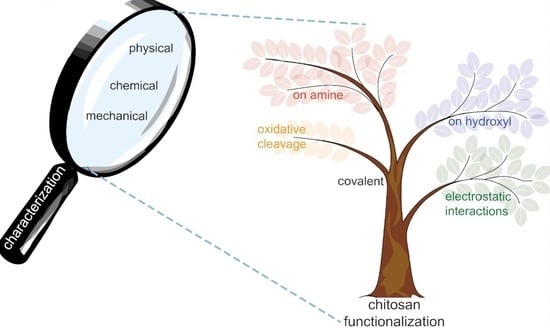

Chitosan Functionalization: Covalent and Non-Covalent Interactions and Their Characterization

Abstract

:1. Introduction

2. Strategies for Covalent Functionalization

2.1. Amine Functionalization

2.1.1. Acylation Leading to Amide Bonds

Amide Bond Formation in the Presence of Coupling Agents

Amide Bond Formation in the Presence of Anhydride Substrates

Selected Examples of CS Functionalization through Amide Bond Formation

| Method | Grafted Substrates | Application | Ref. |

|---|---|---|---|

| EDC.HCl (+/− NHS) | CSK peptide | Polymeric nanocarrier to promote drug absorption and oral bioavailability in anticancer therapy | [46] |

| Folic acid | Polymeric NPs for tumor targeted drug delivery | [28] | |

| SWCN | NPs for mediated-chloroplasts transgene delivery | [47] | |

| DEACMS | CS-coumarin-derived micelles for pesticide release | [45] | |

| GBA; LA | Targeted delivery of DOX to CXCR 4 tumor cells | [48] | |

| HCA | Surgical adhesive | [49] | |

| OA; GA | MRI guided theranostic cancer therapy | [30] | |

| 4-pentynoic acid | Food packaging material with improved shelf-life | [50] | |

| PBA-COOH | Curcumin encapsulation and ROS-triggered drug release | [51] | |

| PCA | Hydrogels for antioxidant material in drug release and tissue engineering | [31] | |

| Anhydride | Methacrylic anhydride | CS-silk fibroin hydrogels for wound dressing | [52] |

| Maleic anhydride | CS-BPEI-Arg NPs for gene therapy | [39] | |

| Succinic anhydride | Gene delivery vehicle | [41] | |

| EDC.HCl and anhydride | Succinic, phthalic, glutaric, and phenylsuccinic anhydrides; TPP | Polymeric NPs for drug delivery | [40] |

| Succinic anhydride; Brij-S20 | Intestinal absorption enhancement of 123-Rhodamine (Pgp substrate) | [32] | |

| Succinyl prednisolone; succinic anhydride | Nanogels for treatment of ulcerative colitis | [53] |

2.1.2. Phthaloylation

2.1.3. Acylation Leading to Urea Bonds

2.1.4. Alkylation

2.1.5. Epoxide and Aziridine Ring Openings

2.1.6. 1,2-Nucleophilic Addition: Imine Formation

2.1.7. 1,4-Nucleophilic Addition

2.2. Hydroxyl Functionalization

2.2.1. Acylation Leading to Carbamate Bonds

2.2.2. Acylation Leading to Ester Bonds

2.2.3. Transacetalisation

2.2.4. Nucleophilic Substitution

2.3. Oxidative Cleavage

3. Non-Covalent Modifications

3.1. Non-Covalent CS Conjugates with Proteins

3.2. Non-Covalent CS Conjugates with Other Biopolymers

3.3. Non-Covalent CS Conjugates with Small Molecules and Nanocomposites

4. Combination of Covalent and Non-Covalent Modifications

4.1. Functionalization Strategies of CS Intended to Non-Covalent Mixing

4.2. Adjuvants Mixed with Functionalized CS

4.2.1. Chitosan-Based Materials with Polymeric Adjuvants

4.2.2. Chitosan-Based Materials with Small Molecular and Nanocomposite Adjuvants

4.2.3. Chitosan-Based Materials with Protein Adjuvants

5. Characterization of CS-Based Materials

5.1. Chemical Characterization

5.1.1. Nuclear Magnetic Resonance

5.1.2. Fourier Transform InfraRed Spectroscopy

5.1.3. Complementary Chemical Characterizations

5.2. Physical Characterization

5.2.1. Gel Permeation Chromatography

5.2.2. Morphological Characterization

5.2.3. Thermal Analysis

5.3. Mechanical and Rheological Characterizations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yadav, M.; Goswami, P.; Paritosh, K.; Kumar, M.; Pareek, N.; Vivekanand, V. Seafood waste: A source for preparation of commercially employable chitin/chitosan materials. Bioresour. Bioprocess. 2019, 6, 8. [Google Scholar] [CrossRef]

- Joseph, S.M.; Krishnamoorthy, S.; Paranthaman, R.; Moses, J.A.; Anandharamakrishnan, C. A review on source-specific chemistry, functionality, and applications of chitin and chitosan. Carbohydr. Polym. Technol. Appl. 2021, 2, 100036. [Google Scholar] [CrossRef]

- Kumar, M.N.V.R.; Muzzarelli, R.A.A.; Muzzarelli, C.; Sashiwa, H.; Domb, A.J. Chitosan chemistry and pharmaceutical perspectives. Chem. Rev. 2004, 104, 6017–6084. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Tan, Y.F.; Wong, Y.S.; Liew, M.W.J.; Venkatraman, S. Recent advances in chitosan-based carriers for gene delivery. Mar. Drugs 2019, 17, 381. [Google Scholar] [CrossRef] [Green Version]

- Kulkarni, N.; Shinde, S.D.; Jadhav, G.S.; Adsare, D.R.; Rao, K.; Kachhia, M.; Maingle, M.; Patil, S.P.; Arya, N.; Sahu, B. Peptide-chitosan engineered scaffolds for biomedical applications. Bioconjugate Chem. 2021, 32, 448–465. [Google Scholar] [CrossRef]

- Steiger, B.G.K.; Wilson, L.D. Modular chitosan-based adsorbents for tunable uptake of sulfate from water. Int. J. Mol. Sci. 2020, 21, 7130. [Google Scholar] [CrossRef]

- Usman, M.; Ahmed, A.; Yu, B.; Wang, S.; Shen, Y.; Cong, H. Simultaneous adsorption of heavy metals and organic dyes by β-cyclodextrin-chitosan based cross-linked adsorbent. Carbohydr. Polym. 2020, 255, 117486. [Google Scholar] [CrossRef]

- Li, J.; Tian, X.; Hua, T.; Fu, J.; Koo, M.; Chan, W.; Poon, T. Chitosan natural polymer material for improving antibacterial properties of textiles. ACS Appl. Bio Mater. 2021, 4, 4014–4038. [Google Scholar] [CrossRef]

- Adiletta, G.; Di Matteo, M.; Petriccione, M. Multifunctional role of chitosan edible coatings on antioxidant systems in fruit crops: A review. Int. J. Mol. Sci. 2021, 22, 2633. [Google Scholar] [CrossRef] [PubMed]

- Zhai, X.; Li, C.; Ren, D.; Wang, J.; Ma, C.; Abd El-Aty, A.M. The impact of chitooligosaccharides and their derivatives on the in vitro and in vivo antitumor activity: A comprehensive review. Carbohydr. Polym. 2021, 266, 118132. [Google Scholar] [CrossRef] [PubMed]

- Aiba, S.-I. Studies on chitosan: 3. Evidence for the presence of random and block copolymer structures in partially N-acetylated chitosans. Int. J. Biol. Macromol. 1991, 13, 40–44. [Google Scholar] [CrossRef]

- Marques, C.; Som, C.; Schmutz, M.; Borges, O.; Borchard, G. How the lack of chitosan characterization precludes implementation of the safe-by-design concept. Front. Bioeng. Biotechnol. 2020, 8, 165. [Google Scholar] [CrossRef] [Green Version]

- Jung, W.-J.; Park, R.-D.; Harding, D.; Sashiwa, H. Bioproduction of chitooligosaccharides: Present and perspectives. Mar. Drugs 2014, 12, 5328–5356. [Google Scholar] [CrossRef] [Green Version]

