Effect of Chitosan Coating Incorporated with Artemisia fragrans Essential Oil on Fresh Chicken Meat during Refrigerated Storage

Abstract

:1. Introduction

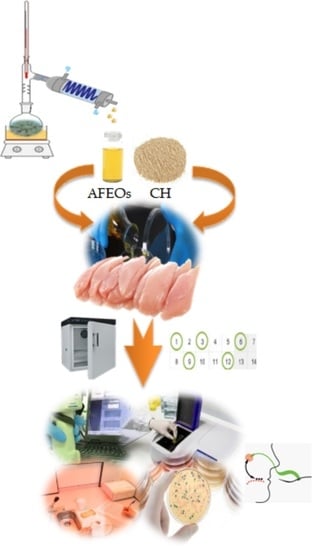

2. Materials and Methods

2.1. Preparation of Artemisia Fragans Essential Oil (AFEOs)

2.2. AFEOs Isolation

2.3. Preparation of Meat Samples

2.4. Proximate Composition and pH

2.5. Measurement of Thiobarbituric Acid Reactive Substances (TBARS)

2.6. Determination of Total Volatile Nitrogen (TVB-N)

2.7. Total Phenolic Content (TPC)

2.8. Determination of Color Parameters

2.9. Microbiological Analysis

2.10. Sensory Properties

2.11. Statistical Analysis

3. Results and Discussion

3.1. Gas Chromatography-Mass Spectrometry Analysis

3.2. Effect of CH-AFEOs Coating on Proximate Composition and pH

3.3. Effect of CH-AFEOs Coating on TBARS and TVB-N

3.4. Effect of CH-AFEOs Coating on TPC

3.5. Effect of CH-AFEOs Coating on Color Parameters

3.6. Effect of CH-AFEOs Coating on Microbiological Analysis

3.7. Effect of CH-AFEOs Coating on Sensory Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Noori, S.; Zeynali, F.; Almasi, H. Antimicrobial and antioxidant efficiency of nanoemulsion-based edible coating containing ginger (Zingiber officinale) essential oil and its effect on safety and quality attributes of chicken breast fillets. Food Control 2018, 84, 312–320. [Google Scholar] [CrossRef]

- Latou, E.; Mexis, S.F.; Badeka, A.V.; Kontakos, S.; Kontominas, M.G. Combined effect of chitosan and modified atmosphere packaging for shelf life extension of chicken breast fillets. LWT Food Sci. Technol. 2014, 55, 263–268. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Batlle, R.; Gómez, M. Extension of the shelf-life of foal meat with two antioxidant active packaging systems. LWT Food Sci. Technol. 2014, 59, 181–188. [Google Scholar] [CrossRef]

- Woraprayote, W.; Malila, Y.; Sorapukdee, S.; Swetwiwathana, A.; Benjakul, S.; Visessanguan, W. Bacteriocins from lactic acid bacteria and their applications in meat and meat products. Meat Sci. 2016, 120, 118–132. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Munekata, P.E.S.; Gómez, B.; Barba, F.J.; Mora, L.; Pérez-Santaescolástica, C.; Toldrá, F. Bioactive peptides as natural antioxidants in food products–A review. Trends Food Sci. Technol. 2018, 79, 136–147. [Google Scholar] [CrossRef]

- Mexis, S.F.; Chouliara, E.; Kontominas, M.G. Shelf life extension of ground chicken meat using an oxygen absorber and a citrus extract. LWT Food Sci. Technol. 2012, 49, 21–27. [Google Scholar] [CrossRef]

- Simona, J.; Dani, D.; Petr, S.; Marcela, N.; Jakub, T.; Bohuslava, T. Edible films from carrageenan/orange essential oil/trehalose—structure, optical properties, and antimicrobial activity. Polymers 2021, 13, 332–351. [Google Scholar] [CrossRef] [PubMed]

- Alirezalu, K.; Hesari, J.; Eskandari, M.H.; Valizadeh, H.; Sirousazar, M. Effect of Green Tea, Stinging Nettle and Olive Leaves Extracts on the Quality and Shelf Life Stability of Frankfurter Type Sausage. J. Food Process. Preserv. 2017, 41, e13100. [Google Scholar] [CrossRef]

- Lin, L.; Gu, Y.; Sun, Y.; Cui, H. Characterization of chrysanthemum essential oil triple-layer liposomes and its application against Campylobacter jejuni on chicken. LWT 2019, 107, 16–24. [Google Scholar] [CrossRef]

