Investigation of Impacts on Printed Circuit Board Laminated Composites Caused by Surface Finish Application

Abstract

:1. Introduction

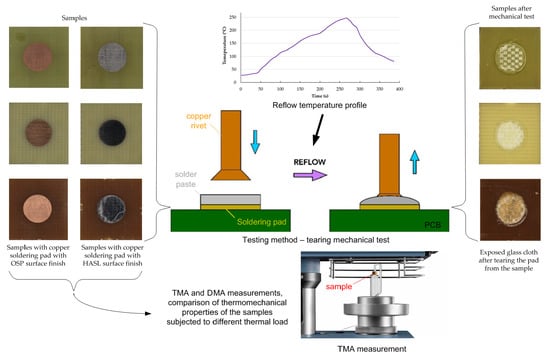

2. Materials and Methods

3. Results

3.1. Bond Strength Evaluation

3.2. Analysis of Thermomechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sirk, T.W.; Khare, K.S.; Karim, M.; Lenhart, J.L.; Andzelm, J.W.; McKenna, G.B.; Khare, R. High Strain Rate Mechanical Properties of a Cross-Linked Epoxy across the Glass Transition. Polymer 2013, 54, 7048–7057. [Google Scholar] [CrossRef]

- Hutapea, P.; Grenestedt, J.L. Effect of Temperature on Elastic Properties of Woven-Glass Epoxy Composites for Printed Circuit Board Applications. J. Electron. Mater. 2003, 32, 221–227. [Google Scholar] [CrossRef]

- Knadle, K.T.; Jadhav, V.R. Proof Is in the PTH—Assuring via Reliability from Chip Carriers to Thick Printed Wiring Boards. In Proceedings of the Proceedings Electronic Components and Technology, ECTC ’05, Lake Buena Vista, FL, USA, 31 May–3 June 2005; Volume 1, pp. 406–414. [Google Scholar]

- Wu, C.; Xu, W. Atomistic Molecular Modelling of Crosslinked Epoxy Resin. Polymer 2006, 47, 6004–6009. [Google Scholar] [CrossRef]

- Lesser, A.J.; Crawford, E. The Role of Network Architecture on the Glass Transition Temperature of Epoxy Resins. J. Appl. Polym. Sci. 1997, 66, 387–395. [Google Scholar] [CrossRef]

- Zhang, J.; Li, T.; Wang, H.; Liu, Y.; Yu, Y. Monitoring Extent of Curing and Thermal–Mechanical Property Study of Printed Circuit Board Substrates. Microelectron. Reliab. 2014, 54, 619–628. [Google Scholar] [CrossRef]

- Jain, R.; Kukreja, P.; Narula, A.K.; Chaudhary, V. Studies of the Curing Kinetics and Thermal Stability of Epoxy Resins Using a Mixture of Amines and Anhydrides. J. Appl. Polym. Sci. 2006, 100, 3919–3925. [Google Scholar] [CrossRef]

- Ehrler, S. The Compatibility of Epoxy--based Printed Circuit Boards with Lead--free Assembly. Circuit World 2005, 31, 3–13. [Google Scholar] [CrossRef]

- Polanský, R.; Mentlík, V.; Prosr, P.; Sušír, J. Influence of Thermal Treatment on the Glass Transition Temperature of Thermosetting Epoxy Laminate. Polym. Test. 2009, 28, 428–436. [Google Scholar] [CrossRef]

- Ma, L.; Sood, B.; Pecht, M. Effect of Moisture on Thermal Properties of Halogen-Free and Halogenated Printed-Circuit-Board Laminates. IEEE Trans. Device Mater. Reliab. 2011, 11, 66–75. [Google Scholar] [CrossRef]

- Xia, W.; Xiao, M.; Chen, Y.; Wu, F.; Liu, Z.; Fu, H. Thermal Warpage Analysis of PBGA Mounted on PCB during Reflow Process by FEM and Experimental Measurement. Solder. Surf. Mt. Technol. 2014, 26, 162–171. [Google Scholar] [CrossRef]

- Kim, S.-W.; Lee, S.-H.; Kim, D.-J.; Kim, S.K. Simulation of Warpage During Fabrication of Printed Circuit Boards. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 884–892. [Google Scholar] [CrossRef]

- Rayasam, M.; Thompson, T.B.; Subbarayan, G.; Gurumurthy, C.; Wilcox, J.R. A Model for Assessing the Shape of Solder Joints in the Presence of PCB and Package Warpage. J. Electron. Packag. 2006, 128, 184–191. [Google Scholar] [CrossRef]