- Singh, R.; Weikert, T.; Basa, S.; Moerschbacher, B.M. Structural and biochemical insight into mode of action and subsite specificity of a chitosan degrading enzyme from Bacillus spec. MN. Sci. Rep. 2019, 9, 1132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qin, C.Q.; Du, Y.M.; Xiao, L. Effect of hydrogen peroxide treatment on the molecular weight and structure of chitosan. Polym. Degrad. Stab. 2002, 76, 211–218. [Google Scholar] [CrossRef]

- Chebotok, E.N.; Novikov, V.Y.; Konovalova, I.N. Depolymerization of chitin and chitosan in the course of base deacetylation. Russ. J. Appl. Chem. 2006, 79, 1162–1166. [Google Scholar] [CrossRef]

- Journot, C.M.A.; Nicolle, L.; Lavanchy, Y.; Gerber-Lemaire, S. Selection of water-soluble chitosan by microwave-assisted degradation and pH-controlled precipitation. Polymers 2020, 12, 1274. [Google Scholar] [CrossRef] [PubMed]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Riaz Rajoka, M.S.; Zhao, L.; Mehwish, H.M.; Wu, Y.; Mahmood, S. Chitosan and its derivatives: Synthesis, biotechnological applications, and future challenges. Appl. Microbiol. Biotechnol. 2019, 103, 1557–1571. [Google Scholar] [CrossRef]

- Mittal, H.; Ray, S.S.; Kaith, B.S.; Bhatia, J.K.; Sukriti; Sharma, J.; Alhassan, S.M. Recent progress in the structural modification of chitosan for applications in diversified biomedical fields. Eur. Polym. J. 2018, 109, 402–434. [Google Scholar] [CrossRef]

- Santos, V.P.; Marques, N.S.S.; Maia, P.C.S.V.; de Lima, M.A.B.; de Oliveira Franco, L.; de Campos-Takaki, G.M. Seafood waste as attractive source of chitin and chitosan production and their applications. Int. J. Mol. Sci. 2020, 21, 4290. [Google Scholar] [CrossRef]

- Ways, T.M.M.; Lau, W.M.; Khutoryanskiy, V.V. Chitosan and its derivatives for application in mucoadhesive drug delivery systems. Polymers 2018, 10, 267. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torkaman, S.; Rahmani, H.; Ashori, A.; Najafi, S.H.M. Modification of chitosan using amino acids for wound healing purposes: A review. Carbohydr. Polym. 2021, 258, 117675. [Google Scholar] [CrossRef]

- Federer, C.; Kurpiers, M.; Bernkop-Schnürch, A. Thiolated chitosans: A multi-talented class of polymers for various applications. Biomacromolecules 2020, 22, 24–56. [Google Scholar] [CrossRef]

- Summonte, S.; Racaniello, G.F.; Lopedota, A.; Denora, N.; Bernkop-Schnürch, A. Thiolated polymeric hydrogels for biomedical application: Cross-linking mechanisms. J. Control. Release 2021, 330, 470–482. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Cho, S.; Kwon, I.C.; Janát-Amsbury, M.M.; Huh, K.M. Preparation and characterization of glycol chitin as a new thermogelling polymer for biomedical applications. Carbohydr. Polym. 2013, 92, 2267–2275. [Google Scholar] [CrossRef]

- Hojo, K.; Ichikawa, H.; Fukumori, Y.; Kawasaki, K. Development of a method for the solid-phase peptide synthesis in water. Int. J. Pept. Res. Ther. 2008, 14, 373–380. [Google Scholar] [CrossRef]

- Zhang, Y.; Tan, X.; Ren, T.; Jia, C.; Yang, Z.; Sun, H. Folate-modified carboxymethyl-chitosan/polyethylenimine/bovine serum albumin based complexes for tumor site-specific drug delivery. Carbohydr. Polym. 2018, 198, 76–85. [Google Scholar] [CrossRef] [PubMed]

- Feng, R.; Wang, W.; Zhu, L.; Xu, H.; Chen, S.; Song, Z. Phenylboronic acid-functionalized F127-oligochitosan conjugate micelles for doxorubicin encapsulation. J. Biomed. Mater. Res. Part B Appl. Biomater. 2020, 108, 3345–3355. [Google Scholar] [CrossRef]

- Zhao, X.; Shen, R.; Bao, L.; Wang, C.; Yuan, H. Chitosan derived glycolipid nanoparticles for magnetic resonance imaging guided photodynamic therapy of cancer. Carbohydr. Polym. 2020, 245, 116509. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Guan, S.; Xu, J.; Gong, W.; Liu, T.; Ma, X.; Sun, C. Preparation, characterization and antioxidant activity of protocatechuic acid grafted carboxymethyl chitosan and its hydrogel. Carbohydr. Polym. 2021, 252, 117210. [Google Scholar] [CrossRef]

- Xiong, W.; Zhao, G.D.; Yin, X.; Linghu, K.G.; Chu, J.M.T.; Wong, G.T.C.; Li, H.; Yu, H.; Wang, Y.T. Brij-grafted-chitosan copolymers with function of P-glycoprotein modulation: Synthesis, characterization and in vitro investigations. Carbohydr. Polym. 2019, 204, 89–96. [Google Scholar] [CrossRef]

- Chong, W.M.; Lim, V.; Kadir, E.A. Hydrophobically modified PEGylated glycol chitosan nanoparticles: Synthesis, characterisation and anticancer properties. New J. Chem. 2021, 45, 11359–11370. [Google Scholar] [CrossRef]

- Elsayed, N.H.; Monier, M.; Youssef, I. Fabrication of photo-active trans-3-(4-pyridyl)acrylic acid modified chitosan. Carbohydr. Polym. 2017, 172, 1–10. [Google Scholar] [CrossRef]

- Hoang, H.T.; Jo, S.H.; Phan, Q.T.; Park, H.; Park, S.H.; Oh, C.W.; Lim, K.T. Dual pH-/thermo-responsive chitosan-based hydrogels prepared using “click” chemistry for colon-targeted drug delivery applications. Carbohydr. Polym. 2021, 260, 117812. [Google Scholar] [CrossRef]

- Rao, W.; Zhang, W.; Poventud-Fuentes, I.; Wang, Y.; Lei, Y.; Agarwal, P.; Weekes, B.; Li, C.; Lu, X.; Yu, J.; et al. Thermally responsive nanoparticle-encapsulated curcumin and its combination with mild hyperthermia for enhanced cancer cell destruction. Acta Biomater. 2014, 10, 831–842. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, H.; Liu, T.; Xu, Y.; Su, G.; Liu, T.; Yu, Y.; Xu, B. Protein corona precoating on redox-responsive chitosan-based nano-carriers for improving the therapeutic effect of nucleic acid drugs. Carbohydr. Polym. 2021, 265, 118071. [Google Scholar] [CrossRef] [PubMed]

- Aiedeh, K.M.; Omar Taha, M.; Aiedeh, K.; Taha, M.O. Synthesis of chitosan succinate and chitosan phthalate and their evaluation as suggested matrices in orally administered, colon-specific drug delivery systems. Arch. Pharm. Pharm. Med. Chem. 1999, 332, 103–107. [Google Scholar] [CrossRef]

- Zhang, X.; Duan, Y.; Wang, D.; Bian, F. Preparation of arginine modified PEI-conjugated chitosan copolymer for DNA delivery. Carbohydr. Polym. 2015, 122, 53–59. [Google Scholar] [CrossRef]

- Dmour, I.; Taha, M.O. Novel nanoparticles based on chitosan-dicarboxylate conjugates via tandem ionotropic/covalent crosslinking with tripolyphosphate and subsequent evaluation as drug delivery vehicles. Int. J. Pharm. 2017, 529, 15–31. [Google Scholar] [CrossRef]

- Nicolle, L.; Casper, J.; Willimann, M.; Journot, C.M.A.; Detampel, P.; Einfalt, T.; Grisch-Chan, H.M.; Thöny, B.; Gerber-Lemaire, S.; Huwyler, J. Development of covalent chitosan-polyethylenimine derivatives as gene delivery vehicle: Synthesis, characterization, and evaluation. Int. J. Mol. Sci. 2021, 22, 3828. [Google Scholar] [CrossRef]

