation. Exp. Mech. 2017, 58, 111–123. [Google Scholar] [CrossRef]

- Rodríguez, M.; Molina-Aldareguía, J.M.; González, C.; LLorca, J. A methodology to measure the interface shear strength by means of the fiber push-in test. Compos. Sci. Technol. 2012, 72, 1924–1932. [Google Scholar] [CrossRef] [Green Version]

- Sharma, R.; Mahajan, P.; Mittal, R.K. Fiber bundle push-out test and image-based finite element simulation for 3D carbon/carbon composites. Carbon 2012, 50, 2717–2725. [Google Scholar] [CrossRef]

- You, J.-H.; Lutz, W.; Gerger, H.; Siddiq, A.; Brendel, A.; Höschen, C.; Schmauder, S. Fiber push-out study of a copper matrix composite with an engineered interface: Experiments and cohesive element simulation. Int. J. Solids. Struct. 2009, 46, 4277–4286. [Google Scholar] [CrossRef] [Green Version]

- Battisti, A.; Esqué-de los Ojos, D.; Ghisleni, R.; Brunner, A.J. Single fiber push-out characterization of interfacial properties of hierarchical CNT-carbon fiber composites prepared by electrophoretic deposition. Compos. Sci. Technol. 2015, 95, 121–127. [Google Scholar] [CrossRef]

- Yang, L.W.; Liu, H.T.; Cheng, H.F. Processing-temperature dependent micro- and macro-mechanical properties of SiC fiber reinforced SiC matrix composites. Compos. B Eng. 2017, 129, 152–161. [Google Scholar] [CrossRef]

- Yang, L.W.; Mayer, C.; Li, N.; Baldwin, J.K.; Mara, N.A.; Chawla, N.; Molina-Aldareguia, J.M.; Llorca, J. Mechanical properties of metal-ceramic nanolaminates: Effect of constraint and temperature. Acta. Mater. 2018, 142, 37–48. [Google Scholar] [CrossRef]

- Mohamad, A.; Ugla, A.A.; Erklig, A. A comparative study on the interlaminar shear strength of carbon, glass, and Kevlar fabric/epoxy laminates filled with SiC particles. J. Compos. Mater. 2017, 51, 1–9. [Google Scholar]

- Seyhan, A.T. Evaluatıng addıtıon of a membrane layer ın vacuum ınfusıon processıng of fıber reinforced epoxy composıtes in terms of flexural propertıes and void content. Anadolu Univ. J. Sci. Technol. A Appl. Sci. Eng. 2017, 18, 456–467. [Google Scholar] [CrossRef]

- Greisel, M.; Jäger, J.; Moosburger-Will, J.; Sause, M.G.R.; Mueller, W.M.; Horn, S. Influence of residual thermal stress in carbon fiber-reinforced thermoplastic composites on interfacial fracture toughness evaluated by cyclic single-fiber push-out tests. Compos. Part A Appl. Sci. Manuf. 2014, 66, 117–127. [Google Scholar] [CrossRef]

- Mueller, W.M.; Moosburger-Will, J.; Sause, M.G.R.; Greisel, M.; Horn, S. Quantification of crack area in ceramic matrix composites at single-fiber push-out testing and influence of pyrocarbon fiber coating thickness on interfacial fracture toughness. J. Eur. Ceram. Soc. 2015, 35, 2981–2989. [Google Scholar] [CrossRef]

- Buet, E.; Sauder, C.; Sornin, D.; Poissonnet, S.; Rouzaud, J.-N.; Vix-Guterl, C. Influence of surface fibre properties and textural organization of a pyrocarbon interphase on the interfacial shear stress of SiC/SiC minicomposites reinforced with Hi-Nicalon S and Tyranno SA3 fibres. J. Eur. Ceram. Soc. 2014, 34, 179–188. [Google Scholar] [CrossRef]

