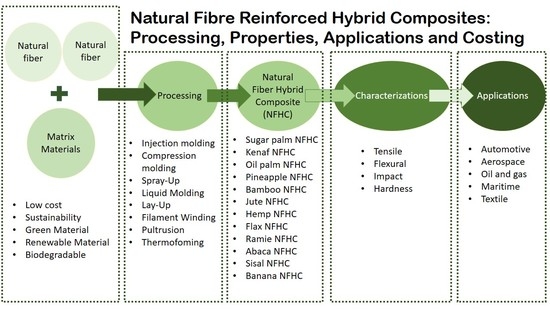

Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost

Abstract

:1. Introduction

2. Natural Fiber (NF)

| Natural Fiber | Source | World Production |

|---|---|---|

| Abaca | Leaf | 70 |

| Banana | Stem | 200 |

| Bamboo | Stem | 10,000 |

| Broom | Stem | Abundant |

| Coir | Fruit | 100 |

| Cotton lint | Seed | 18,500 |

| Elephant | Stem | Abundant |

| Flax | Stem | 810 |

| Hemp | Stem | 215 |

| Jute | Stem | 2500 |

| Kenaf | Stem | 770 |

| Linseed | Fruit | Abundant |

| Oil Palm Fruit | Fruit | Abundant |

| Ramie | Stem | 100 |

| Rice Husk | Grain | Abundant |

| Roselle | Stem | 250 |

| Sisal | Leaf | 380 |

| Sun hemp | Stem | 70 |

| Wood | Stem | 1,750,000 |

3. Recent Development of Natural Fiber Reinforced Hybrid Composites

3.1. Sugar Palm Fiber Reinforced Hybrid Composites

3.2. Kenaf Fiber Reinforced Hybrid Composites

3.3. Oil Palm Fiber Reinforced Hybrid Composites (OPRPC)

3.4. Pineapple Leaf Fiber Reinforced Hybrid Composites (PARPC)

3.5. Bamboo Fiber Reinforced Hybrid Composites (BRPC)

3.6. Jute Fiber Reinforced Hybrid Composites (JRPC)

3.7. Hemp Fiber Reinforced Hybrid Composites (HRPC)

3.8. Flax Fiber Reinforced Hybrid Composites (FRPC)

3.9. Ramie Fiber Reinforced Hybrid Composites (RRPC)

3.10. Abaca/Banana Fiber Reinforced Hybrid Composites (ARPC)

3.11. Sisal Fiber Reinforced Hybrid Composites (SRPC)

4. Mechanical Properties of NF Reinforcement Hybrid Composites

4.1. Tensile Properties

4.2. Flexural Properties

4.3. Impact Properties

4.4. Hardness Properties

5. Current Application on NF Reinforcement Hybrid Composites

5.1. Automotive

5.2. Aerospace

5.3. Oil and Gas

5.4. Maritime

5.5. Textiles

6. Estimated Costing for NF as Reinforcement in Hybrid Composites

7. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Haris, N.I.N.; Ilyas, R.A.; Hassan, M.Z.; Sapuan, S.M.; Afdzaluddin, A.; Jamaludin, K.R.; Zaki, S.A.; Ramlie, F. Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. Polymers 2021, 13, 3343. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical properties of longitudinal basalt/woven-glass-fiber-reinforced unsaturated polyester-resin hybrid composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef] [PubMed]

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of Natural Fibers and Its Composites: An Overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef] [Green Version]

- Sanjay, M.R.; Arpitha, G.R.; Senthamaraikannan, P.; Kathiresan, M.; Saibalaji, M.A.; Yogesha, B. The Hybrid Effect of Jute/Kenaf/E-Glass Woven Fabric Epoxy Composites for Medium Load Applications: Impact, Inter-Laminar Strength, and Failure Surface Characterization. J. Nat. Fibers 2019, 16, 600–612. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Senthamaraikannan, P.; Pradeep, S.; Saravanakumar, S.S.; Yogesha, B. A review on synthesis and characterization of commercially available natural fibers: Part II. J. Nat. Fibers 2019, 16, 25–36. [Google Scholar] [CrossRef]

- Ghelli, D.; Minak, G. Low velocity impact and compression after impact tests on thin carbon/epoxy laminates. Compos. Part. B Eng. 2011, 42, 2067–2079. [Google Scholar] [CrossRef]

- Boria, S.; Pavlovic, A.; Fragassa, C.; Santulli, C. Modeling of falling weight impact behavior of hybrid basalt/flax vinylester composites. Procedia Eng. 2016, 167, 223–230. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Rashid, U.; Khalina, A. Development and Characterization of Polypropylene Waste from Personal Protective Equipment (PPE)-Derived Char-Filled Sugar Palm Starch Biocomposite Briquettes. Polymers 2021, 13, 1707. [Google Scholar] [CrossRef]

- Chan, J.X.; Wong, J.F.; Petrů, M.; Hassan, A.; Nirmal, U.; Othman, N.; Ilyas, R.A. Effect of Nanofillers on Tribological Properties of Polymer Nanocomposites: A Review on Recent Development. Polymers 2021, 13, 2867. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical Performance and Applications of CNTs Reinforced Polymer Composites—A Review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Poodts, E.; Minak, G.; Mazzocchetti, L.; Giorgini, L. Fabrication, process simulation and testing of a thick CFRP component using the RTM process. Compos. Part. B Eng. 2014, 56, 673–680. [Google Scholar] [CrossRef]

- Malkapuram, R.; Kumar, V.; Singh Negi, Y. Recent development in natural fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2009, 28, 1169–1189. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Rashid, U.; Khalina, A.; Ilyas, R.A. Pyrolysis of polypropylene plastic waste into carbonaceous char: Priority of plastic waste management amidst COVID-19 pandemic. Sci. Total Environ. 2021, 149911. [Google Scholar] [CrossRef]

- De Paola, S.; Fragassa, C.; Minak, G.; Pavlovic, A. Green Composites: A review of state of art. Carbon N.Y. 2013, 1, 230–240. [Google Scholar]

- Hyseni, A.; De Paola, S.; Minak, G.; Fragassa, C. Mechanical characterization of ecocomposites. In Proceedings of the 30th Danubia Adria Symposium on Advanced Mechanics, Damir Semenski, Zagreb, Croatia, 25 September 2013; pp. 25–28. [Google Scholar]

- Alotaibi, M.D.; Alshammari, B.A.; Saba, N.; Alothman, O.Y.; Sanjay, M.R.; Almutairi, Z.; Jawaid, M. Characterization of natural fiber obtained from different parts of date palm tree (Phoenix dactylifera L.). Int. J. Biol. Macromol. 2019, 135, 69–76. [Google Scholar] [CrossRef]

- Vinod, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.R.; Siengchin, S.; Yagnaraj, Y.; Khan, S. Extraction and characterization of natural fiber from stem of cardiospermum halicababum. J. Nat. Fibers 2021, 18, 898–908. [Google Scholar] [CrossRef]

- Kadier, A.; Ilyas, R.A.; Huzaifah, M.R.M.; Harihastuti, N.; Sapuan, S.M.; Harussani, M.M.; Azlin, M.N.M.; Yuliasni, R.; Ibrahim, R.; Atikah, M.S.N.; et al. Use of Industrial Wastes as Sustainable Nutrient Sources for Bacterial Cellulose (BC) Production: Mechanism, Advances, and Future Perspectives. Polymers 2021, 13, 3365. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Garkhail, S.K.; Heijenrath, R.W.H.; Peijs, T. Mechanical properties of natural-fibre-mat-reinforced thermoplastics based on flax fibres and polypropylene. Appl. Compos. Mater. 2000, 7, 351–372. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Nurazzi, N.M.; Norli, A.; Harussani, M.M.; Rafiqah, S.; Aisyah, H.A.; Ramli, N. The Challenges and Future Perspective of Woven Kenaf Reinforcement in Thermoset Polymer Composites in Malaysia: A Review. Polymers 2021, 13, 1390. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Rao, K.M.M.; Rao, K.M. Extraction and tensile properties of natural fibers: Vakka, date and bamboo. Compos. Struct. 2007, 77, 288–295. [Google Scholar] [CrossRef]

- Jha, K.; Tyagi, Y.K.; Kumar, R.; Sharma, S.; Roslim, M.; Huzaifah, M.; Li, C.; Ilyas, R.A.; Dwivedi, S.P.; Saxena, A.; et al. Assessment of Dimensional Stability, Biodegradability, and Fracture Energy of Bio-Composites Reinforced with Novel Pine Cone. Polymers 2021, 13, 3260. [Google Scholar] [CrossRef]

- Kumari, N.; Bangar, S.P.; Petrů, M.; Ilyas, R.A.; Singh, A.; Kumar, P. Development and Characterization of Fenugreek Protein-Based Edible Film. Foods 2021, 10, 1976. [Google Scholar] [CrossRef]

- Tarique, J.; Sapuan, S.M.; Khalina, A.; Sherwani, S.F.K.; Yusuf, J.; Ilyas, R.A. Recent developments in sustainable arrowroot (Maranta arundinacea Linn) starch biopolymers, fibres, biopolymer composites and their potential industrial applications: A review. J. Mater. Res. Technol. 2021, 13, 1191–1219. [Google Scholar] [CrossRef]

- Misri, S.; Leman, Z.; Sapuan, S.M.; Ishak, M.R. Mechanical properties and fabrication of small boat using woven glass/sugar palm fibres reinforced unsaturated polyester hybrid composite. IOP Conf. Ser. Mater. Sci. Eng. 2010, 11, 012015. [Google Scholar] [CrossRef] [Green Version]

- Kamaruddin, Z.H.; Jumaidin, R.; Selamat, M.Z.; Ilyas, R.A. Characteristics and Properties of Lemongrass (Cymbopogan Citratus): A Comprehensive Review. J. Nat. Fibers 2021, 18, 1–18. [Google Scholar] [CrossRef]

