Thermo Compression of Thermoplastic Agar-Xanthan Gum-Carboxymethyl Cellulose Blend

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

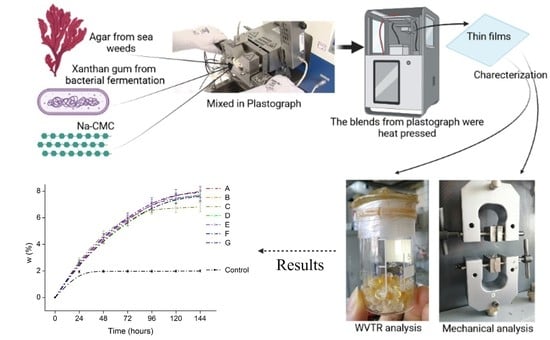

2.2. Preparation of Agar Based Thermoplastic Mixture

2.3. Film Production by Thermo-Compression of the Mixture

2.4. Characterization of the Films

2.5. Statistical Analysis

3. Results and Discussions

3.1. Morphology and Structure of Films

3.2. Mechanical and Rheological Properties of the Films

3.3. Physical Properties of the Films

3.4. Thermal Properties of the Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Wilpiszewska, K.; Antosik, A.K.; Schmidt, B.; Janik, J.; Rokicka, J. Hydrophilic Films Based on Carboxymethylated Derivatives of Starch and Cellulose. Polymers 2020, 12, 2447. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Mostafavi, F.S.; Zaeim, D. Agar-Based Edible Films for Food Packaging Applications—A Review. Int. J. Biol. Macromol. 2020, 159, 1165–1176. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; Gómez-Mascaraque, L.G.; Ballester, A.R.; Martínez-Abad, A.; Brodkorb, A.; López-Rubio, A. Production of Unpurified Agar-Based Extracts from Red Seaweed Gelidium Sesquipedale by Means of Simplified Extraction Protocols. Algal Res. 2019, 38, 101420. [Google Scholar] [CrossRef]

- Patel, J.; Maji, B.; Moorthy, N.S.H.N.; Maiti, S. Xanthan Gum Derivatives: Review of Synthesis, Properties and Diverse Applications. RSC Adv. 2020, 10, 27103–27136. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Kulshrestha, S.; Bhardwaj, K.; Jangir, R. A Review on Properties and Applications of Xanthan Gum. In Microbial Polymers: Applications and Ecological Perspectives; Vaishnav, A., Choudhary, D.K., Eds.; Springer: Singapore, 2021; pp. 87–107. ISBN 9789811600456. [Google Scholar]

- Demirkesen, I.; Kelkar, S.; Campanella, O.H.; Sumnu, G.; Sahin, S.; Okos, M. Characterization of Structure of Gluten-Free Breads by Using X-Ray Microtomography. Food Hydrocoll. 2014, 36, 37–44. [Google Scholar] [CrossRef]

- Marimuthu, M.; Ilansuriyan, P.; Yap, T.N. Munisamy Shanmugam Interaction of Semi-Refined Carrageenan (E407a) with Nano Quanta of Some Food Hydrocolloids and Their Physiochemical, Functional and Rheological Properties. J. Microbiol. Biotechnol. Food Sci. 2021, 2021, 1049–1053. [Google Scholar]

- Nagar, M.; Sharanagat, V.S.; Kumar, Y.; Singh, L. Development and Characterization of Elephant Foot Yam Starch–Hydrocolloids Based Edible Packaging Film: Physical, Optical, Thermal and Barrier Properties. J. Food Sci. Technol. 2020, 57, 1331–1341. [Google Scholar] [CrossRef] [PubMed]

- Yaradoddi, J.S.; Banapurmath, N.R.; Ganachari, S.V.; Soudagar, M.E.M.; Mubarak, N.M.; Hallad, S.; Hugar, S.; Fayaz, H. Biodegradable Carboxymethyl Cellulose Based Material for Sustainable Packaging Application. Sci. Rep. 2020, 10, 21960. [Google Scholar] [CrossRef]

