Durability of Externally Bonded Fiber-Reinforced Polymer Composites in Concrete Structures: A Critical Review

Abstract

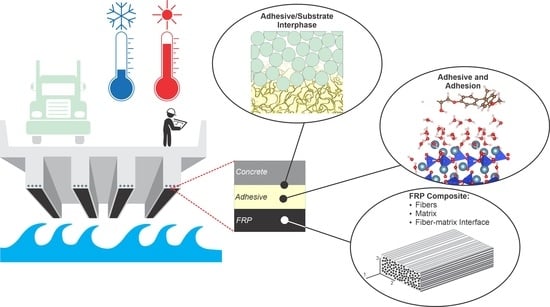

:1. Introduction

2. Current State of Practice: EB FRP Installation

2.1. Bond-critical vs. Contact-Critical

2.2. Surface Preparation and Installation

2.3. Quality Control

3. Materials Selection, Environmental Exposure, and Load Conditions

3.1. Resins and Adhesives

3.2. Fibers and Composites

3.3. EB FRP Bond to Concrete

3.4. Materials Development

4. Design Guidelines

4.1. Overview of Design Guidance

- United States: American Concrete Institute (ACI) 440.2R-08: “Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures”; American Association of State and Highway Transportation Officials (AASHTO) FRPS-1, [132]: “Guide Specifications for Design of Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements”.

- Canada: Intelligent Sensing for Innovative Structures (ISIS) [133] Design Manual 4, FRP Rehabilitation of Reinforced Concrete Structures.

- Japan: Japan Society of Civil Engineers (JSCE) [134]. “Recommendations for Upgrading of Concrete Structures with use of Continuous Fiber Sheets”.

- United Kingdom: United Kingdom Concrete Society Technical Report 55 (TR55) [135]. “Design Guidance for Strengthening Concrete Structures Using Fibre Composite Materials”.

- Italy: Italian National Research Council Technical Document 200 (CNR-DT200) [136]. “Guide for the Design and Construction of Externally Bonded FRP Systems”.

4.2. Standard Test Method for EB FRP/Concrete Bond Durability

5. Concluding Remarks

6. Future Perspectives and Recommendations

- The complexity of the involved deterioration mechanisms limits our ability to mechanistically model the EB FRP deterioration under realistic environmental exposures and develop accurate service life prediction models from the short-term accelerated conditioning test data. This is one of the top research priorities. Progress in EB FRP service life estimation will lead to refined durability design guidelines that will allow for economical yet safe EB FRP strengthening.

- Interestingly, even though the durability of the bond between EB FRP and concrete is a critical factor, explicit treatment of EB FRP/concrete bond durability is not suggested by any of the available design guidelines. It is, thus, imperative that these concerns be addressed either through qualification testing requirements, bond durability design factors, or both.

- Advancements in materials for EB FRP applications are necessary to meet the performance requirements imposed on EB FRP strengthening systems in harsh environments. Future progress in composites for construction likely lies at an intersection between classical structural engineering and materials science. With the emerging materials and technologies, an interdisciplinary approach to addressing the problems in the next-generation infrastructure will be paramount.

Funding

Conflicts of Interest

References

- Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Meier, U.; Deuring, M. The application of fiber composites in bridge repair—A world premiere at the gates of Lucerne. Str. Verk. 1991, 77, 534–535. [Google Scholar]

- Meier, U. Strengthening of structures using carbon fibre epoxy composites. Constr. Build. Mater 1995, 9, 341–351. [Google Scholar] [CrossRef]

- Czaderski, C.; Meier, U. EBR Strengthening Technique for Concrete, Long-Term Behaviour and Historical Survey. Polymers 2018, 10, 77. [Google Scholar] [CrossRef] [Green Version]

- Karbhari, V.M. Durability of FRP Composites for Civil Infrastructure—Myth, Mystery or Reality. Adv. Struct. Eng. 2003, 6, 243–255. [Google Scholar] [CrossRef]

- Frigione, M.; Lattieri, M. Durability Issues and Challenges for Material Advancements in FRP Employed in the Construction Industry. Polymers 2018, 10, 247. [Google Scholar] [CrossRef] [Green Version]

- Federal Aviation Administration Acceptance Guidance on Material Procurement and Process Specifications for Polymer Matrix Composite Systems; United States Department of Transportation, Federal Aviation Administration: Washington, DC, USA, 2003.

- Federal Aviation Administration Material Qualification and Equivalency for Polymer Matrix Composite Material Systems: Updated Procedure; United States Department of Transportation, Federal Aviation Administration: Washington, DC, USA, 2003.