- Dashtizadeh, Z.; Abdan, K.; Jawaid, M.; Khan, M.A.; Behmanesh, M.; Dashtizadeh, M.; Cardona, F.; Ishak, M. Mechanical and thermal properties of natural fibre based hybrid composites: A review. Pertanika J. Sci. Technol. 2017, 25, 1103–1122. [Google Scholar]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric Analysis Properties of Cellulosic Natural Fiber Polymer Composites: A Review on Influence of Chemical Treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Lok, H.Y.; Ishak, M.R.; Misri, S. Mechanical properties of hybrid glass/sugar palm fibre reinforced unsaturated polyester composites. Chin. J. Polym. Sci. 2013, 31, 1394–1403. [Google Scholar] [CrossRef]

- Afzaluddin, A.; Jawaid, M.; Salit, M.S.; Ishak, M.R. Physical and mechanical properties of sugar palm/glass fiber reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 950–959. [Google Scholar] [CrossRef]

- Baihaqi, N.M.Z.N.; Khalina, A.; Nurazzi, N.M.; Aisyah, H.A.; Sapuan, S.M.; Ilyas, R.A. Effect of fiber content and their hybridization on bending and torsional strength of hybrid epoxy composites reinforced with carbon and sugar palm fibers. Polimery 2021, 66, 36–43. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Shah, A.U.M. Characterization of benzoyl treated sugar palm/glass fibre hybrid composites. J. Mater. Res. Technol. 2020, 9, 11563–11573. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Abdul Majid, M.S. Analysis of dynamic mechanical, low-velocity impact and compression after impact behaviour of benzoyl treated sugar palm/glass/epoxy composites. Compos. Struct. 2019, 226, 111308. [Google Scholar] [CrossRef]

- Jumaidin, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Thermal, mechanical, and physical properties of seaweed/sugar palm fibre reinforced thermoplastic sugar palm Starch/Agar hybrid composites. Int. J. Biol. Macromol. 2017, 97, 606–615. [Google Scholar] [CrossRef]

- Radzi, A.M.; Sapuan, S.M.; Jawaid, M.; Mansor, M.R. Water absorption, thickness swelling and thermal properties of roselle/sugar palm fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J. Mater. Res. Technol. 2020, 9, 200–211. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.; Khalina, A.; Sapuan, S.M.; Rahmah, M. Development of sugar palm yarn/glass fibre reinforced unsaturated polyester hybrid composites. Mater. Res. Express 2018, 5, 045308. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Cassava/sugar palm fiber reinforced cassava starch hybrid composites: Physical, thermal and structural properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef]

- Bachtiar, D.; Siregar, J.P.; bin Sulaiman, A.S.; bin Mat Rejab, M.R. Tensile Properties of Hybrid Sugar Palm/Kenaf Fibre Reinforced Polypropylene Composites. Appl. Mech. Mater. 2014, 695, 155–158. [Google Scholar]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M.; Edhirej, A. Processing and Characterization of Cornstalk/Sugar Palm Fiber Reinforced Cornstarch Biopolymer Hybrid Composites. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 35–46. [Google Scholar]

- Siregar, J.P.; Zalinawati, M.; Cionita, T.; Rejab, M.R.M.; Mawarnie, I.; Jaafar, J.; Hamdan, M.H.M. Mechanical properties of hybrid sugar palm/ramie fibre reinforced epoxy composites. Mater. Today Proc. 2021, 46, 1729–1734. [Google Scholar] [CrossRef]

- Razali, N.; Sapuan, S.M.; Razali, N. Mechanical Properties and Morphological Analysis of Roselle/Sugar Palm Fiber Reinforced Vinyl Ester Hybrid Composites. In Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2018; pp. 169–180. [Google Scholar]

- Mukhtar, I.; Leman, Z.; Zainudin, E.S.; Ishak, M.R. Hybrid and Nonhybrid Laminate Composites of Sugar Palm and Glass Fibre-Reinforced Polypropylene: Effect of Alkali and Sodium Bicarbonate Treatments. Int. J. Polym. Sci. 2019, 2019, 12. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Atiqah, A.; Maleque, M.A.; Jawaid, M.; Iqbal, M. Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos. Part. B Eng. 2014, 56. [Google Scholar] [CrossRef]

- Jaafar, C.N.A.; Zainol, I.; Rizal, M.A.M. Preparation and characterisation of epoxy/silica/kenaf composite using hand lay-up method. In Proceedings of the 27th Scientific Conference of the Microscopy Society Malaysia (27th SCMSM 2018), Melaka, Malaysia, 3 December 2018; pp. 2–6. [Google Scholar]

- Aiza Jaafar, C.N.; Zainol, I.; Ishak, N.S.; Ilyas, R.A.; Sapuan, S.M. Effects of the Liquid Natural Rubber (LNR) on Mechanical Properties and Microstructure of Epoxy/Silica/Kenaf Hybrid Composite for Potential Automotive Applications. J. Mater. Res. Technol. 2021, 12, 1026–1038. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Alothman, O.Y.; Fouad, H. Effects of Nanoclay on Mechanical and Dynamic Mechanical Properties of Bamboo/Kenaf Reinforced Epoxy Hybrid Composites. Polymers 2021, 13, 395. [Google Scholar] [CrossRef]

- Hammami, H.; Jawaid, M.; Kallel, A. Effects of oil palm and montmorillonite nanofillers on stiffness and interfacial adhesion of kenaf/epoxy hybrid nanocomposites. Polym. Compos. 2021, 42, 2948–2957. [Google Scholar] [CrossRef]

- Mirzaei, J.; Fereidoon, A.; Ghasemi-Ghalebahman, A. Experimental study on mechanical properties of polypropylene nanocomposites reinforced with a hybrid graphene/PP-g-MA/kenaf fiber by response surface methodology. J. Elastomers Plast. 2021, 11, 009524432110153. [Google Scholar] [CrossRef]

- Sabaruddin, F.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Abdul Khalil, H.P.S. The effects of unbleached and bleached nanocellulose on the thermal and flammability of polypropylene-reinforced kenaf core hybrid polymer bionanocomposites. Polymers 2020, 13, 116. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Ya, H.H.; Hisham, H.N. Effect of winding orientation on energy absorption and failure modes of filament wound kenaf/glass fibre reinforced epoxy hybrid composite tubes under intermediate-velocity impact (IVI) load. J. Mater. Res. Technol. 2021, 10, 1–14. [Google Scholar] [CrossRef]

- Suriani, M.J.; Zainudin, H.A.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M.; Ruzaidi, C.M.; Mustapha, R. Kenaf Fiber/Pet Yarn Reinforced Epoxy Hybrid Polymer Composites: Morphological, Tensile, and Flammability Properties. Polymers 2021, 13, 1532. [Google Scholar] [CrossRef] [PubMed]

- Tamrakar, S.; Kiziltas, A.; Mielewski, D.; Zander, R. Characterization of kenaf and glass fiber reinforced hybrid composites for underbody shield applications. Compos. Part. B Eng. 2021, 216, 108805. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Mechanical performance of woven kenaf-Kevlar hybrid composites. J. Reinf. Plast. Compos. 2014, 33, 2242–2254. [Google Scholar] [CrossRef]

- Alavudeen, A.; Rajini, N.; Karthikeyan, S.; Thiruchitrambalam, M.; Venkateshwaren, N. Mechanical properties of banana/kenaf fiber-reinforced hybrid polyester composites: Effect of woven fabric and random orientation. Mater. Des. 2015, 66, 246–257. [Google Scholar] [CrossRef]

- Nampoothiri, E.N.; Bensam Raj, J.; Thanigaivelan, R.; Karuppasamy, R. Experimental investigation on mechanical and biodegradation properties of indian almond–kenaf fiber-reinforced hybrid composites for construction applications. J. Nat. Fibers 2020, 17, 1–11. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Gokulkumar, S.; Sathish, S.; Sanjay, M.R.; Siengchin, S. Mechanical, chemical and sound absorption properties of glass/kenaf/waste tea leaf fiber-reinforced hybrid epoxy composites. J. Ind. Text. 2020, 1528083720957392. [Google Scholar] [CrossRef]

- Hanan, F.; Jawaid, M.; Md Tahir, P. Mechanical performance of oil palm/kenaf fiber-reinforced epoxy-based bilayer hybrid composites. J. Nat. Fibers 2020, 17, 155–167. [Google Scholar] [CrossRef]

- Dhar Malingam, S.; Ng, L.F.; Chan, K.H.; Subramaniam, K.; Selamat, M.Z.; Zakaria, K.A. The static and dynamic mechanical properties of kenaf/glass fibre reinforced hybrid composites. Mater. Res. Express 2018, 5, 95304. [Google Scholar] [CrossRef]

- Sosiati, H.; Shofie, Y.A.; Nugroho, A.W. Tensile properties of Kenaf/E-glass reinforced hybrid polypropylene (PP) composites with different fiber loading. Ph.D. Thesis, Kyushu University, Fukuoka, Japan, 2018. [Google Scholar]

- Ismail, A.S.; Jawaid, M.; Naveen, J. Void content, tensile, vibration and acoustic properties of kenaf/bamboo fiber reinforced epoxy hybrid composites. Materials 2019, 12, 2094. [Google Scholar] [CrossRef] [Green Version]

- Mirbagheri, J.; Tajvidi, M.; Hermanson, J.C.; Ghasemi, I. Tensile Properties of Wood Flour/Kenaf Fiber Polypropylene Hybrid Composites. J. Appl. Polym. Sci. 2007, 105, 3054–3059. [Google Scholar] [CrossRef]

- Haryati, A.; Razali, N.; Petrů, M.; Taha, M.; Muhammad, N.; Ilyas, R.A. Effect of Chemically Treated Kenaf Fibre on Mechanical and Thermal Properties of PLA Composites Prepared through Fused Deposition Modeling (FDM). Polymers 2021, 13, 3299. [Google Scholar] [CrossRef]

- Suriani, M.J.; Radzi, F.S.M.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M.; Ruzaidi, C.M. Flammability, Tensile, and Morphological Properties of Oil Palm Empty Fruit Bunches Fiber/Pet Yarn-Reinforced Epoxy Fire Retardant Hybrid Polymer Composites. Polymers 2021, 13, 1282. [Google Scholar] [CrossRef]

