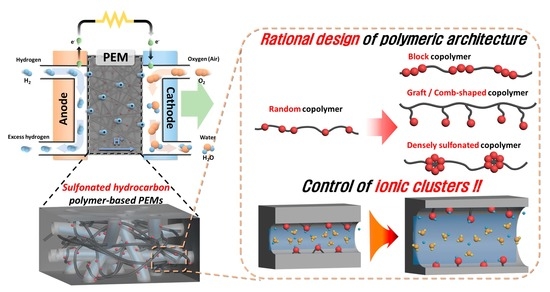

Study on Control of Polymeric Architecture of Sulfonated Hydrocarbon-Based Polymers for High-Performance Polymer Electrolyte Membranes in Fuel Cell Applications

Abstract

:1. Introduction

2. Structural Engineering of Sulfonated Hydrocarbon Polymers for PEMFC Applications

2.1. Block Copolymer-Based PEMs

2.2. Graft/Comb-Shaped Copolymer-Based PEMs

2.3. Densely Sulfonated Copolymer-Based PEMs

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vijayalekshmi, V.; Khastgir, D. Eco-friendly methanesulfonic acid and sodium salt of dodecylbenzene sulfonic acid doped cross-linked chitosan based green polymer electrolyte membranes for fuel cell applications. J. Membr. Sci. 2017, 523, 45–59. [Google Scholar] [CrossRef]

- Mitra, M. A study on advances in hydrogen fuel cells. Elect. Eng. Open A Open J. 2019, 1, 1–4. [Google Scholar]

- Férriz, A.M.; Bernad, A.; Mori, M.; Fiorot, S. End-of-life of fuel cell and hydrogen products: A state of the art. Int. J. Hydrog. Energy 2019, 44, 12872–12879. [Google Scholar] [CrossRef]

- UNFCCC, V. Adoption of the Paris Agreement. I: Proposal by the President (Draft Decision); United Nations Office: Geneva, Switzerland, 2015. [Google Scholar]

- Carrette, L.; Friedrich, K.; Stimming, U. Fuel cells-fundamentals and applications. Fuel Cells 2001, 1, 5–39. [Google Scholar] [CrossRef]

- Scofield, M.E.; Liu, H.; Wong, S.S. A concise guide to sustainable PEMFCs: Recent advances in improving both oxygen reduction catalysts and proton exchange membranes. Chem. Soc. Rev. 2015, 44, 5836–5860. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mekhilef, S.; Saidur, R.; Safari, A. Comparative study of different fuel cell technologies. Renew. Sustain. Energy Rev. 2012, 16, 981–989. [Google Scholar] [CrossRef]

- Song, C. Fuel processing for low-temperature and high-temperature fuel cells: Challenges, and opportunities for sustainable development in the 21st century. Catal. Today 2002, 77, 17–49. [Google Scholar] [CrossRef]

- Hickner, M.A.; Ghassemi, H.; Kim, Y.S.; Einsla, B.R.; McGrath, J.E. Alternative polymer systems for proton exchange membranes (PEMs). Chem. Rev. 2004, 104, 4587–4612. [Google Scholar] [CrossRef] [PubMed]

- Smitha, B.; Sridhar, S.; Khan, A. Solid polymer electrolyte membranes for fuel cell applications—A review. J. Membr. Sci. 2005, 259, 10–26. [Google Scholar] [CrossRef]

- Kim, K.; Bae, J.; Lim, M.-Y.; Heo, P.; Choi, S.-W.; Kwon, H.-H.; Lee, J.-C. Enhanced physical stability and chemical durability of sulfonated poly(arylene ether sulfone) composite membranes having antioxidant grafted graphene oxide for polymer electrolyte membrane fuel cell applications. J. Membr. Sci. 2017, 525, 125–134. [Google Scholar] [CrossRef]

- Lee, K.H.; Chu, J.Y.; Mohanraj, V.; Kim, A.R.; Song, M.H.; Yoo, D.J. Enhanced ion conductivity of sulfonated poly(arylene ether sulfone) block copolymers linked by aliphatic chains constructing wide-range ion cluster for proton conducting electrolytes. Int. J. Hydrog. Energy 2020, 45, 29297–29307. [Google Scholar] [CrossRef]

- Sharma, P.P.; Tinh, V.D.C.; Kim, D. Enhanced Ion Cluster Size of Sulfonated Poly(Arylene Ether Sulfone) for Proton Exchange Membrane Fuel Cell Application. Polymers 2021, 13, 1111. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Zhang, Z.; Ran, J.; Zhou, D.; Li, C.; Xu, T. Advances in proton-exchange membranes for fuel cells: An overview on proton conductive channels (PCCs). Phys. Chem. Chem. Phys. 2013, 15, 4870–4887. [Google Scholar] [CrossRef] [PubMed]