- Cabral-Fonseca, S.; Correia, J.R.; Custódio, J.; Silva, H.M.; Machado, A.M.; Sousa, J. Durability of FRP—concrete bonded joints in structural rehabilitation: A review. Int. J. Adhes. Adhes. 2018, 83, 153–167. [Google Scholar] [CrossRef]

- Chajes, M.J.; Thomson, T.; Finch, W.; Januszka, T.F. Flexural Strengthening of Concrete Beams Using Externally Bonded Composite Materials. Constr. Build. Mater. 1994, 9, 191–210. [Google Scholar] [CrossRef]

- Chajes, M.J.; Januszka, T.F.; Mertz, D.R.; Thomson, T.A.; Finch, W.W. Shear Strengthening of Reinforced Concrete Beams Using Externally Applied Composite Fabrics. ACI Struct. J. 1994, 92, 295–303. [Google Scholar]

- Tatar, J.; Hamilton, H.R. Bond Durability Factor for Externally Bonded CFRP Systems in Concrete Structure. J. Compos. Constr. 2015, 20, 04015027. [Google Scholar] [CrossRef]

- Tatar, J.; Hamilton, H.R. Implementation of Bond Durability in the Design of Flexural Members with Externally Bonded FRP. J. Compos. Constr. 2015, 20, 04015072. [Google Scholar] [CrossRef]

- Micelli, F.; Mazzotta, R.; Leone, M.; Aiello, M. Review Study on the Durability of FRP-Confined Concrete. J. Compos. Constr. 2015, 19, 04014056. [Google Scholar] [CrossRef]

- Qin, R.; Lau, D.; Tam, L.; Liu, T.; Zou, D.; Zhou, A. Experimental Investigation on Interfacial Defect Criticality of FRP-Confined Concrete Columns. Sensors 2019, 19, 468. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iovinella, A.; Prota, A.; Mazzotti, C. Influence of surface roughness on the bond of FRP laminates to concrete. Constr. Build. Mater. 2013, 40, 533–542. [Google Scholar] [CrossRef]

- Yin, Y.; Fan, Y. Influence of Roughness on Shear Bonding Performance of CFRP-Concrete Interface. Materials 2018, 11, 1875. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- NCHRP 514 Bonded Repair and Retrofit of Concrete Structures Using FRP Composites—Recommended Construction Specifications and Process Control Manual; National Cooperative Highway Progress Report 514; National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2004.

- ACI-440.2R Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute Community: Farmington Hills, MI, USA, 2017.

- ACI 546R Guide to Concrete Repair; American Concrete Institute Community: Farmington Hills, MI, USA, 2014.

- ICRI 310.2R Selecting and Specifying Concrete Surface Preparation for Sealers, Coatings, Polymer Overlays, and Concrete Repair; The International Concrete Repair Institute: St. Paul, MN, USA, 2013.

- Wan, B.; Petrou, M.; Harries, K.A. The Effect of the Presence of Water on the Durability of Bond between CFRP and Concrete. J. Reinf. Plast. Compos. 2006, 25, 875–890. [Google Scholar] [CrossRef]

- ICRI 330.2 Guide Specifications for Externally Bonded FRP Fabric; The International Concrete Repair Institute: St. Paul, MN, USA, 2016.

- Shaw, I.; Andrawes, B. Repair of damaged end regions of PC beams using externally bonded FRP shear reinforcement. Constr. Build. Mater. 2017, 148, 184–194. [Google Scholar] [CrossRef]

- ACI-440.9R Guide to Accelerated Conditioning Protocols for Durability Assessment of Internal and External Fiber-Reinforced (FRP) Reinforcement; American Concrete Institute Community: Farmington Hills, MI, USA, 2015.

- Harries, K.A.; Sweriduk, M.E. Factors Affecting Direct Tension Pull-Off Test Results of Materials Bonded to Concrete. Adv. Civ. Eng. Mater. 2016, 5, 353–370. [Google Scholar] [CrossRef]

- Starnes, M.A.; Carino, N.J.; Kausel, E.A. Preliminary Thermography Studies for Quality Control of Concrete Structures Strengthened with Fiber-Reinforced Polymer Composites. J. Mater. Civ. Eng. 2003, 15, 266–273. [Google Scholar] [CrossRef] [Green Version]

- Chang, P.C.; Liu, S.C. Recent Research in Nondestructive Evaluation of Civil Infrastructures. J. Mater. Civ. Eng. 2003, 15, 298–304. [Google Scholar] [CrossRef]

- Huo, L.; Cheng, H.; Kong, Q.; Chen, X. Bond-slip monitoring of concrete structures using smart sensors—A review. Sensors 2019, 19, 1231. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Antonucci, V.; Giordano, M. Prota, Fiber Optics Technique for Quality Control and Monitoring of FRP Installations. Spec. Publ. 230-12 2005, 230, 195–208. [Google Scholar]

- ASTM D7522 Standard Test Method for Pull-off Strength for FRP Bonded to Concrete Substrate; ASTM International: West Conshohocken, PA, USA, 2015.

