Mechanical Response and Analysis of Cracking Process in Hybrid TRM Composites with Flax Textile and Curauá Fibres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Textile

2.2. Short Fibres

2.3. Mortar

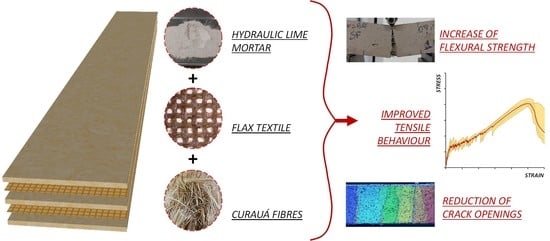

2.4. TRM Composite System

- Flax TRM: composite specimens including impregnated flax textile and plain mortar.

- SF_Flax TRM: composite specimens including impregnated flax textile and short curauá fibre-reinforced mortar.

3. Results and Discussion

3.1. Tensile Stress-Strain Response

3.2. Analysis of the Crack Pattern

4. Conclusions

- The addition of short curauá fibre in the amount of 1% in weight increased the flexural strength of the mortar, but significantly reduced its workability at the fresh state: the addition of superplasticizer admixtures is needed to guarantee a proper implementation of the composite.

- Flax TRMs, either including or not including short curauá fibres, showed the typical tri-phase tensile behaviour of plant-based TRMs; moreover, the use of impregnated textile reduced the deformability of the composite in stage II, making its response closer to that of conventional TRMs with respect to plant-based TRMs, including non-treated textiles [15].

- SF_Flax TRM specimens, including the fibre-reinforced mortar, exhibited a higher value of the stress corresponding to the occurrence of the first crack, σ1, and in general, a higher average stress in the entire stage II. SF_Flax TRM specimens exhibited a mean value of the dissipated energy in stage II, ΓII, of about 45% higher than that shown in Flax TRM specimens.

- No specific influence of the short fibre addition was observed in terms of deformability of the composite (ε2 and εmax): this aspect is mainly affected by the type of reinforcing textile adopted.

- SF_Flax TRM specimens exhibited a denser crack pattern with respect to Flax TRM specimens; in fact, due to the bridging effect of short curauá fibres, a general beneficial influence was observed, resulting in a higher number of cracks, and in a significant reduction of their width.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Donnini, J.; Maracchini, G.; Lenci, S.; Corinaldesi, V.; Quagliarini, E. TRM reinforced tuff and fired clay brick masonry: Experimental and analytical investigation on their in-plane and out-of-plane behavior. Constr. Build. Mater. 2021, 272, 121643. [Google Scholar] [CrossRef]

- Kouris, L.A.S.; Triantafillou, T.C. State-of-the-art on strengthening of masonry structures with textile reinforced mortar (TRM). Constr. Build. Mater. 2018, 188, 1221–1233. [Google Scholar] [CrossRef]

- De Felice, G.; D’Antino, T.; De Santis, S.; Meriggi, P.; Roscini, F. Lessons Learned on the Tensile and Bond Behavior of Fabric Reinforced Cementitious Matrix (FRCM) Composites. Front. Built. Environ. 2020, 6, 5. [Google Scholar] [CrossRef]

- Ferrara, G.; Caggegi, C.; Gabor, A.; Martinelli, E. Experimental Study on the Adhesion of Basalt Textile Reinforced Mortars (TRM) to Clay Brick Masonry: The Influence of Textile Density. Fibers 2019, 7, 103. [Google Scholar] [CrossRef] [Green Version]

- Ferrara, G.; Caggegi, C.; Gabor, A.; Martinelli, E. Recommendation of RILEM TC 232-TDT: Test methods and design of textile reinforced concrete: Uniaxial tensile test: Test method to determine the load bearing behavior of tensile specimens made of textile reinforced concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef] [Green Version]

