Modification of Mechanical and Electromechanical Resonances of Cellular Ferroelectret Films Depending on the External Load

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- the transmission coefficient of the FE sample,

- the electrical voltage generated in the FE sample when an ultrasonic wave impinges on the it (electromechanical response in Rx mode),

- the ultrasonic signal emitted by the FE sample when an electrical excitation is applied to it (electromechanical response in Tx mode).

2.2. Methods

2.2.1. Measurement of the Mechanical Response of the FE Sample: Transmission Coefficient

2.2.2. Measurement of the Electromechanical Response: Rx Mode

2.2.3. Measurement of the Electromechanical Response: Tx Mode

3. Results

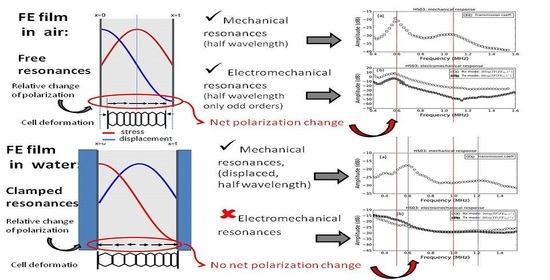

3.1. FE Response in Air

3.2. FE Response in Water

4. Discussion

4.1. Discussion of the Modification of the FE Mechanical Response for Two Different External Loads: Air and Water

4.2. Electromechanical Response of the FE Films in Air and in Water

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Savolainen, A.; Kirjavainen, K. Electrothermomechanical film. Part I. Design and characteristics. J. Macromol. Sci. A-Chem. 1989, 26, 583–591. [Google Scholar] [CrossRef]

- Sessler, G.M.; Hillenbrand, J. Electromechanical response of cellular electret films. Appl. Phys. Lett. 1999, 75, 3405–3407. [Google Scholar] [CrossRef]

- Gibson, L.; Ashby, M.F.; Brendan, A.H. Cellular Materials in Nature and Medicine; Cambridge University Press: Cambridge, UK, 2010; ISBN 9780521195447. [Google Scholar]

- Restrepo, D.; Mankame, N.D.; Zavattieri, P.D. Programmable materials based on periodic cellular solids. Part I: Experiments. Int. J. Solids Struct. 2016, 100–101, 485–504. [Google Scholar] [CrossRef]

- Wegener, M.; Wirges, W.; Fohlmeister, J.; Tiersch, B.; Gerhard-Multhaupt, R. Two-step inflation of cellular polypropylene films: Void-thickness increase and enhanced electromechanical properties. J. Phys. D Appl. Phys. 2004, 37, 623–627. [Google Scholar] [CrossRef]

- Altafim, R.A.P.; Qiu, X.; Wirges, W.; Gerhard, R.; Basso, H.C.; Jenninger, W.; Wagner, J. Template-based fluoroethylenepropylene piezoelectrets with tubular channels for transducer applications. J. Appl. Phys. 2009, 106, 014106. [Google Scholar] [CrossRef]

- Zhang, X.; Sessler, G.M.; Wang, Y. Fluoroethylenepropylene ferroelectret films with cross-tunnel structure for piezoelectric transducers and micro energy harvesters. J. Appl. Phys. 2014, 116, 074109. [Google Scholar] [CrossRef]

- Dali, O.B.; Zhukov, S.; Rutsch, M.; Hartman, C.; von Seggern, H.; Sessler, G.M.; Kupnik, M. Biodegradable additive manufactured ferroelectret ultrasonic transducer with large output pressure. In Proceedings of the IEEE International Ulrasonic Symposium, Xi’an, China, 12–15 September 2021. [Google Scholar]

- Qiu, X.; Wegener, M.; Wirges, W.; Zhang, X.; Hillenbrand, J.; Xia, Z.; Gerhard-Multhaupt, R.; Sessler, G.M. Penetration of sulfur hexafluoride into cellular polypropylene films and its effect on the electric charging and electromechanical response of ferroelectrets. J. Phys. D Appl. Phys. 2005, 38, 649–654. [Google Scholar] [CrossRef]

- Wegener, M.; Wirges, W.; Gerhard-Multhaupt, R.; Bauer-Gogonea, S.; Paajanen, M.; Minkkinen, H.; Raukola, J.; Dansachmüller, M.; Schwodiauer, R.; Bauer, S. Controlled inflation of voids in cellular polymer ferroelectrets: Optimizing electromechanical transducer properties. Appl. Phys. Lett. 2004, 84, 392–395. [Google Scholar] [CrossRef]

- Mellinger, A.; Wegener, M.; Wirges, W.; Mallepally, R.R.; Gerhard-Multhaupt, R. Thermal and Temporal Stability of Ferroelectret Films Made from Cellular Polypropylene/Air Composites. Ferroelectrics 2006, 331, 189–199. [Google Scholar] [CrossRef]