- De Haro, J.C.; Tatsi, E.; Fagiolari, L.; Bonomo, M.; Barolo, C.; Turri, S.; Bella, F.; Griffini, G. Lignin-Based Polymer Electrolyte Membranes for Sustainable Aqueous Dye-Sensitized Solar Cells. ACS Sustain. Chem. Eng. 2021, 9, 8550–8560. [Google Scholar] [CrossRef]

- Rahman, N.A.; Hanifah, S.A.; Mobarak, N.N.; Ahmad, A.; Ludin, N.A.; Bella, F.; Su’ait, M.S. Chitosan as a paradigm for biopolymer electrolytes in solid-state dye-sensitised solar cells. Polymer 2021, 230, 124092. [Google Scholar] [CrossRef]

- Galliano, S.; Bella, F.; Bonomo, M.; Viscardi, G.; Gerbaldi, C.; Boschloo, G.; Barolo, C. Hydrogel electrolytes based on xanthan gum: Green route towards stable dye-sensitized solar cells. Nanomaterials 2020, 10, 1585. [Google Scholar] [CrossRef] [PubMed]

- Nakazawa, S.; Matsuda, Y.; Ochiai, M.; Inafune, Y.; Yamato, M.; Tanaka, M.; Kawakami, H. Enhancing Lithium ion conductivity and all-solid-state secondary battery performance in polymer composite electrolyte membranes with β-Crystalline-rich Poly(vinylidene fluoride) Nanofibers. Electrochim. Acta 2021, 394, 139114. [Google Scholar] [CrossRef]

- Jiang, H.; Wu, Y.; Ma, J.; Liu, Y.; Wang, L.; Yao, X.; Xiang, H. Ultrathin polymer-in-ceramic and ceramic-in-polymer bilayer composite solid electrolyte membrane for high-voltage lithium metal batteries. J. Membr. Sci. 2021, 640, 119840. [Google Scholar] [CrossRef]

- Amici, J.; Torchio, C.; Versaci, D.; Dessantis, D.; Marchisio, A.; Caldera, F.; Bella, F.; Francia, C.; Bodoardo, S. Nanosponge-Based Composite Gel Polymer Electrolyte for Safer Li-O2 Batteries. Polymers 2021, 13, 1625. [Google Scholar] [CrossRef] [PubMed]

- Piana, G.; Ricciardi, M.; Bella, F.; Cucciniello, R.; Proto, A.; Gerbaldi, C. Poly(glycidyl ether)s recycling from industrial waste and feasibility study of reuse as electrolytes in sodium-based batteries. Chem. Eng. J. 2020, 382, 122934. [Google Scholar] [CrossRef]

- Piana, G.; Bella, F.; Geobaldo, F.; Meligrana, G.; Gerbaldi, C.J. PEO/LAGP hybrid solid polymer electrolytes for ambient temperature lithium batteries by solvent-free,“one pot” preparation. J. Energy Storage 2019, 26, 100947. [Google Scholar] [CrossRef]

- Liang, M.; Fu, C.; Xiao, B.; Luo, L.; Wang, Z. A fractal study for the effective electrolyte diffusion through charged porous media. Int. J. Heat Mass Transf. 2019, 137, 365–371. [Google Scholar] [CrossRef]

- Liang, M.; Liu, Y.; Xiao, B.; Yang, S.; Wang, Z.; Han, H. An analytical model for the transverse permeability of gas diffusion layer with electrical double layer effects in proton exchange membrane fuel cells. Int. J. Hydrog. Energy 2018, 43, 17880–17888. [Google Scholar] [CrossRef]

- Redmond, E.L.; Maruyama, M.; Liu, W.K.; Cleghorn, S. Advancement of Thin, Reinforced Membranes for High-Performing, Long-Lasting Proton Exchange Membrane Fuel Cells. In Proceedings of the AiMES 2018 Meeting, Cancun, Mexico, 30 September–4 October 2018; p. 1455. [Google Scholar]

- Energies, B. Encyclopedia of Inorganic Chemistry; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; p. 3. [Google Scholar]

- Zhang, Y.; Li, J.; Ma, L.; Cai, W.; Cheng, H. Recent developments on alternative proton exchange membranes: Strategies for systematic performance improvement. Energy Technol. 2015, 3, 675–691. [Google Scholar] [CrossRef]

- Akbarian-Feizi, L.; Mehdipour-Ataei, S.; Yeganeh, H. Survey of sulfonated polyimide membrane as a good candidate for nafion substitution in fuel cell. Int. J. Hydrog. Energy 2010, 35, 9385–9397. [Google Scholar] [CrossRef]

- Adjemian, K.; Lee, S.; Srinivasan, S.; Benziger, J.; Bocarsly, A.B. Silicon oxide nafion composite membranes for proton-exchange membrane fuel cell operation at 80–140 °C. J. Electrochem. Soc. 2002, 149, A256. [Google Scholar] [CrossRef]