- Pateiro, M.; Barba, F.J.; Domínguez, R.; Sant’Ana, A.S.; Mousavi Khaneghah, A.; Gavahian, M.; Gómez, B.; Lorenzo, J.M. Essential oils as natural additives to prevent oxidation reactions in meat and meat products: A review. Food Res. Int. 2018, 113, 156–166. [Google Scholar] [CrossRef]

- Alirezalu, A.; Ahmadi, N.; Salehi, P.; Sonboli, A.; Alirezalu, K.; Mousavi Khaneghah, A.; Barba, F.J.; Munekata, P.E.S.; Lorenzo, J.M. Physicochemical Characterization, Antioxidant Activity, and Phenolic Compounds of Hawthorn (Crataegus spp.) Fruits Species for Potential Use in Food Applications. Foods 2020, 9, 436. [Google Scholar] [CrossRef] [Green Version]

- Lorenzo, J.M.; Munekata, P.E.S. Phenolic compounds of green tea: Health benefits and technological application in food. Asian Pac. J. Trop. Biomed. 2016, 6, 709–719. [Google Scholar] [CrossRef] [Green Version]

- Umaraw, P.; Munekata, P.E.S.; Verma, A.K.; Barba, F.J.; Singh, V.P.; Kumar, P.; Lorenzo, J.M. Edible films/coating with tailored properties for active packaging of meat, fish and derived products. Trends Food Sci. Technol. 2020, 98, 10–24. [Google Scholar] [CrossRef]

- Lorenzo, J.M.J.M.; Sineiro, J.; Amado, I.R.; Franco, D. Influence of natural extracts on the shelf life of modified atmosphere-packaged pork patties. Meat Sci. 2014, 96, 526–534. [Google Scholar] [CrossRef]

- Domínguez, R.; Barba, F.J.; Gómez, B.; Putnik, P.; Bursać Kovačević, D.; Pateiro, M.; Santos, E.M.; Lorenzo, J.M. Active packaging films with natural antioxidants to be used in meat industry: A review. Food Res. Int. 2018, 113, 93–101. [Google Scholar] [CrossRef] [PubMed]

- Mulla, M.; Ahmed, J.; Al-Attar, H.; Castro-Aguirre, E.; Arfat, Y.A.; Auras, R. Antimicrobial efficacy of clove essential oil infused into chemically modified LLDPE film for chicken meat packaging. Food Control 2017, 73, 663–671. [Google Scholar] [CrossRef]

- Hashemi, S.M.B.; Mousavi Khaneghah, A. Characterization of novel basil-seed gum active edible films and coatings containing oregano essential oil. Prog. Org. Coatings 2017, 110, 35–41. [Google Scholar] [CrossRef]

- Cui, H.; Wu, J.; Li, C.; Lin, L. Improving anti-listeria activity of cheese packaging via nanofiber containing nisin-loaded nanoparticles. LWT Food Sci. Technol. 2017, 81, 233–242. [Google Scholar] [CrossRef]

- Lin, L.; Xue, L.; Duraiarasan, S.; Haiying, C. Preparation of ε-polylysine/chitosan nanofibers for food packaging against Salmonella on chicken. Food Packag. Shelf Life 2018, 17, 134–141. [Google Scholar] [CrossRef]

- Alirezalu, K.; Hesari, J.; Yaghoubi, M.; Khaneghah, A.M.; Alirezalu, A.; Pateiro, M.; Lorenzo, J.M. Combined effects of ε-polylysine and ε-polylysine nanoparticles with plant extracts on the shelf life and quality characteristics of nitrite-free frankfurter-type sausages. Meat Sci. 2021, 172, 108318. [Google Scholar] [CrossRef]

- Alirezalu, K.; Hesari, J.; Nemati, Z.; Munekata, P.E.S.; Barba, F.J.; Lorenzo, J.M. Combined effect of natural antioxidants and antimicrobial compounds during refrigerated storage of nitrite-free frankfurter-type sausage. Food Res. Int. 2019, 120, 839–850. [Google Scholar] [CrossRef]

- Farajzadeh, F.; Motamedzadegan, A.; Shahidi, S.A.; Hamzeh, S. The effect of chitosan-gelatin coating on the quality of shrimp (Litopenaeus vannamei) under refrigerated condition. Food Control 2016, 67, 163–170. [Google Scholar] [CrossRef]

