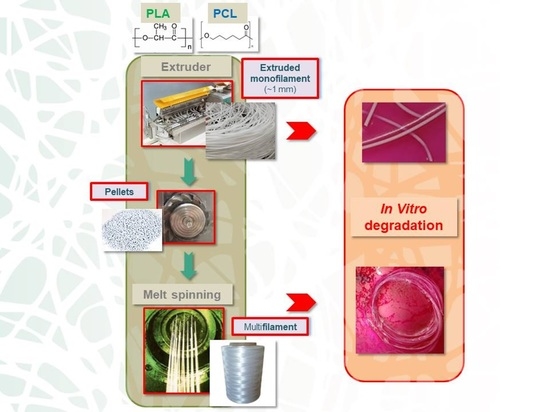

Study of the Influence of PCL on the In Vitro Degradation of Extruded PLA Monofilaments and Melt-Spun Filaments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- The PLA INGEO 6202D was supplied by NatureWorks (Minnetonka, MN, USA). The characteristics of the PLA are Mn(PLA) = 112,890 g/mol, polydispersity index (Mw/Mn) = 2.07, and D isomer content: <2%. The glass transition temperature Tg(PLA) is between 55 and 60 °C.

- The PCL CAPA 6400 was supplied by Perstorp (Malmö, Sweden). The characteristics of the PCL are Mn(PCL) = 53,122 g/mol; polydispersity index (Mw/Mn) = 1.75, and glass transition temperature Tg(PCL) = −60 °C.

- The Gibco Dulbecco’s Modified Eagle Medium (DMEM) was supplied in solid form by Fischer Scientific (Waltham, MA, USA), where 1.5 g/L NaHCO3 was added in order to reach a neutral pH of 7.4 ± 0.2.

- The acetic acid was supplied by Fischer Scientific.

2.2. Processing

2.3. Material Degradation Method

2.4. Characterization Methods

2.4.1. Thermal Properties

2.4.2. Morphological Properties

PCL Phase Extraction

Scanning Electron Microscopy

2.4.3. Linear Density

2.4.4. Molecular Weight and Polydispersity Index

2.4.5. Mechanical Properties

Mechanical Properties of the Spun Melt

Mechanical Properties of the Extruded Monofilament

3. Results and Discussion

3.1. PLA/PCL Blends’ Characteristics

3.1.1. Morphology of the Extruded Monofilaments and Melt-Spun Filaments

3.1.2. Mechanical Properties

3.2. Degradation Study

3.2.1. Extruded Monofilament

3.2.2. Filaments Extracted from the Multifilaments

3.3. Discussion on the Influence of the Two Types of Shapes: Extruded Monofilament and Melt-Spun Filament

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gupta, B.S. 4—Shaped biotextiles for medical implants. In Biotextiles as Med. Implant; King, M.W., Gupta, B.S., Guidoin, R., Eds.; Woodhead Publishing: Sawston, UK, 2013; pp. 113–136. [Google Scholar] [CrossRef]

- Guerra, A.J.; San, J.; Ciurana, J. Fabrication of PCL/PLA Composite Tube for Stent Manufacturing. Proc. CIRP 2017, 65, 231–235. [Google Scholar] [CrossRef]

- Guerra, A.J.; Cano, P.; Rabionet, M.; Puig, J. Ciurana, 3D-printed PCL/PLA composite stents: Towards a new solution to cardiovascular problems. Materials 2018, 11, 1679. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Mei, L.; Song, C.; Cui, X.; Wang, P. The in vivo degradation, absorption and excretion of PCL-based implant. Biomaterials 2006, 27, 1735–1740. [Google Scholar] [CrossRef]

- Spenlehauer, G.; Vert, M.; Benoit, J.P.; Boddaert, A. In vitro and In vivo degradation of poly (D, L lactide/glycolide) type microspheres made by solvent evaporation method. Biomaterials 1989, 10, 557–563. [Google Scholar] [CrossRef]

- Mondal, D.; Griffith, M.; Venkatraman, S.S. Polycaprolactone-based biomaterials for tissue engineering and drug delivery: Current scenario and challenges. Int. J. Polym. Mater. Polym. Biomater. 2016, 65, 255–265. [Google Scholar] [CrossRef]

