Accelerated Aging Effect on Mechanical Properties of Common 3D-Printing Polymers

Abstract

:1. Introduction

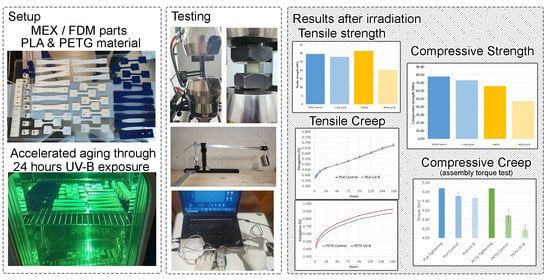

2. Materials and Methods

3. Results

3.1. Visual and Dimensional Inspection

3.2. Tensile Strength and Stiffness

3.3. Compressive Strength

3.4. Creep Testing

3.5. Scanning Electron Microscopy (SEM)

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cai, M.; Luo, J. Influence of COVID-19 on Manufacturing Industry and Corresponding Countermeasures from Supply Chain Perspective. J. Shanghai Jiaotong Univ. Sci. 2020, 25, 409–416. [Google Scholar] [CrossRef]

- Ijaz, M.; Yar, M.K.; Badar, I.H.; Ali, S.; Islam, M.S.; Jaspal, M.H.; Hayat, Z.; Sardar, A.; Ullah, S.; Guevara-Ruiz, D. Meat Production and Supply Chain Under COVID-19 Scenario: Current Trends and Future Prospects. Front. Vet. Sci. 2021, 8, 660736. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Luthra, S.; Mangla, S.K.; Kazançoğlu, Y. COVID-19 impact on sustainable production and operations management. Sustain. Oper. Comput. 2020, 1, 1–7. [Google Scholar] [CrossRef]

- Deloitte, CFO Signals: 3Q 2021, CFO Signals, What North America’s Top Finance Executives are Thinking—And Doing, 3rd Quarter 2021. Available online: https://www2.deloitte.com/content/dam/Deloitte/us/Documents/finance/us-3q21-cfo-signals-high-level-report.pdf (accessed on 30 October 2021).

- Flynn, B.; Cantor, D.; Pagell, M.; Dooley, K.J.; Azadegan, A. From the Editors: Introduction to Managing Supply Chains Beyond Covid-19—Preparing for the Next Global Mega-Disruption. J. Supply Chain Manag. 2021, 57, 3–6. [Google Scholar] [CrossRef]

- Andreoni, V.; Miola, A. Climate Vulnerability of the Supply-Chain: Literature and Methodological Review; EUR 26994, JRC93420; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Dasaklis, T.; Pappis, C. Supply chain management in view of climate change: An overview of possible impacts and the road ahead. J. Ind. Eng. Manag. 2013, 6, 1139–1161. [Google Scholar] [CrossRef] [Green Version]

- Ghadge, A.; Wurtmann, H.; Seuring, S. Managing climate change risks in global supply chains: A review and research agenda. Int. J. Prod. Res. 2019, 53, 44–64. [Google Scholar] [CrossRef]

- Mohr, S.; Khan, O. 3D Printing and Supply Chains of the Future. In Innovations and Strategies for Logistics and Supply Chains: Technologies, Business Models and Risk Management, Proceedings of the Hamburg International Conference of Logistics HICL, Hamburg, Germany, 24–25 September 2015; Kersten, W.B., Thorsten, R., Christian, M., Eds.; Epubli GmbH: Berlin, Germany, 2015; Volume 20, pp. 147–174. ISBN 978-3-7375-4059-9. [Google Scholar]

- Ben-Ner, A.; Siemsen, E. Decentralization and Localization of Production: The Organizational and Economic Consequences of Additive Manufacturing (3D Printing). Calif. Manag. Rev. 2017, 59, 5–23. [Google Scholar] [CrossRef]

- Kubáč, L.; Kodym, O. The Impact of 3D Printing Technology on Supply Chain. MATEC Web Conf. 2017, 134, 00027. [Google Scholar] [CrossRef] [Green Version]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Crump, S. Apparatus and Method for Creating Three-Dimensional Objects. US Patent No. US5121329A, 9 June 1992. [Google Scholar]

- Steenhuis, H.J.; Pretorius, L. Consumer additive manufacturing or 3D printing adoption: An exploratory study. J. Manuf. Technol. Manag. 2016, 27, 990–1012. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Shi, A.; Yang, L.; Shirowzhan, S.; Edwards, D.J. Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review. Buildings 2020, 10, 231. [Google Scholar] [CrossRef]