- Mehdizadeh, T.; Tajik, H.; Langroodi, A.M.; Molaei, R.; Mahmoudian, A. Chitosan-starch film containing pomegranate peel extract and Thymus kotschyanus essential oil can prolong the shelf life of beef. Meat Sci. 2020, 163, 108073. [Google Scholar] [CrossRef] [PubMed]

- Mehdizadeh, T.; Mojaddar Langroodi, A. Chitosan coatings incorporated with propolis extract and Zataria multiflora Boiss oil for active packaging of chicken breast meat. Int. J. Biol. Macromol. 2019, 141, 401–409. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liang, Y.; Li, X.; Kang, H. Effect of chitosan-gelatin coating containing nano-encapsulated tarragon essential oil on the preservation of pork slices. Meat Sci. 2020, 166, 108137. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Liu, L.; Gong, X.; Chi, F.; Ma, Z. Fabrication and comparison of active films from chitosan incorporating different spice extracts for shelf life extension of refrigerated pork. LWT 2021, 135, 110181. [Google Scholar] [CrossRef]

- Bora, K.S.; Sharma, A. The Genus Artemisia: A Comprehensive Review. Pharm. Biol. 2011, 49, 101–109. [Google Scholar] [CrossRef] [Green Version]

- Orhan, I.E.; Belhattab, R.; Şenol, F.S.; Gülpinar, A.R.; Hoşbaş, S.; Kartal, M. Profiling of cholinesterase inhibitory and antioxidant activities of Artemisia absinthium, A. herba-alba, A. fragrans, Marrubium vulgare, M. astranicum, Origanum vulgare subsp. glandulossum and essential oil analysis of two Artemisia species. Ind. Crops Prod. 2010, 32, 566–571. [Google Scholar] [CrossRef]

- Baldino, L.; Reverchon, E.; Della Porta, G. An optimized process for SC-CO2 extraction of antimalarial compounds from Artemisia annua L. J. Supercrit Fluids 2017, 128, 89–93. [Google Scholar] [CrossRef]

- Wan, X.L.; Song, Z.H.; Niu, Y.; Cheng, K.; Zhang, J.F.; Ahmad, H.; Zhang, L.L.; Wang, T. Evaluation of enzymatically treated Artemisia annua L. on growth performance, meat quality, and oxidative stability of breast and thigh muscles in broilers. Poult. Sci. 2017, 96, 844–850. [Google Scholar] [CrossRef]

- Kim, C.H.; Kim, G.B.; Chang, M.B.; Bae, G.S.; Paik, I.K.; Kil, D.Y. Effect of dietary supplementation of Lactobacillus-fermented Artemisia princeps on growth performance, meat lipid peroxidation, and intestinal microflora in Hy-line Brown male chickens. Poult. Sci. 2012, 91, 2845–2851. [Google Scholar] [CrossRef] [PubMed]

- Karsli, B.; Caglak, E.; Prinyawiwatkul, W. Effect of high molecular weight chitosan coating on quality and shelf life of refrigerated channel catfish fillets. LWT Food Sci. Technol. 2021, 142, 111034. [Google Scholar] [CrossRef]

- Liu, D.C.; Tsau, R.T.; Lin, Y.C.; Jan, S.S.; Tan, F.J. Effect of various levels of rosemary or Chinese mahogany on the quality of fresh chicken sausage during refrigerated storage. Food Chem. 2009, 117, 106–113. [Google Scholar] [CrossRef]

- Goulas, A.E.; Kontominas, M.G. Effect of salting and smoking-method on the keeping quality of chub mackerel (Scomber japonicus): Biochemical and sensory attributes. Food Chem. 2005, 93, 511–520. [Google Scholar] [CrossRef]

- León, K.; Mery, D.; Pedreschi, F.; León, J. Color measurement in L*a*b* units from RGB digital images. Food Res. Int. 2006, 39, 1084–1091. [Google Scholar] [CrossRef]

- FDA. Bacteriological Analytical Manual for Foods; US Government Printing Office: Washington, DC, USA, 2013.

