Properties and Application of Edible Modified Bacterial Cellulose Film Based Sago Liquid Waste as Food Packaging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

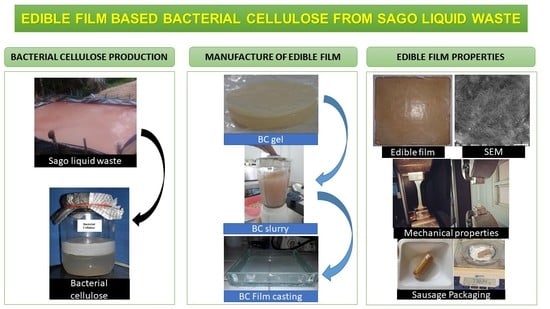

2.2. Production of Bacterial Cellulose

2.3. Production of Edible Film

2.4. Physical Properties

2.4.1. Film Thickness

2.4.2. Water Solubility (WS)

2.4.3. Moisture Content (MC)

2.5. Mechanical Properties Measurement

2.6. Fourier Transformed Infrared (FT-IR) Spectroscopy

2.7. Scanning Electron Microscopy (SEM)

2.8. Application of Edible BC Film

3. Results and Discussions

3.1. Product of Edible Bacterial Cellulose Film Based Sago Liquid Waste

3.2. Physical Properties of Edible Film

3.3. Mechanical Properties of Edible Film

3.4. Chemical Structure Characteristics of Edible Film Using FTIR

3.5. Surface Morphology of Edible BC Film Using SEM

3.6. Application of Edible Film as Food Packaging

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ncube, L.; Ude, A.; Ogunmuyiwa, E.; Zulkifli, R.; Beas, I. An Overview of Plastic Waste Generation and Management in Food Packaging Industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Freeman, S. Plastic food contact articles—food chemical safety unwrapped. Environ. Heal. Rev. 2018, 61, 92–97. [Google Scholar] [CrossRef] [Green Version]

- Yanti, N.A.; Sembiring, L.; Margino, S.; Muhiddin, N.H.; Ahmad, S.W.; Ardiansyah, A. Polyphasic Identification of Amylolytic Bacteria Producing Bioplastic Poly-β-hydroxybutyrate (PHB). Sains Malays. 2019, 48, 2663–2673. [Google Scholar] [CrossRef]

- Yanti, N.A.; Sembiring, L.; Margino, S.; Ahmad, S.W. Bacterial Production of Poly-β-hydroxybutyrate (PHB): Converting Starch into Bioplastics. In Bioplastics for Sustainable Development; Springer: London, UK, 2021; pp. 259–276. [Google Scholar]

- Ludwicka, K.; Kaczmarek, M.; Białkowska, A. Bacterial Nanocellulose—A Biobased Polymer for Active and Intelligent Food Packaging Applications: Recent Advances and Developments. Polymer 2020, 12, 2209. [Google Scholar] [CrossRef]

- Yanti, N.A.; Ahmad, S.W.; Muhiddin, N.H.; Ramadhan, L.O.A.N.; Suriana; Walhidayah, T. Characterization of Bacterial Cellulose Produced by Acetobacter xylinum Strain LKN6 Using Sago Liquid Waste as Nutrient Source. Pak. J. Biol. Sci. 2021, 24, 335–344. [Google Scholar] [CrossRef] [PubMed]

- Lestari, P.; Elfrida, N.; Suryani, A.; Suryadi, Y. Study on the Production of Bacterial Cellulose from Acetobacter Xylinum Using Agro-Waste. Jordan J. Biol. Sci. 2014, 7, 75–80. [Google Scholar] [CrossRef] [Green Version]

- Tsouko, E.; Kourmentza, C.; Ladakis, D.; Kopsahelis, N.; Mandala, I.; Papanikolaou, S.; Paloukis, F.; Alves, V.; Koutinas, A. Bacterial Cellulose Production from Industrial Waste and by-Product Streams. Int. J. Mol. Sci. 2015, 16, 14832–14849. [Google Scholar] [CrossRef] [PubMed]

- Yanti, N.A.; Ahmad, S.W.; Muhiddin, N.H. Evaluation of inoculum size and fermentation period for bacterial cellulose production from sago liquid waste. J. Physics Conf. Ser. 2018, 1116, 052076. [Google Scholar] [CrossRef]

- Yanti, N.A.; Ahmad, S.W.; Ambardini, S.; Muhiddin, N.H.; Sulaiman, L.O.I. Screening of Acetic Acid Bacteria from Pineapple Waste for Bacterial Cellulose Production using Sago Liquid Waste. Biosaintifika J. Biol. Biol. Educ. 2017, 9, 387–393. [Google Scholar] [CrossRef] [Green Version]