- Straubinger, D.; Bozsóki, I.; Bušek, D.; Illés, B.; Géczy, A. Modelling of Temperature Distribution along PCB Thickness in Different Substrates during Reflow. Circuit World 2019, 46, 85–92. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, C.; Park, C.Y.; Wang, Y.; Liu, L.; Zou, G.; Cai, J.; Wang, Q. Effects of Package Warpage on Head-in-Pillow Defect. Mater. Trans. 2015, 56, 1037–1042. [Google Scholar] [CrossRef] [Green Version]

- Albrecht, O.; Wohlrabe, H.; Meier, K. Impact of Warpage Effects on Quality and Reliability of Solder Joints. In Proceedings of the 2019 42nd International Spring Seminar on Electronics Technology (ISSE), Wroclaw, Poland, 15–19 May 2019; pp. 1–6. [Google Scholar]

- Zhang, Q.; Lo, J.C.C.; Lee, S.W.R. Correlation of Board and Joint Level Test Methods with Strain Dominant Failure Criteria for Improving the Resistance to Pad Cratering. In Proceedings of the 2016 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; pp. 1–6. [Google Scholar]

- Roggeman, B.; Borgesen, P.; Li, J.; Godbole, G.; Tumne, P.; Srihari, K.; Levo, T.; Pitarresi, J. Assessment of PCB Pad Cratering Resistance by Joint Level Testing. In Proceedings of the 2008 58th Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 27–30 May 2008; pp. 884–892. [Google Scholar]

- Godbole, G.; Roggeman, B.; Borgesen, P.; Srihari, K. On the Nature of Pad Cratering. In Proceedings of the 2009 59th Electronic Components and Technology Conference, San Diego, CA, USA, 26–29 May 2009; pp. 100–108. [Google Scholar]

- Xie, D. Pad Cratering and Role of Thermal Stresses. In Encyclopedia of Thermal Stresses; Hetnarski, R.B., Ed.; Springer: Dordrecht, The Netherlands, 2014; pp. 3593–3608. ISBN 978-94-007-2739-7. [Google Scholar]

- Cai, M.; Xie, D.J.; Chen, W.B.; Wu, B.Y.; Yang, D.G.; Zhang, G.Q. A Novel Soldering Method to Evaluate PCB Pad Cratering for Pin-Pull Testing. Microelectron. Reliab. 2013, 53, 1568–1574. [Google Scholar] [CrossRef]

- Yang, C.; Song, F.; Lee, S.W.R.; Newman, K. Comparative Study of PWB Pad Cratering Subject to Reflow Soldering and Thermal Impact. In Proceedings of the 2010 Proceedings 60th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 1–4 June 2010; pp. 464–470. [Google Scholar]

- Dušek, K.; Rudajevová, A.; Plaček, M. Influence of Latent Heat Released from Solder Joints on the Reflow Temperature Profile. J. Mater. Sci. Mater. Electron. 2016, 27, 543–549. [Google Scholar] [CrossRef]

- Cheat, L.W.; Sing, L.S. Copper Discoloration: Correlation Between Copper Oxidation States and Their Colors. In Proceedings of the 2018 IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), Singapore, 16–19 July 2018; pp. 1–3. [Google Scholar]

- Ramirez, M.; Henneken, L.; Virtanen, S. Oxidation Kinetics of Thin Copper Films and Wetting Behaviour of Copper and Organic Solderability Preservatives (OSP) with Lead-Free Solder. Appl. Surf. Sci. 2011, 257, 6481–6488. [Google Scholar] [CrossRef]

- Su, S.; Jian, M.; Hamasha, S. Effects of Surface Finish on the Shear Fatigue of SAC-Based Solder Alloys. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 457–466. [Google Scholar] [CrossRef]

- Hamasha, S.; Akkara, F.; Abueed, M.; Rababah, M.; Zhao, C.; Su, S.; Suhling, J.; Evans, J. Effect of Surface Finish and High Bi Solder Alloy on Component Reliability in Thermal Cycling. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 29 May–1 June 2018; pp. 2032–2040. [Google Scholar]

- Collins, M.N.; Punch, J.; Coyle, R. Surface Finish Effect on Reliability of SAC 305 Soldered Chip Resistors. Solder. Surf. Mt. Technol. 2012, 24, 240–248. [Google Scholar] [CrossRef]