- Economou, T.; Pournis, N.; Ntzimani, A.; Savvaidis, I.N. Nisin-EDTA treatments and modified atmosphere packaging to increase fresh chicken meat shelf-life. Food Chem. 2009, 114, 1470–1476. [Google Scholar] [CrossRef]

- Gahruie, H.H.; Ziaee, E.; Eskandari, M.H.; Hosseini, S.M.H. Characterization of basil seed gum -based edible films incorporated with Zataria multiflora essential oil nanoemulsion. Carbohydr. Polym. 2017, 166, 93–103. [Google Scholar] [CrossRef]

- Agregán, R.; Barba, F.J.; Gavahian, M.; Franco, D.; Khaneghah, A.M.; Carballo, J.; Ferreira, I.C.F.R.C.; da Silva Barretto, A.C.; Lorenzo, J.M.; Silva Barretto, A.C.; et al. Fucus vesiculosus extracts as natural antioxidants for improvement of physicochemical properties and shelf life of pork patties formulated with oleogels. J. Sci. Food Agric. 2019, 99, 4561–4570. [Google Scholar] [CrossRef] [Green Version]

- De Carvalho, F.A.L.; Lorenzo, J.M.; Pateiro, M.; Bermúdez, R.; Purriños, L.; Trindade, M.A. Effect of guarana (Paullinia cupana) seed and pitanga (Eugenia uniflora L.) leaf extracts on lamb burgers with fat replacement by chia oil emulsion during shelf life storage at 2 °C. Food Res. Int. 2019, 125, 108554. [Google Scholar] [CrossRef] [PubMed]

- Cullere, M.; Dalle Zotte, A.; Tasoniero, G.; Giaccone, V.; Szendrő, Z.; Szín, M.; Odermatt, M.; Gerencsér, Z.; Dal Bosco, A.; Matics, Z. Effect of diet and packaging system on the microbial status, pH, color and sensory traits of rabbit meat evaluated during chilled storage. Meat Sci. 2018, 141, 36–43. [Google Scholar] [CrossRef]

- Alirezalu, K.; Shafaghi Molan, H.; Yaghoubi, M.; Pateiro, M.; Lorenzo, J.M. ɛ-polylysine coating with stinging nettle extract for fresh beef preservation. Meat Sci. 2021. [Google Scholar] [CrossRef]

- Radha Krishnan, K.; Babuskin, S.; Azhagu Saravana Babu, P.; Sasikala, M.; Sabina, K.; Archana, G.; Sivarajan, M.; Sukumar, M. Antimicrobial and antioxidant effects of spice extracts on the shelf life extension of raw chicken meat. Int. J. Food Microbiol. 2014, 171, 32–40. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Chang, W.; Chen, M.; Xu, F.; Ma, J.; Zhong, F. Tailoring physicochemical properties of chitosan films and their protective effects on meat by varying drying temperature. Carbohydr. Polym. 2019, 212, 150–159. [Google Scholar] [CrossRef]

- Vaithiyanathan, S.; Naveena, B.M.; Muthukumar, M.; Girish, P.S.; Kondaiah, N. Effect of dipping in pomegranate (Punica granatum) fruit juice phenolic solution on the shelf life of chicken meat under refrigerated storage (4 °C). Meat Sci. 2011, 88, 409–414. [Google Scholar] [CrossRef]

- Berizi, E.; Hosseinzadeh, S.; Shekarforoush, S.S.; Barbieri, G. Microbial, chemical, textural and sensory properties of coated rainbow trout by chitosan combined with pomegranate peel extract during frozen storage. Int. J. Biol. Macromol. 2018, 106, 1004–1013. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A comprehensive review on lipid oxidation in meat and meat products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Guo, X.; Ji, M.; Wu, J.; Zhu, W.; Wang, J.; Cheng, C.; Chen, L.; Zhang, Q. Preservative effects of fish gelatin coating enriched with CUR/βCD emulsion on grass carp (Ctenopharyngodon idellus) fillets during storage at 4 °C. Food Chem. 2019, 272, 643–652. [Google Scholar] [CrossRef] [PubMed]

- Jonaidi Jafari, N.; Kargozari, M.; Ranjbar, R.; Rostami, H.; Hamedi, H. The effect of chitosan coating incorporated with ethanolic extract of propolis on the quality of refrigerated chicken fillet. J. Food Process. Preserv. 2018, 42, e13336. [Google Scholar] [CrossRef]

- Sogut, E.; Seydim, A.C. The effects of chitosan- and polycaprolactone-based bilayer films incorporated with grape seed extract and nanocellulose on the quality of chicken breast fillets. LWT Food Sci. Technol. 2019, 101, 799–805. [Google Scholar] [CrossRef]