- Guigon, M.; Klinklin, E. The interface and interphase in carbon fibre-reinforced composites. Composites 1994, 25, 534–539. [Google Scholar] [CrossRef]

- Jesson, D.A.; Watts, J.F. The Interface and Interphase in Polymer Matrix Composites: Effect on Mechanical Properties and Methods for Identification. Polym. Rev. 2012, 52, 321–354. [Google Scholar] [CrossRef]

- Tatar, J.; Taylor, C.R.; Hamilton, H.R. A multiscale micromechanical model of adhesive interphase between cement paste and epoxy supported by nanomechanical evidence. Compos. B Eng. 2019, 172, 679–689. [Google Scholar] [CrossRef]

- Tatar, J. Nanomechanical Properties of Cement Paste-Epoxy Interphase following Hygrothermal Conditioning by Water Immersion. Constr. Build. Mater. 2021, 282C, 122695. [Google Scholar] [CrossRef]

- Aiello, M.A.; Frigione, M.; Acierno, D. Effects of environmental conditions on performance of polymeric adhesives for restoration of concrete structures. J. Mater. Civ. Eng. 2002, 14, 185–189. [Google Scholar] [CrossRef]

- Doblies, A.; Boll, B.; Fiedler, B. Prediction of thermal exposure and mechanical behavior of epoxy resin using artificial neural networks and Fourier transform infrared spectroscopy. Polymers 2019, 11, 363. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, M.; Johnson, M.; Taheri, F. On the Thermal Fatigue of a Room-Cured Neat Epoxy and Its Composite. Open J. Compos. Mater. 2019, 9, 145–163. [Google Scholar] [CrossRef] [Green Version]

- Sciolti, M.S.; Aiello, M.A.; Frigione, M. Effect of thermo-hygrometric exposure on FRP, natural stone and their adhesive interface. Compos. Part B Eng. 2015, 80, 162–176. [Google Scholar] [CrossRef]

- Lettieri, M.; Frigione, M. Natural and Artificial Weathering Effects on Cold-Cured Epoxy Resins. J. Appl. Polym. Sci. 2011, 119, 1635–1645. [Google Scholar] [CrossRef]

- Tatar, J.; Hamilton, H.R. Comparison of laboratory and field environmental conditioning on FRP-concrete bond durability. Constr. Build. Mater. 2014, 122, 525–536. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Ghosh, K. Comparative durability evaluation of ambient temperature cured externally bonded CFRP and GFRP composite systems for repair of bridges. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1353–1363. [Google Scholar] [CrossRef]

- Odegard, G.M.; Bandyopadhyay, A. Physical aging of epoxy polymers and their composites. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1695–1716. [Google Scholar] [CrossRef]

- Fernandes, P.; Sena-Cruz, J.; Xavier, J.; Silva, P.; Pereira, E.; Cruz, J. Durability of bond in NSM CFRP-concrete systems under different environmental conditions. Compos. Part B Eng. 2018, 138, 19–34. [Google Scholar] [CrossRef] [Green Version]

- Hamilton, H.R.; Brown, J.; Tatar, J.; Lisek, M.; Brenkus, N.R. Durability Evaluation of Florida’s Fiber-Reinforced Polymer (FRP) Composite Reinforcement for Concrete Structures; Florida Department of Transportation: Tallahassee, FL, USA, 2017. [Google Scholar]

- Siavashi, S.; Eamon, C.D.; Makkawy, A.A.; Wu, H.C. Long-Term Durability of FRP Bond in the Midwest United States for Externally Strengthened Bridge Components. J. Compos. Constr. 2019, 23, 05019001. [Google Scholar] [CrossRef]

- Atadero, R.A.; Allen, D.G. Long Term Monitoring of Mechanical Properties of FRP Repair Materials; Color Department of Transportation Report No. CDOT-2013-13; Colorado. Dept. of Transportation. Research Branch: Denver, CO, USA, 2013. [Google Scholar]

- Al Azzawi, M.; Hopkins, P.; Mullins, G.; Sen, R. FRP-Concrete Bond after 12-Year Exposure in Tidal Waters. J. Compos. Constr. 2018, 22, 1–15. [Google Scholar] [CrossRef]