- Roy, S.; Kim, H.-J.; Rhim, J.-W. Effect of Blended Colorants of Anthocyanin and Shikonin on Carboxymethyl Cellulose/Agar-Based Smart Packaging Film. Int. J. Biol. Macromol. 2021, 183, 305–315. [Google Scholar] [CrossRef] [PubMed]

- Nur Hazirah, M.A.S.P.; Isa, M.I.N.; Sarbon, N.M. Effect of Xanthan Gum on the Physical and Mechanical Properties of Gelatin-Carboxymethyl Cellulose Film Blends. Food Packag. Shelf Life 2016, 9, 55–63. [Google Scholar] [CrossRef]

- Sousa, A.M.M.; Souza, H.K.S.; Liu, L.; Gonçalves, M.P. Alternative Plasticizers for the Production of Thermo-Compressed Agar Films. Int. J. Biol. Macromol. 2015, 76, 138–145. [Google Scholar] [CrossRef] [PubMed]

- Lopez, O.; Garcia, M.A.; Villar, M.A.; Gentili, A.; Rodriguez, M.S.; Albertengo, L. Thermo-Compression of Biodegradable Thermoplastic Corn Starch Films Containing Chitin and Chitosan. LWT Food Sci. Technol. 2014, 57, 106–115. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Saha, N.; Saha, P. Characterization of Bacterial Cellulose Produced Using Media Containing Waste Apple Juice. Appl. Biochem. Microbiol. 2018, 54, 649–657. [Google Scholar] [CrossRef]

- Chen, Y. Packaging Selection for Solid Oral Dosage Forms. In Developing Solid Oral Dosage Forms; Elsevier: Amsterdam, The Netherlands, 2017; pp. 637–651. ISBN 978-0-12-802447-8. [Google Scholar]

- Zhang, R.; Wang, X.; Cheng, M. Preparation and Characterization of Potato Starch Film with Various Size of Nano-SiO2. Polymers 2018, 10, 1172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alias, S.A.; Mhd Sarbon, N. Rheological, Physical, and Mechanical Properties of Chicken Skin Gelatin Films Incorporated with Potato Starch. NPJ Sci. Food 2019, 3, 26. [Google Scholar] [CrossRef]

- Bao, S.; Xu, S.; Wang, Z. Antioxidant Activity and Properties of Gelatin Films Incorporated with Tea Polyphenol-Loaded Chitosan Nanoparticles. J. Sci. Food Agric. 2009, 89, 2692–2700. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Saha, N.; Zandraa, O.; Pummerová, M.; Sáha, P. Essential Oil Based PVP-CMC-BC-GG Functional Hydrogel Sachet for ‘Cheese’: Its Shelf Life Confirmed with Anthocyanin (Isolated from Red Cabbage) Bio Stickers. Foods 2020, 9, 307. [Google Scholar] [CrossRef] [Green Version]

- Pagano, C.; Puglia, D.; Luzi, F.; Michele, A.D.; Scuota, S.; Primavilla, S.; Ceccarini, M.R.; Beccari, T.; Iborra, C.A.V.; Ramella, D.; et al. Development and Characterization of Xanthan Gum and Alginate Based Bioadhesive Film for Pycnogenol Topical Use in Wound Treatment. Pharmaceutics 2021, 13, 324. [Google Scholar] [CrossRef]

- Wu, Y.; Geng, F.; Chang, P.R.; Yu, J.; Ma, X. Effect of Agar on the Microstructure and Performance of Potato Starch Film. Carbohydr. Polym. 2009, 76, 299–304. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.; Yunus, W.; Hussein, M. Effects of Graphene Nanopletelets on Poly(Lactic Acid)/Poly(Ethylene Glycol) Polymer Nanocomposites. Polymers 2013, 6, 93–104. [Google Scholar] [CrossRef] [Green Version]

- Kamyar, S.; Ahmad, M.; Jazayeri, S.D.; Sedaghat, S.; Shabanzadeh, P.; Jahangirian, H. (kamran); Mahdavi, M.; Abdollahi, Y. Synthesis and Characterization of Polyethylene Glycol Mediated Silver Nanoparticles by the Green Method. Int. J. Mol. Sci. 2012, 13, 6639–6650. [Google Scholar] [CrossRef] [Green Version]