- Kamoun, E.A. N-succinyl chitosan–dialdehyde starch hybrid hydrogels for biomedical applications. J. Adv. Res. 2016, 7, 69–77. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pandit, A.H.; Mazumdar, N.; Imtiyaz, K.; Alam Rizvi, M.M.; Ahmad, S. Self-healing and injectable hydrogels for anticancer drug delivery: A study with multialdehyde gum arabic and succinic anhydride chitosan. ACS Appl. Bio Mater. 2020, 3, 8460–8470. [Google Scholar] [CrossRef]

- Seong, J.S.; Yun, M.E.; Park, S.N. Surfactant-stable and pH-sensitive liposomes coated with N-succinyl-chitosan and chitooligosaccharide for delivery of quercetin. Carbohydr. Polym. 2018, 181, 659–667. [Google Scholar] [CrossRef]

- Feng, S.; Wang, J.; Zhang, L.; Chen, Q.; Yue, W.; Ke, N.; Xie, H. Coumarin-containing light-responsive carboxymethyl chitosan micelles as nanocarriers for controlled release of pesticide. Polymers 2020, 12, 2268. [Google Scholar] [CrossRef]

- Chen, G.; Svirskis, D.; Lu, W.; Ying, M.; Huang, Y.; Wen, J. N-trimethyl chitosan nanoparticles and CSKSSDYQC peptide: N-trimethyl chitosan conjugates enhance the oral bioavailability of gemcitabine to treat breast cancer. J. Control. Release 2018, 277, 142–153. [Google Scholar] [CrossRef]

- Kwak, S.-Y.; Lew, T.T.S.; Sweeney, C.J.; Koman, V.B.; Wong, M.H.; Bohmert-Tatarev, K.; Snell, K.D.; Seo, J.S.; Chua, N.-H.; Strano, M.S. Chloroplast-selective gene delivery and expression in planta using chitosan-complexed single-walled carbon nanotube carriers. Nat. Nanotechnol. 2019, 14, 447–455. [Google Scholar] [CrossRef]

- Kong, F.; Tang, C.; Yin, C. Benzylguanidine and galactose double-conjugated chitosan nanoparticles with reduction responsiveness for targeted delivery of doxorubicin to CXCR 4 positive tumors. Bioconjugate Chem. 2020, 31, 2446–2455. [Google Scholar] [CrossRef]

- Park, M.K.; Li, M.X.; Yeo, I.; Jung, J.; Yoon, B.I.L.; Joung, Y.K. Balanced adhesion and cohesion of chitosan matrices by conjugation and oxidation of catechol for high-performance surgical adhesives. Carbohydr. Polym. 2020, 248, 116760. [Google Scholar] [CrossRef] [PubMed]

- Mei, L.; Jiang, F.; Zhang, F.; Zhang, J.; Li, Y.; Liu, Y.; Luo, Y.; Wang, Q. Alkynyl silver modified chitosan and its potential applications in food area. Carbohydr. Polym. 2021, 254, 117416. [Google Scholar] [CrossRef]

- Wang, J.; Liu, L.G.; Jiao, W.Q.; Yang, H.; Liu, J.; Liu, D. Phenylboronic acid-conjugated chitosan nanoparticles for high loading and efficient delivery of curcumin. Carbohydr. Polym. 2021, 256, 117497. [Google Scholar] [CrossRef] [PubMed]

- Bozuyuk, U.; Yasa, O.; Yasa, I.C.; Ceylan, H.; Kizilel, S.; Sitti, M. Light-triggered drug release from 3D-printed magnetic chitosan microswimmers. ACS Nano 2018, 12, 9617–9625. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Ichikawa, A.; Ikeuchi-Takahashi, Y.; Hattori, Y.; Onishi, H. Nanogels of succinylated glycol chitosan-succinyl prednisolone conjugate: Preparation, in vitro characteristics and therapeutic potential. Pharmaceutics 2019, 11, 333. [Google Scholar] [CrossRef] [Green Version]

- Nishimura, S.-I.; Kohgo, O.; Kurita, K.; Kuzuhara, H. Chemospecific manipulations of a rigid polysaccharide: Syntheses of novel chitosan derivatives with excellent solubility in common organic solvents by regioselective chemical modifications. Macromolecules 1991, 24, 4745–4748. [Google Scholar] [CrossRef]

- Kurita, K.; Ikeda, H.; Yoshida, Y.; Shimojoh, M.; Harata, M. Chemoselective protection of the amino groups of chitosan by controlled phthaloylation: Facile preparation of a precursor useful for chemical modifications. Biomacromolecules 2002, 3, 1–4. [Google Scholar] [CrossRef]

- Ghiggi, F.F.; Pollo, L.D.; Cardozo, N.S.M.; Tessaro, I.C. Preparation and characterization of polyethersulfone/N-phthaloyl-chitosan ultrafiltration membrane with antifouling property. Eur. Polym. J. 2017, 92, 61–70. [Google Scholar] [CrossRef]

- Edson, J.A.; Ingato, D.; Wu, S.; Lee, B.; Kwon, Y.J. Aqueous-soluble, acid-transforming chitosan for efficient and stimuli-responsive gene silencing. Biomacromolecules 2018, 19, 1508–1516. [Google Scholar] [CrossRef]

- Gao, J.Q.; Zhao, Q.Q.; Lv, T.F.; Shuai, W.P.; Zhou, J.; Tang, G.P.; Liang, W.Q.; Tabata, Y.; Hu, Y.L. Gene-carried chitosan-linked-PEI induced high gene transfection efficiency with low toxicity and significant tumor-suppressive activity. Int. J. Pharm. 2010, 387, 286–294. [Google Scholar] [CrossRef]

- Lu, H.; Dai, Y.; Lv, L.; Zhao, H. Chitosan-graft-Polyethylenimine/DNA nanoparticles as novel non-viral gene delivery vectors targeting osteoarthritis. PLoS ONE 2014, 9, e84703. [Google Scholar] [CrossRef]

- Jeong, G.W.; Nah, J.W. Evaluation of disulfide bond-conjugated LMWSC-g-bPEI as non-viral vector for low cytotoxicity and efficient gene delivery. Carbohydr. Polym. 2017, 178, 322–330. [Google Scholar] [CrossRef]

- Padiya, K.J.; Gavade, S.; Kardile, B.; Tiwari, M.; Bajare, S.; Mane, M.; Gaware, V.; Varghese, S.; Harel, D.; Kurhade, S. Unprecedented “in water” imidazole carbonylation: Paradigm shift for preparation of urea and carbamate. Org. Lett. 2012, 14, 2814–2817. [Google Scholar] [CrossRef]

- Zhang, P.; Cao, M. Preparation of a novel organo-soluble chitosan grafted polycaprolactone copolymer for drug delivery. Int. J. Biol. Macromol. 2014, 65, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Demeyer, S.; Athipornchai, A.; Pabunrueang, P.; Trakulsujaritchok, T. Development of mangiferin loaded chitosan-silica hybrid scaffolds: Physicochemical and bioactivity characterization. Carbohydr. Polym. 2021, 261, 117905. [Google Scholar] [CrossRef] [PubMed]

- Bi, R.; Yue, L.; Niazi, S.; Khan, I.M.; Sun, D.; Wang, B.; Wang, Z.; Jiang, Q.; Xia, W. Facile synthesis and antibacterial activity of geraniol conjugated chitosan oligosaccharide derivatives. Carbohydr. Polym. 2020, 251, 117099. [Google Scholar] [CrossRef] [PubMed]

- Mao, S.; Wang, B.; Yue, L.; Xia, W. Effects of citronellol grafted chitosan oligosaccharide derivatives on regulating anti-inflammatory activity. Carbohydr. Polym. 2021, 262, 117972. [Google Scholar] [CrossRef] [PubMed]

- Alirezvani, Z.; Dekamin, M.G.; Davoodi, F.; Valiey, E. Melamine-functionalized chitosan: A new bio-based reusable bifunctional organocatalyst for the synthesis of cyanocinnamonitrile intermediates and densely functionalized nicotinonitrile derivatives. ChemistrySelect 2018, 3, 10450–10463. [Google Scholar] [CrossRef]

- Fabiano, A.; Beconcini, D.; Migone, C.; Piras, A.M.; Zambito, Y. Quaternary ammonium chitosans: The importance of the positive fixed charge of the drug delivery systems. Int. J. Mol. Sci. 2020, 21, 6617. [Google Scholar] [CrossRef]