- Kim, K.; Choi, S.-W.; Park, J.O.; Kim, S.-K.; Lim, M.-Y.; Kim, K.-H.; Ko, T.; Lee, J.-C. Proton conductive cross-linked benzoxazine-benzimidazole copolymers as novel porous substrates for reinforced pore-filling membranes in fuel cells operating at high temperatures. J. Membr. Sci. 2017, 536, 76–85. [Google Scholar]

- Kim, J.; Kim, K.; Han, J.; Lee, H.; Kim, H.; Kim, S.; Sung, Y.E.; Lee, J.C. End-group cross-linked membranes based on highly sulfonated poly(arylene ether sulfone) with vinyl functionalized graphene oxide as a cross-linker and a filler for proton exchange membrane fuel cell application. J. Polym. Sci. 2020, 58, 3456–3466. [Google Scholar] [CrossRef]

- Ko, H.; Kim, M.; Nam, S.Y.; Kim, K. Research of cross-linked hydrocarbon based polymer electrolyte membranes for polymer electrolyte membrane fuel cell applications. Membr. J. 2020, 30, 395–408. [Google Scholar] [CrossRef]

- Gross, M.; Maier, G.; Fuller, T.; MacKinnon, S.; Gittleman, C. Design rules for the improvement of the performance of hydrocarbon-based membranes for proton exchange membrane fuel cells (PEMFC). In Handbook of Fuel Cells; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Gubler, L.; Nauser, T.; Coms, F.D.; Lai, Y.-H.; Gittleman, C.S. Perspective—prospects for durable hydrocarbon-based fuel cell membranes. J. Electrochem. Soc. 2018, 165, F3100. [Google Scholar] [CrossRef] [Green Version]

- Byun, G.H.; Kim, J.A.; Kim, N.Y.; Cho, Y.S.; Park, C.R. Molecular engineering of hydrocarbon membrane to substitute perfluorinated sulfonic acid membrane for proton exchange membrane fuel cell operation. Mater. Today Energy 2020, 17, 100483. [Google Scholar] [CrossRef]

- Shin, D.W.; Lee, S.Y.; Lee, C.H.; Lee, K.-S.; Park, C.H.; McGrath, J.E.; Zhang, M.; Moore, R.B.; Lingwood, M.D.; Madsen, L.A. Sulfonated poly(arylene sulfide sulfone nitrile) multiblock copolymers with ordered morphology for proton exchange membranes. Macromolecules 2013, 46, 7797–7804. [Google Scholar] [CrossRef]

- Oh, K.; Ketpang, K.; Kim, H.; Shanmugam, S. Synthesis of sulfonated poly(arylene ether ketone) block copolymers for proton exchange membrane fuel cells. J. Membr. Sci. 2016, 507, 135–142. [Google Scholar] [CrossRef]

- Han, J.; Kim, K.; Kim, J.; Kim, S.; Choi, S.-W.; Lee, H.; Kim, J.-j.; Kim, T.-H.; Sung, Y.-E.; Lee, J.-C. Cross-linked highly sulfonated poly(arylene ether sulfone) membranes prepared by in-situ casting and thiol-ene click reaction for fuel cell application. J. Membr. Sci. 2019, 579, 70–78. [Google Scholar] [CrossRef]

- Kim, K.; Heo, P.; Han, J.; Kim, J.; Lee, J.-C. End-group cross-linked sulfonated poly(arylene ether sulfone) via thiol-ene click reaction for high-performance proton exchange membrane. J. Power Sources 2018, 401, 20–28. [Google Scholar] [CrossRef]

- Kim, K.; Heo, P.; Hwang, W.; Baik, J.-H.; Sung, Y.-E.; Lee, J.-C. Cross-linked sulfonated poly(arylene ether sulfone) containing a flexible and hydrophobic bishydroxy perfluoropolyether cross-linker for high-performance proton exchange membrane. ACS Appl. Mater. Interfaces 2018, 10, 21788–21793. [Google Scholar] [CrossRef]

- Kim, K.; Kim, S.-K.; Park, J.O.; Choi, S.-W.; Kim, K.-H.; Ko, T.; Pak, C.; Lee, J.-C. Highly reinforced pore-filling membranes based on sulfonated poly(arylene ether sulfone)s for high-temperature/low-humidity polymer electrolyte membrane fuel cells. J. Membr. Sci. 2017, 537, 11–21. [Google Scholar] [CrossRef]

- Kim, K.; Heo, P.; Ko, T.; Kim, K.-H.; Kim, S.-K.; Pak, C.; Lee, J.-C. Poly(arlyene ether sulfone) based semi-interpenetrating polymer network membranes containing cross-linked poly(vinyl phosphonic acid) chains for fuel cell applications at high temperature and low humidity conditions. J. Power Sources 2015, 293, 539–547. [Google Scholar] [CrossRef]