- Furukawa, Y.; Hatta, H.; Kogo, Y. Interfacial shear strength of C/C composites. Carbon 2003, 41, 1819–1826. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Morigaki, T.; Cai, Z. The consolidation of laminate composites. J. Compos. Mater. 1987, 21, 172–188. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Cai, Z.; Bauer, S.; Boucher, D.; Kingery, J.; Wineman, S. Consolidation experiments for laminate composites. J. Compos. Mater. 1987, 21, 650–669. [Google Scholar] [CrossRef]

- Gallo, C.S.; Li, X.; Zhang, Z.; Charitidis, C.; Dong, H. Viscoelastic response of carbon fibre reinforced polymer during push-out tests. Compos. Part A Appl. Sci. Manuf. 2018, 112, 178–185. [Google Scholar] [CrossRef]

- Kotani, M.; Konaka, K.; Ogihara, S. The effect on the tensile properties of PIP-processed SiC/SiC composite of a chemical vapor-infiltrated SiC layer overlaid on the pyrocarbon interface layer. Compos. Part A Appl. Sci. Manuf. 2016, 87, 123–130. [Google Scholar] [CrossRef]

- Yu, H.; Zhou, X.; Zhang, W.; Peng, H.; Zhang, C. Mechanical behavior of SiCf/SiC composites with alternating PyC/SiC multilayer interphases. Mater. Design 2013, 44, 320–324. [Google Scholar] [CrossRef]

- Yu, H.J.; Zhou, X.G.; Zhang, W.; Peng, H.X.; Zhang, C.R.; Huang, Z.L. Mechanical properties of 3D KD-I SiCf/SiC composites with engineered fibre–matrix interfaces. Compos. Sci. Technol. 2011, 71, 699–704. [Google Scholar] [CrossRef]

- Yang, L.W.; Wang, J.Y.; Liu, H.T.; Jiang, R.; Cheng, H.F. Sol-gel temperature dependent ductile-to-brittle transition of aluminosilicate fiber reinforced silica matrix composite. Compos. B Eng. 2017, 119, 79–89. [Google Scholar] [CrossRef]

| Material | E1 (GPa) | E2 (GPa) | G12 (GPa) | G23 (GPa) | v12 | α1 (10−6/°C) | α2 (10−6/°C) |

|---|---|---|---|---|---|---|---|

| Fiber | 282 | 11.38 | 6.37 | 3.84 | 0.33 | −0.56 | 5.6 |

| Matrix | 4.68 | 4.68 | 1.80 | 1.80 | 0.35 | 40 | 40 |

| Interface | 10.8 | 10.8 | 4.6 | 4.6 | 0.18 | 28 | 28 |

| Composite | 185 | 9.03 | 4.75 | 3.15 | 0.34 | 13.6 | 17.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Zhan, L.; Peng, Y.; Liu, C.; Xiong, R. Interface Controlled Micro- and Macro-Mechanical Properties of Vibration Processed Carbon Fiber/Epoxy Composites. Polymers 2021, 13, 2764. https://doi.org/10.3390/polym13162764

Yang X, Zhan L, Peng Y, Liu C, Xiong R. Interface Controlled Micro- and Macro-Mechanical Properties of Vibration Processed Carbon Fiber/Epoxy Composites. Polymers. 2021; 13(16):2764. https://doi.org/10.3390/polym13162764

Chicago/Turabian StyleYang, Xiaobo, Lihua Zhan, Yifeng Peng, Cong Liu, and Rui Xiong. 2021. "Interface Controlled Micro- and Macro-Mechanical Properties of Vibration Processed Carbon Fiber/Epoxy Composites" Polymers 13, no. 16: 2764. https://doi.org/10.3390/polym13162764

APA StyleYang, X., Zhan, L., Peng, Y., Liu, C., & Xiong, R. (2021). Interface Controlled Micro- and Macro-Mechanical Properties of Vibration Processed Carbon Fiber/Epoxy Composites. Polymers, 13(16), 2764. https://doi.org/10.3390/polym13162764