- De Felice, G.; Aiello, M.A.; Caggegi, C.; Ceroni, F.; De Santis, S.; Garbin, E.; Gattesco, N.; Hojdys, L.; Krajewski, P.; Kwiecień, A.; et al. Recommendation of RILEM Technical Committee 250-CSM: Test method for Textile Reinforced Mortar to substrate bond characterization. Mater. Struct. 2018, 51, 95. [Google Scholar] [CrossRef]

- Balea, A.; Blanco, A.; Negro, C. Nanocelluloses: Natural-based materials for fiber-reinforced cement composites. A critical review. Polymers 2019, 11, 518. [Google Scholar] [CrossRef] [Green Version]

- Behera, P.; Noman, M.T.; Petrů, M. Enhanced Mechanical Properties of Eucalyptus-Basalt-Based Hybrid-Reinforced Cement Composites. Polymers 2020, 12, 2837. [Google Scholar] [CrossRef]

- Ban, Y.; Zhi, W.; Fei, M.; Liu, W.; Yu, D.; Fu, T.; Qiu, R. Preparation and Performance of Cement Mortar Reinforced by Modified Bamboo Fibers. Polymers 2020, 12, 2650. [Google Scholar] [CrossRef]

- Abbass, A.; Lourenço, P.B.; Oliveira, D.V. The use of natural fibers in repairing and strengthening of cultural heritage buildings. Mater. Today 2020, 31, S321–S328. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- De Carvalho Bello, C.B.; Cecchi, A.; Meroi, E.; Oliveira, D.V. Experimental and numerical investigations on the behaviour of masonry walls reinforced with an innovative sisal FRCM system. Key Eng. Mater. 2017, 747, 190–195. [Google Scholar] [CrossRef]

- De Carvalho Bello, C.B.; Boem, I.; Cecchi, A.; Gattesco, N.; Oliveira, D.V. Experimental tests for the characterization of sisal fiber reinforced cementitious matrix for strengthening masonry structures. Constr. Build. Mater. 2019, 219, 44–55. [Google Scholar] [CrossRef] [Green Version]

- Ferrara, G.; Martinelli, E. Tensile behaviour of Textile Reinforced Mortar composite systems with flax fibres. In Proceedings of the 12th Fib International PhD Symposium in Civil Engineering, Prague, Czech Republic, 29–31 August 2018; pp. 863–869. [Google Scholar]

- Olivito, R.S.; Cevallos, O.A.; Carrozzini, A. Development of durable cementitious composites using sisal and flax fabrics for reinforcement of masonry structures. Mater. Struct. 2014, 57, 258–268. [Google Scholar] [CrossRef]

- Bassani, M.; Tefa, L.; Coppola, B.; Palmero, P. Alkali-activation of aggregate fines from construction and demolition waste: Valorisation in view of road pavement subbase applications. J. Clean. Prod. 2019, 234, 71–84. [Google Scholar] [CrossRef]

- Trochoutsou, N.; Di Benedetti, M.; Pilakoutas, K.; Guadagnini, M. Mechanical Characterisation of Flax and Jute Textile-Reinforced Mortars. Constr Build Mater. 2020, 121564. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Martinelli, E.; Pepe, M.; De Andrade Silva, F.; Toledo Filho, R.D. Inverse identification of the bond behavior for jute fibers in cementitious matrix. Compos. B. Eng. 2016, 15, 440–452. [Google Scholar] [CrossRef]

- Codispoti, R.; Oliveira, D.V.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical performance of natural fiber-reinforced composites for the strengthening of masonry. Compos. B. Eng. 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Mercedes, L.; Bernat-Maso, E.; Gil, L. Analytical model for masonry walls strengthened with vegetal fabric reinforced cementitious matrix (FRCM) composites and subjected to cyclic loads. Mater. Struct. 2020, 53, 148. [Google Scholar] [CrossRef]

- Ferrara, G.; Caggegi, C.; Martinelli, E.; Gabor, A. Shear capacity of masonry walls externally strengthened using Flax-TRM composite systems: Experimental tests and comparative assessment. Constr. Build. Mater. 2020, 261, 120490. [Google Scholar] [CrossRef]