- Park, J.E.; Kim, J.; Han, J.; Kim, K.; Park, S.; Kim, S.; Park, H.S.; Cho, Y.-H.; Lee, J.-C.; Sung, Y.-E. High-performance proton-exchange membrane water electrolysis using a sulfonated poly(arylene ether sulfone) membrane and ionomer. J. Membr. Sci. 2021, 620, 118871. [Google Scholar] [CrossRef]

- Han, J.; Kim, K.; Kim, S.; Lee, H.; Kim, J.; Ko, T.; Bae, J.; Choi, W.J.; Sung, Y.-E.; Lee, J.-C. Cross-linked sulfonated poly(ether ether ketone) membranes formed by poly(2, 5-benzimidazole)-grafted graphene oxide as a novel cross-linker for direct methanol fuel cell applications. J. Power Sources 2020, 448, 227427. [Google Scholar] [CrossRef]

- Şengül, E.; Erdener, H.; Akay, R.G.; Yücel, H.; Bac, N.; Eroğlu, İ. Effects of sulfonated polyether-etherketone (SPEEK) and composite membranes on the proton exchange membrane fuel cell (PEMFC) performance. Int. J. Hydrog. Energy 2009, 34, 4645–4652. [Google Scholar] [CrossRef]

- Asano, N.; Aoki, M.; Suzuki, S.; Miyatake, K.; Uchida, H.; Watanabe, M. Aliphatic/aromatic polyimide ionomers as a proton conductive membrane for fuel cell applications. J. Am. Chem. Soc. 2006, 128, 1762–1769. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Shen, P.K. Advances in the high performance polymer electrolyte membranes for fuel cells. Chem. Soc. Rev. 2012, 41, 2382–2394. [Google Scholar] [CrossRef]

- Ko, T.; Kim, K.; Kim, S.-K.; Lee, J.-C. Organic/inorganic composite membranes comprising of sulfonated Poly(arylene ether sulfone) and core–shell silica particles having acidic and basic polymer shells. Polymer 2015, 71, 70–81. [Google Scholar] [CrossRef]

- Kim, K.; Jung, B.-K.; Ko, T.; Kim, T.-H.; Lee, J.-C. Comb-shaped polysulfones containing sulfonated polytriazole side chains for proton exchange membranes. J. Membr. Sci. 2018, 554, 232–243. [Google Scholar] [CrossRef]

- Robertson, G.P.; Mikhailenko, S.D.; Wang, K.; Xing, P.; Guiver, M.D.; Kaliaguine, S. Casting solvent interactions with sulfonated poly(ether ether ketone) during proton exchange membrane fabrication. J. Membr. Sci. 2003, 219, 113–121. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.-S.; Lane, O.; McGrath, J.E. Development of multiblock copolymers with novel hydroquinone-based hydrophilic blocks for proton exchange membrane (PEM) applications. J. Power Sources 2010, 195, 1772–1778. [Google Scholar] [CrossRef]

- Miyatake, K.; Hay, A.S. Synthesis and properties of poly(arylene ether)s bearing sulfonic acid groups on pendant phenyl rings. J. Polym. Sci. A Polym. Chem. 2001, 39, 3211–3217. [Google Scholar] [CrossRef]

- Ko, T.; Kim, K.; Jung, B.-K.; Cha, S.-H.; Kim, S.-K.; Lee, J.-C. Cross-linked sulfonated poly(arylene ether sulfone) membranes formed by in situ casting and click reaction for applications in fuel cells. Macromolecules 2015, 48, 1104–1114. [Google Scholar] [CrossRef]

- Liu, D.; Xie, Y.; Cui, N.; Han, X.; Zhang, J.; Pang, J.; Jiang, Z. Structure and properties of sulfonated poly(arylene ether)s with densely sulfonated segments containing mono-, di-and tri-tetraphenylmethane as proton exchange membrane. J. Membr. Sci. 2021, 620, 118856. [Google Scholar] [CrossRef]

- Lee, K.H.; Chu, J.Y.; Kim, A.R.; Yoo, D.J. Enhanced performance of a sulfonated poly(arylene ether ketone) block copolymer bearing pendant sulfonic acid groups for polymer electrolyte membrane fuel cells operating at 80% relative humidity. ACS Appl. Mater. Interfaces 2018, 10, 20835–20844. [Google Scholar] [CrossRef]

- Kang, K.; Kim, D. Pendant dual-sulfonated poly(arylene ether ketone) multi-block copolymer membranes for enhanced proton conductivity at reduced water swelling. J. Membr. Sci. 2019, 578, 103–110. [Google Scholar] [CrossRef]

- Endoh, E. Highly durable PFSA membranes. In Handbook of Fuel Cells; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2010. [Google Scholar]