- Costa-Pinto, A.R.; Martins, A.M.; Castelhano-Carlos, M.J.; Correlo, V.M.; Sol, P.C.; Longatto-Filho, A.; Battacharya, M.; Reis, R.L.; Neves, N.M. In vitro degradation and in vivo biocompatibility of chitosan-poly (butylene succinate) fiber mesh scaffolds. J. Bioact. Compat. Polym. 2014, 29, 137–151. [Google Scholar] [CrossRef] [Green Version]

- Bonartsev, A.P.; Myshkina, V.L.; Nikolaeva, D.A.; Furina, E.K.; Makhina, T.A.; Livshits, V.A.; Boskhomdzhiev, A.P.; Ivanov, E.A.; Iordanskii, A.L.; Bonartseva, G.A. Biosynthesis, Biodegradation, and Application of Poly (3- Hydroxybutyrate) and Its Copolymers -Natural Polyesters Produced by Diazotrophic Bacteria. 2007. Available online: http://www.formatex.org/microbio/pdf/Pages295-307.pdf (accessed on 7 March 2018).

- Harrison, K. 1—Introduction to polymeric scaffolds for tissue engineering. In Biomedicals Polymer; Jenkins, M., Ed.; Woodhead Publishing: Sawston, UK, 2007; pp. 1–32. [Google Scholar] [CrossRef]

- Jones, J.R. 19—Scaffolds for tissue engineering. In Biomaterials Artificial Organs and Tissue Engineering; Hench, L.L., Jones, J.R., Eds.; Woodhead Publishing: Sawston, UK, 2005; pp. 201–214. [Google Scholar] [CrossRef]

- Navarro-Baena, I.; Sessini, V.; Dominici, F.; Torre, L.; Kenny, J.M.; Peponi, L. Design of biodegradable blends based on PLA and PCL: From morphological, thermal and mechanical studies to shape memory behavior. Polym. Degrad. Stab. 2016, 132, 97–108. [Google Scholar] [CrossRef]

- Vieira, A.C.; Vieira, J.C.; Ferra, J.M.; Magalhães, F.D.; Guedes, R.M.; Marques, A.T. Mechanical study of PLA-PCL fibers during in vitro degradation. J. Mech. Behav. Biomed. Mater. 2011, 4, 451–460. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Matta, A.K.; Rao, R.U.; Suman, K.N.S.; Rambabu, V. Preparation and Characterization of Biodegradable PLA/PCL Polymeric Blends. Proc. Mater. Sci. 2014, 6, 1266–1270. [Google Scholar] [CrossRef] [Green Version]

- Fukushima, K.; Feijoo, J.L.; Yang, M.C. Comparison of abiotic and biotic degradation of PDLLA, PCL and partially miscible PDLLA/PCL blend. Eur. Polym. J. 2013, 49, 706–717. [Google Scholar] [CrossRef]

- Grizzi, I.; Garreau, H.; Li, S.; Vert, M. Hydrolytic degradation of devices based on poly (m-lactic acid) size- dependence. Biomateriak 1995, 16, 305–311. Available online: https://ac.els-cdn.com/014296129593258F/1-s2.0-014296129593258F-main.pdf?_tid=5fad66ff-100a-4613-a3f4-c59299b59894&acdnat=1521214481_0b5bb6afcf4c612f0ad0bff31cf62fdf (accessed on 16 March 2018). [CrossRef]

- Von Burkersroda, F.; Schedl, L.; Opferich, A.G. Why degradable polymers undergo surface erosion or bulk erosion. Biomaterials 2002, 23, 4221–4231. Available online: https://ac.els-cdn.com/S0142961202001709/1-s2.0-S0142961202001709-main.pdf?_tid=0f459159-5f15-4d03-bd04-fd4427d37b62&acdnat=1522251110_d02bd9ab980db2d64b992a3648738800 (accessed on 28 March 2018). [CrossRef]

- Padilla-Lopez, H.; Vázquez, M.O.; González-Núñez, R.; Rodrigue, D. Influence of Post-Extrusion Parameters on the Final Morphology of Polystyrene/High Density Polyethylene Blends. Polym. Eng. Sci. 2003, 43, 1646–1656. [Google Scholar] [CrossRef]