- Saarimaki, E.; Paajanen, M.; Savijarvi, A.; Minkkinen, H.; Wegener, M.; Voronina, O.; Schulze, R.; Wirges, W.; Gerhard-Multhaupt, R. Novel heat durable electromechanical film: Processing for electromechanical and electret applications. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 963–972. [Google Scholar] [CrossRef]

- Qiu, X.; Mellinger, A.; Wegener, M.; Wirges, W.; Gerhard, R. Barrier discharges in cellular polypropylene ferroelectrets: How do they influence the electromechanical properties? J. Appl. Phys. 2007, 101, 104112. [Google Scholar] [CrossRef] [Green Version]

- Fang, P.; Wirges, W.; Wegener, M.; Zirkel, L.; Gerhard, R. Cellular polyethylene-naphthalate films for ferroelectret applications: Foaming, inflation and stretching, assessment of electromechanically relevant structural features. e-Polymers 2008, 8, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Álvarez-Arenas, T.E.G.; Calás, H.; Cuello, J.E.; Fernández, A.R.; Muñoz, M. Noncontact ultrasonic spectroscopy applied to the study of polypropylene ferroelectrets. J. Appl. Phys. 2010, 108, 074110. [Google Scholar] [CrossRef]

- Mohebbi, A.; Mighri, F.; Ajji, A.; Rodrigue, D. Cellular Polymer Ferroelectret: A Review on Their Development and Their Piezoelectric Properties. Adv. Polym. Technol. 2018, 37, 468–483. [Google Scholar] [CrossRef]

- Liu, B.; Han, L.; Pan, L.; Li, H.; Zhao, J.; Dong, Y.; Wang, X. Flexible Multiscale Pore Hybrid Self-Powered Sensor for Heart Sound Detection. Sensors 2021, 21, 4508. [Google Scholar] [CrossRef]

- Sessler, G.M.; Hillenbrand, J. Novel Silicon and Polymer Sensors in Acoustics. In Proceedings of the SENSOR+TEST Conference, Nürnberg, Germany, 26–28 May 2009; pp. 9–14. [Google Scholar] [CrossRef]

- Luo, Z.; Shi, J.; Beeby, S.P. Novel thick-foam ferroelectret with engineered voids for energy harvesting applications. J. Phys. Conf. Ser. 2016, 773, 012030. [Google Scholar] [CrossRef]

- Zhang, Y.; Bowen, C.R.; Ghosh, S.K.; Mandal, D.; Khanbareh, H.; Arafa, M.; Wan, C. Ferroelectret materials and devices for energy harvesting applications. Nano Energy 2019, 57, 118–140. [Google Scholar] [CrossRef]

- Zhang, X.; Pondrom, P.; Sessler, G.M.; Ma, X. Ferroelectret nanogenerator with large transverse piezoelectric activity. Nano Energy 2018, 50, 52–61. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, X.; Fang, P. Flexible film-transducers based on polypropylene piezoelectrets: Fabrication, properties, and applications in wearable devices. Sens. Actuators A Phys. 2017, 256, 35–42. [Google Scholar] [CrossRef]

- Shi, J.; Beeby, S. Textile based ferroelectret for foot pressure sensor. In Proceedings of the IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Glasgow, UK, 8–10 July 2019; pp. 1–3. [Google Scholar] [CrossRef]

- Buchberger, G.; Schwödiauer, R.; Arnold, N.; Bauer, S. Cellular ferroelectrets for flexible touchpads, keyboards and tactile sensors. Proc. IEEE Sens. 2008, 2008, 1520–1523. [Google Scholar] [CrossRef]

- Sborikas, M.; Wegener, M. Cellular-foam polypropylene ferroelectrets with increased film thickness and reduced resonance frequency. Appl. Phys. Lett. 2013, 103, 252901. [Google Scholar] [CrossRef]

- Kressmann, R. New piezoelectric polymer for air-borne and water-borne sound transducers. J. Acoust. Soc. Am. 2001, 109, 1412–1416. [Google Scholar] [CrossRef]

- Wegener, M.; Tuncer, E.; Wirges, W.; Gerhard, R.; Dansachmuller, M.; Bauergogonea, S.; Schwodiauer, R.; Bauer, S. Ferroelectrets: Highly anisotropic electrically charged polymer foams for electromechanical transducer applications. Proc. IEEE Ultrason. Symp. 2004, 62, 1138–1141. [Google Scholar] [CrossRef]

- Döring, J.; Bartusch, J.; Beck, U.; Erhard, A. EMFIT ferroelectret film transducers for non-contact ultrasonic testing. In Proceedings of the European Conference NDT, Berlin, Germany, 25–29 September 2006; pp. 1–10. [Google Scholar]

- Ealo, J.; Seco, F.; Jimenez, A. Broadband EMFi-based transducers for ultrasonic air applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 919–929. [Google Scholar] [CrossRef]

- Gaal, M.; Bartusch, J.; Doring, J.; Dohse, E.; Lange, T.; Hillger, W.; Kreutzbruck, M. Air-coupled ferroelectret ultrasonic transducers applied to testing of fiber-reinforced polymers. In Proceedings of the International Conference of the Slovenian Society for Non-Destructive Testing, Portorož, Slovenia, 4–6 September 2013; pp. 43–49. [Google Scholar]