- Pabast, M.; Shariatifar, N.; Beikzadeh, S.; Jahed, G. Effects of chitosan coatings incorporating with free or nano-encapsulated Satureja plant essential oil on quality characteristics of lamb meat. Food Control 2018, 91, 185–192. [Google Scholar] [CrossRef]

- Fang, Z.; Lin, D.; Warner, R.D.; Ha, M. Effect of gallic acid/chitosan coating on fresh pork quality in modified atmosphere packaging. Food Chem. 2018, 260, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Nouri Ala, M.A.; Shahbazi, Y. The effects of novel bioactive carboxymethyl cellulose coatings on food-borne pathogenic bacteria and shelf life extension of fresh and sauced chicken breast fillets. LWT 2019, 111, 602–611. [Google Scholar] [CrossRef]

- Mojaddar Langroodi, A.; Tajik, H.; Mehdizadeh, T.; Moradi, M.; Moghaddas Kia, E.; Mahmoudian, A. Effects of sumac extract dipping and chitosan coating enriched with Zataria multiflora Boiss oil on the shelf-life of meat in modified atmosphere packaging. LWT 2018, 98, 372–380. [Google Scholar] [CrossRef]

- Abdou, E.S.; Galhoum, G.F.; Mohamed, E.N. Curcumin loaded nanoemulsions/pectin coatings for refrigerated chicken fillets. Food Hydrocoll. 2018, 83, 445–453. [Google Scholar] [CrossRef]

- Alirezalu, K.; Pateiro, M.; Yaghoubi, M.; Alirezalu, A.; Peighambardoust, S.H.; Lorenzo, J.M. Phytochemical constituents, advanced extraction technologies and techno-functional properties of selected Mediterranean plants for use in meat products. A comprehensive review. Trends Food Sci. Technol. 2020, 100, 292–306. [Google Scholar] [CrossRef]

- Pateiro, M.; Vargas, F.C.; Chincha, A.A.I.A.; Sant’Ana, A.S.; Strozzi, I.; Rocchetti, G.; Barba, F.J.; Domínguez, R.; Lucini, L.; do Amaral Sobral, P.J.; et al. Guarana seed extracts as a useful strategy to extend the shelf life of pork patties: UHPLC-ESI/QTOF phenolic profile and impact on microbial inactivation, lipid and protein oxidation and antioxidant capacity. Food Res. Int. 2018, 114, 55–63. [Google Scholar] [CrossRef]

- Suman, S.P.; Joseph, P. Myoglobin chemistry and meat color. Annu. Rev. Food Sci. Technol. 2013, 4, 79–99. [Google Scholar] [CrossRef] [Green Version]

- Zarringhalami, S.; Sahari, M.A.; Hamidi-Esfehani, Z. Partial replacement of nitrite by annatto as a colour additive in sausage. Meat Sci. 2009, 81, 281–284. [Google Scholar] [CrossRef]

- OJEU Commission regulation (EU) no 2073/2005 of 15 November 2005 on microbiological criteria for foodstuffs. Off. J. Eur. Union 2005, L338, 1–26.

- Alirezalu, K.; Yaghoubi, M.; Nemati, Z.; Farmani, B.; Mousavi Khaneghah, A. Efficacy of stinging nettle extract in combination with ε-polylysine on the quality, safety, and shelf life of rainbow trout fillets. Food Sci. Nut. 2021. [Google Scholar] [CrossRef]

- Bazargani-Gilani, B.; Aliakbarlu, J.; Tajik, H. Effect of pomegranate juice dipping and chitosan coating enriched with Zataria multiflora Boiss essential oil on the shelf-life of chicken meat during refrigerated storage. Innov. Food Sci. Emerg. Technol. 2015, 29, 280–287. [Google Scholar] [CrossRef]

- Duan, J.; Jiang, Y.; Cherian, G.; Zhao, Y. Effect of combined chitosan-krill oil coating and modified atmosphere packaging on the storability of cold-stored lingcod (Ophiodon elongates) fillets. Food Chem. 2010, 122, 1035–1042. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Munekata, P.E.S.; Dominguez, R.; Pateiro, M.; Saraiva, J.A.; Franco, D. Main Groups of Microorganisms of Relevance for Food Safety and Stability: General Aspects and Overall Description. In Innovative Technologies for Food Preservation Inactivation of Spoilage and Pathogenic Microorganisms; Barba, F.J., Sant’Ana, A.S., Orlie, V., Koubaa, M., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 53–107. ISBN 9780128110324. [Google Scholar]