- Hanan, F.; Jawaid, M.; Paridah, M.T.; Naveen, J. Characterization of Hybrid Oil Palm Empty Fruit Bunch/Woven Kenaf Fabric-Reinforced Epoxy Composites. Polymers 2020, 12, 2052. [Google Scholar] [CrossRef]

- Suradi, S.S.; Yunus, R.M.; Beg, M.D.H.; Rivai, M.; Yusof, Z.A.M. Oil palm bio-fiber reinforced thermoplastic composites-effects of matrix modification on mechanical and thermal properties. J. Appl. Sci. 2010, 10, 3271–3276. [Google Scholar] [CrossRef] [Green Version]

- Ramlee, N.A.; Jawaid, M.; Zainudin, E.S.; Yamani, S.A.K. Tensile, physical and morphological properties of oil palm empty fruit bunch/sugarcane bagasse fibre reinforced phenolic hybrid composites. J. Mater. Res. Technol. 2019, 8, 3466–3474. [Google Scholar] [CrossRef]

- Muhammad Amir, S.M.; Hameed Sultan, M.T.; Md Shah, A.U.; Jawaid, M.; Safri, S.N.A.; Mohd, S.; Mohd Salleh, K.A. Low Velocity Impact and Compression after Impact Properties on Gamma Irradiated Kevlar/Oil Palm Empty Fruit Bunch Hybrid Composites. Coatings 2020, 10, 646. [Google Scholar] [CrossRef]

- Islam, M.; Gupta, A.; Rivai, M.; Beg, M. Characterization of microwave-treated oil palm empty fruit bunch/glass fibre/polypropylene composites. J. Thermoplast. Compos. Mater. 2017, 30, 986–1002. [Google Scholar] [CrossRef] [Green Version]

- Khalil, H.P.S.A.; Hanida, S.; Kang, C.W.; Fuaad, N.A.N. Agro-hybrid composite: The effects on mechanical and physical properties of oil palm fiber (EFB)/glass hybrid reinforced polyester composites. J. Reinf. Plast. Compos. 2007, 26, 203–218. [Google Scholar] [CrossRef]

- Rozman, H.D.; Tay, G.S.; Kumar, R.N.; Abusamah, A.; Ismail, H.; Mohd, I.Z.A. The effect of oil extraction of the oil palm empty fruit bunch on the mechanical properties of polypropylene–oil palm empty fruit bunch–glass fibre hybrid composites. Polym. Plast. Technol. Eng. 2001, 40, 103–115. [Google Scholar] [CrossRef]

- Hashim, M.K.R.; Abdul Majid, M.S.; Jamir, M.R.M.; Kasim, F.H.; Sultan, M.T.H. The Effect of Stacking Sequence and Ply Orientation on the Mechanical Properties of Pineapple Leaf Fibre (PALF)/Carbon Hybrid Laminate Composites. Polymers 2021, 13, 455. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.R.; Siengchin, S.; Fouad, H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. XPRESS Polym. Lett. 2020, 14, 717–730. [Google Scholar] [CrossRef]

- Zin, M.H.; Abdan, K.; Mazlan, N.; Zainudin, E.S.; Liew, K.E.; Norizan, M.N. Automated spray up process for Pineapple Leaf Fibre hybrid biocomposites. Compos. Part. B Eng. 2019, 177, 107306. [Google Scholar] [CrossRef]

- Venkata Deepthi, P.; Sita Rama Raju, K.; Indra Reddy, M. Dynamic mechanical analysis of banana, pineapple leaf and glass fibre reinforced hybrid polyester composites. Mater. Today Proc. 2019, 18, 2114–2117. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Saba, N.; Jawaid, M.; Alothman, O.Y.; Nasir, M.; Almutairi, Z. Thermal, physical properties and flammability of silane treated kenaf/pineapple leaf fibres phenolic hybrid composites. Compos. Struct. 2018, 202, 1330–1338. [Google Scholar] [CrossRef]

- Sathees Kumar, S.; Muthalagu, R.; Nithin Chakravarthy, C. Effects of fiber loading on mechanical characterization of pineapple leaf and sisal fibers reinforced polyester composites for various applications. Mater. Today Proc. 2021, 44, 546–553. [Google Scholar] [CrossRef]

- Osorio, L.; Trujillo, E.; Van Vuure, A.W.; Verpoest, I. Morphological aspects and mechanical properties of single bamboo fibers and flexural characterization of bamboo/epoxy composites. J. Reinf. Plast. Compos. 2011, 30, 396–408. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mohanty, S.; Samal, S.K. Influence of short bamboo/glass fiber on the thermal, dynamic mechanical and rheological properties of polypropylene hybrid composites. Mater. Sci. Eng. A 2009, 523, 32–38. [Google Scholar] [CrossRef]

- Samal, S.K.; Mohanty, S.; Nayak, S.K. Polypropylene bamboo/glass fiber hybrid composites: Fabrication and analysis of mechanical, morphological, thermal, and dynamic mechanical behavior. J. Reinf. Plast. Compos. 2009, 28, 2729–2747. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Environmental effects on bamboo-glass/polypropylene hybrid composites. J. Mater. Sci. 2003, 38, 363–376. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos. Sci. Technol. 2003, 63, 375–387. [Google Scholar] [CrossRef]

- Biswas, S.; Satapathy, A.; Patnaik, A. Effect of ceramic Fillers On Mechanical Properties of Bamboo Fiber Reinforced Epoxy Composites: A Comparative Study. In Proceedings of the Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2010; Volume 123, pp. 1031–1034. [Google Scholar]

- Krishnan, G.S.; Velmurugan, P. Investigation on the characteristics of bamboo/jute reinforced hybrid epoxy polymer composites. Mater. Res. Express 2019, 6, 105346. [Google Scholar]

- Shukla, R.; Srivastava, A.K. FTIR analysis of Bamboo and Flax (BFBF) Mat Reinforced Epoxy Hybrid Composite. Int. J. Sci. Res. Sci. Eng. Technol. 2019, 6, 119–124. [Google Scholar]

- Getu, D.; Nallamothu, R.B.; Masresha, M.; Nallamothu, S.K.; Nallamothu, A.K. Production and characterization of bamboo and sisal fiber reinforced hybrid composite for interior automotive body application. Mater. Today Proc. 2021, 38, 2853–2860. [Google Scholar] [CrossRef]

- Aruchamy, K.; Pavayee Subramani, S.; Palaniappan, S.K.; Sethuraman, B.; Velu Kaliyannan, G. Study on mechanical characteristics of woven cotton/bamboo hybrid reinforced composite laminates. J. Mater. Res. Technol. 2020, 9, 718–726. [Google Scholar] [CrossRef]

- Olaniran, O.; Uwaifo, O.; Bamidele, E.; Olaniran, B. An investigation of the mechanical properties of organic silica, bamboo leaf ash and rice husk reinforced aluminium hybrid composite. Mater. Sci. Eng. Int. J. 2019, 3, 129–134. [Google Scholar] [CrossRef]

- Sarkar, B.K.; Ray, D. Effect of the defect concentration on the impact fatigue endurance of untreated and alkali treated jute–vinylester composites under normal and liquid nitrogen atmosphere. Compos. Sci. Technol. 2004, 64, 2213–2219. [Google Scholar] [CrossRef]

- Ramana, M.V.; Ramprasad, S. Experimental investigation on jute/carbon fibre reinforced epoxy based hybrid composites. Mater. Today Proc. 2017, 4, 8654–8664. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S.; Naidu, A.C.B. Elastic properties, notched strength and fracture criterion in untreated woven jute–glass fabric reinforced polyester hybrid composites. Mater. Des. 2007, 28, 2287–2294. [Google Scholar] [CrossRef]

- Tezara, C.; Zalinawati, M.; Siregar, J.P.; Jaafar, J.; Hamdan, M.H.M.; Oumer, A.N.; Chuah, K.H. Effect of Stacking Sequences, Fabric Orientations, and Chemical Treatment on the Mechanical Properties of Hybrid Woven Jute–Ramie Composites. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 1–13. [Google Scholar] [CrossRef]

- Pandita, S.D.; Yuan, X.; Manan, M.A.; Lau, C.H.; Subramanian, A.S.; Wei, J. Evaluation of jute/glass hybrid composite sandwich: Water resistance, impact properties and life cycle assessment. J. Reinf. Plast. Compos. 2014, 33, 14–25. [Google Scholar] [CrossRef]

- Akil, H.M.; Santulli, C.; Sarasini, F.; Tirillò, J.; Valente, T. Environmental effects on the mechanical behaviour of pultruded jute/glass fibre-reinforced polyester hybrid composites. Compos. Sci. Technol. 2014, 94, 62–70. [Google Scholar] [CrossRef]

- Chaudhary, V.; Bajpai, P.K.; Maheshwari, S. Studies on mechanical and morphological characterization of developed jute/hemp/flax reinforced hybrid composites for structural applications. J. Nat. Fibers 2018, 15, 80–97. [Google Scholar] [CrossRef]

- Joseph, K.; De Carvalho, L.H. Jute/cotton woven Fabric Reinforced Polyester Composites: Effect of Hybridization. In Proceedings of the ISNaPol/2000: Third International Symposium on Natural Polymers and Composites and the Workshop on Progress in Production and Processing of Cellulosic Fibres and Natural Polymers; Embrapa Instrumentação Agropecuária: Sao Carlos, Brazil, 2000; pp. 454–459. [Google Scholar]

- Prasath, K.A.; Krishnan, B.R.; Arun, C.K. Mechanical properties of woven fabric Basalt/jute fibre reinforced polymer hybrid composites. Int. J. Mech. Eng. 2013, 2, 279–290. [Google Scholar]

- Ramesh, M.; Deepa, C.; Arpitha, G.R.; Gopinath, V. Effect of hybridization on properties of hemp-carbon fibre-reinforced hybrid polymer composites using experimental and finite element analysis. World J. Eng. 2019, 16, 248–259. [Google Scholar] [CrossRef]

- Thiagamani, S.M.K.; Krishnasamy, S.; Muthukumar, C.; Tengsuthiwat, J.; Nagarajan, R.; Siengchin, S.; Ismail, S.O. Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 2019, 140, 637–646. [Google Scholar] [CrossRef]