- Cevallos, O.A.; Olivito, R.S.; Codispoti, R.; Ombres, L. Flax and polyparaphenylene benzobisoxazole cementitious composites for the strengthening of masonry elements subjected to eccentric loading. Compos. B. Eng. 2015, 71, 82–95. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Durante, M.; Zinno, A.; Balsamo, A.; Prota, A. Structural behaviour of masonry panels strengthened with an innovative hemp fibre composite grid. Constr. Build. Mater. 2015, 100, 111–121. [Google Scholar] [CrossRef]

- Ferrara, G.; Coppola, B.; Di Maio, L.; Incarnato, L.; Martinelli, E. Tensile strength of flax fabrics to be used as reinforcement in cement-based composites: Experimental tests under different environmental exposures. Compos. B. Eng. 2019, 168, 511–523. [Google Scholar] [CrossRef]

- Mercedes, L.; Gil, L.; Bernat-Maso, E. Mechanical performance of vegetal fabric reinforced cementitious matrix (FRCM) composites. Constr. Build. Mater. 2018, 175, 161–173. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Toledo Filho, R.D. Influence of an impregnation treatment on the morphology and mechanical behaviour of flax yarns embedded in hydraulic lime mortar. Fibers 2019, 7, 30. [Google Scholar] [CrossRef] [Green Version]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Toledo Filho, R.D. Influence of Fibres Impregnation on the Tensile Response of Flax Textile Reinforced Mortar Composite Systems. RILEM-fib Int. Symp. Fibre Reinf. Concr. 2020, 983–990. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites–A review. Compos. B. Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: A comprehensive review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, X.; Liu, L.; Zhou, F.; Zhu, D.; Pan, W. Flexural behaviour of carbon textile-reinforced concrete with prestress and steel fibres. Polymers 2018, 10, 98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pereira, M.V.; Fujiyama, R.; Darwish, F.; Alves, G.T. On the strengthening of cement mortar by natural fibers. Mater. Res. 2015, 18, 1. [Google Scholar] [CrossRef] [Green Version]

- D’Almeida, A.L.F.S.; Mello Filho, J.; Toledo Filho, R. Use of curauá fibers as reinforcement in cement composites. Chem. Eng. Trans. 2009, 17, 1717–1722. [Google Scholar] [CrossRef]

- Zukowski, B.; Dos Santos Mendonça, Y.G.; De Andrade Silva, F.; Toledo Filho, R.D. Effect of moisture movement on the tensile stress–strain behavior of SHCC with alkali treated curauá fiber. Mater. Struct. 2020, 53, 49. [Google Scholar] [CrossRef]

- Zukowski, B.; Dos Santos, E.R.F.; Dos Santos Mendonça, Y.G.; De Andrade Silva, F.; Toledo Filho, R.D. The durability of SHCC with alkali treated curauá fiber exposed to natural weathering. Cem. Concr. Compos. 2018, 94, 116–125. [Google Scholar] [CrossRef]

- Zukowski, B.; De Andrade Silva, F.; Toledo Filho, R.D. Design of strain hardening cement-based composites with alkali treated natural curauá fiber. Cem. Concr. Compos. 2018, 89, 150–159. [Google Scholar] [CrossRef]

- D’Anna, J.; Amato, G.; Chen, J.F.; Minafò, G.; La Mendola, L. Experimental application of digital image correlation for the tensile characterization of basalt FRCM composites. Constr. Build. Mater. 2021, 271, 121770. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; De Lima, T.E.; Fediuk, R.; Olisov, A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Soltan, D.G.; Das Neves, P.; Olvera, A.; Junior, H.S.; Li, V.C. Introducing a curauá fiber reinforced cement-based composite with strain-hardening behavior. Ind. Crops. Prod. 2017, 103, 1–12. [Google Scholar] [CrossRef]

- Emdadi, A.; Mehdipour, I.; Libre, N.A.; Shekarchi, M. Optimized workability and mechanical properties of FRCM by using fiber factor approach: Theoretical and experimental study. Mater. Struct. 2015, 48, 1149–1161. [Google Scholar] [CrossRef]