- Higashihara, T.; Matsumoto, K.; Ueda, M. Sulfonated aromatic hydrocarbon polymers as proton exchange membranes for fuel cells. Polymers 2009, 50, 5341–5357. [Google Scholar] [CrossRef] [Green Version]

- Devanathan, R. Recent developments in proton exchange membranes for fuel cells. Energy Environ. Sci. 2008, 1, 101–119. [Google Scholar] [CrossRef]

- Tsang, E.M.W.; Shi, Z.; Holdcroft, S. Ionic purity and connectivity of proton-conducting channels in fluorous-ionic diblock copolymers. Macromolecules 2011, 44, 8845–8857. [Google Scholar] [CrossRef]

- Tsang, E.M.; Zhang, Z.; Shi, Z.; Soboleva, T.; Holdcroft, S. Considerations of macromolecular structure in the design of proton conducting polymer membranes: Graft versus diblock polyelectrolytes. J. Am. Chem. Soc. 2007, 129, 15106–15107. [Google Scholar] [CrossRef]

- Elabd, Y.A.; Hickner, M.A. Block copolymers for fuel cells. Macromolecules 2011, 44, 1–11. [Google Scholar] [CrossRef]

- Li, N.; Lee, S.Y.; Liu, Y.-L.; Lee, Y.M.; Guiver, M.D. A new class of highly-conducting polymer electrolyte membranes: Aromatic ABA triblock copolymers. Energy Environ. Sci. 2012, 5, 5346–5355. [Google Scholar] [CrossRef] [Green Version]

- Badami, A.S.; Lane, O.; Lee, H.-S.; Roy, A.; McGrath, J.E. Fundamental investigations of the effect of the linkage group on the behavior of hydrophilic–hydrophobic poly(arylene ether sulfone) multiblock copolymers for proton exchange membrane fuel cells. J. Membr. Sci. 2009, 333, 1–11. [Google Scholar] [CrossRef]

- Li, N.; Guiver, M.D. Ion transport by nanochannels in ion-containing aromatic copolymers. Macromolecules 2014, 47, 2175–2198. [Google Scholar] [CrossRef] [Green Version]

- Shin, D.W.; Guiver, M.D.; Lee, Y.M. Hydrocarbon-based polymer electrolyte membranes: Importance of morphology on ion transport and membrane stability. Chem. Rev. 2017, 117, 4759–4805. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Ann, J.; Lee, H.; Kim, J.-H.; Kim, C.-S.; Yang, T.-H.; Bae, B. Synthesis and characterization of crosslink-free highly sulfonated multi-block poly(arylene ether sulfone) multi-block membranes for fuel cells. J. Mater. Chem. A 2015, 3, 1833–1836. [Google Scholar] [CrossRef]

- Lee, H.-S.; Roy, A.; Badami, A.S.; McGrath, J.E. Synthesis and characterization of sulfonated poly(arylene ether) polyimide multiblock copolymers for proton exchange membranes. Macromol. Res. 2007, 15, 160–166. [Google Scholar] [CrossRef]

- Einsla, M.L.; Kim, Y.S.; Hawley, M.; Lee, H.-S.; McGrath, J.E.; Liu, B.; Guiver, M.D.; Pivovar, B.S. Toward improved conductivity of sulfonated aromatic proton exchange membranes at low relative humidity. Chem. Mater. 2008, 20, 5636–5642. [Google Scholar] [CrossRef] [Green Version]

- Dimitrov, I.; Takamuku, S.; Jankova, K.; Jannasch, P.; Hvilsted, S. Polysulfone functionalized with phosphonated poly(pentafluorostyrene) grafts for potential fuel cell applications. Macromol. Rapid Commun. 2012, 33, 1368–1374. [Google Scholar] [CrossRef] [PubMed]

- Dimitrov, I.; Takamuku, S.; Jankova, K.; Jannasch, P.; Hvilsted, S. Proton conducting graft copolymers with tunable length and density of phosphonated side chains for fuel cell membranes. J. Membr. Sci. 2014, 450, 362–368. [Google Scholar] [CrossRef]

- Hickner, M.; Pivovar, B. The chemical and structural nature of proton exchange membrane fuel cell properties. Fuel Cells 2005, 5, 213–229. [Google Scholar] [CrossRef]

- Norsten, T.B.; Guiver, M.D.; Murphy, J.; Astill, T.; Navessin, T.; Holdcroft, S.; Frankamp, B.L.; Rotello, V.M.; Ding, J. Highly fluorinated comb-shaped copolymers as proton exchange membranes (PEMs): Improving PEM properties through rational design. Adv. Funct. Mater. 2006, 16, 1814–1822. [Google Scholar] [CrossRef] [Green Version]