- Haq, M.; Burgueño, R.; Mohanty, A.K.; Misra, M. Hybrid bio-based composites from blends of unsaturated polyester and soybean oil reinforced with nanoclay and natural fibers. Compos. Sci. Technol. 2008, 68, 3344–3351. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly(lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Sergi, C.; Seghini, M.C.; Cozzarini, L.; Graupner, N. Effect of basalt fibre hybridisation and sizing removal on mechanical and thermal properties of hemp fibre reinforced HDPE composites. Compos. Struct. 2018, 188, 394–406. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, M.A.A.; Abdul Majid, M.S.; Ridzuan, M.J.M.; Mazlee, M.N.; Gibson, A.G. Dynamic mechanical analysis and effects of moisture on mechanical properties of interwoven hemp/polyethylene terephthalate (PET) hybrid composites. Constr. Build. Mater. 2018, 179, 265–276. [Google Scholar] [CrossRef] [Green Version]

- Paturel, A.; Dhakal, H.N. Influence of water absorption on the low velocity falling weight impact damage behaviour of flax/glass reinforced vinyl ester hybrid composites. Molecules 2020, 25, 278. [Google Scholar] [CrossRef] [Green Version]

- Arbelaiz, A.; Fernandez, B.; Ramos, J.A.; Mondragon, I. Thermal and crystallization studies of short flax fibre reinforced polypropylene matrix composites: Effect of treatments. Thermochim. Acta 2006, 440, 111–121. [Google Scholar] [CrossRef]

- Di Landro, L.; Lorenzi, W. Static and dynamic properties of thermoplastic matrix/natural fiber composites. J. Biobased Mater. Bioenergy 2009, 3, 238–244. [Google Scholar] [CrossRef]

- Liu, Q.; Hughes, M. The fracture behaviour and toughness of woven flax fibre reinforced epoxy composites. Compos. Part. A Appl. Sci. Manuf. 2008, 39, 1644–1652. [Google Scholar] [CrossRef]

- Almansour, F.A.; Dhakal, H.N.; Zhang, Z.Y. Investigation into Mode II interlaminar fracture toughness characteristics of flax/basalt reinforced vinyl ester hybrid composites. Compos. Sci. Technol. 2018, 154, 117–127. [Google Scholar] [CrossRef] [Green Version]

- Cheour, K.; Assarar, M.; Scida, D.; Ayad, R.; Gong, X.-L. Long-term immersion in water of flax-glass fibre hybrid composites: Effect of stacking sequence on the mechanical and damping properties. Fibers Polym. 2020, 21, 162–169. [Google Scholar] [CrossRef]

- Arulmurugan, M.; Selvakumar, A.S.; Prabu, K.; Rajamurugan, G. Effect of barium sulphate on mechanical, DMA and thermal behaviour of woven aloevera/flax hybrid composites. Bull. Mater. Sci. 2020, 43, 58. [Google Scholar] [CrossRef]

- Xu, H.; Wang, L.; Teng, C.; Yu, M. Biodegradable composites: Ramie fibre reinforced PLLA-PCL composite prepared by in situ polymerization process. Polym. Bull. 2008, 61, 663–670. [Google Scholar] [CrossRef]

- Romanzini, D.; Ornaghi Junior, H.L.; Amico, S.C.; Zattera, A.J. Preparation and characterization of ramie-glass fiber reinforced polymer matrix hybrid composites. Mater. Res. 2012, 15, 415–420. [Google Scholar] [CrossRef] [Green Version]

- Marsyahyo, E.; Jamasri; Rochardjo, H.S.B.; Soekrisno. Preliminary investigation on bulletproof panels made from ramie fiber reinforced composites for NIJ level II, IIA, and IV. J. Ind. Text. 2009, 39, 13–26. [Google Scholar] [CrossRef]

- Wen, L.E.I.; LEI, W.; Chao, R.E.N. Effect of volume fraction of ramie cloth on physical and mechanical properties of ramie cloth/UP resin composite. Trans. Nonferrous Met. Soc. China 2006, 16, s474–s477. [Google Scholar]

- Bledzki, A.K.; Mamun, A.A.; Faruk, O. Abaca fibre reinforced PP composites and comparison with jute and flax fibre PP composites. Express Polym. Lett. 2007. [Google Scholar] [CrossRef]

- Savastano, H., Jr.; Santos, S.F.; Radonjic, M.; Soboyejo, W.O. Fracture and fatigue of natural fiber-reinforced cementitious composites. Cem. Concr. Compos. 2009, 31, 232–243. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Jaszkiewicz, A.; Erdmann, K. Polypropylene composites with enzyme modified abaca fibre. Compos. Sci. Technol. 2010, 70, 854–860. [Google Scholar] [CrossRef]

- Ortega, Z.; Monzón, M.D.; Benítez, A.N.; Kearns, M.; McCourt, M.; Hornsby, P.R. Banana and abaca fiber-reinforced plastic composites obtained by rotational molding process. Mater. Manuf. Process. 2013, 28, 879–883. [Google Scholar] [CrossRef]

- Prasad, N.; Agarwal, V.K.; Sinha, S. Banana fiber reinforced low-density polyethylene composites: Effect of chemical treatment and compatibilizer addition. Iran. Polym. J. 2016, 25, 229–241. [Google Scholar] [CrossRef]

- Agung, E.H.; Sapuan, S.M.; Hamdan, M.M.; Zaman, H.; Mustofa, U. Optimization of the mechanical properties of abaca fibre-reinforced high impact polystyrene (HIPS) composites using box-behnken design of experiments. Polym. Polym. Compos. 2011, 19, 697–710. [Google Scholar] [CrossRef]

- Iqbal, M.; Aminanda, Y.; Firsa, T.; Ali, M. Bending Strength of Polyester Composites Reinforced with Stitched Random Orientation And Plain Weave Abaca Fiber. In Proceedings of the IOP Conference Series: Materials science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 739, p. 12035. [Google Scholar]

- Rana, R.S.; Rana, S.; Nigrawal, A. Preparation and mechanical properties evaluation of polyvinyl alcohol and banana fibres composite. Mater. Today Proc. 2020, 26, 3145–3147. [Google Scholar] [CrossRef]

- Zhong, L.X.; Fu, S.Y.; Zhou, X.S.; Zhan, H.Y. Effect of surface microfibrillation of sisal fibre on the mechanical properties of sisal/aramid fibre hybrid composites. Compos. Part. A Appl. Sci. Manuf. 2011, 42, 244–252. [Google Scholar] [CrossRef]

- Asaithambi, B.; Ganesan, G.; Ananda Kumar, S. Bio-composites: Development and mechanical characterization of banana/sisal fibre reinforced poly lactic acid (PLA) hybrid composites. Fibers Polym. 2014, 15, 847–854. [Google Scholar] [CrossRef]

- Noorunnisa Khanam, P.; Abdul Khalil, H.P.S.; Jawaid, M.; Ramachandra Reddy, G.; Surya Narayana, C.; Venkata Naidu, S. Sisal/Carbon Fibre Reinforced Hybrid Composites: Tensile, Flexural and Chemical Resistance Properties. J. Polym. Environ. 2010, 18, 727–733. [Google Scholar] [CrossRef]

- Aslan, M.; Tufan, M.; Küçükömeroğlu, T. Tribological and mechanical performance of sisal-filled waste carbon and glass fibre hybrid composites. Compos. Part. B Eng. 2018, 140, 241–249. [Google Scholar] [CrossRef]

- Gupta, M.K. Effect of frequencies on dynamic mechanical properties of hybrid jute/sisal fibre reinforced epoxy composite. Adv. Mater. Process. Technol. 2017, 3, 651–664. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Ishak, M.R.; Leman, Z.; Huzaifah, M.R.M.; Ilyas, R.A.; Ammar, I.M.; Ishak, M.H.A.; Yana, I. Pokok Enau: Potensi Dan Pembangunan Produk, 1st ed.; Sapuan, S.M., Ed.; Penerbit Universiti Putra Malaysia: Serdang, Selangor, 2017; ISBN 9789673447473. [Google Scholar]

- Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.A.; Anwar, U.M.K.K.; Siregar, J.P. Sugar palm (Arenga pinnata): Its fibres, polymers and composites. Carbohydr. Polym. 2013, 91, 699–710. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Sugar palm nanofibrillated cellulose (Arenga pinnata (Wurmb.) Merr): Effect of cycles on their yield, physic-chemical, morphological and thermal behavior. Int. J. Biol. Macromol. 2019, 123, 379–388. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Asrofi, M.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; et al. Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: A comprehensive approach from macro to nano scale. J. Mater. Res. Technol. 2019, 8, 2753–2766. [Google Scholar] [CrossRef]

- Norizan, M.N.; Abdan, K.; Ilyas, R.A.; Biofibers, S.P. Effect of fiber orientation and fiber loading on the mechanical and thermal properties of sugar palm yarn fiber reinforced unsaturated polyester resin composites. Polimery 2020, 65, 34–43. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A.; Rafiqah, S.A.; Hanafee, Z.M. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 2020, 9, 1606–1618. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Effect of delignification on the physical, thermal, chemical, and structural properties of sugar palm fibre. BioResources 2017, 12, 8734–8754. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Rafiqah, S.A.; Aisyah, H.A.; Nurazzi, N.M.; Norrrahim, M.N.F. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text. Res. J. 2021, 91, 152–167. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M.; Zainudin, E.S.; Maleque, M.A. Physico-chemical and thermal properties of starch derived from sugar palm tree (Arenga pinnata). Asian J. Chem. 2014, 26, 955–959. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Effect of plasticizer type and concentration on physical properties of biodegradable films based on sugar palm (arenga pinnata) starch for food packaging. J. Food Sci. Technol. 2016, 53, 326–336. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Sugar palm nanocrystalline cellulose reinforced sugar palm starch composite: Degradation and water-barrier properties. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012006. [Google Scholar] [CrossRef] [Green Version]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Water transport properties of bio-nanocomposites reinforced by sugar palm (Arenga Pinnata) nanofibrillated cellulose. J. Adv. Res. Fluid Mech. Therm. Sci. J. 2018, 51, 234–246. [Google Scholar]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Tawakkal, I.S.M.A.; Ilyas, R.A. Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites. Nanotechnol. Rev. 2021, 10, 431–442. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atiqah, A.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Nurazzi, N.M.; Atikah, M.S.N.; Ansari, M.N.M.; et al. Sugar palm (Arenga pinnata [Wurmb.] Merr) starch films containing sugar palm nanofibrillated cellulose as reinforcement: Water barrier properties. Polym. Compos. 2020, 41, 459–467. [Google Scholar] [CrossRef]