- EN 1015-3: 1999. Methods of Test Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Flow Table); European Committee for Standardization: Brussels, Belgium, 1999. [Google Scholar]

- EN 196-1:1994. Methods of Testing Cement—Part 1: Determination of Strength; European Committee for Standardization: Brussels, Belgium, 1994. [Google Scholar]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Toledo Filho, R.D. Tensile behavior of Flax Textile Reinforced Lime-Mortar: Influence of reinforcement amount and textile impregnation. Cem. Concr. Compos. 2021. [Google Scholar] [CrossRef]

- Saidi, M.; Gabor, A. Experimental measurement of load-transfer length in textile-reinforced cementitious matrix composites using distributed optical fibres. Eur. J. Environ. Civ. Eng. 2020, 1–19. [Google Scholar] [CrossRef]

| Properties | Units | Mean | Co.V. (%) | |

|---|---|---|---|---|

| Flax thread | ||||

| filament diameter | (mm) | 16.8 | 30 | |

| density | (g/cm3) | 1.19 | 3 | |

| linear density | (Tex) | 302 | 15 | |

| No. threads/cm | (threads/cm) | 4.3 | - | |

| cross section | (mm2) | 0.25 | 17 | |

| Young modulus | (GPa) | 9.4 | 11 | |

| strain to failure | (%) | 3.9 | 13 | |

| tensile strength | (MPa) | 353.7 | 12 | |

| Impregnated flax textile strip | ||||

| No. of threads per strip | (threads/strip) | 12 | - | |

| cross section | (mm2) | 6.1 | 17 | |

| Young modulus | (GPa) | 12.4 | 14 | |

| strain to failure | (%) | 3.1 | 18 | |

| tensile strength | (MPa) | 266 | 13 | |

| Curauá fibres filament | ||||

| diameter | (μm) | 77.7 | 11 | |

| length | (mm) | 20 | - | |

| tensile strength | (MPa) | 697.2 | 22 | |

| Plain mortar | ||||

| spreading | (mm) | 223 | 2 | |

| compressive strength | (MPa) | 8.4 | 8 | |

| flexural strength | (MPa) | 3.9 | 8 | |

| Fibre-reinforced mortar | ||||

| spreading | (mm) | 153 | 2 | |

| compressive strength | (MPa) | 9.9 | 4 | |

| flexural strength | (MPa) | 5.9 | 4 |

| Series | σ1 (MPa) | ε2 (%) | εmax (%) | ΓII (J) |

|---|---|---|---|---|

| Flax TRM | 0.65 | 2.0 | 5.1 | 3.55 |

| Co.V. | 42% | 40% | 13% | 24% |

| SF_Flax TRM | 0.83 | 2.1 | 5.0 | 5.24 |

| Co.V. | 15% | 26% | 6% | 12% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrara, G.; Pepe, M.; Toledo Filho, R.D.; Martinelli, E. Mechanical Response and Analysis of Cracking Process in Hybrid TRM Composites with Flax Textile and Curauá Fibres. Polymers 2021, 13, 715. https://doi.org/10.3390/polym13050715

Ferrara G, Pepe M, Toledo Filho RD, Martinelli E. Mechanical Response and Analysis of Cracking Process in Hybrid TRM Composites with Flax Textile and Curauá Fibres. Polymers. 2021; 13(5):715. https://doi.org/10.3390/polym13050715

Chicago/Turabian StyleFerrara, Giuseppe, Marco Pepe, Romildo Dias Toledo Filho, and Enzo Martinelli. 2021. "Mechanical Response and Analysis of Cracking Process in Hybrid TRM Composites with Flax Textile and Curauá Fibres" Polymers 13, no. 5: 715. https://doi.org/10.3390/polym13050715

APA StyleFerrara, G., Pepe, M., Toledo Filho, R. D., & Martinelli, E. (2021). Mechanical Response and Analysis of Cracking Process in Hybrid TRM Composites with Flax Textile and Curauá Fibres. Polymers, 13(5), 715. https://doi.org/10.3390/polym13050715