- Xing, P.; Robertson, G.P.; Guiver, M.D.; Mikhailenko, S.D.; Kaliaguine, S. Sulfonated poly(aryl ether ketone)s containing the hexafluoroisopropylidene diphenyl moiety prepared by direct copolymerization, as proton exchange membranes for fuel cell application. Macromolecules 2004, 37, 7960–7967. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.S.; Kim, Y.S.; Guiver, M.D.; Ding, J.; Pivovar, B.S. Highly fluorinated comb-shaped copolymer as proton exchange membranes (PEMs): Fuel cell performance. J. Power Sources 2008, 182, 100–105. [Google Scholar] [CrossRef] [Green Version]

- Iojoiu, C.; Chabert, F.; Maréchal, M.; Kissi, N.E.; Guindet, J.; Sanchez, J.-Y. From polymer chemistry to membrane elaboration: A global approach of fuel cell polymeric electrolytes. J. Power Sources 2006, 153, 198–209. [Google Scholar] [CrossRef]

- Olsson, J.S.; Pham, T.H.; Jannasch, P. Functionalizing Polystyrene with N-Alicyclic Piperidine-Based Cations via Friedel–Crafts Alkylation for Highly Alkali-Stable Anion-Exchange Membranes. Macromolecules 2020, 53, 4722–4732. [Google Scholar] [CrossRef] [PubMed]

- Qiao, X.; Wang, X.; Liu, S.; Shen, Y.; Li, N. The alkaline stability and fuel cell performance of poly(N-spirocyclic quaternary ammonium) ionenes as anion exchange membrane. J. Membr. Sci. 2021, 630, 119325. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, C.H.; Guiver, M.D.; Lee, Y.M. Sulfonated hydrocarbon membranes for medium-temperature and low-humidity proton exchange membrane fuel cells (PEMFCs). Prog. Polym. Sci. 2011, 36, 1443–1498. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Wang, C.; Lee, S.Y.; Park, C.H.; Lee, Y.M.; Guiver, M.D. Enhancement of Proton Transport by Nanochannels in Comb-Shaped Copoly(arylene ether sulfone)s. Angew. Chem. 2011, 123, 9324–9327. [Google Scholar] [CrossRef]

- Han, J.; Lee, H.; Kim, J.; Kim, S.; Kim, H.; Kim, E.; Sung, Y.-E.; Kim, K.; Lee, J.-C. Sulfonated poly(arylene ether sulfone) composite membrane having sulfonated polytriazole grafted graphene oxide for high-performance proton exchange membrane fuel cells. J. Membr. Sci. 2020, 612, 118428. [Google Scholar] [CrossRef]

- Chang, Y.; Mohanty, A.D.; Smedley, S.B.; Abu-Hakmeh, K.; Lee, Y.H.; Morgan, J.E.; Hickner, M.A.; Jang, S.S.; Ryu, C.Y.; Bae, C. Effect of superacidic side chain structures on high conductivity aromatic polymer fuel cell membranes. Macromolecules 2015, 48, 7117–7126. [Google Scholar] [CrossRef]

- Liu, Y.-L. Developments of highly proton-conductive sulfonated polymers for proton exchange membrane fuel cells. Polym. Chem. 2012, 3, 1373–1383. [Google Scholar] [CrossRef]

- Wang, C.; Li, N.; Shin, D.W.; Lee, S.Y.; Kang, N.R.; Lee, Y.M.; Guiver, M.D. Fluorene-based poly(arylene ether sulfone)s containing clustered flexible pendant sulfonic acids as proton exchange membranes. Macromolecules 2011, 44, 7296–7306. [Google Scholar] [CrossRef] [Green Version]

- Han, X.; Pang, J.; Liu, D.; Zhang, H.; Jiang, Z. Novel branched sulfonated poly(arylene ether)s based on carbazole derivative for proton exchange membrane. Int. J. Hydrog. Energy 2020, 45, 4644–4652. [Google Scholar] [CrossRef]

- Han, X.; Xie, Y.; Liu, D.; Chen, Z.; Zhang, H.; Pang, J.; Jiang, Z. Synthesis and properties of novel poly(arylene ether)s with densely sulfonated units based on carbazole derivative. J. Membr. Sci. 2019, 589, 117230. [Google Scholar] [CrossRef]

- Long, Z.; Miyake, J.; Miyatake, K. Proton exchange membranes containing densely sulfonated quinquephenylene groups for high performance and durable fuel cells. J. Mater. Chem. A 2020, 8, 12134–12140. [Google Scholar] [CrossRef]

- Huang, T.-S.; Hsieh, T.-L.; Lai, C.-C.; Wen, H.-Y.; Huang, W.-Y.; Chang, M.-Y. Highly Proton-Conducting Membranes Based on Poly(arylene ether)s with Densely Sulfonated and Partially Fluorinated Multiphenyl for Fuel Cell Applications. Membranes 2021, 11, 626. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Chen, S.; Chen, D.; Ye, Z. Sulfonated binaphthyl-containing poly(arylene ether ketone)s with rigid backbone and excellent film-forming capability for proton exchange membranes. Polymers 2018, 10, 1287. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bae, B.; Miyatake, K.; Watanabe, M. Sulfonated poly(arylene ether sulfone ketone) multiblock copolymers with highly sulfonated block. Synthesis and properties. Macromolecules 2010, 43, 2684–2691. [Google Scholar] [CrossRef]