- Zhang, C. 3D Printing, Open-Source Technology and Their Applications. In Research, Open Access Master’s Report; Michigan Technological University: Houghton, MI, USA, 2015. [Google Scholar] [CrossRef]

- Sells, E.; Smith, Z.; Bailard, S.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. Handb. Res. Mass Cust. Pers. 2010, 1, 568–580. [Google Scholar] [CrossRef] [Green Version]

- Laureto, J.J.; Pearce, J.M. Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing. Technologies 2017, 5, 36. [Google Scholar] [CrossRef] [Green Version]

- Gwamuri, J.; Pearce, J.M. Open source 3D printers: An appropriate technology for building low cost optics labs for the developing communities. In Proceedings of the SPIE 10452, 14th Conference on Education and Training in Optics and Photonics ETOP, Hangzhou, China, 29–31 May 2017; p. 104522. [Google Scholar] [CrossRef] [Green Version]

- Price, A.J.N.; Capel, A.J.; Lee, R.J.; Pradel, P.; Christie, S.D.R. An open source toolkit for 3D printed fluidics. J. Flow Chem. 2021, 11, 37–51. [Google Scholar] [CrossRef]

- Sculpteo The State of 3D Printing Report: 2020. Available online: https://www.sculpteo.com/en/ebooks/state-of-3d-printing-report-2020/ (accessed on 30 October 2021).

- Cantrell, J.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental Characterization of the Mechanical Properties of 3D Printed ABS and Polycarbonate Parts. In Advancement of Optical Methods in Experimental Mechanics; Yoshida, S., Lamberti, L., Sciammarella, C., Eds.; Conference Proceedings of the Society for Experimental Mechanics Series; Springer: Cham, Switzerland, 2017; Volume 3. [Google Scholar] [CrossRef]

- Naveed, N. Investigating the Material Properties and Microstructural Changes of Fused Filament Fabricated PLA and Tough-PLA Parts. Polymers 2021, 13, 1487. [Google Scholar] [CrossRef] [PubMed]

- Hsueh, M.-H.; Lai, C.-J.; Chung, C.-F.; Wang, S.-H.; Huang, W.-C.; Pan, C.-Y.; Zeng, Y.-S.; Hsieh, C.-H. Effect of Printing Parameters on the Tensile Properties of 3D-Printed Polylactic Acid (PLA) Based on Fused Deposition Modeling. Polymers 2021, 13, 2387. [Google Scholar] [CrossRef] [PubMed]

- Hsueh, M.-H.; Lai, C.-J.; Wang, S.-H.; Zeng, Y.-S.; Hsieh, C.-H.; Pan, C.-Y.; Huang, W.-C. Effect of Printing Parameters on the Thermal and Mechanical Properties of 3D-Printed PLA and PETG, Using Fused Deposition Modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef] [PubMed]

- Kováčová, M.; Kozakovičová, J.; Procházka, M.; Janigová, I.; Vysopal, M.; Černičková, I.; Krajčovič, J.; Špitalský, Z. Novel Hybrid PETG Composites for 3D Printing. Appl. Sci. 2020, 10, 3062. [Google Scholar] [CrossRef]

- Mercado-Colmenero, J.M.; Martin-Doñate, C.; Moramarco, V.; Attolico, M.A.; Renna, G.; Rodriguez-Santiago, M.; Casavola, C. Mechanical Characterization of the Plastic Material GF-PA6 Manufactured Using FDM Technology for a Compression Uniaxial Stress Field via an Experimental and Numerical Analysis. Polymers 2020, 12, 246. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tuan Rahim, T.N.A.; Abdullah, A.M.; Akil, H.M.; Mohamad, D.; Rajion, Z.A. Preparation and characterization of a newly developed polyamide composite utilising an affordable 3D printer. J. Reinf. Plast. Compos. 2015, 34, 1628–1638. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. Springerplus 2013, 2, 398. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Andrady, A.L.; Hamid, S.H.; Hu, X.; Torikai, A. Effects of increased solar ultraviolet radiation on materials. J. Photochem. Photobiol. B Biol. 1998, 46, 96–103. [Google Scholar] [CrossRef]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef] [Green Version]

- White, J.R. Polymer ageing: Physics, chemistry or engineering? Time to reflect. Comptes. Rendus. Chim. 2006, 9, 1396–1408. [Google Scholar] [CrossRef]

- Allara, D. Aging of Polymers. Environ. Health Perspect. 1975, 11, 29–33. [Google Scholar] [CrossRef]

