Experimental and Numerical Study on the Compressive Failure of Composite Laminates with Fiber Waviness Defects

Abstract

:1. Introduction

2. Manufacture Process of Composite Stringers

3. Experimental Study

3.1. Manufacturing of Specimens with Waviness

3.2. Compression Testing

3.3. Testing Results

4. Finite Element Modeling

4.1. Constitutive Law

4.1.1. Progressive Failure Analysis

4.1.2. Cohesive Interfaces for Delamination

4.2. Meshing and Boundary Conditions

4.3. FE Analysis Results

5. Parametric Study

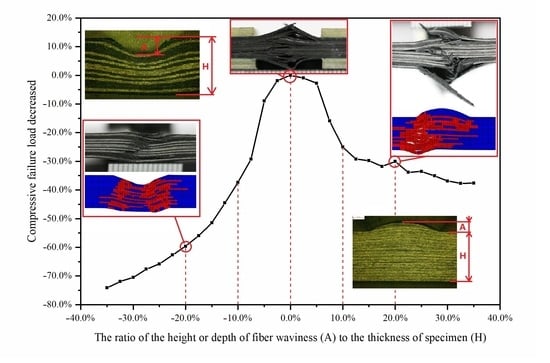

5.1. Influence of A/H

5.2. Influence of the Number of Plies with Fiber Waviness

6. Conclusions

- (1)

- Experiments and FE simulations were carried out with the fiber waviness ratio A/H of −20%, −10%, 10%, 20% and waviness-free specimens. The numerical results and failure modes have a good agreement with those from testing. Therefore, the 3D FE model in this paper can be used to predict the compressive failure load and failure mode of composite laminates with out-of-plane waviness defects.

- (2)

- With the increase of the fiber waviness ratio A/H (absolute value), the compressive failure load of both convex and concave fiber waviness decreases. It also shows a nonlinear relationship between them. For the current lay-up, the fiber waviness ratio A/H has little influence on the compressive failure load when it is less than 5%. Therefore, this value may be identified as an acceptance criterion during the manufacturing process of the composite stringers, beyond which a significant reduction of compressive failure load may occur.

- (3)

- It seems that the effect of the number of plies with fiber waviness n varies under different A/H conditions for convex fiber waviness. We investigated a low, moderate and high level of A/H (i.e., A/H = 7.5%, 15.0% and 25.0%). When it is 7.5%, the compressive failure load only has a slight reduction as n increases. In addition, the curve tends to be flat when n >= 6.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alves, M.P.; Cimini Junior, C.A.; Ha, S.K. Fiber waviness and its effect on the mechanical performance of fiber reinforced polymer composites: An enhanced review. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106526. [Google Scholar] [CrossRef]

- Kulkarni, P.; Mali, K.D.; Singh, S. An overview of the formation of fibre waviness and its effect on the mechanical performance of fibre reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 2020, 137, 106013. [Google Scholar] [CrossRef]

- Kugler, D.; Moon, T.J. Identification of the Most Significant Processing Parameters on the Development of Fiber Waviness in Thin Laminates. J. Compos. Mater. 2002, 36, 1451–1479. [Google Scholar] [CrossRef]

- Potter, K.; Khan, B.; Wisnom, M.; Bell, T.; Stevens, J. Variability, fibre waviness and misalignment in the determination of the properties of composite materials and structures. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1343–1354. [Google Scholar] [CrossRef]

- Lightfoot, J.S.; Wisnom, M.R.; Potter, K. A new mechanism for the formation of ply wrinkles due to shear between plies. Compos. Part A Appl. Sci. Manuf. 2013, 49, 139–147. [Google Scholar] [CrossRef]

- Hsiao, H.M.; Daniel, I.M. Effect of fiber waviness on stiffness and strength reduction of unidirectional composites under compressive loading. Compos. Sci. Technol. 1996, 56, 581–593. [Google Scholar] [CrossRef]

- Hallander, P.; Sjölander, J.; Åkermo, M. Forming induced wrinkling of composite laminates with mixed ply material properties; an experimental study. Compos. Part A Appl. Sci. Manuf. 2015, 78, 234–245. [Google Scholar] [CrossRef]

- Beakou, A.; Cano, M.; Le Cam, J.B.; Verney, V. Modelling slit tape buckling during automated prepreg manufacturing: A local approach. Compos. Struct. 2011, 93, 2628–2635. [Google Scholar] [CrossRef] [Green Version]

- Nimbal, S.S.; Banker, M.M.; Roopa, A.; Varughese, B.; Sundaram, R. Effect of Gap Induced Waviness on Compressive Strength of Laminated Composites. Mater. Today Proc. 2017, 4, 8355–8369. [Google Scholar] [CrossRef]

- Dodwell, T.J.; Butler, R.; Hunt, G.W. Out-of-plane ply wrinkling defects during consolidation over an external radius. Compos. Sci. Technol. 2014, 105, 151–159. [Google Scholar] [CrossRef] [Green Version]