- Freitas, E.D.; Moura, C.F.; Kerwald, J.; Beppu, M.M. An overview of current knowledge on the properties, synthesis and applications of quaternary chitosan derivatives. Polymers 2020, 12, 2878. [Google Scholar] [CrossRef]

- Curti, E.; de Britto, D.; Campana-Filho, S.P. Methylation of chitosan with iodomethane: Effect of reaction conditions on chemoselectivity and degree of substitution. Macromol. Biosci. 2003, 3, 571–576. [Google Scholar] [CrossRef]

- Illy, N.; Robitzer, M.; Auvergne, R.; Caillol, S.; David, G.; Boutevin, B. Synthesis of water-soluble allyl-functionalized oligochitosan and its modification by thiol-ene addition in water. J. Polym. Sci. Part A Polym. Chem. 2014, 52, 39–48. [Google Scholar] [CrossRef]

- Yin, M.; Li, X.; Liu, Y.; Ren, X. Functional chitosan/glycidyl methacrylate-based cryogels for efficient removal of cationic and anionic dyes and antibacterial applications. Carbohydr. Polym. 2021, 266, 118129. [Google Scholar] [CrossRef]

- Zhu, C.; Wu, J.; Jin, X.; Yan, Y.; Ding, C.F.; Tang, K.; Zhang, D. Post-synthesis of biomimetic chitosan with honeycomb-like structure for sensitive recognition of phosphorylated peptides. J. Chromatogr. A 2021, 1643, 462072. [Google Scholar] [CrossRef]

- Fan, Q.; Miao, C.; Huang, Y.; Yue, H.; Wu, A.; Wu, J.; Wu, J.; Ma, G. Hydroxypropyltrimethyl ammonium chloride chitosan-based hydrogel as the split H5N1 mucosal adjuvant: Structure-activity relationship. Carbohydr. Polym. 2021, 266, 118139. [Google Scholar] [CrossRef] [PubMed]

- Wong, K.; Sun, G.; Zhang, X.; Dai, H.; Liu, Y.; He, C.; Leong, K.W. PEI-g-chitosan, a novel gene delivery system with transfection efficiency comparable to polyethylenimine in vitro and after liver administration in vivo. Bioconjugate Chem. 2006, 17, 152–158. [Google Scholar] [CrossRef]

- Shaabani, A.; Sedghi, R. Preparation of chitosan biguanidine/PANI-containing self-healing semi-conductive waterborne scaffolds for bone tissue engineering. Carbohydr. Polym. 2021, 264, 118045. [Google Scholar] [CrossRef]

- Yue, L.; Li, J.; Chen, W.; Liu, X.; Jiang, Q.; Xia, W. Geraniol grafted chitosan oligosaccharide as a potential antibacterial agent. Carbohydr. Polym. 2017, 176, 356–364. [Google Scholar] [CrossRef]

- Ding, H.; Li, B.; Jiang, Y.; Liu, G.; Pu, S.; Feng, Y.; Jia, D.; Zhou, Y. pH-responsive UV crosslinkable chitosan hydrogel via “thiol-ene” click chemistry for active modulating opposite drug release behaviors. Carbohydr. Polym. 2020, 251, 117101. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Gou, S.; Zhou, L.; Tang, L.; Liu, T.; Liu, L.; Duan, M. Amidoxime-functionalized polyacrylamide-modified chitosan containing imidazoline groups for effective removal of Cu2+ and Ni2+. Carbohydr. Polym. 2021, 252, 117160. [Google Scholar] [CrossRef] [PubMed]

- Olewnik-Kruszkowska, E.; Gierszewska, M.; Grabska-Zielińska, S.; Skopińska-Wiśniewska, J.; Jakubowska, E. Examining the impact of squaric acid as a crosslinking agent on the properties of chitosan-based films. Int. J. Mol. Sci. 2021, 22, 3329. [Google Scholar] [CrossRef] [PubMed]

- Gularte, M.S.; Anghinoni, J.M.; Abenante, L.; Voss, G.T.; de Oliveira, R.L.; Vaucher, R.A.; Luchese, C.; Wilhelm, E.A.; Lenardão, E.J.; Fajardo, A.R. Synthesis of chitosan derivatives with organoselenium and organosulfur compounds: Characterization, antimicrobial properties and application as biomaterials. Carbohydr. Polym. 2019, 219, 240–250. [Google Scholar] [CrossRef] [PubMed]

- Takeshita, S.; Konishi, A.; Takebayashi, Y.; Yoda, S.; Otake, K. Aldehyde approach to hydrophobic modification of chitosan aerogels. Biomacromolecules 2017, 18, 2172–2178. [Google Scholar] [CrossRef]

- Xia, L.; Wang, S.; Jiang, Z.; Chi, J.; Yu, S.; Li, H.; Zhang, Y.; Li, L.; Zhou, C.; Liu, W.; et al. Hemostatic performance of chitosan-based hydrogel and its study on biodistribution and biodegradability in rats. Carbohydr. Polym. 2021, 264, 117965. [Google Scholar] [CrossRef]

- Zhang, M.; Qiao, X.; Han, W.; Jiang, T.; Liu, F.; Zhao, X. Alginate-chitosan oligosaccharide-ZnO composite hydrogel for accelerating wound healing. Carbohydr. Polym. 2021, 266, 118100. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Yan, J.; Liu, C.; Zhang, J.; Wang, H.; Gao, X.; Yan, H.; Niu, B.; Li, W. Preparation and characterization of catechol-grafted chitosan/gelatin/modified chitosan-AgNP blend films. Carbohydr. Polym. 2020, 247, 116643. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Ding, S.; Liu, S.; Yang, K.; Cai, J.; Li, F.; Wang, C.; Lin, S.; Tian, F. Polysaccharides-modified chitosan as improved and rapid hemostasis foam sponges. Carbohydr. Polym. 2021, 264, 118028. [Google Scholar] [CrossRef] [PubMed]

- Ho, D.-K.; Frisch, S.; Biehl, A.; Terriac, E.; De Rossi, C.; Schwarzkopf, K.; Lautenschläger, F.; Loretz, B.; Murgia, X.; Lehr, C.-M. Farnesylated glycol chitosan as a platform for drug delivery: Synthesis, characterization, and investigation of mucus–particle interactions. Biomacromolecules 2018, 19, 3489–3501. [Google Scholar] [CrossRef]

- Chen, Q.; Ye, Z.; Tang, L.; Wu, T.; Jiang, Q.; Lai, N. Synthesis and solution properties of a novel hyperbranched polymer based on chitosan for enhanced oil recovery. Polymers 2020, 12, 2130. [Google Scholar] [CrossRef]

- Sirviö, J.A.; Kantola, A.M.; Komulainen, S.; Filonenko, S. Aqueous modification of chitosan with itaconic acid to produce strong oxygen barrier film. Biomacromolecules 2021, 22, 2119–2128. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhao, Y.; Cui, S.; Zhi, D.; Zhang, S.; Peng, X. 6-O-dodecyl-chitosan carbamate-based pH-responsive polymeric micelles for gene delivery. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Fathi, M.; Sahandi Zangabad, P.; Barar, J.; Aghanejad, A.; Erfan-Niya, H.; Omidi, Y. Thermo-sensitive chitosan copolymer-gold hybrid nanoparticles as a nanocarrier for delivery of erlotinib. Int. J. Biol. Macromol. 2018, 106, 266–276. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Zhuang, P.; Wang, Z.; Li, Y.; Jiang, Z.; Hu, Q.; Liu, M.; Zhao, Q. One-pot synthesis of chitosan-g-(PEO-PLLA-PEO) via “click” chemistry and “sET-NRC” reaction. Carbohydr. Polym. 2012, 90, 1515–1521. [Google Scholar] [CrossRef] [PubMed]

- Fei Liu, X.; Lin Guan, Y.; Zhi Yang, D.; Yao, K. DE Antibacterial action of chitosan and carboxymethylated chitosan. J. Appl. Polym. Sci. 2000, 79, 1324–1335. [Google Scholar] [CrossRef]

- Anitha, A.; Maya, S.; Deepa, N.; Chennazhi, K.P.; Nair, S.V.; Tamura, H.; Jayakumar, R. Efficient water soluble O-carboxymethyl chitosan nanocarrier for the delivery of curcumin to cancer cells. Carbohydr. Polym. 2011, 83, 452–461. [Google Scholar] [CrossRef]