- Yang, Y. Failure Analysis for Bad Wetting on HASL PCB. In Proceedings of the 2017 18th International Conference on Electronic Packaging Technology (ICEPT), Harbin, China, 16–19 August 2017; pp. 126–129. [Google Scholar]

- Tong, K.H.; Ku, M.T.; Hsu, K.L.; Tang, Q.; Chan, C.Y.; Yee, K.W. The Evolution of Organic Solderability Preservative (OSP) Process in PCB Application. In Proceedings of the 2013 8th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 22–25 October 2013; pp. 43–46. [Google Scholar]

- Dušek, K.; Bušek, D.; Petráč, A.; Plaček, M.; Kozák, M.; Molhanec, M.; Beshajová Pelikánová, I. Comparison of Mechanical Resistance of SnCu and SnBi of Solder Joints. In Proceedings of the 2017 40th International Spring Seminar on Electronics Technology (ISSE), Sofia, Bulgaria, 10–14 May 2017; pp. 1–4. [Google Scholar]

- Vasko, C.; Novotny, M.; Szendiuch, I. Impact of Solder Pad Shape on Lead-Free Solder Joint Reliability. In Proceedings of the 2008 31st International Spring Seminar on Electronics Technology, Budapest, Hungary, 7–11 May 2008; pp. 433–445. [Google Scholar]

- Zhou, P.; Jiang, T.; Yang, D.; You, Z.; Ma, Y.; Ren, R. The Effect of Interface Reaction with Different Finishes and SnAgCu on the Reliability of Solder Joints. In Proceedings of the 2010 11th International Conference on Electronic Packaging Technology & High Density Packaging, Xi’an, China, 16–19 August 2010; pp. 998–1002. [Google Scholar]

- Wiechmann, R. Experiences with Peel Strength. Circuit World 2006, 32, 30–39. [Google Scholar] [CrossRef]

- Ikegawa, N.; Hamada, H.; Yamanouchi, M. Evaluation of Adhesion between Glass/Epoxy Composite Substrate and Copper Foil for Printed Circuit Board Applications. Compos. Interfaces 2002, 9, 235–245. [Google Scholar] [CrossRef]

- Liu, F.; Wan, B.; Wang, F.; Chen, W. Effect of Thermal Shock Process on the Microstructure and Peel Resistance of Single–Sided Copper Clad Laminates Used in Waste Printed Circuit Boards. J. Air Waste Manag. Assoc. 2019, 69, 1490–1502. [Google Scholar] [CrossRef] [PubMed]

- Yong, A.X.H.; Sims, G.D.; Gnaniah, S.J.P.; Ogin, S.L.; Smith, P.A. Heating Rate Effects on Thermal Analysis Measurement of Tg in Composite Materials. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 43–51. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, M.; Burlingame, J.; Guirguis, C. Validated Test Method to Characterize and Quantify Pad Cratering under BGA Pads on Printed Circuit Boards. In Proceedings of the IPC APEX Expo, San Jose, CA, USA, 25–27 January 2022; pp. 1–13. [Google Scholar]

- Ray, B.C. Effect of Thermal Shock on Interlaminar Strength of Thermally Aged Glass Fiber-Reinforced Epoxy Composites. J. Appl. Polym. Sci. 2006, 100, 2062–2066. [Google Scholar] [CrossRef]

- Roggeman, B.; Jones, W. Characterizing the Lead-Free Impact on PCB Pad Craters. In Proceedings of the IPC APEX Expo, San Diego, CA, USA, 20–21 July 2010. [Google Scholar]

- Rudajevová, A.; Dušek, K. Influence of Manufacturing Mechanical and Thermal Histories on Dimensional Stabilities of FR4 Laminate and FR4/Cu-Plated Holes. Materials 2018, 11, 2114. [Google Scholar] [CrossRef] [Green Version]

- Margem, F.M.; Monteiro, S.N.; Bravo Neto, J.; Rodriguez, R.J.S.; Soares, B.G. The Dynamic-Mechanical Behavior of Epoxy Matrix Composites Reinforced with Ramie Fibers. Matér. Rio Jan. 2010, 15, 164–171. [Google Scholar] [CrossRef] [Green Version]