- Kachel, M.; Matwijczuk, A.; Gagoś, M. Analysis of the Physicochemical Properties of Post-Manufacturing Waste Derived from Production of Methyl Esters from Rapeseed Oil. Int. Agrophysics 2017, 31, 1–8. [Google Scholar] [CrossRef]

- Usha Rani, G.; Konreddy, A.K.; Mishra, S.; Sen, G. Synthesis and Applications of Polyacrylamide Grafted Agar as a Matrix for Controlled Drug Release of 5-ASA. Int. J. Biol. Macromol. 2014, 65, 375–382. [Google Scholar] [CrossRef]

- Chiș, A.; Fetea, F.; Taoutaou, A.; Socaciu, C. Application of FTIR Spectroscopy for a Rapid Determination of Some Hydrolytic Enzymes Activity on Sea Buckthorn Substrate. Rom. Biotechnol. Lett. 2010, 15, 5738–5744. [Google Scholar]

- Bandyopadhyay, S.; Saha, N.; Brodnjak, U.V.; Saha, P. Bacterial Cellulose Based Greener Packaging Material: A Bioadhesive Polymeric Film. Mater. Res. Express 2018, 5, 115405. [Google Scholar] [CrossRef]

- Shamsuri, A.; Daik, R. Utilization of an Ionic Liquid/Urea Mixture as a Physical Coupling Agent for Agarose/Talc Composite Films. Materials 2013, 6, 682–698. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-hefian, E.A.; Nasef, M.M.; Yahaya, A.H. Preparation and Characterization of Chitosan/Agar Blended Films: Part 1. Chemical Structure and Morphology. E-J. Chem. 2012, 9, 1431–1439. [Google Scholar] [CrossRef] [Green Version]

- Sharma, K.; Kumar, V.; Swart, C.; Chaudhary, B.; Swart, H. Synthesis, Characterization and Anti-Microbial Activity of Superabsorbents Based on Agar-Poly(Methacrylic Acid-Glycine). J. Bioact. Compat. Polym. 2016, 32. [Google Scholar] [CrossRef]

- Sharma, V.; Pathak, K. Modified Xanthan Gum as Rapidly Disintegrating Hydrophilic Excipient for Time-Controlled Disintegrating Tablets of Roxithromycin. Indian J. Pharm. Educ. Res. 2013, 47, 79–87. [Google Scholar] [CrossRef] [Green Version]

- Basu, P.; Uttamchand, N.K.; Arunachalam, R.; Devi, S.; Inderchand, M. Characterization and Evaluation of Carboxymethyl Cellulose-Based Films for Healing of Full-Thickness Wounds in Normal and Diabetic Rats. ACS Omega 2018, 3, 12622–12632. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, M.; Tay, M.; Kamyar, S.; Hussein, M.; Lim, J. Green Synthesis and Characterization of Silver/Chitosan/Polyethylene Glycol Nanocomposites without Any Reducing Agent. Int. J. Mol. Sci. 2011, 12, 4872–4884. [Google Scholar] [CrossRef]

- Barron, M.; Young, T.; Johnston, K.; Williams, R. Investigation of Processing Parameters of Spray Freezing into Liquid to Prepare Polyethylene Glycol Polymeric Particles for Drug Delivery. AAPS PharmSciTech 2003, 4, E12. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Zhang, B.; Zhao, S.; Qiao, D.; Xie, F. Plasticized Starch/Agar Composite Films: Processing, Morphology, Structure, Mechanical Properties and Surface Hydrophilicity. Coatings 2021, 11, 311. [Google Scholar] [CrossRef]

- Rusli, A.; Mulyati, M.T.; Metusalach, M.; Salengke, S. Physical and Mechanical Properties of Agar Based Edible Film with Glycerol Plasticizer. Int. Food Res. J. 2016, 24, 1669–1675. [Google Scholar] [CrossRef]

- Rhim, J.-W. Physical-Mechanical Properties of Agar/κ-Carrageenan Blend Film and Derived Clay Nanocomposite Film. J. Food Sci. 2012, 77, N66–N73. [Google Scholar] [CrossRef] [PubMed]