- Álvarez-Arenas, T.E.G. Air-coupled piezoelectric transducers with active polypropylene foam matching layers. Sensors 2013, 13, 5996–6013. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gaal, M.; Bartusch, J.; Dohse, E.; Schadow, F.; Köppe, E. Focusing of ferroelectret air-coupled ultrasound transducers. AIP Conf. 2016, 1706, 080001. [Google Scholar]

- Tang, J.; Tong, L.; Xiang, Y.; Qiu, X.; Deng, M.; Xuan, F. Design, fabrication and characterization of Emfi-based ferroelectret air-coupled ultrasonic transducer. Sens. Actuators A Phys. 2019, 296, 52–60. [Google Scholar] [CrossRef]

- Döring, J.; Bovtun, V.; Gaal, M.; Bartusch, J.; Erhard, A.; Kreutzbruck, M.; Yakymenko, Y. Piezoelectric and electrostrictive effects in ferroelectret ultrasonic transducers. J. Appl. Phys. 2012, 112, 084505. [Google Scholar] [CrossRef]

- Bovtun, V.; Döring, J.; Bartusch, J.; Gaal, M.; Erhard, A.; Kreutzbruck, M. Enhanced electromechanical response of ferroelectret ultrasonic transducers under high voltage excitation. Adv. Appl. Ceram. 2013, 112, 97–102. [Google Scholar] [CrossRef]

- De Medeiros, L.J.; Kamimura, H.A.S.; Altafim, R.A.P.; Carneiro, A.A.O.; Amorim, M.F.; Altafim, R.A.C. Piezoelectret-based hydrophone: An alternative device for vibro-acoustography. Meas. Sci. Technol. 2015, 26, 095102. [Google Scholar] [CrossRef]

- Palitó, T.T.C.; Assagra, Y.A.O.; Altafim, R.A.P.; Carmo, J.P.; Altafim, R.A.C. Low-cost electro-acoustic system based on ferroelectret transducer for characterizing liquids. Meas. J. Int. Meas. Confed. 2019, 131, 42–49. [Google Scholar] [CrossRef]

- De Luna, D.R.; Palitó, T.; Assagra, Y.; Altafim, R.; Carmo, J.; Carneiro, A.; de Sousa, J.V.A. Ferroelectret-based hydrophone employed in oil identification-A machine learning approach. Sensors 2020, 20, 2979. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Arenas, T.E.G.; Diez, L. Ferroelectret transducers for water immersion and medical imaging. In Proceedings of the IEEE International Ultrasonic Symposium (IUS), Tours, France, 18–21 September 2016; pp. 4–7. [Google Scholar]

- Aguilar, J.Q.; Álvarez-Arenas, T.E.G. Optimization of ferroelectret transducers for pulse-echo water immersion operation. In Proceedings of the IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; pp. 2604–2607. [Google Scholar] [CrossRef]

- Aguilar, J.Q.; Svilainis, L.; Camacho, J.; Álvarez-Arenas, T.E.G. Ferroelectret Ultrasonic Transducers for Pulse-Echo Water Immersion. Appl. Sci. 2020, 10, 8771. [Google Scholar] [CrossRef]

- Aguilar, J.Q.; Munoz, M.; Álvarez-Arenas, T.E.G. Interpretation of the Thickness Resonances in Ferroelectret Films Based on a Layered Sandwich Mesostructure and a Cellular Microstructure. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 1245–1252. [Google Scholar] [CrossRef] [PubMed]

| Material | Thickness (μm) | Density (kg/m3) | λ/2 Resonant Frequency, Thickness Mode (MHz) | Impedance (MRayl) |

|---|---|---|---|---|

| HS03 | 70 | 530 | 0.638 | 0.046 |

| HS06 | 90 | 370 | 1.120 | 0.065 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguilar, J.Q.; Gómez Álvarez-Arenas, T. Modification of Mechanical and Electromechanical Resonances of Cellular Ferroelectret Films Depending on the External Load. Polymers 2021, 13, 3239. https://doi.org/10.3390/polym13193239

Aguilar JQ, Gómez Álvarez-Arenas T. Modification of Mechanical and Electromechanical Resonances of Cellular Ferroelectret Films Depending on the External Load. Polymers. 2021; 13(19):3239. https://doi.org/10.3390/polym13193239

Chicago/Turabian StyleAguilar, Julio Quirce, and Tomás Gómez Álvarez-Arenas. 2021. "Modification of Mechanical and Electromechanical Resonances of Cellular Ferroelectret Films Depending on the External Load" Polymers 13, no. 19: 3239. https://doi.org/10.3390/polym13193239

APA StyleAguilar, J. Q., & Gómez Álvarez-Arenas, T. (2021). Modification of Mechanical and Electromechanical Resonances of Cellular Ferroelectret Films Depending on the External Load. Polymers, 13(19), 3239. https://doi.org/10.3390/polym13193239