- Moraczewski, K.; Stepczyńska, M.; Malinowski, R.; Karasiewicz, T.; Jagodziński, B.; Rytlewski, P. The Effect of Accelerated Aging on Polylactide Containing Plant Extracts. Polymers 2019, 11, 575. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Masek, A.; Cichosz, S.; Piotrowska, M. Biocomposites of Epoxidized Natural Rubber/Poly(lactic acid) Modified with Natural Fillers (Part I). Int. J. Mol. Sci. 2021, 22, 3150. [Google Scholar] [CrossRef] [PubMed]

- Grzelak, K.; Łaszcz, J.; Polkowski, J.; Mastalski, P.; Kluczyński, J.; Łuszczek, J.; Torzewski, J.; Szachogłuchowicz, I.; Szymaniuk, R. Additive Manufacturing of Plastics Used for Protection against COVID19—The Influence of Chemical Disinfection by Alcohol on the Properties of ABS and PETG Polymers. Materials 2021, 14, 4823. [Google Scholar] [CrossRef] [PubMed]

- Moreno Nieto, D.; Alonso-García, M.; Pardo-Vicente, M.-A.; Rodríguez-Parada, L. Product Design by Additive Manufacturing for Water Environments: Study of Degradation and Absorption Behavior of PLA and PETG. Polymers 2021, 13, 1036. [Google Scholar] [CrossRef] [PubMed]

- Cuiffo, M.A.; Snyder, J.; Elliott, A.M.; Romero, N.; Kannan, S.; Halada, G.P. Impact of the Fused Deposition (FDM) Printing Process on Polylactic Acid (PLA) Chemistry and Structure. Appl. Sci. 2017, 7, 579. [Google Scholar] [CrossRef] [Green Version]

- Martins, C.; Pinto, V.; Guedes, R.M.; Marques, A.T. Creep and Stress Relaxation Behaviour of PLA-PCL Fibres—A Linear Modelling Approach. Procedia Eng. 2015, 114, 768–775. [Google Scholar] [CrossRef] [Green Version]

- Morreale, M.; Mistretta, M.C.; Fiore, V. Creep Behavior of Poly(lactic acid) Based Biocomposites. Materials 2017, 10, 395. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Radiation. International Agency for Research on Cancer: Lyon, France, 2012; IARC Monographs on the Evaluation of Carcinogenic Risks to Humans, No. 100D. Solar and Ultraviolet Radiation. Available online: https://www.ncbi.nlm.nih.gov/books/NBK304366/ (accessed on 17 November 2021).

- De Miguel, A.; Bilbao, J.; Román, R.; Mateos, D. Measurements and attenuation of erythemal radiation in Central Spain. Int. J. Clim. 2011, 32, 929–940. [Google Scholar] [CrossRef]

- Iqbal, M. An Introduction to Solar Radiation, 1st ed.; Elsevier BV: Amsterdam, The Netherlands, 1983; ISBN 9780323151818. [Google Scholar]

- Standard ISO 4892-3:2016, Plastics—Methods of Exposure to Laboratory Light Sources—Part 3: Fluorescent UV Lamps. Available online: https://www.iso.org/standard/67793.html (accessed on 30 October 2021).

- Fountoulakis, I.; Zerefos, C.S.; Bais, A.F.; Kapsomenakis, J.; Koukouli, M.-E.; Ohkawara, N.; Fioletov, V.; De Backer, H.; Lakkala, K.; Karppinen, T.; et al. Twenty-five years of spectral UV-B measurements over Canada, Europe and Japan: Trends and effects from changes in ozone, aerosols, clouds, and surface reflectivity. Comptes Rendus Geosci. 2018, 350, 393–402. [Google Scholar] [CrossRef]

- Bilbao, J.; de Miguel, A. Estimation of UV-B irradiation from total global solar meteorological data in central Spain. J. Geophys. Res. 2010, 115, D00I09. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Qian, L.; Peng, X.; Huang, Z.; Yang, Y.; He, C.; Fang, P. New Aspects of Degradation in Silicone Rubber under UVA and UVB Irradiation: A Gas Chromatography–Mass Spectrometry Study. Polymers 2021, 13, 2215. [Google Scholar] [CrossRef] [PubMed]

- Amaro-Ortiz, A.; Yan, B.; D’Orazio, J.A. Ultraviolet Radiation, Aging and the Skin: Prevention of Damage by Topical cAMP Manipulation. Molecules 2014, 19, 6202–6219. [Google Scholar] [CrossRef]

- Standard ASTM D638—14, Standard Test Method for Tensile Properties of Plastics. Available online: https://www.astm.org/Standards/D638 (accessed on 30 October 2021).