- Hazrol, M.D.; Sapuan, S.M.; Ilyas, R.A.; Othman, M.L.; Sherwani, S.F.K. Electrical properties of sugar palm nanocrystalline cellulose reinforced sugar palm starch nanocomposites. Polimery 2020, 65, 363–370. [Google Scholar] [CrossRef]

- Atikah, M.S.N.; Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Ibrahim, R.; Atiqah, A.; Ansari, M.N.M.; Jumaidin, R. Degradation and physical properties of sugar palm starch/sugar palm nanofibrillated cellulose bionanocomposite. Polimery 2019, 64, 680–689. [Google Scholar] [CrossRef] [Green Version]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atiqah, A.; Atikah, M.S.N.; Syafri, E.; Asrofi, M.; et al. Thermal, Biodegradability and Water Barrier Properties of Bio-Nanocomposites Based on Plasticised Sugar Palm Starch and Nanofibrillated Celluloses from Sugar Palm Fibres. J. Biobased Mater. Bioenergy 2020, 14, 234–248. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N.; Mohd Nurazzi, N.; Atiqah, A.; Ansari, M.N.M.; et al. Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata (Wurmb.) Merr) starch. J. Mater. Res. Technol. 2019, 8, 4819–4830. [Google Scholar] [CrossRef]

- Suriani, M.J.; Sapuan, S.M.; Ruzaidi, C.M.; Nair, D.S.; Ilyas, R.A. Flammability, morphological and mechanical properties of sugar palm fiber/polyester yarn-reinforced epoxy hybrid biocomposites with magnesium hydroxide flame retardant filler. Text. Res. J. 2021. [Google Scholar] [CrossRef]

- Ishak, M.R.; Leman, Z.; Sapuan, S.M.; Salleh, M.Y.; Misri, S. Effect of Sea Water Treatment on the Impact and Flexural Strength of Sugar Palm Fibre Reinforced Epoxy Composites. Int. J. Mech. Mater. Eng. (IJMME) 2009, 4, 316–320. [Google Scholar]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Leman, Z.; Sastra, H.Y.; Sapuan, S.M.; Hamdan, M.M.H.M.; Maleque, M.A. Study on impact properties of Arenga pinnata fibre reinforced epoxy composites. J. Appl. Technol. 2005, 3, 14–19. [Google Scholar]

- Bachtiar, D.; Sapuan, S.M.; Hamdan, M.M. Flexural properties of alkaline treated sugar palm fibre reinforced epoxy composites. Int. J. Automot. Mech. Eng. 2010, 1, 79–90. [Google Scholar] [CrossRef]

- Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.; Anwar, U.M.K. Characterization of sugar palm (Arenga pinnata) fibres. J. Therm. Anal. Calorim. 2012, 109, 981–989. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Harussani, M.M.; Zulaikha, N.D.S.; Norhana, A.H.; Syakir, M.I.; Norli, A. Composites based on conductive polymer with carbon nanotubes in DMMP gas sensors—An overview. Polimery 2021, 66, 85–97. [Google Scholar] [CrossRef]

- Rozilah, A.; Jaafar, C.N.A.; Sapuan, S.M.; Zainol, I.; Ilyas, R.A. The Effects of Silver Nanoparticles Compositions on the Mechanical, Physiochemical, Antibacterial, and Morphology Properties of Sugar Palm Starch Biocomposites for Antibacterial Coating. Polymers 2020, 12, 2605. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R.; Alothman, O.Y. Thermal Properties of Sugar Palm/Glass Fiber Reinforced Thermoplastic Polyurethane hybrid composites. Compos. Struct. 2018. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R.; Ansari, M.N.M.; Ilyas, R.A. Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 3726–3732. [Google Scholar] [CrossRef]

- Nishino, T.; Hirao, K.; Kotera, M.; Nakamae, K.; Inagaki, H. Kenaf reinforced biodegradable composite. Compos. Sci. Technol. 2003, 63, 1281–1286. [Google Scholar] [CrossRef]

- Nor, A.F.M.; Hassan, M.Z.; Rasid, Z.A.; Aziz, S.A.; Sarip, S.; Md Daud, M.Y. Optimization on Tensile Properties of Kenaf/Multi-walled CNT Hybrid Composites with Box-Behnken Design. Appl. Compos. Mater. 2021, 28, 607–632. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, J.; Yu, J.; Lacy, T.E., Jr.; Xue, Y.; Toghiani, H.; Horstemeyer, M.F.; Pittman, C.U., Jr. Kenaf bast fiber bundle–reinforced unsaturated polyester composites. IV: Effects of fiber loadings and aspect ratios on composite tensile properties. For. Prod. J. 2010, 60, 582–591. [Google Scholar] [CrossRef]

- Bonnia, N.N.; Ahmad, S.H.; Zainol, I.; Mamun, A.A.; Beg, M.D.H.; Bledzki, A.K. Mechanical properties and environmental stress cracking resistance of rubber toughened polyester/kenaf composite. Express Polym. Lett 2010, 4, 55–61. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Stress relaxation behaviour in oil palm fibres. Mater. Lett. 2001, 50, 263–273. [Google Scholar] [CrossRef]

- Agarwal, R.; Saxena, N.S.; Sharma, K.B.; Thomas, S.; Sreekala, M.S. Effect of different treatments on the thermal behavior of reinforced phenol–formaldehyde polymer composites. J. Appl. Polym. Sci. 2000, 78, 603–608. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Huzaifah, M.R.M.; Farid, M.A.A.; Shazleen, S.S.; Misenan, M.S.M.; Yasim-Anuar, T.A.T.; Naveen, J.; Nurazzi, N.M.; Rani, M.S.A.; Hakimi, M.I.; et al. Greener Pretreatment Approaches for the Valorisation of Natural Fibre Biomass into Bioproducts. Polymers 2021, 13, 2971. [Google Scholar] [CrossRef]

- Khalid, M.; Ratnam, C.T.; Chuah, T.G.; Ali, S.; Choong, T.S.Y. Comparative study of polypropylene composites reinforced with oil palm empty fruit bunch fiber and oil palm derived cellulose. Mater. Des. 2008, 29, 173–178. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Issam, A.M.; Shakri, M.T.A.; Suriani, R.; Awang, A.Y. Conventional agro-composites from chemically modified fibres. Ind. Crop. Prod. 2007, 26, 315–323. [Google Scholar] [CrossRef]

- Kaddami, H.; Dufresne, A.; Khelifi, B.; Bendahou, A.; Taourirte, M.; Raihane, M.; Issartel, N.; Sautereau, H.; Gerard, J.-F.; Sami, N. Short palm tree fibers–Thermoset matrices composites. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 1413–1422. [Google Scholar] [CrossRef]

- Amor, I.B.; Rekik, H.; Kaddami, H.; Raihane, M.; Arous, M.; Kallel, A. Studies of dielectric relaxation in natural fiber–polymer composites. J. Electrostat. 2009, 67, 717–722. [Google Scholar] [CrossRef]

- Threepopnatkul, P.; Kaerkitcha, N.; Athipongarporn, N. Polycarbonate with pineapple leaf fiber to produce functional composites. In Proceedings of the Advanced Materials Research; Trans Tech Publisher: Bristol, UK, 2008; Volume 47, pp. 674–677. [Google Scholar]

- Norizan, M.N.; Moklis, M.H.; Alias, A.H.; Rushdan, A.I.; Norrrahim, M.N.F.; Abdan, K.; Abdullah, N. Treatments of Natural Fibre as Reinforcement in Polymer Composites-Short Review. Funct. Compos. Struct. 2021, 3, 024002. [Google Scholar] [CrossRef]

- Mangal, R.; Saxena, N.S.; Sreekala, M.S.; Thomas, S.; Singh, K. Thermal properties of pineapple leaf fiber reinforced composites. Mater. Sci. Eng. A 2003, 339, 281–285. [Google Scholar] [CrossRef]

- Mishra, S.; Misra, M.; Tripathy, S.S.; Nayak, S.K.; Mohanty, A.K. Potentiality of pineapple leaf fibre as reinforcement in PALF-polyester composite: Surface modification and mechanical performance. J. Reinf. Plast. Compos. 2001, 20, 321–334. [Google Scholar] [CrossRef]

- Shih, Y. Mechanical and thermal properties of waste water bamboo husk fiber reinforced epoxy composites. Mater. Sci. Eng. A 2007, 446, 289–295. [Google Scholar] [CrossRef]

- Lopattananon, N.; Panawarangkul, K.; Sahakaro, K.; Ellis, B. Performance of pineapple leaf fiber–natural rubber composites: The effect of fiber surface treatments. J. Appl. Polym. Sci. 2006, 102, 1974–1984. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Pac, M.-J.; Ayad, R. Mode-I interlaminar fracture toughness of flax, glass and hybrid flax-glass fibre woven composites: Failure mechanism evaluation using acoustic emission analysis. Polym. Test. 2019, 75, 246–253. [Google Scholar] [CrossRef]

- Arun, P.V.R.; Rajadurai, A. Inter laminar shear strength behavior of acid, base and silane treated E-glass fibre epoxy resin composites on drilling process. Def. Technol. 2017, 13, 40–46. [Google Scholar] [CrossRef]

- Suriani, M.J.; Rapi, H.Z.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M. Delamination and Manufacturing Defects in Natural Fiber-Reinforced Hybrid Composite: A Review. Polymers 2021, 13, 1323. [Google Scholar] [CrossRef]

- Riccio, A. Delamination in the context of composite structural design. Delamination Behav. Compos. A Vol. Woodhead Publ. Ser. Compos. Sci. Eng. 2008, 28–64. [Google Scholar] [CrossRef]