- Norouzian, D.; Farhangi, A.; Tolooei, A.; Saffari, Z.; Mehrabi, M.R.; Chiani, M.; Ghassemi, S.; Farahnak, M.; Akbarzadeh, A. Study of nano-fiber cellulose production by Glu-canacetobacter xylinum ATCC 10245. Pak. J. Biol. Sci. 2011, 14, 780–784. [Google Scholar] [CrossRef]

- Vazquez, A.; Foresti, M.L.; Cerrutti, P.; Galvagno, M. Bacterial cellulose from simple and low cost production media by Glu-conacetobacter xylinus. J. Polym. Environ. 2013, 21, 545–554. [Google Scholar] [CrossRef]

- Esa, F.; Tasirin, S.M.; Rahman, N.A. Overview of Bacterial Cellulose Production and Application. Agric. Agric. Sci. Procedia 2014, 2, 113–119. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Ullah, N.; Sun, X.; Guo, Y.; Chen, L.; Li, Z.; Feng, X. Development and characterization of bacterial cellulose reinforced biocomposite films based on protein from buckwheat distiller’s dried grains. Int. J. Biol. Macromol. 2017, 96, 353–360. [Google Scholar] [CrossRef] [PubMed]

- ASTM D638-14:2014. Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International; Association of 457 Official Analysis Chemists International: Gaithersburg, MD, USA, 2007. [Google Scholar]

- Auras, R.; Arroyo, B.; Selke, S. Production and Properties of Spin-Coated Cassava-Starch-Glycerol-Beeswax Films. Starch-Starke 2009, 61, 463–471. [Google Scholar] [CrossRef]

- Laith, S.A.; Al-Hashimi, A.G. Mechanical Properties of Carboxymethyl Cellulose Edible Films, Basrah. J. Agric. Sci. 2019, 32, 68–78. [Google Scholar]

- Ahmadi, R.; Kalbasi-Ashtari, A.; Oromiehie, A.; Yarmand, M.-S.; Jahandideh, F. Development and characterization of a novel biodegradable edible film obtained from psyllium seed (Plantago ovata Forsk). J. Food Eng. 2012, 109, 745–751. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Almasi, H.; Entezami, A.A. Physical properties of edible modified starch/carboxymethyl cellulose films. Innov. Food Sci. Emerg. Technol. 2010, 11, 697–702. [Google Scholar] [CrossRef]

- Lintang, M.; Tandi, O.; Layuk, P.; Karouw, S.; Dirpan, A. Characterization edible films of sago with glycerol as a plasticizer. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 807, p. 022070. [Google Scholar]

- Arham, R.; Salengke, S.; Metusalach, M.; Mulyati, M.T. Optimization of agar and glycerol concentration in the manufacture of edible film. Int. Food Res. J. 2018, 25, 1845–1851. [Google Scholar]

- Lan, W.; He, L.; Liu, Y. Preparation and Properties of Sodium Carboxymethyl Cellulose/Sodium Alginate/Chitosan Composite Film. Coatings 2018, 8, 291. [Google Scholar] [CrossRef] [Green Version]

- Atta, O.; Manan, S.; Ahmed, A.; Awad, M.; Ul-Islam, M.; Subhan, F.; Ullah, M.; Yang, G. Development and Characterization of Yeast-Incorporated Antimicrobial Cellulose Biofilms for Edible Food Packaging Application. Polymer 2021, 13, 2310. [Google Scholar] [CrossRef]

- Andrade, R.M.S.; Ferreira, M.S.L.; Gonçalves, É.C.B.A. Development and Characterization of Edible Films Based on Fruit and Vegetable Residues. J. Food Sci. 2016, 81, E412–E418. [Google Scholar] [CrossRef]

- Pandey, M.; Abeer, M.M.; Amin, M.C.I. Dissolution study of bacterial cellulose (nata de coco) from local food industry: Solubility behavior & structural changes. Int. J. Pharm. Pharm. Sci. 2014, 6, 89–93. [Google Scholar]

- Rangel-Marrón, M.; Montalvo-Paquini, C.; Palou, E.; López-Malo, A. Optimization of the moisture content, thickness, water solubility and water vapor permeability of sodium alginate edible films using experimental design. In Proceedings of the 4th WSEAS International Conference in Recent Advances on Chemical Engineering, Biochemistry and Computational Chemistry, Paris, France, 29–31 October 2013. [Google Scholar]

- Díaz-Montes, E.; Castro-Muñoz, R. Edible Films and Coatings as Food-Quality Preservers: An Overview. Foods 2021, 10, 249. [Google Scholar] [CrossRef] [PubMed]