- Upadhyaya, L.; Singh, J.; Agarwal, V.; Tewari, R.P. The implications of recent advances in carboxymethyl chitosan based targeted drug delivery and tissue engineering applications. J. Control. Release 2014, 186, 54–87. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Han, B.; Yang, Y.; Liu, W. Synthesis, characterization and biological safety of O-carboxymethyl chitosan used to treat Sarcoma 180 tumor. Carbohydr. Polym. 2011, 86, 231–238. [Google Scholar] [CrossRef]

- Vold, I.M.N.; Christensen, B.E. Periodate oxidation of chitosans with different chemical compositions. Carbohydr. Res. 2005, 340, 679–684. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.L.; Kim, Y.K.; Arote, R.; Nah, J.W.; Cho, M.H.; Choi, Y.J.; Akaike, T.; Cho, C.S. Chitosan-graft-polyethylenimine as a gene carrier. J. Control. Release 2007, 117, 273–280. [Google Scholar] [CrossRef]

- Kristiansen, K.A.; Potthast, A.; Christensen, B.E. Periodate oxidation of polysaccharides for modification of chemical and physical properties. Carbohydr. Res. 2010, 345, 1264–1271. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Zhang, Y.; Xu, X.; Guo, T.; Xie, D.; Zhu, R.; Chen, S.; Ramakrishna, S.; He, L. RGD/TAT-functionalized chitosan-graft-PEI-PEG gene nanovector for sustained delivery of NT-3 for potential application in neural regeneration. Acta Biomater. 2018, 72, 266–277. [Google Scholar] [CrossRef] [PubMed]

- Keshk, S.M.A.S.; Ramadan, A.M.; Al-Sehemi, A.G.; Irfan, A.; Bondock, S. An unexpected reactivity during periodate oxidation of chitosan and the affinity of its 2, 3-di-aldehyde toward sulfa drugs. Carbohydr. Polym. 2017, 175, 565–574. [Google Scholar] [CrossRef]

- Hanafy, M.S.; Desoky, W.M.; Hussein, E.M.; El-Shaer, N.H.; Gomaa, M.; Gamal, A.A.; Esawy, M.A.; Guirguis, O.W. Biological applications study of bio-nanocomposites based on chitosan/TiO2 nanoparticles polymeric films modified by oleic acid. J. Biomed. Mater. Res. Part A 2021, 109, 232–247. [Google Scholar] [CrossRef] [PubMed]

- Elsabahy, M.; Hamad, M.A. Design and preclinical evaluation of chitosan/kaolin nanocomposites with enhanced hemostatic efficiency. Mar. Drugs 2021, 19, 50. [Google Scholar] [CrossRef]

- Chen, M.; Li, L.; Xia, L.; Jiang, S.; Kong, Y.; Chen, X.; Wang, H. The kinetics and release behaviour of curcumin loaded pH-responsive PLGA/chitosan fibers with antitumor activity against HT-29 cells. Carbohydr. Polym. 2021, 265, 118077. [Google Scholar] [CrossRef]

- Lagassé, H.A.D.; Alexaki, A.; Simhadri, V.L.; Katagiri, N.H.; Jankowski, W.; Sauna, Z.E.; Kimchi-Sarfaty, C. Recent advances in (therapeutic protein) drug development. F1000Research 2017, 6, 113. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, Z.; Eini, M.; Rastegari, A.; Tehrani, M.R. Chitosan as a machine for biomolecule delivery: A review. Carbohydr. Polym. 2021, 256, 117414. [Google Scholar] [CrossRef]

- Ding, L.; Huang, Y.; Cai, X.X.; Wang, S. Impact of pH, ionic strength and chitosan charge density on chitosan/casein complexation and phase behavior. Carbohydr. Polym. 2019, 208, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Popescu, R.; Ghica, M.V.; Dinu-Pîrvu, C.E.; Anuța, V.; Lupuliasa, D.; Popa, L. New opportunity to formulate intranasal vaccines and drug delivery systems based on chitosan. Int. J. Mol. Sci. 2020, 21, 5016. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.P.; Martínez, J.H.; Martínez, K.D.; Farías, M.E.; Leskow, F.C.; Pérez, O.E. Proposed molecular model for electrostatic interactions between insulin and chitosan. Nano-complexation and activity in cultured cells. Colloids Surf. A Physicochem. Eng. Asp. 2018, 537, 425–434. [Google Scholar] [CrossRef] [Green Version]

- Hajam, I.A.; Senevirathne, A.; Hewawaduge, C.; Kim, J.; Lee, J.H. Intranasally administered protein coated chitosan nanoparticles encapsulating influenza H9N2 HA2 and M2e mRNA molecules elicit protective immunity against avian influenza viruses in chickens. Vet. Res. 2020, 51, 37. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Farooq, M.A.; Li, T.; Geng, T.; Kutoka, P.T.; Wang, B. Cationic chitosan-modified silica nanoparticles for oral delivery of protein vaccine. J. Biomed. Mater. Res. Part A 2021, 109, 2111–2119. [Google Scholar] [CrossRef] [PubMed]

- Lekshmi, R.G.K.; Rahima, M.; Chatterjee, N.S.; Tejpal, C.S.; Anas, K.K.; Vishnu, K.V.; Sarika, K.; Asha, K.K.; Anandan, R.; Suseela, M. Chitosan—Whey protein as efficient delivery system for squalene: Characterization and functional food application. Int. J. Biol. Macromol. 2019, 135, 855–863. [Google Scholar] [CrossRef] [PubMed]

- De Queiroz, J.L.C.; De Araújo Costa, R.O.; Rodrigues Matias, L.L.; De Medeiros, A.F.; Teixeira Gomes, A.F.; Dos Santos Pais, T.; Passos, T.S.; Maciel, B.L.L.; Dos Santos, E.A.; De Araújo Morais, A.H. Chitosan-whey protein nanoparticles improve encapsulation efficiency and stability of a trypsin inhibitor isolated from Tamarindus indica L. Food Hydrocoll. 2018, 84, 247–256. [Google Scholar] [CrossRef]

- Farsanipour, A.; Khodanazary, A.; Hosseini, S.M. Effect of chitosan-whey protein isolated coatings incorporated with tarragon Artemisia dracunculus essential oil on the quality of Scomberoides commersonnianus fillets at refrigerated condition. Int. J. Biol. Macromol. 2020, 155, 766–771. [Google Scholar] [CrossRef]

- Ye, L.; Chen, H. Characterization of the interactions between chitosan/whey protein at different conditions. Food Sci. Technol. 2019, 39, 163–169. [Google Scholar] [CrossRef] [Green Version]

- Peppas, N.A.; Khare, A.R. Preparation, structure and diffusional behavior of hydrogels in controlled release. Adv. Drug Deliv. Rev. 1993, 11, 1–35. [Google Scholar] [CrossRef] [Green Version]

- Pan, J.; Li, Y.; Chen, K.; Zhang, Y.; Zhang, H. Enhanced physical and antimicrobial properties of alginate/chitosan composite aerogels based on electrostatic interactions and noncovalent crosslinking. Carbohydr. Polym. 2021, 266, 118102. [Google Scholar] [CrossRef]

- Yao, M.; Lu, Y.; Zhang, T.; Xie, J.; Han, S.; Zhang, S.; Fei, Y.; Ling, Z.; Wu, J.; Hu, Y.; et al. Improved functionality of Ligilactobacillus salivarius Li01 in alleviating colonic inflammation by layer-by-layer microencapsulation. NPJ Biofilms Microbiomes 2021, 7, 58. [Google Scholar] [CrossRef]

- Hamsan, M.H.; Nofal, M.M.; Aziz, S.B.; Brza, M.A.; Dannoun, E.M.A.; Murad, A.R.; Kadir, M.F.Z.; Muzakir, S.K. Plasticized polymer blend electrolyte based on chitosan for energy storage application: Structural, circuit modeling, morphological and electrochemical properties. Polymers 2021, 13, 1233. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Yang, F.; Guo, Z. The chitosan hydrogels: From structure to function. New J. Chem. 2018, 42, 17162–17180. [Google Scholar] [CrossRef]