- Takeda, T. Micromechanics model for three-dimensional effective elastic properties of composite laminates with ply wrinkles. Compos. Struct. 2018, 189, 419–427. [Google Scholar] [CrossRef]

- Joyce, P.J.; Kugler, D.; Moon, T.J. A Technique for Characterizing Process-Induced Fiber Waviness in Unidirectional Composite Laminates-Using Optical Microscopy. J. Compos. Mater. 1997, 31, 1694–1727. [Google Scholar] [CrossRef]

- Chan, W.S.; Wang, J.S. Influence of Fiber Waviness on the Structural Response of Composite Laminates. J. Thermoplast. Compos. Mater. 1994, 7, 243–260. [Google Scholar] [CrossRef]

- O’Hare Adams, D.; Hyer, M.W. Effects of Layer Waviness on the Compression Strength of Thermoplastic Composite Laminates. J. Reinf. Plast. Compos. 1993, 12, 414–429. [Google Scholar] [CrossRef]

- El-Hajjar, R.F.; Petersen, D.R. Gaussian function characterization of unnotched tension behavior in a carbon/epoxy composite containing localized fiber waviness. Compos. Struct. 2011, 93, 2400–2408. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Jones, M.I.; Hallett, S.R. Compressive failure of laminates containing an embedded wrinkle; experimental and numerical study. Compos. Part A Appl. Sci. Manuf. 2015, 73, 132–142. [Google Scholar] [CrossRef] [Green Version]

- Bloom, L.D.; Wang, J.; Potter, K.D. Damage progression and defect sensitivity: An experimental study of representative wrinkles in tension. Compos. Part B Eng. 2013, 45, 449–458. [Google Scholar] [CrossRef]

- Hu, H.; Cao, D.; Cao, Z.; Li, S. Experimental and numerical investigations of wrinkle effect on failure behavior of curved composite laminates. Compos. Struct. 2021, 261, 113541. [Google Scholar] [CrossRef]

- Xu, X.; Jones, M.I.; Ali, H.; Wisnom, M.R.; Hallett, S.R. Effect of out-of-plane wrinkles in curved multi-directional carbon/epoxy laminates. Compos. Sci. Technol. 2020, 197, 108282. [Google Scholar] [CrossRef]

- Dattoma, V.; Gambino, B.; Nobile, R.; Panella, F.W. Mechanical behaviour of composite material in presence of wrinkles. Procedia Struct. Integr. 2018, 8, 444–451. [Google Scholar] [CrossRef]

- Wu, C.; Gu, Y.; Luo, L.; Xu, P.; Wang, S.; Li, M.; Zhang, Z. Influences of in-plane and out-of-plane fiber waviness on mechanical properties of carbon fiber composite laminate. J. Reinf. Plast. Compos. 2018, 37, 877–891. [Google Scholar] [CrossRef]

- Nartey, M.; Zhang, T.; Gong, B.W.; Wang, J.Z.; Peng, S.Y.; Wang, H.; Peng, H.X. Understanding the impact of fibre wrinkle architectures on composite laminates through tailored gaps and overlaps. Compos. Part B Eng. 2020, 196, 108097. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Atkinson, J.W. Compressive Failure Due to Shear Instability: Experimental Investigation of Waviness and Correlation with Analysis. J. Reinf. Plast. Compos. 1996, 15, 420–439. [Google Scholar] [CrossRef]

- Garnich, M.R.; Karami, G. Finite Element Micromechanics for Stiffness and Strength of Wavy Fiber Composites. J. Compos. Mater. 2004, 38, 273–292. [Google Scholar] [CrossRef]

- Garnich, M.R.; Karami, G. Localized Fiber Waviness and Implications for Failure in Unidirectional Composites. J. Compos. Mater. 2005, 39, 1225–1245. [Google Scholar] [CrossRef]

- Lemanski, S.L.; Wang, J.; Sutcliffe, M.P.F.; Potter, K.D.; Wisnom, M.R. Modelling failure of composite specimens with defects under compression loading. Compos. Part A Appl. Sci. Manuf. 2013, 48, 26–36. [Google Scholar] [CrossRef] [Green Version]

- Lemanski, S.L.; Sutcliffe, M.P.F. Compressive failure of finite size unidirectional composite laminates with a region of fibre waviness. Compos. Part A Appl. Sci. Manuf. 2012, 43, 435–444. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Jones, M.I.; Hallett, S.R. Tensile failure of laminates containing an embedded wrinkle; numerical and experimental study. Compos. Part A Appl. Sci. Manuf. 2015, 77, 219–228. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Nixon-Pearson, O.J.; Hallett, S.R. An experimental and numerical study on fatigue damage development in laminates containing embedded wrinkle defects. Int. J. Fatigue 2018, 107, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Davidson, P.; Waas, A.M. The effects of defects on the compressive response of thick carbon composites: An experimental and computational study. Compos. Struct. 2017, 176, 582–596. [Google Scholar] [CrossRef]