- Li, N.; Hwang, D.S.; Lee, S.Y.; Liu, Y.-L.; Lee, Y.M.; Guiver, M.D. Densely sulfophenylated segmented copoly(arylene ether sulfone) proton exchange membranes. Macromolecules 2011, 44, 4901–4910. [Google Scholar] [CrossRef] [Green Version]

- Matsumura, S.; Hlil, A.R.; Lepiller, C.; Gaudet, J.; Guay, D.; Hay, A.S. Ionomers for proton exchange membrane fuel cells with sulfonic acid groups on the end groups: Novel linear aromatic poly(sulfide−ketone)s. Macromolecules 2008, 41, 277–280. [Google Scholar] [CrossRef]

- Matsumura, S.; Hlil, A.R.; Du, N.; Lepiller, C.; Gaudet, J.; Guay, D.; Shi, Z.; Holdcroft, S.; Hay, A.S. Ionomers for proton exchange membrane fuel cells with sulfonic acid groups on the end-groups: Novel branched poly(ether-ketone)s with 3,6-ditrityl-9H-carbazole end-groups. J. Polym. Sci. A Polym. Chem. 2008, 46, 3860–3868. [Google Scholar] [CrossRef]

- Matsumura, S.; Hlil, A.R.; Lepiller, C.; Gaudet, J.; Guay, D.; Shi, Z.; Holdcroft, S.; Hay, A.S. Ionomers for proton exchange membrane fuel cells with sulfonic acid groups on the end groups: Novel branched poly(ether−ketone)s. Macromolecules 2008, 41, 281–284. [Google Scholar] [CrossRef]

- Matsumoto, K.; Higashihara, T.; Ueda, M. Locally and densely sulfonated poly(ether sulfone)s as proton exchange membrane. Macromolecules 2009, 42, 1161–1166. [Google Scholar] [CrossRef]

- Matsumoto, K.; Higashihara, T.; Ueda, M. Locally sulfonated poly(ether sulfone)s with highly sulfonated units as proton exchange membrane. J. Polym. Sci. A Polym. Chem. 2009, 47, 3444–3453. [Google Scholar] [CrossRef]

- Chang, Y.; Brunello, G.F.; Fuller, J.; Hawley, M.; Kim, Y.S.; Disabb-Miller, M.; Hickner, M.A.; Jang, S.S.; Bae, C. Aromatic ionomers with highly acidic sulfonate groups: Acidity, hydration, and proton conductivity. Macromolecules 2011, 44, 8458–8469. [Google Scholar] [CrossRef]

- Eikerling, M.; Paddison, S.; Zawodzinski, T. Molecular orbital calculations of proton dissociation and hydration of various acidic moieties for fuel cell polymers. J. New Mater. Electrochem. Syst. 2002, 5, 15–24. [Google Scholar]

- Jo, S.G.; Kim, T.-H.; Yoon, S.J.; Oh, S.-G.; Cha, M.S.; Shin, H.Y.; Ahn, J.M.; Lee, J.Y.; Hong, Y.T. Synthesis and investigation of random-structured ionomers with highly sulfonated multi-phenyl pendants for electrochemical applications. J. Membr. Sci. 2016, 510, 326–337. [Google Scholar] [CrossRef]

| AFC | MCFC | SOFC | PEMFC | |

|---|---|---|---|---|

| Electrolyte | Aqueous solution of potassium hydroxide soaked in a matrix | Liquid solution of lithium, sodium and/or potassium carbonates, soaked in a matrix | Yttria stabilized zirconie | Solid organic polymer, poly-perfluorosulfonic acid |

| Fuel | Pure H2 | H2, CO, CH4, other | H2, CO, CH4, other | Pure H2 |

| Charge carrier | OH− | CO32− | O2− | H+ |

| Operating temperature | 90–100 °C | 600–700 °C | 600–1000 °C | 50–100 °C |

| Efficiency | 60% | 45–47% | 35–43% | 53–58% |

| Application | Military, Space | Electric utility, Large distributed generation | Auxiliary power, Electric utility, Large distributed generation | Backup power, Portable power, Small distributed generation, Transportation |

| Polymer | Structure |

|---|---|

| SPAES a |  |

| SPEEK b |  |

| SPPO c |  |

| SPI d |  |

| Sample | IEC (meq g−1) | Water Uptake | Proton Conductivity | References | |||

|---|---|---|---|---|---|---|---|

| Value (%) | Conditions (°C, % RH) | Value (mS cm−1) | Conditions (°C, % RH) | ||||