- Chermoshentseva, A.S.; Pokrovskiy, A.M.; Bokhoeva, L.A. The behavior of delaminations in composite materials—Experimental results. IOP Conf. Ser. Mater. Sci. Eng. 2016, 116. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.U.; Kim, J.K. Impact and delamination failure of multiscale carbon nanotube-fiber reinforced polymer composites: A review. Int. J. Aeronaut. Sp. Sci. 2011, 12, 115–133. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Technology, M.S.-C.S. Undefined Impact and Delamination Failure of Woven-Fabric Composites; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Dhanawade, A.; Kumar, S. Experimental study of delamination and kerf geometry of carbon epoxy composite machined by abrasive water jet. J. Compos. Mater. 2017, 51, 3373–3390. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Chandrasekar, M.; Jawaid, M.; Rajini, N.; Alothman, O.Y.; Siengchin, S. Evaluation of mechanical and free vibration properties of the pineapple leaf fibre reinforced polyester composites. Constr. Build. Mater. 2019, 195, 423–431. [Google Scholar] [CrossRef]

- Feng, N.L.; Malingam, S.D.; Razali, N.; Subramonian, S. Alkali and Silane Treatments towards Exemplary Mechanical Properties of Kenaf and Pineapple Leaf Fibre-reinforced Composites. J. Bionic Eng. 2020, 17, 380–392. [Google Scholar] [CrossRef]

- Shah, D.U.; Konnerth, J.; Ramage, M.H.; Gusenbauer, C. Mapping thermal conductivity across bamboo cell walls with scanning thermal microscopy. Sci. Rep. 2019, 9, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zakikhani, P.; Zahari, R.; Sultan, M.T.H.; Majid, D.L. Extraction and preparation of bamboo fibre-reinforced composites. Mater. Des. 2014, 63, 820–828. [Google Scholar] [CrossRef]

- Azammi, A.M.N.; Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Atikah, M.S.N.; Asrofi, M.; Atiqah, A. Characterization Studies Of Biopolymeric Matrix And Cellulose Fibres Based Composites Related To Functionalized Fibre-Matrix Interface. In Interfaces in Particle and Fibre Reinforced Composites; Elsevier: London, UK, 2020; pp. 29–93. ISBN 9780081026656. [Google Scholar]

- Thwe, M.M.; Liao, K. Effects of environmental aging on the mechanical properties of bamboo–glass fiber reinforced polymer matrix hybrid composites. Compos. Part. A Appl. Sci. Manuf. 2002, 33, 43–52. [Google Scholar] [CrossRef]

- Ying-Chen, Z.; Hong-Yan, W.; Yi-Ping, Q. Morphology and properties of hybrid composites based on polypropylene/polylactic acid blend and bamboo fiber. Bioresour. Technol. 2010, 101, 7944–7950. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 1–14. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Lim, J.K. Stress corrosion cracking (SCC) in polymer composites. In Stress Corrosion Cracking; Elsevier: Amsterdam, The Netherlands, 2011; pp. 485–536. [Google Scholar]

- Mohanty, A.K.; Khan, M.A.; Hinrichsen, G. Surface modification of jute and its influence on performance of biodegradable jute-fabric/Biopol composites. Compos. Sci. Technol. 2000, 60, 1115–1124. [Google Scholar] [CrossRef]

- Zaman, H.U.; Khan, R.A.; Haque, M.E.; Khan, M.A.; Khan, A.; Huq, T.; Noor, N.; Rahman, M.; Mustafizur Rahman, K.; Huq, D. Preparation and mechanical characterization of jute reinforced polypropylene/natural rubber composite. J. Reinf. Plast. Compos. 2010, 29, 3064–3065. [Google Scholar] [CrossRef]

- Acha, B.A.; Reboredo, M.M.; Marcovich, N.E. Creep and dynamic mechanical behavior of PP–jute composites: Effect of the interfacial adhesion. Compos. Part. A Appl. Sci. Manuf. 2007, 38, 1507–1516. [Google Scholar] [CrossRef]

- Wang, X.; Cui, Y.; Xu, Q.; Xie, B.; Li, W. Effects of alkali and silane treatment on the mechanical properties of jute-fiber-reinforced recycled polypropylene composites. J. Vinyl Addit. Technol. 2010, 16, 183–188. [Google Scholar] [CrossRef]

- Hong, C.K.; Hwang, I.; Kim, N.; Park, D.H.; Hwang, B.S.; Nah, C. Mechanical properties of silanized jute–polypropylene composites. J. Ind. Eng. Chem. 2008, 14, 71–76. [Google Scholar] [CrossRef]

- Sampath, A.; Martin, G.C. Enhancement of Natural Fiber-Epoxy Interaction Using Bi-Functional Surface Modifiers (963). In Proceedings of the Technical Papers of the Annual Technical Conference; Society of Plastics Engineers (SPE) Incorporated: Danbury, CT, USA, 2000; Volume 2, pp. 2274–2278. [Google Scholar]

- Dwivedi, U.K.; Chand, N. Influence of fibre orientation on friction and sliding wear behaviour of jute fibre reinforced polyester composite. Appl. Compos. Mater. 2009, 16, 93–100. [Google Scholar] [CrossRef]

- Singh, B.; Gupta, M.; Verma, A. The durability of jute fibre-reinforced phenolic composites. Compos. Sci. Technol. 2000, 60, 581–589. [Google Scholar] [CrossRef]

- Alves, C.; Ferrão, P.M.C.; Silva, A.J.; Reis, L.G.; Freitas, M.; Rodrigues, L.B.; Alves, D.E. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Mir, A.; Zitoune, R.; Collombet, F.; Bezzazi, B. Study of mechanical and thermomechanical properties of jute/epoxy composite laminate. J. Reinf. Plast. Compos. 2010, 29, 1669–1680. [Google Scholar] [CrossRef]

- Sarikanat, M. The influence of oligomeric siloxane concentration on the mechanical behaviors of alkalized jute/modified epoxy composites. J. Reinf. Plast. Compos. 2010, 29, 807–817. [Google Scholar] [CrossRef]

- Fraga, A.N.; Frullloni, E.; De la Osa, O.; Kenny, J.M.; Vázquez, A. Relationship between water absorption and dielectric behaviour of natural fibre composite materials. Polym. Test. 2006, 25, 181–187. [Google Scholar] [CrossRef]

- Santulli, C. Post-impact damage characterisation on natural fibre reinforced composites using acoustic emission. NDT E Int. 2001, 34, 531–536. [Google Scholar] [CrossRef]

- Dash, B.N.; Rana, A.K.; Mishra, H.K.; Nayak, S.K.; Tripathy, S.S. Novel low-cost jute–polyester composites. III. Weathering and thermal behavior. J. Appl. Polym. Sci. 2000, 78, 1671–1679. [Google Scholar] [CrossRef]

- Sever, K.; Sarikanat, M.; Seki, Y.; Erkan, G.; Erdoğan, Ü.H. The mechanical properties of γ-methacryloxypropyltrimethoxy silane-treated jute/polyester composites. J. Compos. Mater. 2010, 44, 1913–1924. [Google Scholar] [CrossRef]

- Pracella, M.; Chionna, D.; Anguillesi, I.; Kulinski, Z.; Piorkowska, E. Functionalization, compatibilization and properties of polypropylene composites with hemp fibres. Compos. Sci. Technol. 2006, 66, 2218–2230. [Google Scholar] [CrossRef]

- Li, Y.; Pickering, K.L. The effect of chelator and white rot fungi treatments on long hemp fibre-reinforced composites. Compos. Sci. Technol. 2009, 69, 1265–1270. [Google Scholar] [CrossRef]

- Li, Y.; Pickering, K.L. Hemp fibre reinforced composites using chelator and enzyme treatments. Compos. Sci. Technol. 2008, 68, 3293–3298. [Google Scholar] [CrossRef]

- Li, Y.; Pickering, K.L.; Farrell, R.L. Determination of interfacial shear strength of white rot fungi treated hemp fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1165–1171. [Google Scholar] [CrossRef]

- Wang, C.; Zuo, Q.; Lin, T.; Anuar, N.I.S.; Mohd Salleh, K.; Gan, S.; Yousfani, S.H.S.; Zuo, H.; Zakaria, S. Predicting thermal conductivity and mechanical property of bamboo fibers/polypropylene nonwovens reinforced composites based on regression analysis. Int. Commun. Heat Mass Transf. 2020, 118, 104895. [Google Scholar] [CrossRef]

- Amin, K.F.; Sharif, A.; Hoque, M.E. Bonding Mechanism and Interface Enhancement of Bamboo Fiber Reinforced Composites. In Bamboo Fiber Composites; Springer: Singapore, 2021; pp. 215–233. [Google Scholar]

- Lobo, A.; Haseebuddin, M.R.; Harsha, S.; Acharya, K.G.; Balaji, G.; Pal, B. Mechanical behavior of disposed fiberglass filled bamboo mat reinforced polyester composite. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- de Araujo Alves Lima, R.; Kawasaki Cavalcanti, D.; de Souza e Silva Neto, J.; Meneses da Costa, H.; Banea, M.D. Effect of surface treatments on interfacial properties of natural intralaminar hybrid composites. Polym. Compos. 2020, 41, 314–325. [Google Scholar] [CrossRef]

- Bourmaud, A.; Baley, C. Rigidity analysis of polypropylene/vegetal fibre composites after recycling. Polym. Degrad. Stab. 2009, 94, 297–305. [Google Scholar] [CrossRef]

- Santulli, C.; Caruso, A.P. Effect of fibre architecture on the falling weight impact properties of hemp/epoxy composites. J. Biobased Mater. Bioenergy 2009, 3, 291–297. [Google Scholar] [CrossRef]

- Cicala, G.; Cristaldi, G.; Recca, G.; Ziegmann, G.; El-Sabbagh, A.; Dickert, M. Properties and performances of various hybrid glass/natural fibre composites for curved pipes. Mater. Des. 2009, 30, 2538–2542. [Google Scholar] [CrossRef]