- Ning, Z.H.; Huo, G.L.; Liu, R.H.; Wu, W.L.; Xie, J.M. Progressive Failure Analysis of Laminates with Embedded Wrinkle Defects Based on an Elastoplastic Damage Model. Materials 2020, 13, 2422. [Google Scholar] [CrossRef] [PubMed]

- Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture; ASTM D6641/D6641M-16e2; ASTM Compass: Vilnius, Lithuania, 2016. [CrossRef]

- Falzon, B.G.; Apruzzese, P. Numerical analysis of intralaminar failure mechanisms in composite structures. Part I: FE implementation. Compos. Struct. 2011, 93, 1039–1046. [Google Scholar] [CrossRef]

- Puck, A.; Mannigel, M. Physically based non-linear stress–strain relations for the inter-fibre fracture analysis of FRP laminates. Compos. Sci. Technol. 2007, 67, 1955–1964. [Google Scholar] [CrossRef]

- Knops, M. Analysis of Failure in Fiber Polymer Laminates—The Theory of Alfred Puck; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

| Fiber Waviness Ratio | Failure Load | Failure Load Decreasing (%) | |

|---|---|---|---|

| Mean (kN) | CV (%) | ||

| 0% (waviness-free) | 36.53 | 5.1 | 0 |

| −20% | 15.27 | 5.3 | 58.1 |

| −10% | 23.21 | 5.1 | 36.5 |

| 10% | 26.55 | 4.9 | 27.1 |

| 20% | 24.73 | 2.6 | 32.3 |

| 142500 | 8540 | 4340 | 3235 | 0.32 |

| (MPa) | (MPa) | (MPa) | (MPa) | (MPa) |

| 2737 | 1585 | 86.4 | 212.8 | 110 |

| 5105 | 3105 | 50 | 90 | 90 |

| 0.3 | 0.9 | 1 |

| A/H | Simulation Value/kN | Experimental Value/kN | Error |

|---|---|---|---|

| 0% | 34.86 | 36.53 | −4.57% |

| −20% | 14.08 | 15.27 | −7.79% |

| −10% | 21.85 | 23.21 | −5.86% |

| 10% | 26.16 | 26.55 | −1.47% |

| 20% | 24.39 | 24.73 | −1.37% |

| A/H | Compressive Failure Load/kN | A/H | Compressive Failure Load/kN |

|---|---|---|---|

| 35.0% | 21.76 | −35.0% | 9.01 |

| 32.5% | 21.72 | −32.5% | 9.79 |

| 30.0% | 22.01 | −30.0% | 10.28 |

| 27.5% | 22.64 | −27.5% | 11.29 |

| 25.0% | 23.17 | −25.0% | 11.92 |

| 22.5% | 23.07 | −22.5% | 13.01 |

| 20.0% | 24.39 | −20.0% | 14.08 |

| 17.5% | 23.79 | −17.5% | 15.37 |

| 15.0% | 24.49 | −15.0% | 16.92 |

| 12.5% | 24.66 | −12.5% | 19.35 |

| 10.0% | 26.16 | −10.0% | 21.85 |

| 7.5% | 29.32 | −7.5% | 24.67 |

| 5.0% | 33.89 | −5.0% | 31.73 |

| 2.5% | 34.55 | −2.5% | 34.21 |

| n | A/H = 7.5% | A/H = 15% | A/H= 25% |

|---|---|---|---|

| 2 | 34.12 | 32.99 | 31.60 |

| 4 | 33.11 | 32.16 | 31.13 |

| 6 | 30.06 | 30.20 | 25.58 |

| 8 | 29.10 | 28.69 | 26.09 |

| 10 | 29.32 | 24.49 | 23.17 |

| 12 | 28.59 | 22.10 | 21.33 |

| 14 | 28.39 | 22.32 | 17.78 |

| 16 | 28.01 | 19.51 | 15.38 |

| 18 | 27.95 | 18.78 | 14.96 |

| 20 | 28.07 | 18.55 | 14.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhu, S.; Li, H.; Zhou, L.; Yi, W. Experimental and Numerical Study on the Compressive Failure of Composite Laminates with Fiber Waviness Defects. Polymers 2021, 13, 3204. https://doi.org/10.3390/polym13193204

Wang Y, Zhu S, Li H, Zhou L, Yi W. Experimental and Numerical Study on the Compressive Failure of Composite Laminates with Fiber Waviness Defects. Polymers. 2021; 13(19):3204. https://doi.org/10.3390/polym13193204

Chicago/Turabian StyleWang, Yuequan, Shuhua Zhu, Hongshuang Li, Long Zhou, and Wentao Yi. 2021. "Experimental and Numerical Study on the Compressive Failure of Composite Laminates with Fiber Waviness Defects" Polymers 13, no. 19: 3204. https://doi.org/10.3390/polym13193204

APA StyleWang, Y., Zhu, S., Li, H., Zhou, L., & Yi, W. (2021). Experimental and Numerical Study on the Compressive Failure of Composite Laminates with Fiber Waviness Defects. Polymers, 13(19), 3204. https://doi.org/10.3390/polym13193204