- Setoyama, M.; Yamamoto, K.; Kadokawa, J. Preparation of Cellulose/Xanthan Gum Composite Films and Hydrogels Using Ionic Liquid. J. Polym. Environ. 2014, 22, 298–303. [Google Scholar] [CrossRef]

- Cazón, P.; Velazquez, G.; Ramírez, J.A.; Vázquez, M. Polysaccharide-Based Films and Coatings for Food Packaging: A Review. Food Hydrocoll. 2017, 68, 136–148. [Google Scholar] [CrossRef]

- Madera-Santana, T.J.; Freile-Pelegrín, Y.; Azamar-Barrios, J.A. Physicochemical and Morphological Properties of Plasticized Poly(Vinyl Alcohol)–Agar Biodegradable Films. Int. J. Biol. Macromol. 2014, 69, 176–184. [Google Scholar] [CrossRef] [PubMed]

- Łopusiewicz, Ł.; Kwiatkowski, P.; Drozłowska, E.; Trocer, P.; Kostek, M.; Śliwiński, M.; Polak-Śliwińska, M.; Kowalczyk, E.; Sienkiewicz, M. Preparation and Characterization of Carboxymethyl Cellulose-Based Bioactive Composite Films Modified with Fungal Melanin and Carvacrol. Polymer 2021, 13, 499. [Google Scholar] [CrossRef] [PubMed]

- Bahmid, N.A.; Dekker, M.; Fogliano, V.; Heising, J. Development of a Moisture-Activated Antimicrobial Film Containing Ground Mustard Seeds and Its Application on Meat in Active Packaging System. Food Packag. Shelf Life 2021, 30, 100753. [Google Scholar] [CrossRef]

- Calle, A.; Fernandez, M.; Montoya, B.; Schmidt, M.; Thompson, J. UV-C LED Irradiation Reduces Salmonella on Chicken and Food Contact Surfaces. Foods 2021, 10, 1459. [Google Scholar] [CrossRef] [PubMed]

- Debnath, S. Low Cost Homemade System to Disinfect Food Items from SARS-CoV-2. J. Med. Syst. 2020, 44, 126. [Google Scholar] [CrossRef] [PubMed]

- Conder, J.R.; Fruitwala, N.A.; Shingari, M.K. Thermal Decomposition of Polyethylene Glycol 20m and Essential Oils in Gas—Liquid Chromatography and the Effect of Traces of Oxygen. J. Chromatogr. A 1983, 269, 171–178. [Google Scholar] [CrossRef]

- Ochoa-Yepes, O.; Di Giogio, L.; Goyanes, S.; Mauri, A.; Famá, L. Influence of Process (Extrusion/Thermo-Compression, Casting) and Lentil Protein Content on Physicochemical Properties of Starch Films. Carbohydr. Polym. 2019, 208, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, Q.-Q.; Hu, Z.; Li, S.-D.; Quan, W.-Y.; Wen, L.-L.; Yang, Z.-M.; Li, P.-W. Thermal Degradation of Agar: Mechanism and Toxicity of Products. Food Chem. 2018, 264, 277–283. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, A.; Mishra, V.; Singh, P.; Srivastava, A.; Kumar, R. Comparative Study of Thermal Degradation Behavior of Graft Copolymers of Polysaccharides and Vinyl Monomers. J. Therm. Anal. Calorim. 2012, 107, 211–223. [Google Scholar] [CrossRef]

- de Britto, D.; Assis, O.B.G. Thermal Degradation of Carboxymethylcellulose in Different Salty Forms. Thermochim. Acta 2009, 494, 115–122. [Google Scholar] [CrossRef]

| Components | Film A | Film B | Film C | Film D | Film E | Film F | Film G |

|---|---|---|---|---|---|---|---|

| RPM | 100 | 100 | 100 | 100 | 80 | 80 | 80 |

| MS, g | 26 | 20 | 20 | 10 | 20 | 20 | 10 |

| Liquid, mL | 20 | 15 | 10 | 10 | 30 | 15 | 10 |

| Time, min | 10 | 7 | 5 | 5 | 7 | 7 | 5 |

| Total mixing volume, cm3 | 50.02 | 42.74 | 38.13 | 23.67 | 56.54 | 42.74 | 23.67 |