- Keusch, S.; Haessler, R. Influence of Surface Treatment of Glass Fibres on the Dynamic Mechanical Properties of Epoxy Resin Composites. Compos. Part Appl. Sci. Manuf. 1999, 30, 997–1002. [Google Scholar] [CrossRef]

| Producer | Type | Grade | Glass Transition Temperature | Samples Marking |

|---|---|---|---|---|

| JIANGSU RODA ELECTRON MATERIAL, Rudong, China | RD140 | FR4 | 135 °C | Tg1 |

| TECHNOLAM, Troisdorf, Germany | NP-175F | FR4 | 170 °C | Tg2 |

| Göttle Leiterplattentechnik, Königsbrunn, Germany | VT-901 | G30 | 250 °C | Tg3 |

| Operation | Motivation |

|---|---|

| Investigation of the effect of surface finish | The impact of the technological process (surface finish application) on the laminate evaluation is crucial. |

| Surface finish choice | Two surface finishes were chosen regarding thermal circumstances during application. HASL application is accompanied by thermal stress, whereas OSP is not. |

| Selection of laminates | Various resins or their modifications have different thermal properties and adhesion to filler. |

| Bond strength assessment | The strength of the adhesion of the soldering pad, specifically resin to filler, is significant in relation to failure–pad cratering occurring on the PCBs. |

| Reflow soldering | Except establishing the mechanical connection, the bond strength results respect the effect of this treatment, which is an essential step in electronic assembly. |

| Preheating | Specimens tested at an elevated temperature were preheated to achieve an equal temperature throughout the sample. Consequent mechanical tests performed at 100 °C were realized in order to simulate field conditions. |

| Exposition to reflow soldering conditions | It was included to verify the effect of surface application, i.e., comparison of slow and rapid heating. |

| Thermomechanical analysis (TMA) and dynamic mechanical analysis (DMA) | Observation of material behavior in the surrounding of Tg and detection of Tg value displacement. Assessment of material response during mechanical loading in conjunction with temperature rise. More measurements cycles were conducted to determine the response during soldering and, consequently, the effect of the thermal loading. |

| Tg1H_AT | Tg2H_AT | Tg3H_AT | Tg1O_AT | Tg2O_AT | Tg3O_AT | Tg1H_ET | Tg2H_ET | Tg3H_ET | Tg1O_ET | Tg2O_ET | Tg3O_ET | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean (N) | 542.0 | 432.5 | 409.6 | 505.0 | 384.2 | 491.9 | 447.2 | 441.2 | 473.9 | 488.8 | 458.2 | 505.6 |

| Minimum (N) | 471.7 | 365.1 | 357.8 | 431.5 | 305.9 | 401.5 | 336.5 | 375.1 | 403.6 | 433.5 | 403.7 | 441.3 |

| Maximum (N) | 614.0 | 503.5 | 461.8 | 565.8 | 441.8 | 566.5 | 543.9 | 486.9 | 551.5 | 573.6 | 513.7 | 569.5 |

| SD (N) | 44.4 | 47.1 | 32.6 | 39.9 | 49.7 | 60.0 | 66.7 | 31.6 | 51.4 | 46.3 | 41.4 | 44.6 |

| Bond strength (N/mm2) | 22.8 | 18.2 | 17.2 | 21.3 | 16.2 | 20.7 | 18.8 | 18.6 | 20.0 | 20.6 | 19.3 | 21.3 |

| Tg1 | Tg1_After Reflow | Tg2 | Tg3 | ||||

|---|---|---|---|---|---|---|---|

| HASL | OSP | HASL | OSP | HASL | OSP | HASL | OSP |

| 116.2 | 127.9 | 115.5 | 123.4 | 177.1 | 176.7 | 228.8 | 221.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Froš, D.; Dušek, K.; Veselý, P. Investigation of Impacts on Printed Circuit Board Laminated Composites Caused by Surface Finish Application. Polymers 2021, 13, 3203. https://doi.org/10.3390/polym13193203

Froš D, Dušek K, Veselý P. Investigation of Impacts on Printed Circuit Board Laminated Composites Caused by Surface Finish Application. Polymers. 2021; 13(19):3203. https://doi.org/10.3390/polym13193203

Chicago/Turabian StyleFroš, Denis, Karel Dušek, and Petr Veselý. 2021. "Investigation of Impacts on Printed Circuit Board Laminated Composites Caused by Surface Finish Application" Polymers 13, no. 19: 3203. https://doi.org/10.3390/polym13193203

APA StyleFroš, D., Dušek, K., & Veselý, P. (2021). Investigation of Impacts on Printed Circuit Board Laminated Composites Caused by Surface Finish Application. Polymers, 13(19), 3203. https://doi.org/10.3390/polym13193203