- Kanatt, S.R.; Chander, R.; Sharma, A. Chitosan and mint mixture: A new preservative for meat and meat products. Food Chem. 2008, 107, 845–852. [Google Scholar] [CrossRef]

- Petrou, S.; Tsiraki, M.; Giatrakou, V.; Savvaidis, I.N. Chitosan dipping or oregano oil treatments, singly or combined on modified atmosphere packaged chicken breast meat. Int. J. Food Microbiol. 2012, 156, 264–271. [Google Scholar] [CrossRef] [PubMed]

| Name | Area (%) Essential Oil |

|---|---|

| 4-carene | 0.42 |

| Methyl Cinnamat | 0.25 |

| 3-carene | 0.20 |

| β-Cymene | 1.37 |

| p-Cymene | 0.45 |

| Camphene | 0.9 |

| Cis-Salvene | 0.2 |

| l-Phellandrene | 0.47 |

| Sabinene | 0.46 |

| α-Terpinolene | 0.75 |

| α-Pinene | 0.2 |

| β-Phellandrene | 0.51 |

| β-Pinene | 0.19 |

| γ-Terpinene | 0.69 |

| verbenene | 0.18 |

| 1,8-Cineole | 21.04 |

| 4-Terpineol | 2.65 |

| l-Camphor | 11.87 |

| cis-Jasmone | 0.54 |

| Isobornyl alcohol | 3.49 |

| l-Carvone | 1.15 |

| Myrtenal | 0.17 |

| Myrtenol | 2.16 |

| Pinocarvone | 0.25 |

| Piperitone | 0.98 |

| Sabinyl acetate | 1.63 |

| Thujone | 40.21 |

| Sesquiterpenes (ST) | 0.37 |

| Germacrene-D | 0.38 |

| Copaene | 0.36 |

| Oxygentated Sesquiterpenes (OST) | 2.08 |

| Carvacrol | 1.12 |

| Cis-Davanone | 0.94 |

| Others (OTH) | 0.40 |

| 1-Octen-3-ol | 0.46 |

| Sample | Moisture | Fat | Ash | Protein |

|---|---|---|---|---|

| T1 | 76.51 ± 1.63 | 1.37 ± 0.14 | 1.20 ± 0.04 | 20.90 ± 0.96 |

| T2 | 76.02 ± 1.79 | 1.40 ± 0.07 | 1.10 ± 0.09 | 20.92 ± 0.99 |

| T3 | 76.26 ± 1.76 | 1.41 ± 0.14 | 1.02 ± 0.02 | 21.11 ± 0.35 |

| T4 | 76.15 ± 0.42 | 1.39 ± 0.23 | 1.10 ± 0.03 | 21.34 ± 0.83 |

| T5 | 76.89 ± 1.44 | 1.41 ± 0.09 | 1.14 ± 0.04 | 20.51 ± 0.85 |

| Sample | Storage (Day) | |||||

|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | ||

| TBARS (mg MDA/kg) | T1 | 1.03 ± 0.006 Ae | 1.16 ± 0.011 Bd | 1.45 ± 0.017 Bc | 1.81 ± 0.014 Ab | 1.92 ± 0.020 Ba |

| T2 | 1.03 ± 0.004 Ae | 1.64 ± 0.017 Ad | 1.73 ± 0.026 Ac | 1.87 ± 0.011 Ab | 2.10 ± 0.007 Aa | |

| T3 | 1.01 ± 0.003 Ad | 1.10 ± 0.002 Bd | 1.33 ± 0.029 Cc | 1.62 ± 0.023 Bb | 1.75 ± 0.023 Ca | |

| T4 | 0.98 ± 0.017 Ad | 1.09 ± 0.001 Bd | 1.28 ± 0.017 Cc | 1.47 ± 0.026 Cb | 1.64 ± 0.029 Da | |

| T5 | 0.96 ± 0.008 Ae | 1.06 ± 0.006 Bd | 1.21 ± 0.018 Dc | 1.41 ± 0.018 Cb | 1.61 ± 0.020 Da | |

| TVB-N (mg/100 g) | T1 | 15.6 ± 0.001 Bd | 36.5 ± 0.012 Bc | 37.2 ± 0.008 Bc | 105.0 ± 0.004 Bb | 151.2 ± 0.004 Ba |

| T2 | 17.9 ± 0.021 Ad | 39.4 ± 0.003 Ac | 41.9 ± 0.008 Ac | 178.3 ± 0.008 Ab | 182.3 ± 0.008 Aa | |