| Blends for Films: | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| Softness/Hardness 1 | 4 | 5 | 6 | 2 | 0 | 3 | 1 |

| Visual appearance/Colour 2 | 5 | 4 | 2 | 1 | 3 | 4 | 0 |

| Remarks 3 | - | - | - | - | Films formed from this blend were sticky | - | Films formed were less sticky than E |

| Components | Film A | Film B | Film C | Film D | Film E | Film F | Film G |

|---|---|---|---|---|---|---|---|

| E, MPa 1 | 9.91 ± 3.50 35.4 | 7.50 ± 3.13 41.81 | 183.22 ± 64.5 35.23 | 8.62 ± 4.23 49.13 | 4.12 ± 0.88 21.44 | 8.76 ± 3.27 37.36 | 5.46 ± 0.99 18.21 |

| σ, MPa 1 | 0.59 ± 0.21 36.58 | 0.59 ± 0.08 14.43 | 0.49 ± 0.03 6.97 | 0.33 ± 0.04 12.95 | 0.10 ± 0.03 27.5 | 0.61 ± 0.04 8.01 | 0.07 ± 0.02 33.1 |

| ε, % 1 | 73.75 ± 19.05 25.8 | 78.40 ± 14.75 18.8 | 16.40 ± 9.36 57.08 | 62.85 ± 14.05 22.3 | 32.39 ± 13.14 40.5 | 73.40 ± 21.20 28.8 | 28.38 ± 2.31 8.13 |

| Film A | Film B | Film C | Film D | Film E | Film F | Film G | |

|---|---|---|---|---|---|---|---|

| WVTR, g/m2.d 1 | 1119.6 a ± 15.8 1.41 | 1105.3 a ± 75.19 6.80 | 1082.8 a ± 21.06 1.94 | 1143.5 a ± 37.2 3.25 | 1178.1 a ± 104.6 8.88 | 1094.9 a ± 66.8 6.10 | 1153.8 a ± 10.3 0.90 |

| Transparency 1 | 16.18 ± 1.33 8.26 | 16.14 ± 1.39 8.62 | 13.80 ± 0.43 3.12 | 12.01 ± 0.99 8.24 | 14.91 ± 0.98 6.57 | 16.98 ± 3.41 20.08 | 11.95 ± 0.42 3.52 |

| Moisture % 1 | 6.34 ± 0.1 1.65 | 7.24 ±5.11 70.65 | 5.84 ±0.39 6.73 | 10.05 ± 1.8 8.69 | 10.83 ± 0.57 5.29 | 6.26 ± 0.29 4.73 | 7.69 ± 0.62 8.06 |

| Thickness, mm 1 | 0.095 ± 0.008 8.32 | 0.099 ± 0.008 8.37 | 0.141 ± 0.005 3.25 | 0.125 ± 0.009 7.56 | 0.099 ± 0.007 6.69 | 0.085 ± 0.022 26.3 | 0.107 ± 0.004 3.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bandyopadhyay, S.; Sáha, T.; Sanétrník, D.; Saha, N.; Sáha, P. Thermo Compression of Thermoplastic Agar-Xanthan Gum-Carboxymethyl Cellulose Blend. Polymers 2021, 13, 3472. https://doi.org/10.3390/polym13203472

Bandyopadhyay S, Sáha T, Sanétrník D, Saha N, Sáha P. Thermo Compression of Thermoplastic Agar-Xanthan Gum-Carboxymethyl Cellulose Blend. Polymers. 2021; 13(20):3472. https://doi.org/10.3390/polym13203472

Chicago/Turabian StyleBandyopadhyay, Smarak, Tomáš Sáha, Daniel Sanétrník, Nabanita Saha, and Petr Sáha. 2021. "Thermo Compression of Thermoplastic Agar-Xanthan Gum-Carboxymethyl Cellulose Blend" Polymers 13, no. 20: 3472. https://doi.org/10.3390/polym13203472

APA StyleBandyopadhyay, S., Sáha, T., Sanétrník, D., Saha, N., & Sáha, P. (2021). Thermo Compression of Thermoplastic Agar-Xanthan Gum-Carboxymethyl Cellulose Blend. Polymers, 13(20), 3472. https://doi.org/10.3390/polym13203472