- Scarponi, C.; Pizzinelli, C.S.; Sánchez-Sáez, S.; Barbero, E. Impact load behaviour of resin transfer moulding (RTM) hemp fibre composite laminates. J. Biobased Mater. Bioenergy 2009, 3, 298–310. [Google Scholar] [CrossRef] [Green Version]

- Eichhorn, S.J.; Young, R.J. Composite micromechanics of hemp fibres and epoxy resin microdroplets. Compos. Sci. Technol. 2004, 64, 767–772. [Google Scholar] [CrossRef]

- Hepworth, D.G.; Hobson, R.N.; Bruce, D.M.; Farrent, J.W. The use of unretted hemp fibre in composite manufacture. Compos. Part. A Appl. Sci. Manuf. 2000, 31, 1279–1283. [Google Scholar] [CrossRef]

- Kunanopparat, T.; Menut, P.; Morel, M.-H.; Guilbert, S. Reinforcement of plasticized wheat gluten with natural fibers: From mechanical improvement to deplasticizing effect. Compos. Part. A Appl. Sci. Manuf. 2008, 39, 777–785. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Chemical modification of flax reinforced polypropylene composites. Compos. Part. A Appl. Sci. Manuf. 2009, 40, 442–448. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Sarasini, F.; Tirilló, J.; Calabrese, L. Salt-fog spray aging of jute-basalt reinforced hybrid structures: Flexural and low velocity impact response. Compos. Part. B Eng. 2017, 116, 99–112. [Google Scholar] [CrossRef]

- Oksman, K. Mechanical properties of natural fibre mat reinforced thermoplastic. Appl. Compos. Mater. 2000, 7, 403–414. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Cantero, G.; Llano-Ponte, R.; Valea, A.; Mondragon, I. Mechanical properties of flax fibre/polypropylene composites. Influence of fibre/matrix modification and glass fibre hybridization. Compos. Part. A Appl. Sci. Manuf. 2005, 36, 1637–1644. [Google Scholar] [CrossRef]

- Duhovic, M.; Horbach, S.; Bhattacharyya, D. Improving the interface strength in flax fibre poly(lactic) acid composites. J. Biobased Mater. Bioenergy 2009, 3, 188–198. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Effect of material and process parameters on the mechanical properties of unidirectional and multidirectional flax/polypropylene composites. Compos. Struct. 2003, 62, 443–448. [Google Scholar] [CrossRef]

- Bos, H.L.; Müssig, J.; van den Oever, M.J.A. Mechanical properties of short-flax-fibre reinforced compounds. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 1591–1604. [Google Scholar] [CrossRef]

- Buttlar, H.B. Natural fibre reinforced construction materials for SMC applications. In Proceedings of the Conference RIKO-2005; Niedersachsen, German, 2005; pp. 1–24. [Google Scholar]

- Stuart, T.; Liu, Q.; Hughes, M.; McCall, R.D.; Sharma, H.S.S.; Norton, A. Structural biocomposites from flax—Part I: Effect of bio-technical fibre modification on composite properties. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 393–404. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Chi Truong, T.; Vangrimde, B.; Verpoest, I. Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 1368–1376. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Ivens, J.; De Coster, A.; Kino, B.; Baetens, E.; Verpoest, I. Influence of processing and chemical treatment of flax fibres on their composites. Compos. Sci. Technol. 2003, 63, 1241–1246. [Google Scholar] [CrossRef]

- Manfredi, L.B.; Rodríguez, E.S.; Wladyka-Przybylak, M.; Vázquez, A. Thermal degradation and fire resistance of unsaturated polyester, modified acrylic resins and their composites with natural fibres. Polym. Degrad. Stab. 2006, 91, 255–261. [Google Scholar] [CrossRef]

- Baley, C.; Busnel, F.; Grohens, Y.; Sire, O. Influence of chemical treatments on surface properties and adhesion of flax fibre–polyester resin. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 1626–1637. [Google Scholar] [CrossRef]

- Yu, T.; Ren, J.; Li, S.; Yuan, H.; Li, Y. Effect of fiber surface-treatments on the properties of poly(lactic acid)/ramie composites. Compos. Part. A Appl. Sci. Manuf. 2010, 41, 499–505. [Google Scholar] [CrossRef]

- Nam, S.; Netravali, A.N. Green composites. I. physical properties of ramie fibers for environment-friendly green composites. Fibers Polym. 2006, 7, 372–379. [Google Scholar] [CrossRef]

- Ishikawa, A.; Okano, T.; Sugiyama, J. Fine structure and tensile properties of ramie fibres in the crystalline form of cellulose I., II, IIII and IVI. Polymers 1997, 38, 463–468. [Google Scholar] [CrossRef]

- Goda, K.; Sreekala, M.S.; Gomes, A.; Kaji, T.; Ohgi, J. Improvement of plant based natural fibers for toughening green composites—Effect of load application during mercerization of ramie fibers. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 2213–2220. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M. Biopolymers and Biocomposites: Chemistry and Technology. Curr. Anal. Chem. 2020, 16, 500–503. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M. The Preparation Methods and Processing of Natural Fibre Bio-polymer Composites. Curr. Org. Synth. 2020, 16, 1068–1070. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A comprehensive review on advanced sustainable woven natural fibre polymer composites. Polymers 2021, 13, 471. [Google Scholar] [CrossRef]

- Müssig, J. Cotton fibre-reinforced thermosets versus ramie composites: A comparative study using petrochemical-and agro-based resins. J. Polym. Environ. 2008, 16, 94–102. [Google Scholar] [CrossRef]

- Lodha, P.; Netravali, A.N. Characterization of stearic acid modified soy protein isolate resin and ramie fiber reinforced ‘green’composites. Compos. Sci. Technol. 2005, 65, 1211–1225. [Google Scholar] [CrossRef]

- Kishi, H.; Fujita, A. Wood-based epoxy resins and the ramie fiber reinforced composites. Environ. Eng. Manag. J. 2008, 7, 517–523. [Google Scholar] [CrossRef]

- Long, C.-G.; He, L.-P.; Zhong, Z.-H.; Chen, S.-G. Studies on the polypropylene composites reinforced by ramier fiber and K2Ti6O13 whisker. Res. Lett. Mater. Sci. 2007, 2007. [Google Scholar] [CrossRef]

- Pothan, L.A.; Thomas, S.; Groeninckx, G. The role of fibre/matrix interactions on the dynamic mechanical properties of chemically modified banana fibre/polyester composites. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 1260–1269. [Google Scholar] [CrossRef]

- El-Meligy, M.G.; Mohamed, S.H.; Mahani, R.M. Study mechanical, swelling and dielectric properties of prehydrolysed banana fiber–Waste polyurethane foam composites. Carbohydr. Polym. 2010, 80, 366–372. [Google Scholar] [CrossRef]

- Teramoto, N.; Urata, K.; Ozawa, K.; Shibata, M. Biodegradation of aliphatic polyester composites reinforced by abaca fiber. Polym. Degrad. Stab. 2004. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Khalina, A.; Rashid, U.; Tarique, J. Slow pyrolysis of disinfected COVID-19 non-woven polypropylene (PP) waste. In Proceedings of the International Symposium on Applied Sciences and Engineering ISASE2021; Office of International Affairs, Atatürk University: Erzurum, Turkey, 2021; pp. 310–312. [Google Scholar]

- Zhong, J.B.; Lv, J.; Wei, C. Mechanical properties of sisal fibre reinforced urea formaldehyde resin composites. Express Polym. Lett. 2007, 1, 681–687. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Kadier, A.; Kalil, M.S.; Atikah, M.S.N.; Ibrahim, R.; Asrofi, M.; Abral, H.; et al. Nanocellulose/starch biopolymer nanocomposites: Processing, manufacturing, and applications. In Advanced Processing, Properties, and Application of Strach and Other Bio-Based Polymer; Al-Oqla, F.M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Azammi, A.M.N.; Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Atikah, M.S.N.; Asrofi, M.; Atiqah, A. Characterization studies of biopolymeric matrix and cellulose fibres based composites related to functionalized fibre-matrix interface. In Interfaces in Particle and Fibre Reinforced Composites- From Macro to Nano Scales; Woodhead Publishing: London, UK, 2019; pp. 1–68. ISBN 9780081026656. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Progress Report on Natural Fiber Reinforced Composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Atikah, M.S.N.; Ibrahim, R.; Dele-Afolabi, T.T.; Hazrol, M.D. Introduction to Biofiller-Reinforced Degradable Polymer Composites. In Biofiller-Reinforced Biodegradable Polymer Composites; Jumaidin, R., Sapuan, S.M., Ismail, H., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 1–23. [Google Scholar]

- Jumaidin, R.; Saidi, Z.A.S.; Ilyas, R.A.; Ahmad, M.N.; Wahid, M.K.; Yaakob, M.Y.; Maidin, N.A.; Rahman, M.H.A.; Osman, M.H. Characteristics of Cogon Grass Fibre Reinforced Thermoplastic Cassava Starch Biocomposite: Water Absorption and Physical Properties. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 62, 43–52. [Google Scholar]

- Sreekumar. Matrices for Natural-Fibre Reinforced Composites; Woodhead Publishing Limited: Brimingham, UK, 2008; ISBN 9781845692674. [Google Scholar]

- Suppakarn, N.; Jarukumjorn, K. Mechanical properties and flammability of sisal/PP composites: Effect of flame retardant type and content. Compos. Part. B Eng. 2009, 40, 613–618. [Google Scholar] [CrossRef]

- Joseph, P.V.; Rabello, M.S.; Mattoso, L.H.C.; Joseph, K.; Thomas, S. Environmental effects on the degradation behaviour of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2002, 62, 1357–1372. [Google Scholar] [CrossRef]

- Dwivedi, U.K.; Chand, N. Influence of MA-g-PP on abrasive wear behaviour of chopped sisal fibre reinforced polypropylene composites. J. Mater. Process. Technol. 2009, 209, 5371–5375. [Google Scholar] [CrossRef]

- Zhang, M.; Rong, M.; Lu, X. Fully biodegradable natural fiber composites from renewable resources: All-plant fiber composites. Compos. Sci. Technol. 2005, 65, 2514–2525. [Google Scholar] [CrossRef]