| T3 | 10.0 ± 0.005 Cd | 14.1 ± 0.004 Cc | 17.1 ± 0.012 Cb | 18.3 ± 0.004 Db | 54.3 ± 0.004 Ca | |

| T4 | 10.0 ± 0.004 Ce | 12.8 ± 0.004 Dd | 14.1 ± 0.004 Dc | 19.7 ± 0.004 Cb | 28.2 ± 0.004 Da | |

| T5 | 8.7 ± 0.009 Dd | 11.1 ± 0.004 Ec | 11.4 ± 0.006 Ec | 18.3 ± 0.004 Db | 25.3 ± 0.004 Ea | |

| Sample | Storage (Day) | |||||

|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | ||

| L* | T1 | 30.94 ± 0.618 Ca | 26.94 ± 0.529 Bb | 27.77 ± 0.309 Bb | 27.44 ± 0.277 Cb | 27.00 ± 0.600 Bb |

| T2 | 31.11 ± 0.493 Ca | 33.00 ± 0.003 Aa | 29.16 ± 0.254 Ba | 33.22 ± 0.309 Ba | 25.83 ± 0.984 Bb | |

| T3 | 38.61 ± 0.111 Ba | 34.33 ± 0.346 Ab | 37.11 ± 0.829 Aa | 33.72 ± 0.364 ABb | 37.05 ± 0.242 Aa | |

| T4 | 38.83 ± 0.346 Aa | 35.50 ± 0.010 Aab | 36.77 ± 0.547 Aa | 32.11 ± 0.618 Bb | 38.05 ± 0.388 Aa | |

| T5 | 37.93 ± 0.693 Aa | 34.44 ± 0.433 Ab | 30.44 ± 0.454 Bc | 36.59 ± 0.746 Aa | 36.38 ± 0.484 Aa | |

| a* | T1 | 0.66 ± 0.166 ABb | 4.94 ± 0.444 Aa | −0.22 ± 0.400 Aab | −2.00 ± 0.384 Ab | −5.33 ± 0.509 Ac |

| T2 | −1.33 ± 0.254 BCb | 2.88 ± 0.200 Aa | −3.77 ± 0.388 Bc | −3.83 ± 0.166 Cc | −4.22 ± 0.337 Cd | |

| T3 | −3.50 ± 0.096 Ca | −3.33 ± 0.096 Ca | −3.94 ± 0.293 Bb | −4.72 ± 0.242 Dc | −4.77 ± 0.400 Bc | |

| T4 | −2.38 ± 0.995 Ca | −4.11 ± 0.364 Cb | −4.94 ± 0.474 Cd | −2.27 ± 0.293 Ba | −4.83 ± 0.096 Bc | |

| T5 | 1.46 ± 0.062 Aa | −1.88 ± 0.493 Bc | −0.77 ± 0.146 Ab | −1.68 ± 0.168 Ac | −4.33 ± 0.509 Cd | |

| b* | T1 | 19.11 ± 0.963 Cbc | 18.94 ± 0.146 Cc | 17.94 ± 0.111 Cd | 16.11 ± 0.200 Ce | 20.38 ± 0.146 Ca |

| T2 | 17.83 ± 0.146 Dd | 20.00 ± 0.192 Cb | 17.87 ± 0.055 Cd | 18.16 ± 0.192 Bc | 22.22 ± 0.585 Ba | |

| T3 | 17.16 ± 0.254 Dd | 22.83 ± 0.166 Ab | 21.61 ± 0.493 ABc | 21.11 ± 0.055 Ac | 24.83 ± 0.333 Aa | |

| T4 | 20.83 ± 0.192 BCb | 21.61 ± 0.111 ABa | 22.11 ± 0.200 Aa | 20.33 ± 0.192 Ab | 22.22 ± 0.222 Ba | |

| T5 | 23.33 ± 0.461 Aa | 20.27 ± 0.293 Bb | 20.44 ± 0.146 Bb | 19.26 ± 0.156 ABb | 23.66 ± 0.288 ABa | |

| Sample | Storage (Day) | |||||

|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | ||

| TVC | T1 | 4.48 ± 0.012 Ac | 5.89 ± 0.196 Bb | 7.77 ± 0.004 Aa | 7.95 ± 0.001 Aa | 8.01 ± 0.012 Aa |