- Avramescu, S.M.; Butean, C.; Popa, C.V.; Ortan, A.; Moraru, I.; Temocico, G. Edible and functionalized films/coatings per-formances and perspectives. Coatings 2020, 10, 687. [Google Scholar] [CrossRef]

- Barbosa, C.; Andrade, M.; Vilarinho, F.; Fernando, A.; Silva, A. Active Edible Packaging. Encyclopedia 2021, 1, 360–370. [Google Scholar] [CrossRef]

- Pereda, M.; Amica, G.; Marcovich, N.E. Development and characterization of edible chitosan/olive oil emulsion films. Carbohydr. Polym. 2012, 87, 1318–1325. [Google Scholar] [CrossRef]

- Nandane, A.S.; Jain, R. Study of mechanical properties of soy protein based edible film as affected by its composition and process parameters by using RSM. J. Food Sci. Technol. 2014, 52, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Tongdeesoontorn, W.; Mauer, L.J.; Wongruong, S.; Sriburi, P.; Rachtanapun, P. Effect of carboxymethyl cellulose concentration on physical properties of biodegradable cassava starch-based films. Chem. Central J. 2011, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Shoemaker, C.F.; Ma, J.; Shen, X.; Zhong, F. Paste viscosity of rice starches of different amylose content and carbox-ymethylcellulose formed by dry heating and the physical properties of their films. Food Chem. 2008, 109, 616–623. [Google Scholar] [CrossRef]

- Asl, S.A.; Mousavi, M.; Labbafi, M. Synthesis and Characterization of Carboxymethyl Cellulose from Sugarcane Bagasse. J. Food Process. Technol. 2017, 8, 1–6. [Google Scholar] [CrossRef]

- Atykyan, N.; Revin, V.; Shutova, V. Raman and FT-IR Spectroscopy investigation the cellulose structural differences from bacteria Gluconacetobacter sucrofermentans during the different regimes of cultivation on a molasses media. AMB Express 2020, 10, 84. [Google Scholar] [CrossRef]

- Indrarti, L.; Indriyati; Syampurwadi, A.; Pujiastuti, S. Physical and mechanical properties of modified bacterial cellulose composite films. In International Symposium on Frontier of Applied Physics (ISFAP) 2015; AIP Publishing LLC: Melville, NY, USA, 2016; Volume 1711, p. 50007. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Ren, Z.; Wang, R.; Liu, L.; Zhang, J.; Ma, F.; Khan, Z.H.; Zhao, D.; Liu, X. Characterization and antibacterial activity of edible films based on carboxymethyl cellulose, Dioscorea opposita mucilage, glycerol and ZnO nanoparticles. Food Chem. 2021, 349, 129208. [Google Scholar] [CrossRef]

- Falguera, V.; Quintero, J.P.; Jiménez, A.; Muñoz, J.A.; Ibarz, A. Edible films and coatings: Structures, active functions and trends in their use. Trends Food Sci. Technol. 2011, 22, 292–303. [Google Scholar] [CrossRef]

- Ščetar, M.; Kurek, M.; Galić, K. Trends in meat and meat products packaging—A review. Croat J. Food Sci. Technol. 2010, 2, 32–48. [Google Scholar]

- Kerry, J.P.; O’Grady, M.N.; Hogan, S.A. Past, current and potential utilisation of active and intelligent packaging systems for meat and muscle-based products: A review. Meat Sci. 2006, 74, 113–130. [Google Scholar] [CrossRef] [PubMed]

- Debeaufort, F.; Quezada-Gallo, J.-A.; Voilley, A. Edible Films and Coatings: Tomorrow’s Packagings: A Review. Crit. Rev. Food Sci. Nutr. 1998, 38, 299–313. [Google Scholar] [CrossRef] [PubMed]

- Wulandari, D.; Erwanto, Y.; Pranoto, Y.; Rusman, R.; Sugianto, S. Quality of Chicken Sausage Coated by Transglutami-nase-crosslinked Bovine Split Hide Gelatin and Soy Protein Isolate Edible Film During Chilled Storage. JITEK 2020, 15, 143–151. [Google Scholar] [CrossRef]

- Zamudio-Flores, P.B.; Ochoa-Reyes, E.; Ornelas-Paz, J.D.J.; Aparicio-Saguilán, A.; Vargas-Torres, A.; Bello-Pérez, L.A.; Ru-bio-Ríos, A.; Cárdenas-Félix, R.G. Effect of storage time on physicochemical and textural properties of sausages covered with oxidized banana starch film with and without betalains. CyTA-J. Food 2015, 13, 456–463. [Google Scholar] [CrossRef] [Green Version]