- Ahmadi, F.; Oveisi, Z.; Samani, S.M.; Amoozgar, Z. Chitosan based hydrogels: Characteristics and pharmaceutical applications. Res. Pharm. Sci. 2015, 10, 1–16. [Google Scholar]

- Pita-López, M.L.; Fletes-Vargas, G.; Espinosa-Andrews, H.; Rodríguez-Rodríguez, R. Physically cross-linked chitosan-based hydrogels for tissue engineering applications: A state-of-the-art review. Eur. Polym. J. 2021, 145, 110176. [Google Scholar] [CrossRef]

- Shirzadian, T.; Nourbakhsh, M.S.; Fattahi, A.; Bahrami, G.; Mohammadi, G. Characterization and optimization of de-esterified Tragacanth-chitosan nanocomposite as a potential carrier for oral delivery of insulin: In vitro and ex vivo studies. J. Biomed. Mater. Res. Part A 2021, 109, 2164–2172. [Google Scholar] [CrossRef]

- Rim, M.A.; Choi, J.H.; Park, A.; Youn, J.; Lee, S.; Kim, N.E.; Song, J.E.; Khang, G. Characterization of gelatin/gellan gum/glycol chitosan ternary hydrogel for retinal pigment epithelial tissue reconstruction materials. ACS Appl. Bio Mater. 2020, 3, 6079–6087. [Google Scholar] [CrossRef]

- Huo, M.-X.; Jin, Y.-L.; Sun, Z.-F.; Ren, F.; Pei, L.; Ren, P.-G. Facile synthesis of chitosan-based acid-resistant composite films for efficient selective adsorption properties towards anionic dyes. Carbohydr. Polym. 2021, 254, 117473. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Zhang, H.; Li, R.; Xing, Y. Preparation and adsorption properties of citrate-crosslinked chitosan salt microspheres by microwave assisted method. Int. J. Biol. Macromol. 2020, 152, 1146–1156. [Google Scholar] [CrossRef]

- Giraldo, J.D.; Campos-Requena, V.H.; Rivas, B.L. Chitosan–tripolyphosphate bead: The interactions that govern its formation. Polym. Bull. 2019, 76, 3879–3903. [Google Scholar] [CrossRef]

- Zhou, H.Y.; Chen, X.G.; Kong, M.; Liu, C.S.; Cha, D.S.; Kennedy, J.F. Effect of molecular weight and degree of chitosan deacetylation on the preparation and characteristics of chitosan thermosensitive hydrogel as a delivery system. Carbohydr. Polym. 2008, 73, 265–273. [Google Scholar] [CrossRef]

- Berger, J.; Reist, M.; Mayer, J.M.; Felt, O.; Peppas, N.A.; Gurny, R. Structure and interactions in covalently and ionically crosslinked chitosan hydrogels for biomedical applications. Eur. J. Pharm. Biopharm. 2004, 57, 19–34. [Google Scholar] [CrossRef]

- Sedyakina, N.; Kuskov, A.; Velonia, K.; Feldman, N.; Lutsenko, S.; Avramenko, G. Modulation of entrapment efficiency and in vitro release properties of BSA-loaded chitosan microparticles cross-linked with citric acid as a potential protein-drug delivery system. Materials 2020, 13, 1989. [Google Scholar] [CrossRef]

- Niu, C.; Zhang, N.; Hu, C.; Zhang, C.; Zhang, H.; Xing, Y. Preparation of a novel citric acid-crosslinked Zn-MOF/chitosan composite and application in adsorption of chromium(VI) and methyl orange from aqueous solution. Carbohydr. Polym. 2021, 258, 117644. [Google Scholar] [CrossRef]

- 21 CFR 184.1033—Citric Acid.—Content Details—CFR-2011-Title21-Vol3-Sec184-1033. Available online: https://www.govinfo.gov/app/details/CFR-2011-title21-vol3/CFR-2011-title21-vol3-sec184-1033/summary (accessed on 21 November 2021).

- Wu, Y.; Zhang, R.; Tran, H.D.N.; Kurniawan, N.D.; Moonshi, S.S.; Whittaker, A.K.; Ta, H.T. Chitosan Nanococktails containing both ceria and superparamagnetic iron oxide nanoparticles for reactive oxygen species-related theranostics. ACS Appl. Nano Mater. 2021, 2021, 3618. [Google Scholar] [CrossRef]

- Mora-Boza, A.; Mancipe Castro, L.M.; Schneider, R.S.; Han, W.M.; García, A.J.; Vázquez-Lasa, B.; San Román, J. Microfluidics generation of chitosan microgels containing glycerylphytate crosslinker for in situ human mesenchymal stem cells encapsulation. Mater. Sci. Eng. C 2021, 120, 111716. [Google Scholar] [CrossRef]

- Khoerunnisa, F.; Nurhayati, M.; Dara, F.; Rizki, R.; Nasir, M.; Aziz, H.A.; Hendrawan, H.; Poh, N.E.; Kaewsaneha, C.; Opaprakasit, P. Physicochemical Properties of TPP-Crosslinked Chitosan Nanoparticles as Potential Antibacterial Agents. Fibers Polym. 2021, 22, 2954–2964. [Google Scholar] [CrossRef]

- Kahdestani, S.A.; Shahriari, M.H.; Abdouss, M. Synthesis and characterization of chitosan nanoparticles containing teicoplanin using sol–gel. Polym. Bull. 2021, 78, 1133–1148. [Google Scholar] [CrossRef]

- Yu, S.H.; Wu, S.J.; Wu, J.Y.; Peng, C.K.; Mi, F.L. Tripolyphosphate cross-linked macromolecular composites for the growth of shape- and size-controlled apatites. Molecules 2013, 18, 27–40. [Google Scholar] [CrossRef]

- Nie, J.; Wang, Z.; Hu, Q. Chitosan hydrogel structure modulated by metal ions. Sci. Rep. 2016, 6, 36005. [Google Scholar] [CrossRef] [Green Version]

- Rashid, S.; Shen, C.; Yang, J.; Liu, J.; Li, J. Preparation and properties of chitosan–metal complex: Some factors influencing the adsorption capacity for dyes in aqueous solution. J. Environ. Sci. 2018, 66, 301–309. [Google Scholar] [CrossRef]

- Abrica-González, P.; Zamora-Justo, J.A.; Sotelo-López, A.; Vázquez-Martínez, G.R.; Balderas-López, J.A.; Muñoz-Diosdado, A.; Ibáñez-Hernández, M. Gold nanoparticles with chitosan, N-acylated chitosan, and chitosan oligosaccharide as DNA carriers. Nanoscale Res. Lett. 2019, 14, 258. [Google Scholar] [CrossRef]

- Abazar, F.; Noorbakhsh, A. Chitosan-carbon quantum dots as a new platform for highly sensitive insulin impedimetric aptasensor. Sens. Actuators B Chem. 2020, 304, 127281. [Google Scholar] [CrossRef]

- Mallakpour, S.; Azadi, E.; Hussain, C.M. Chitosan/carbon nanotube hybrids: Recent progress and achievements for industrial applications. New J. Chem. 2021, 45, 3756–3777. [Google Scholar] [CrossRef]

- Daniyal, W.M.E.M.M.; Fen, Y.W.; Saleviter, S.; Chanlek, N.; Nakajima, H.; Abdullah, J.; Yusof, N.A. X-ray photoelectron spectroscopy analysis of chitosan–graphene oxide-based composite thin films for potential optical sensing applications. Polymers 2021, 13, 478. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Wu, J. Recent development in chitosan nanocomposites for surface-based biosensor applications. Electrophoresis 2019, 40, 2084–2097. [Google Scholar] [CrossRef] [PubMed]

- Said, H.A.; Noukrati, H.; Youcef, H.B.; Bayoussef, A.; Oudadesse, H.; Barroug, A. Mechanical behavior of hydroxyapatite-chitosan composite: Effect of processing parameters. Minerals 2021, 11, 213. [Google Scholar] [CrossRef]

- Wu, J.; Li, H.; Lai, X.; Chen, Z.; Zeng, X. Conductive and superhydrophobic F-rGO@CNTs/chitosan aerogel for piezoresistive pressure sensor. Chem. Eng. J. 2020, 386, 123998. [Google Scholar] [CrossRef]