| T2 | 4.47 ± 0.115 Ac | 6.22 ± 0.114 Ab | 8.04 ± 0.022 Aa | 8.13 ± 0.020 Aa | 8.21 ± 0.015 Aa | |

| T3 | 2.29 ± 0.013 Be | 3.02 ± 0.026 Cd | 4.42 ± 0.018 Bc | 5.67 ± 0.005 Bb | 7.41 ± 0.012 Ba | |

| T4 | 2.33 ± 0.032 Be | 2.85 ± 0.009 Cd | 3.45 ± 0.017 Cc | 5.55 ± 0.008 Bb | 6.90 ± 0.027 Ca | |

| T5 | 2.27 ± 0.015 Bd | 2.30 ± 0.007 Dd | 3.27 ± 0.013 Cc | 4.61 ± 0.010 Cb | 5.32 ± 0.014 Da | |

| Coliforms | T1 | 4.21 ± 0.132 Ad | 4.71 ± 0.052 Bc | 7.82 ± 0.009 Ab | 8.05 ± 0.014 Ab | 8.58 ± 0.019 Aa |

| T2 | 4.08 ± 0.044 Ad | 6.18 ± 0.006 Ac | 8.23 ± 0.012 Ab | 8.38 ± 0.005 Ab | 8.84 ± 0.004 Aa | |

| T3 | 1.47 ± 0.013 Bc | 1.31 ± 0.318 Dc | 3.33 ± 0.017 Bb | 3.64 ± 0.028 Bb | 4.47 ± 0.004 Ba | |

| T4 | ND | 1.78 ± 0.015 Cd | 3.12 ± 0.067 BCc | 3.50 ± 0.046 Bb | 4.18 ± 0.009 BCa | |

| T5 | ND | 1.47 ± 0.012 Dd | 2.86 ± 0.019 Cc | 3.03 ± 0.009 Cb | 3.87 ± 0.031 Ca | |

| Molds and yeast | T1 | 3.34 ± 0.022 Be | 3.68 ± 0.046 Bd | 6.03 ± 0.004 Bc | 7.28 ± 0.011 Bb | 7.55 ± 0.015 Ba |

| T2 | 3.66 ± 0.029 Ae | 4.13 ± 0.025 Ad | 6.96 ± 0.006 Ac | 7.78 ± 0.012 Ab | 8.02 ± 0.020 Aa | |

| T3 | 1.60 ± 0.012 Ce | 1.94 ± 0.013 Cd | 3.97 ± 0.023 Cc | 4.59 ± 0.007 Cb | 4.92 ± 0.026 Ca | |

| T4 | 1.30 ± 0.013 De | 1.84 ± 0.012 Cd | 3.49 ± 0.057 Dc | 4.38 ± 0.046 Db | 4.61 ± 0.013 Da | |

| T5 | 1.00 ± 0.015 Ee | 1.69 ± 0.015 Dd | 2.99 ± 0.025 Ec | 3.97 ± 0.022 Eb | 4.27 ± 0.015 Ea | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaghoubi, M.; Ayaseh, A.; Alirezalu, K.; Nemati, Z.; Pateiro, M.; Lorenzo, J.M. Effect of Chitosan Coating Incorporated with Artemisia fragrans Essential Oil on Fresh Chicken Meat during Refrigerated Storage. Polymers 2021, 13, 716. https://doi.org/10.3390/polym13050716

Yaghoubi M, Ayaseh A, Alirezalu K, Nemati Z, Pateiro M, Lorenzo JM. Effect of Chitosan Coating Incorporated with Artemisia fragrans Essential Oil on Fresh Chicken Meat during Refrigerated Storage. Polymers. 2021; 13(5):716. https://doi.org/10.3390/polym13050716

Chicago/Turabian StyleYaghoubi, Milad, Ali Ayaseh, Kazem Alirezalu, Zabihollah Nemati, Mirian Pateiro, and José M. Lorenzo. 2021. "Effect of Chitosan Coating Incorporated with Artemisia fragrans Essential Oil on Fresh Chicken Meat during Refrigerated Storage" Polymers 13, no. 5: 716. https://doi.org/10.3390/polym13050716

APA StyleYaghoubi, M., Ayaseh, A., Alirezalu, K., Nemati, Z., Pateiro, M., & Lorenzo, J. M. (2021). Effect of Chitosan Coating Incorporated with Artemisia fragrans Essential Oil on Fresh Chicken Meat during Refrigerated Storage. Polymers, 13(5), 716. https://doi.org/10.3390/polym13050716