| SP3O-b-PAES-b-SP3O | X100 | 0.97 | 47.4 | 20, 100 | 9 | 90, 30 | [63] |

| SPAE100-BPS0-HFB | 5k–5k | 1.30 | 35 | rt, 100 | 50 | 30, 100 | [64] |

| 10k–10k | 1.38 | 68 | 100 | ||||

| 15k–15k | 1.40 | 79 | 110 | ||||

| SPAE100-BPS0-DFBP | 10k–5k | 1.83 | 100 | 160 | |||

| 15k–10k | 1.71 | 90 | 140 | ||||

| Block-SPAES | X10Y10 | 2.90 | 390 | rt, 100 | 480 | 80, 90 | [67] |

| BPSH-x-PI-x | 5–5 | 1.65 | 59 | rt, 100 | 80 | 30, 100 | [68] |

| 15–15 | 1.55 | 85 | 100 | ||||

| 20–20 | 1.22 | 57 | 100 | ||||

| Sample | IEC (meq g−1) | Water Uptake | Proton Conductivity | References | |||

|---|---|---|---|---|---|---|---|

| Value (%) | Conditions (°C, % RH) | Value (mS cm−1) | Conditions (°C, % RH) | ||||

| Mac-x | 1a | 0.87 | 20–25 | 80, 100 | 150 | 80–85, 100 | [73] |

| 2a | 1.40 | 45 | 430–450 | ||||

| 3a | 1.75 | 105 | 570–580 | ||||

| SPPO | X5-Y6 | 0.92 | 28.2 | rt, 100 | 150 | rt, 100 | [80] |

| X5-Y9 | 1.28 | 52.3 | 190 | ||||

| X3-Y14 | 1.26 | 60.5 | 140 | ||||

| X5-Y14 | 1.27 | 75.6 | 210 | ||||

| Comb-X | 3 | 1.81 | 47.4 | 30, 100 | 195 | 80, 90 | [49] |

| 7 | 2.06 | 107.1 | 213 | ||||

| PSU-R | S1 | 1.83 | 24 | 30, 98 | 8 | 100, 50 | [82] |

| S4 | 1.96 | 29 | 10 | ||||

| S5 | 1.99 | 29 | 3 | ||||

| S6 | 2.23 | 37 | 20 | ||||

| Sample | IEC (meq g−1) | Water Uptake | Proton Conductivity | References | |||

|---|---|---|---|---|---|---|---|

| Value (%) | Conditions (°C, % RH) | Value (%) | Conditions (°C, % RH) | ||||

| 6x-SO3H | b | 0.48 | 8.3 | rt, 100 | 6.9 | rt, 100 | [92] |

| c | 0.47 | 7.8 | 3.7 | ||||

| X-SO3H | 18 | 1.09 | 43 | rt, 100 | 91 | rt, 100 | [93,94] |

| 24 | 1.25 | 52 | 95 | ||||

| 8-SPES | 17:83 | 1.80 | 25 | 80, 95 | 4–5 | 80, 50 | [95,96] |

| 20:80 | 2.03 | 55 | 20–23 | ||||

| 2.4 | soluble | - | - | - | |||

| 10-SPES | 13:87 | 1.96 | 40–43 | 10 | |||

| 15:85 | 2.21 | 50–53 | 15–20 | ||||

| SPPFPB-o | 5.5 | 2.58 | 71 | rt, 100 | 258 | 70, 100 | [99] |

| 8.0 | 2.08 | 48 | 170 | ||||

| 13.2 | 1.47 | 27 | 95 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.; Ko, H.; Nam, S.Y.; Kim, K. Study on Control of Polymeric Architecture of Sulfonated Hydrocarbon-Based Polymers for High-Performance Polymer Electrolyte Membranes in Fuel Cell Applications. Polymers 2021, 13, 3520. https://doi.org/10.3390/polym13203520

Kim M, Ko H, Nam SY, Kim K. Study on Control of Polymeric Architecture of Sulfonated Hydrocarbon-Based Polymers for High-Performance Polymer Electrolyte Membranes in Fuel Cell Applications. Polymers. 2021; 13(20):3520. https://doi.org/10.3390/polym13203520

Chicago/Turabian StyleKim, Mijeong, Hansol Ko, Sang Yong Nam, and Kihyun Kim. 2021. "Study on Control of Polymeric Architecture of Sulfonated Hydrocarbon-Based Polymers for High-Performance Polymer Electrolyte Membranes in Fuel Cell Applications" Polymers 13, no. 20: 3520. https://doi.org/10.3390/polym13203520

APA StyleKim, M., Ko, H., Nam, S. Y., & Kim, K. (2021). Study on Control of Polymeric Architecture of Sulfonated Hydrocarbon-Based Polymers for High-Performance Polymer Electrolyte Membranes in Fuel Cell Applications. Polymers, 13(20), 3520. https://doi.org/10.3390/polym13203520