- Alshabanah, L.A.; Gomha, S.M.; Al-Mutabagani, L.A.; Abolibda, T.Z.; Abd El-Ghany, N.A.; El-Enany, W.A.M.A.; El-Ziaty, A.K.; Ali, R.S.; Mohamed, N.A. Cross-linked chitosan/multi-walled carbon nanotubes composite as ecofriendly biocatalyst for synthesis of some novel benzil bis-thiazoles. Polymers 2021, 13, 1728. [Google Scholar] [CrossRef]

- Ni, P.; Li, R.; Ye, S.; Shan, J.; Yuan, T.; Liang, J.; Fan, Y.; Zhang, X. Lactobionic acid-modified chitosan thermosensitive hydrogels that lift lesions and promote repair in endoscopic submucosal dissection. Carbohydr. Polym. 2021, 263, 118001. [Google Scholar] [CrossRef]

- Shahdeo, D.; Kesarwani, V.; Suhag, D.; Ahmed, J.; Alshehri, S.M.; Gandhi, S. Self-assembled chitosan polymer intercalating peptide functionalized gold nanoparticles as nanoprobe for efficient imaging of urokinase plasminogen activator receptor in cancer diagnostics. Carbohydr. Polym. 2021, 266, 118138. [Google Scholar] [CrossRef]

- Zhuang, L.; Zhi, X.; Du, B.; Yuan, S. Preparation of elastic and antibacterial chitosan-citric membranes with high oxygen barrier ability by in situ cross-linking. ACS Omega 2020, 5, 1086–1097. [Google Scholar] [CrossRef] [PubMed]

- Andreica, B.I.; Cheng, X.; Marin, L. Quaternary ammonium salts of chitosan. A critical overview on the synthesis and properties generated by quaternization. Eur. Polym. J. 2020, 139, 110016. [Google Scholar] [CrossRef]

- Hsu, C.W.; Hsieh, M.H.; Xiao, M.C.; Chou, Y.H.; Wang, T.H.; Chiang, W.H. pH-responsive polymeric micelles self-assembled from benzoic-imine-containing alkyl-modified PEGylated chitosan for delivery of amphiphilic drugs. Int. J. Biol. Macromol. 2020, 163, 1106–1116. [Google Scholar] [CrossRef]

- Tao, Y.; Qu, D.; Tian, C.; Huang, Y.; Xue, L.; Ju, C.; Hao, M.; Zhang, C. Modular synthesis of amphiphilic chitosan derivatives based on copper-free click reaction for drug delivery. Int. J. Pharm. 2021, 605, 120798. [Google Scholar] [CrossRef]

- Schoeller, J.; Itel, F.; Wuertz-Kozak, K.; Gaiser, S.; Luisier, N.; Hegemann, D.; Ferguson, S.J.; Fortunato, G.; Rossi, R.M. pH-responsive chitosan/alginate polyelectrolyte complexes on electrospun PLGA nanofibers for controlled drug release. Nanomaterials 2021, 11, 1850. [Google Scholar] [CrossRef]

- Rusu, A.G.; Chiriac, A.P.; Nita, L.E.; Bercea, M.; Tudorachi, N.; Ghilan, A.; Pamfil, D.; Rusu, D.; Cojocaru, F.D. Interpenetrated polymer network with modified chitosan in composition and self-healing properties. Int. J. Biol. Macromol. 2019, 132, 374–384. [Google Scholar] [CrossRef]

- Sánchez-Cardona, Y.; Echeverri-Cuartas, C.E.; López, M.E.L.; Moreno-Castellanos, N. Chitosan/gelatin/pva scaffolds for beta pancreatic cell culture. Polymers 2021, 13, 2372. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, R.; Espinosa-Andrews, H.; Velasquillo-Martínez, C.; García-Carvajal, Z.Y. Composite hydrogels based on gelatin, chitosan and polyvinyl alcohol to biomedical applications: A review. Int. J. Polym. Mater. Polym. Biomater. 2020, 69, 1–20. [Google Scholar] [CrossRef]

- Gong, J.; Schuurmans, C.C.L.; van Genderen, A.M.; Cao, X.; Li, W.; Cheng, F.; He, J.J.; López, A.; Huerta, V.; Manríquez, J.; et al. Complexation-induced resolution enhancement of 3D-printed hydrogel constructs. Nat. Commun. 2020, 11, 1267. [Google Scholar] [CrossRef]

- Zhou, W.; He, Y.; Liu, F.; Liao, L.; Huang, X.; Li, R.; Zou, Y.; Zhou, L.; Zou, L.; Liu, Y.; et al. Carboxymethyl chitosan-pullulan edible films enriched with galangal essential oil: Characterization and application in mango preservation. Carbohydr. Polym. 2021, 256, 117579. [Google Scholar] [CrossRef]

- Harrison, Z.L.; Bumgardner, J.D.; Fujiwara, T.; Baker, D.L.; Jennings, J.A. In vitro evaluation of loaded chitosan membranes for pain relief and infection prevention. J. Biomed. Mater. Res. Part B Appl. Biomater. 2021, 109, 1735–1743. [Google Scholar] [CrossRef]

- Gull, N.; Khan, S.M.; Zahid Butt, M.T.; Khalid, S.; Shafiq, M.; Islam, A.; Asim, S.; Hafeez, S.; Khan, R.U. In vitro study of chitosan-based multi-responsive hydrogels as drug release vehicles: A preclinical study. RSC Adv. 2019, 9, 31078–31091. [Google Scholar] [CrossRef] [Green Version]

- Rusu, A.G.; Chiriac, A.P.; Nita, L.E.; Rosca, I.; Rusu, D.; Neamtu, I. Self-assembled nanocarriers based on modified chitosan for biomedical applications: Preparation and characterization. Polymers 2020, 12, 2593. [Google Scholar] [CrossRef]

- Fasiku, V.O.; Omolo, C.A.; Devnarain, N.; Ibrahim, U.H.; Rambharose, S.; Faya, M.; Mocktar, C.; Singh, S.D.; Govender, T. Chitosan-based hydrogel for the dual delivery of antimicrobial agents against bacterial methicillin-resistant Staphylococcus aureus biofilm-infected wounds. ACS Omega 2021, 6, 21994–22010. [Google Scholar] [CrossRef]

- Wang, S.; Liu, J.; Huang, Y.; Yang, N. Selective sensing of Mn2+ based on ZnCdS/ZnS QD/carboxymethyl chitosan/g-C3N4 nanosheet nanocomposite film by the conformational regulation of polymer chain. Appl. Surf. Sci. 2020, 530, 147255. [Google Scholar] [CrossRef]

- Yuan, D.; Liu, W.; Wang, J.; Cui, J.; He, L.; Yan, C.; Kou, Y.; Li, J. Facile preparation of EDTA-functionalized magnetic chitosan for removal of co(II) from aqueous solutions. Environ. Technol. 2021, 42, 1313–1325. [Google Scholar] [CrossRef]

- Alirezvani, Z.; Dekamin, M.G.; Valiey, E. Cu(II) and magnetite nanoparticles decorated melamine-functionalized chitosan: A synergistic multifunctional catalyst for sustainable cascade oxidation of benzyl alcohols/Knoevenagel condensation. Sci. Rep. 2019, 9, 17758. [Google Scholar] [CrossRef] [Green Version]

- Apriceno, A.; Silvestro, I.; Girelli, A.; Francolini, I.; Pietrelli, L.; Piozzi, A. Preparation and characterization of chitosan-coated manganese-ferrite nanoparticles conjugated with laccase for environmental bioremediation. Polymers 2021, 13, 1453. [Google Scholar] [CrossRef]

- Ji, S.; Liu, W.; Su, S.; Gan, C.; Jia, C. Chitosan derivative functionalized carbon nanotubes as carriers for enzyme immobilization to improve synthetic efficiency of ethyl caproate. LWT 2021, 149, 111897. [Google Scholar] [CrossRef]

- Cui, Z.K.; Kim, S.; Baljon, J.J.; Wu, B.M.; Aghaloo, T.; Lee, M. Microporous methacrylated glycol chitosan-montmorillonite nanocomposite hydrogel for bone tissue engineering. Nat. Commun. 2019, 10, 3523. [Google Scholar] [CrossRef] [Green Version]