- Siparsky, G.L. Degradation kinetics of poly(hydroxy) acids: PLA and PCL. ACS Symp. Ser. 2000, 764, 230–251. [Google Scholar] [CrossRef]

- Guedes, R.M. Degradation and viscoelastic properties of PLA-PCL, PGA-PCL, PDO and PGA Degradation and Viscoelastic properties of PLA-PCL, PGA-PCL, PDO and PGA fibres. Mater. Sci. Forum 2010. [Google Scholar] [CrossRef] [Green Version]

- Tsuji, H.; Mizuno, A.; Ikada, Y. Properties and Morphology of Poly (L -lactide). III. Effects of Initial Crystallinity on Long-Term In Vitro Hydrolysis of High Molecular Weight Poly (L -lactide) Film in Phosphate-Buffered Solution. J. Appl. Polym. Sci. 2000, 1452–1464. [Google Scholar] [CrossRef]

- Urquijo, J.; Guerrica-Echevarría, G.; Eguiazábal, J.I. Melt processed PLA/PCL blends: Effect of processing method on phase structure, morphology, and mechanical properties. J. Appl. Polym. Sci. 2015, 132, 1–9. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, Y.; Zhang, M.; Zhou, W. Phase behavior and its viscoelastic response of polylactide/poly(ε-caprolactone) blend. Eur. Polym. J. 2008, 44, 2171–2183. [Google Scholar] [CrossRef]

- Ostafinska, A.; Fortelny, I.; Nevoralova, M.; Hodan, J.; Kredatusova, J.; Slouf, M. Synergistic effects in mechanical properties of PLA/PCL blends with optimized composition, processing, and morphology. RSC Adv. 2015, 5, 98971–98982. [Google Scholar] [CrossRef]

- Broz, M.E.; VanderHart, D.L.; Washburn, N.R. Structure and mechanical properties of poly(D,L-lactic acid)/poly(ε-caprolactone) blends. Biomaterials 2003, 24, 4181–4190. [Google Scholar] [CrossRef]

- Sengupta, R.; Chakraborty, S.; Bandyopadhyay, S.; Dasgupta, S.; Mukhopadhyay, R.; Auddy, K.; Deuri, A.S. A Short Review on Rubber/Clay Nanocomposites with Emphasis on Mechanical Properties. Engineering 2007, 47, 21–25. [Google Scholar] [CrossRef]

- Laycock, B.; Nikolí, M.; Colwell, J.M.; Gauthier, E.; Halley, P.; Bottle, S.; George, G. Lifetime prediction of biodegradable polymers. Prog. Polym. Sci. 2017, 71, 144–189. [Google Scholar] [CrossRef] [Green Version]

- Shawe, S.; Buchanan, F.; Harkin-Jones, E.; Farrar, D. A study on the rate of degradation of the bioabsorbable polymer polyglycolic acid (PGA). J. Mater. Sci. 2006, 41, 4832–4838. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barral, V.; Dropsit, S.; Cayla, A.; Campagne, C.; Devaux, É. Study of the Influence of PCL on the In Vitro Degradation of Extruded PLA Monofilaments and Melt-Spun Filaments. Polymers 2021, 13, 171. https://doi.org/10.3390/polym13020171

Barral V, Dropsit S, Cayla A, Campagne C, Devaux É. Study of the Influence of PCL on the In Vitro Degradation of Extruded PLA Monofilaments and Melt-Spun Filaments. Polymers. 2021; 13(2):171. https://doi.org/10.3390/polym13020171

Chicago/Turabian StyleBarral, Vivien, Sophie Dropsit, Aurélie Cayla, Christine Campagne, and Éric Devaux. 2021. "Study of the Influence of PCL on the In Vitro Degradation of Extruded PLA Monofilaments and Melt-Spun Filaments" Polymers 13, no. 2: 171. https://doi.org/10.3390/polym13020171

APA StyleBarral, V., Dropsit, S., Cayla, A., Campagne, C., & Devaux, É. (2021). Study of the Influence of PCL on the In Vitro Degradation of Extruded PLA Monofilaments and Melt-Spun Filaments. Polymers, 13(2), 171. https://doi.org/10.3390/polym13020171