- Athijayamani, A.; Thiruchitrambalam, M.; Natarajan, U.; Pazhanivel, B. Effect of moisture absorption on the mechanical properties of randomly oriented natural fibers/polyester hybrid composite. Mater. Sci. Eng. A 2009, 517, 344–353. [Google Scholar] [CrossRef]

- Sangthong, S.; Pongprayoon, T.; Yanumet, N. Mechanical property improvement of unsaturated polyester composite reinforced with admicellar-treated sisal fibers. Compos. Part. A Appl. Sci. Manuf. 2009, 40, 687–694. [Google Scholar] [CrossRef]

- Megiatto, J.D., Jr.; Silva, C.G.; Rosa, D.S.; Frollini, E. Sisal chemically modified with lignins: Correlation between fibers and phenolic composites properties. Polym. Degrad. Stab. 2008, 93, 1109–1121. [Google Scholar] [CrossRef]

- Megiatto, J.D., Jr.; Ramires, E.C.; Frollini, E. Phenolic matrices and sisal fibers modified with hydroxy terminated polybutadiene rubber: Impact strength, water absorption, and morphological aspects of thermosets and composites. Ind. Crop. Prod. 2010, 31, 178–184. [Google Scholar] [CrossRef]

- Ramires, E.C.; Megiatto, J.D., Jr.; Gardrat, C.; Castellan, A.; Frollini, E. Biobased composites from glyoxal–phenolic resins and sisal fibers. Bioresour. Technol. 2010, 101, 1998–2006. [Google Scholar] [CrossRef]

- Athijayamani, A.; Thiruchitrambalam, M.; Natarajan, U.; Pazhanivel, B. Influence of alkali-treated fibers on the mechanical properties and machinability of roselle and sisal fiber hybrid polyester composite. Polym. Compos. 2010, 31, 723–731. [Google Scholar] [CrossRef]

- Chand, N.; Jain, D. Effect of sisal fibre orientation on electrical properties of sisal fibre reinforced epoxy composites. Compos. Part. A Appl. Sci. Manuf. 2005, 36, 594–602. [Google Scholar] [CrossRef]

- Meddahi, A.; Ait Tahar, K.; Bibi, M. Studies of sisal fiber-containing composites. J. Nat. Fibers 2008, 5, 36–46. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Mobasher, B.; Toledo Filho, R.D. Cracking mechanisms in durable sisal fiber reinforced cement composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Santos, S.F.; Joaquim, A.P.; Savastano, H., Jr. Effect of accelerated carbonation on cementitious roofing tiles reinforced with lignocellulosic fibre. Constr. Build. Mater. 2010, 24, 193–201. [Google Scholar] [CrossRef]

- Towo, A.N.; Ansell, M.P. Fatigue of sisal fibre reinforced composites: Constant-life diagrams and hysteresis loop capture. Compos. Sci. Technol. 2008, 68, 915–924. [Google Scholar] [CrossRef]

- Wongsorat, W.; Suppakarn, N.; Jarukumjorn, K. Mechanical Properties, Morphological Properties, and Cure Characteristics of Sisal Fiber/Natural Rubber Composites: Effects of Fiber and Compatibilizer Content. Adv. Mater. Res. 2010, 123, 1171–1174. [Google Scholar]

- de Paula, M.P.; Lacerda, T.M.; Frollini, E. Sisal cellulose acetates obtained from heterogeneous reactions. Express Polym. Lett 2008, 2, 423–428. [Google Scholar] [CrossRef]

- Bakare, I.O.; Okieimen, F.E.; Pavithran, C.; Khalil, H.P.S.A.; Brahmakumar, M. Mechanical and thermal properties of sisal fiber-reinforced rubber seed oil-based polyurethane composites. Mater. Des. 2010, 31, 4274–4280. [Google Scholar] [CrossRef]

- Favaro, S.L.; Ganzerli, T.A.; de Carvalho Neto, A.G.V.; da Silva, O.; Radovanovic, E. Chemical, morphological and mechanical analysis of sisal fiber-reinforced recycled high-density polyethylene composites. Express Polym. Lett. 2010, 4, 465–473. [Google Scholar] [CrossRef]

- Diyana, Z.N.; Jumaidin, R.; Selamat, M.Z.; Ghazali, I.; Julmohammad, N.; Huda, N.; Ilyas, R.A. Physical Properties of Thermoplastic Starch Derived from Natural Resources and Its Blends: A Review. Polymers 2021, 13, 1396. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Sapuan, S.M.; Jawaid, M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syamsir, A. Crashworthiness Response of Filament Wound Kenaf/Glass Fibre-reinforced Epoxy Composite Tubes with Influence of Stacking Sequence under Intermediate-velocity Impact Load. Fibers Polym. 2021, 1–12. [Google Scholar] [CrossRef]

- Kandachar, P.; Brouwer, R. Applications of bio-composites in industrial products. MRS Online Proc. Libr. 2001, 702, 1–12. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Baillie, C.A.; Zafeiropoulos, N.; Mwaikambo, L.Y.; Ansell, M.P.; Dufresne, A.; Entwistle, K.M.; Herrera-Franco, P.J.; Escamilla, G.C.; Groom, L. Current international research into cellulosic fibres and composites. J. Mater. Sci. 2001, 36, 2107–2131. [Google Scholar] [CrossRef]

- Jústiz-Smith, N.G.; Virgo, G.J.; Buchanan, V.E. Potential of Jamaican banana, coconut coir and bagasse fibres as composite materials. Mater. Charact. 2008, 59, 1273–1278. [Google Scholar] [CrossRef]

- Van De Velde, K.; Kiekens, P. Thermal degradation of flax: The determination of kinetic parameters with thermogravimetric analysis. J. Appl. Polym. Sci. 2002, 83, 2634–2643. [Google Scholar] [CrossRef]

- Srinivasan, V.; Rajendra Boopathy, S.; Sangeetha, D.; Vijaya Ramnath, B. Evaluation of mechanical and thermal properties of banana–flax based natural fibre composite. Mater. Des. 2014, 60, 620–627. [Google Scholar] [CrossRef]

- Olusegun, D.S.; Stephen, A.; Adekanye, T.A. Assessing mechanical properties of natural fibre reinforced composites for engineering applications. J. Miner. Mater. Charact. Eng. 2012, 11, 780–784. [Google Scholar]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part. B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Ho, M.; Wang, H.; Lee, J.-H.; Ho, C.; Lau, K.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fibre composites. Compos. Part. B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Sukumaran, K.; Mukherjee, P.S.; Pavithran, C.; Pillai, S.G.K. Natural fibre-polymer composites. Cem. Concr. Compos. 1990, 12, 117–136. [Google Scholar] [CrossRef]

- Brischetto, S. A comparative study of composite structures reinforced with carbon, glass or natural fibers. Multidiscip. Model. Mater. Struct. 2017, 17, 165–187. [Google Scholar] [CrossRef]

- Joseph, S.; Sreekala, M.S.; Oommen, Z.; Koshy, P.; Thomas, S. A comparison of the mechanical properties of phenol formaldehyde composites reinforced with banana fibres and glass fibres. Compos. Sci. Technol. 2002, 62, 1857–1868. [Google Scholar] [CrossRef]

- Aziz, S.H.; Ansell, M.P. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 1—Polyester resin matrix. Compos. Sci. Technol. 2004, 64, 1219–1230. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Effect of water absorption on the mechanical properties of n-SiC filled recycled cellulose fibre reinforced epoxy eco-nanocomposites. Polym. Test. 2012, 31, 810–818. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Mechanical properties and water absorption behaviour of recycled cellulose fibre reinforced epoxy composites. Polym. Test. 2012, 31, 620–628. [Google Scholar] [CrossRef]

- Dittenber, D.B.; Gangarao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part. A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Press forming of short natural fiber-reinforced biodegradable resin: Effects of fiber volume and length on flexural properties. Polym. Test. 2005, 24, 1005–1011. [Google Scholar] [CrossRef]

- Pothan, L.A.; Thomas, S.; Neelakantan, N.R. Short banana fiber reinforced polyester composites: Mechanical, failure and aging characteristics. J. Reinf. Plast. Compos. 1997, 16, 744–765. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Bose, N.R. Impact fatigue behaviour of vinylester resin matrix composites reinforced with alkali treated jute fibres. Compos. Part. A Appl. Sci. Manuf. 2002, 33, 233–241. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Laxmana Naik, L.; Gopalakrishna, K.; Yogesh, B. Studies on mechanical properties of banana/e-glass fabrics reinforced polyester hybrid composites. J. Mater. Environ. Sci. 2016, 7, 3179–3192. [Google Scholar]

- Zampaloni, M.; Pourboghrat, F.; Yankovich, S.A.; Rodgers, B.N.; Moore, J.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Kenaf natural fiber reinforced polypropylene composites: A discussion on manufacturing problems and solutions. Compos. Part. A Appl. Sci. Manuf. 2007, 38, 1569–1580. [Google Scholar] [CrossRef]

- Magurno, A. Vegetable fibres in automotive interior components. Die Angew. Makromol. Chem. 1999, 272, 99–107. [Google Scholar] [CrossRef]

- Schuh, T.G. Renewable Materials for Automotive Applications; Daimler-Chrysler, A., Ed.; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Wahab, M.; Sapuan, S.M.; Harussani, M.M.; Zuhri, M.Y.M.; Saleh, A.A. Conceptual Design of Glass/Renewable Natural Fibre-Reinforced Polymer Hybrid Composite Motorcycle Side Cover. J. Renew. Mater. 2021, 9, 1973–1989. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Sathish, S.; Gokulkumar, S.; Karthi, N.; Rajeshkumar, L.; Balaji, D.; Vigneshkumar, N.; Elango, K.S. A review on natural fiber reinforced hybrid composites: Chemical treatments, manufacturing methods and potential applications. Mater. Today Proc. 2021, 45, 8080–8085. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part. A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Yu, H.N.; Kim, S.S.; Hwang, I.U. Application of natural fiber reinforced composites to trenchless rehabilitation of underground pipes. Compos. Struct. 2008, 86, 285–290. [Google Scholar] [CrossRef]