- Standard ISO 291:2008, Plastics—Standard Atmospheres for Conditioning and Testing. Available online: https://www.iso.org/standard/50572.html (accessed on 30 October 2021).

- Standard ASTM D2990-01, Standard Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics. Available online: https://www.astm.org/Standards/D2990.htm (accessed on 30 October 2021).

- Wang, X.; Zhao, L.; Fuh, J.Y.H.; Lee, H.P. Effect of Porosity on Mechanical Properties of 3D Printed Polymers: Experiments and Micromechanical Modeling Based on X-ray Computed Tomography Analysis. Polymers 2019, 11, 1154. [Google Scholar] [CrossRef] [Green Version]

- Laureto, J.; Pearce, J. Anisotropic mechanical property variance between ASTM D638-14 type i and type iv fused filament fabricated specimens. Polym. Test. 2018, 68, 294–301. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Cai, L.; Golub, M.; Zhang, Y.; Yang, X.; Schlarman, K.; Zhang, J. Tensile, Creep, and Fatigue Behaviors of 3D-Printed Acrylonitrile Butadiene Styrene. J. Materi. Eng. Perform. 2018, 27, 57–62. [Google Scholar] [CrossRef] [Green Version]

- Popescu, D.; Zapciu, A.; Amza, C.G.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

| Material | Nozzle Diameter | Layer Height | Contours | Infill | Infill Pattern | Extrusion Temp. | Bed Temp. |

|---|---|---|---|---|---|---|---|

| PLA | 0.40 mm | 0.20 mm | 2 | 100% | Grid 45°/−45° | 205 °C | 45 °C |

| PETG | 235 °C | 65 °C |

| Property | PLA Control | PLA UV-B | PETG Control | PETG UV-B |

|---|---|---|---|---|

| Tensile strength [MPa] | 29.54 ± 0.35 | 27.99 ± 0.36 | 31.30 ± 0.24 | 19.98 ± 0.63 |

| Young’s Modulus [MPa] | 2775 ± 26.3 | 2760 ± 44 | 1648 ± 21.5 | 1629 ± 14.6 |

| Elongation at break [%] | 1.68 ± 0.02 | 1.43 ± 0.05 | 3.06 ± 0.04 | 1.36 ± 0.06 |

| Property | PLA (Control) | PLA (UV-B) | PETG (Control) | PETG (UV-B) |

|---|---|---|---|---|

| Compressive str. | 78.06 ± 0.55 | 73.17 ± 0.17 | 65.94 ± 9.0 | 47.04 ± 0.16 |

| Material | Tensile Properties | Compressive Properties | ||||||

|---|---|---|---|---|---|---|---|---|

| Strength [MPa] | Creep Test [MPa] | Target Load [N] | Used Load [N] | Strength [MPa] | Torque [N·m] | Used Load [N] | Creep Test [MPa] | |

| PLA | 29.54 | 7.5 | 117 | 12.5 × 9.4 | 78.06 | 5.07 | 2816 | 40.9 |

| PETG | 31.3 | 8 | 125 | 12.5 × 10 | 65.94 | 5.07 | 2816 | 40.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amza, C.G.; Zapciu, A.; Baciu, F.; Vasile, M.I.; Nicoara, A.I. Accelerated Aging Effect on Mechanical Properties of Common 3D-Printing Polymers. Polymers 2021, 13, 4132. https://doi.org/10.3390/polym13234132

Amza CG, Zapciu A, Baciu F, Vasile MI, Nicoara AI. Accelerated Aging Effect on Mechanical Properties of Common 3D-Printing Polymers. Polymers. 2021; 13(23):4132. https://doi.org/10.3390/polym13234132

Chicago/Turabian StyleAmza, Catalin Gheorghe, Aurelian Zapciu, Florin Baciu, Mihai Ion Vasile, and Adrian Ionut Nicoara. 2021. "Accelerated Aging Effect on Mechanical Properties of Common 3D-Printing Polymers" Polymers 13, no. 23: 4132. https://doi.org/10.3390/polym13234132

APA StyleAmza, C. G., Zapciu, A., Baciu, F., Vasile, M. I., & Nicoara, A. I. (2021). Accelerated Aging Effect on Mechanical Properties of Common 3D-Printing Polymers. Polymers, 13(23), 4132. https://doi.org/10.3390/polym13234132