- Ziegler, G.; Rizvi, S.S.H.; Acton, J.C. Relationship of Water Content to Textural Characteristics, Water Activity, and Thermal Conductivity of Some Commercial Sausages. J. Food Sci. 1987, 52, 901–905. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Krochta, J.M. Edible Packaging Materials. Annu. Rev. Food Sci. Technol. 2010, 1, 415–448. [Google Scholar] [CrossRef]

- Rodríguez, M.; Osés, J.; Ziani, K.; Maté, J.I. Combined effect of plasticizers and surfactants on the physical properties of starch based edible films. Food Res. Int. 2006, 39, 840–846. [Google Scholar] [CrossRef]

- Lestari, R.B.; Permadi, E.; Harahap, R.P. Decrease Quality during Storage Packaged Beef Sausage Edible Coating by Durian Seeds Starch-Chitosan with the Addition of Kesum Leaf Extract. IOP Conf. Series Earth Environ. Sci. 2020, 478, 012036. [Google Scholar] [CrossRef]

- Chowdhury, K.; Khan, S.; Karim, R.; Obaid, M.; Hasan, G. Effect of Moisture, Water Activity and Packaging Materials on Quality and Shelf Life of Some Locally Packed Chanachur. Bangladesh J. Sci. Ind. Res. 2011, 46, 33–40. [Google Scholar] [CrossRef]

- Martins, G.E.; Casini, C.; Da Costa, J.-P.; Geny, L.; Lonvaud, A.; Masneuf-Pomarède, I. Correlation between water activity (aw) and microbial epiphytic communities associated with grapes berries. OENO One 2020, 54, 49–61. [Google Scholar] [CrossRef] [Green Version]

| Treatment Code | Comparison of edible film Composition | ||

|---|---|---|---|

| CMC (%) | Glycerol (%) | Slurry Biocellulose (%) | |

| EF0-0 | 0 | 0 | 100 |

| EF1-1 | 0.5 | 0.5 | 99 |

| EF2-2 | 1 | 1 | 98 |

| EF3-3 | 1.5 | 1.5 | 97 |

| Samples | Thickness (mm) | WS (%) | MC (%) |

|---|---|---|---|

| EF0-0 | 0.045 ± 0.006 | 30.81 ± 2.34 | 17.15 ± 0.82 |

| EF1-1 | 0.065 ± 0.009 | 43.92 ± 2.80 | 19.30 ± 1.36 |

| EF2-2 | 0.074 ± 0.004 | 42.54 ± 1.78 | 27.06 ± 0.64 |

| EF3-3 | 0.083 ± 0.004 | 32.02 ± 1.10 | 33.72 ± 0.68 |

| Treatment Code | Mechanical Properties | ||

|---|---|---|---|

| Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (GPa) | |

| EF0-0 | 5.02 ± 0.70 | 10.27 ± 1.46 | 2.93 ± 0.44 |

| EF1-1 | 9.30 ± 1.31 | 21.82 ± 1.08 | 4.49 ± 0.57 |

| EF2-2 | 17.47 ± 1.17 | 25.60 ± 1.45 | 6.54 ± 0.12 |

| EF3-3 | 7.67 ± 0.82 | 29.67 ± 1.04 | 5.78 ± 0.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yanti, N.A.; Ahmad, S.W.; Ramadhan, L.O.A.N.; Jamili; Muzuni; Walhidayah, T.; Mamangkey, J. Properties and Application of Edible Modified Bacterial Cellulose Film Based Sago Liquid Waste as Food Packaging. Polymers 2021, 13, 3570. https://doi.org/10.3390/polym13203570

Yanti NA, Ahmad SW, Ramadhan LOAN, Jamili, Muzuni, Walhidayah T, Mamangkey J. Properties and Application of Edible Modified Bacterial Cellulose Film Based Sago Liquid Waste as Food Packaging. Polymers. 2021; 13(20):3570. https://doi.org/10.3390/polym13203570

Chicago/Turabian StyleYanti, Nur Arfa, Sitti Wirdhana Ahmad, La Ode Ahmad Nur Ramadhan, Jamili, Muzuni, Taufik Walhidayah, and Jendri Mamangkey. 2021. "Properties and Application of Edible Modified Bacterial Cellulose Film Based Sago Liquid Waste as Food Packaging" Polymers 13, no. 20: 3570. https://doi.org/10.3390/polym13203570

APA StyleYanti, N. A., Ahmad, S. W., Ramadhan, L. O. A. N., Jamili, Muzuni, Walhidayah, T., & Mamangkey, J. (2021). Properties and Application of Edible Modified Bacterial Cellulose Film Based Sago Liquid Waste as Food Packaging. Polymers, 13(20), 3570. https://doi.org/10.3390/polym13203570