- Budnyak, T.M.; Yanovska, E.S.; Kichkiruk, O.Y.; Sternik, D.; Tertykh, V.A. Natural minerals coated by biopolymer chitosan: Synthesis, physicochemical, and adsorption Properties. Nanoscale Res. Lett. 2016, 11, 492. [Google Scholar] [CrossRef] [Green Version]

- Zou, L.; Zhang, Y.; Liu, X.; Chen, J.; Zhang, Q. Biomimetic mineralization on natural and synthetic polymers to prepare hybrid scaffolds for bone tissue engineering. Colloids Surf. B Biointerfaces 2019, 178, 222–229. [Google Scholar] [CrossRef]

- Mora-Boza, A.; López-Ruiz, E.; López-Donaire, M.L.; Jiménez, G.; Aguilar, M.R.; Marchal, J.A.; Pedraz, J.L.; Vázquez-Lasa, B.; Román, J.S.; Gálvez-Martín, P. Evaluation of glycerylphytate crosslinked semi- and interpenetrated polymer membranes of hyaluronic acid and chitosan for tissue engineering. Polymers 2020, 12, 2661. [Google Scholar] [CrossRef]

- Sharmeen, S.; Rahman, A.F.M.M.; Lubna, M.M.; Salem, K.S.; Islam, R.; Khan, M.A. Polyethylene glycol functionalized carbon nanotubes/gelatin-chitosan nanocomposite: An approach for significant drug release. Bioact. Mater. 2018, 3, 236–244. [Google Scholar] [CrossRef]

- Leonhardt, E.E.; Kang, N.; Hamad, M.A.; Wooley, K.L.; Elsabahy, M. Absorbable hemostatic hydrogels comprising composites of sacrificial templates and honeycomb-like nanofibrous mats of chitosan. Nat. Commun. 2019, 10, 2307. [Google Scholar] [CrossRef] [Green Version]

- Koyani, R.D.; Andrade, M.; Quester, K.; Gaytán, P.; Huerta-Saquero, A.; Vazquez-Duhalt, R. Surface modification of protein enhances encapsulation in chitosan nanoparticles. Appl. Nanosci. 2018, 8, 1197–1203. [Google Scholar] [CrossRef]

- Feng, S.; Du, X.; Bat-Amgalan, M.; Zhang, H.; Miyamoto, N.; Kano, N. Adsorption of REEs from aqueous solution by EDTA-chitosan modified with Zeolite Imidazole Framework (ZIF-8). Int. J. Mol. Sci. 2021, 22, 3447. [Google Scholar] [CrossRef]

- Situ, W.; Xiang, T.; Liang, Y. Chitosan-based particles for protection of proteins during storage and oral administration. Int. J. Biol. Macromol. 2018, 117, 308–314. [Google Scholar] [CrossRef]

- Shen, Y.; Xu, Y.; Yi, B.; Wang, X.; Tang, H.; Chen, C.; Zhang, Y. Engineering a highly biomimetic chitosan-based cartilage scaffold by using short fibers and a cartilage-decellularized matrix. Biomacromolecules 2021, 22, 2284–2297. [Google Scholar] [CrossRef]

- He, X.; Liu, X.; Yang, J.; Du, H.; Chai, N.; Sha, Z.; Geng, M.; Zhou, X.; He, C. Tannic acid-reinforced methacrylated chitosan/methacrylated silk fibroin hydrogels with multifunctionality for accelerating wound healing. Carbohydr. Polym. 2020, 247, 116689. [Google Scholar] [CrossRef]

| 2nd Polymer + Adjuvant | Improved Characteristics | Field of Application | Ref. |

|---|---|---|---|

| Alg + Ca2+, TiO2 NP | Mechanical and thermal stabilization, cross-linking gelation, antibacterial | Food packaging | [116] |

| Alg + Ca2+, Zn2+ | Layer-by-layer cell encapsulation | Cell encapsulation for IBD | [117] |

| Tragacanth gum | Solubilization, gelification, fucose and xylose cell targeting | Oral delivery of insulin | [122] |

| Dextran + NH4I, glycerol, Zn (II)-metal complex | Mechanical properties, plasticizing effect | Electrochemical material | [118] |

| Polyvinyl alcohol + Kaolin | Increased mechanical resistance, heterogeneous gel, hemostatic agent | Wound healing | [102] |

| Poly(lactic-glycolide) | Mechanical properties, degradable polymer, stabilization of hydrophobic drug | Antitumoral drug delivery | [103] |

| Gelatin, Gelam gum | Similar as targeted tissue, cell adhesion binding agent, stabilization | Tissue reconstruction | [123] |

| Cellulose | Porous nanofibers, provides scaffold for increased rigidity | Wastewater treatment | [124] |

| Substrate for the Initial Conjugation | Conjugation Method | Secondary Polymeric Adjuvant | Improved Characteristics | Ref. |

|---|---|---|---|---|

| DCD | 1,2 nucleophilic addition | Polyaniline Polyurethane-based polymer | Solubility, electroconductivity, scaffolding, self-healing polymer, promote cell growth, and mineralization | [75] |

| Maleic anhydride | N-acylation | DMAEMA and BisAAm copolymer | Electrostatic interaction to additional carboxylic groups | [154] |

| Catechol paraformaldehyde | Mannich reaction | Gelatin AgNP | Solubility, mechanical properties and water vapor barrier, antibacterial effect | [84] |

| Lactobionic acid | EDC.HCl/NHS | CS β-glycerophosphate | Solubility, fluidity, bio-adhesion, protein phosphatase inhibitor | [147] |

| TMC | commercial source | HA methacrylate, Glu-alg, MA-gel, pluronic copolymer | Solubility, cross-linked CS and control shrinkage, sacrificial printing | [157] |

| Substrate for the Initial Conjugation | Conjugation Method | Secondary Adjuvant | Improved Characteristics | Ref |

|---|---|---|---|---|

| CA | EDC.HCl | Glycerine, CA | Elasticity | [149] |

| MeI Nona-arginine | Quaternization SPDP | TPP | Solubility, electrostatic cross-linking, nucleic penetration | [37] |

| Hexanoic anhydride | N-acylation | CDA | Electrostatic cross-linking, prevent infection, anesthetics (pain killer) | [159] |

| Maleic anhydride | N-acylation | Amoxicillin | Electrostatic interaction to additional carboxylic groups, anti-bacterial | [161] |

| Substrate for the First Conjugation | Conjugation Method | Additional Inorganic NP | Improved Characteristics | Ref. |

|---|---|---|---|---|

| ICP and TPS | Formation of hybrid scaffold through sol-gel process | Magiferin ZnO NP | Sol-gel formation of hybrid scaffold, stability, reduce gel swelling, anti-inflammatory effect, promote osteoblastic bone formation | [63] |

| 1,3-bromopropane Mel | N-alkylation | Fe3O4 NP Cu(III) NP | Cross-linked CS, magnetic catalyst | [165] |

| GFD and SMB peptides | CDI 1 | AuNP | Nanocarrier, scaffolding | [148] |

| EDTA dianhydride | Anhydride ring opening | Fe3O4 NP | Magnetic purification system | [164] |

| Glutaraldehyde laccase | Mannich reaction | Magnetic NP (MnFe2O4) | Scaffold rigidity, improved enzyme activity | [166] |

| Cinnamaldehyde | Aldehyde reactivity | CNT, PPL | Themostability, hydrolysis | [167] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nicolle, L.; Journot, C.M.A.; Gerber-Lemaire, S. Chitosan Functionalization: Covalent and Non-Covalent Interactions and Their Characterization. Polymers 2021, 13, 4118. https://doi.org/10.3390/polym13234118

Nicolle L, Journot CMA, Gerber-Lemaire S. Chitosan Functionalization: Covalent and Non-Covalent Interactions and Their Characterization. Polymers. 2021; 13(23):4118. https://doi.org/10.3390/polym13234118

Chicago/Turabian StyleNicolle, Laura, Céline M. A. Journot, and Sandrine Gerber-Lemaire. 2021. "Chitosan Functionalization: Covalent and Non-Covalent Interactions and Their Characterization" Polymers 13, no. 23: 4118. https://doi.org/10.3390/polym13234118

APA StyleNicolle, L., Journot, C. M. A., & Gerber-Lemaire, S. (2021). Chitosan Functionalization: Covalent and Non-Covalent Interactions and Their Characterization. Polymers, 13(23), 4118. https://doi.org/10.3390/polym13234118