- Pritchard, G. Reinforced Plastics Durability; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Zheng, X.H.; Huang, P.Y.; Chen, G.M.; Tan, X.M. Fatigue behavior of FRP—concrete bond under hygrothermal environment. Constr. Build. Mater. 2015, 95, 898–909. [Google Scholar] [CrossRef]

- Michels, J.; França, P.; Pereira, E. Durability of RC slabs strengthened with prestressed CFRP laminate strips under different environmental and loading conditions. Compos. Part B Eng. 2017, 125, 71–88. [Google Scholar]

- Xie, J.H.; Wei, M.W.; Huang, P.Y.; Zhang, H.; Chen, P.S. Fatigue behavior of the basalt fiber-reinforced polymer/concrete interface under wet-dry cycling in a marine environment. Constr. Build. Mater. 2019, 228, 117065. [Google Scholar] [CrossRef]

- Aidoo, J.; Harries, K.A.; Petrou, M.F. Fatigue Behavior of Carbon Fiber Reinforced Polymer-Strengthened Reinforced Concrete Bridge Girders. J. Compos. Constr. 2004, 8, 501–509. [Google Scholar] [CrossRef]

- Curtis, P.T. The fatigue behaviour of fibrous composite materials. J. Strain Anal. Eng. Des. 1989, 24, 235–244. [Google Scholar] [CrossRef]

- Konur, O.; Matthews, F.L. Effect of the properties of the constituents on the fatigue performance of composites: A review. Composites 1989, 20, 317–328. [Google Scholar] [CrossRef]

- Harries, K.; Aidoo, J. Deterioration of FRP-to-concrete bond under fatigue loading. In Proceedings of the International Symposium Bond Behaviour of FRP in Structures BBFS, Hong Kong, China, 7–9 December 2005; Volume 9, pp. 553–558. [Google Scholar]

- Houhou, N.; Benzarti, K.; Quiertant, M.; Chataigner, S.; Fléty, A.; Marty, C. Analysis of the nonlinear creep behavior of concrete/FRP-bonded assemblies. J. Adhes. Sci. Technol. 2014, 28, 1345–1366. [Google Scholar] [CrossRef]

- Choi, K.K.; Meshgin, P.; Reda Taha, M.M. Shear creep of epoxy at the concrete-FRP interfaces. Compos. Part B Eng. 2007, 38, 772–780. [Google Scholar] [CrossRef]

- Kirby, J.E.; Orton, S.L. Residual Strength of Impact-Damaged CFRP Used to Strengthen Concrete Structures. J. Compos. Constr. 2011, 15, 782–789. [Google Scholar] [CrossRef]

- Hou, Y.; Tie, Y.; Li, C.; Sapanathan, T.; Rachik, M. Low-velocity impact behaviors of repaired CFRP laminates: Effect of impact location and external patch configurations. Compos. Part B Eng. 2019, 163, 669–680. [Google Scholar] [CrossRef]

- Mays, G.C.; Hutchinson, A.R. Adhesives in Civil Engineering; Cambridge University Press: Cambridge, UK, 1992. [Google Scholar]

- Savvilotidou, M.; Vassilopoulos, A.P.; Frigione, M.; Keller, T. Effects of aging in dry environment on physical and mechanical properties of a cold-curing structural epoxy adhesive for bridge construction. Constr. Build. Mater. 2017, 140, 552–561. [Google Scholar] [CrossRef]

- Marouani, S.; Curtil, L.; Hamelin, P. Ageing of carbon/epoxy and carbon/vinylester composites used in the reinforcement and/or the repair of civil engineering structures. Compos. Part B Eng. 2012, 43, 2020–2030. [Google Scholar] [CrossRef]

- Marouani, S.; Curtil, L.; Hamelin, P. Composites realized by hand lay-up process in a civil engineering environment: Initial properties and durability. Mater. Struct. Constr. 2008, 41, 831–851. [Google Scholar] [CrossRef]

- Choi, S.; Maul, S.; Stewart, A.; Hamilton, H.R.; Douglas, E.P. Effect of silane coupling agent on the durability of epoxy adhesion for structural strengthening applications. J. Appl. Polym. Sci. 2012, 125, 3778–3787. [Google Scholar] [CrossRef]

- Blackburn, B.P.; Tatar, J.; Douglas, E.P.; Hamilton, H.R. Effects of Hygrothermal Conditioning on Epoxy Adhesives Used in FRP Composites. Constr. Build. Mater. 2015, 96, 679–689. [Google Scholar] [CrossRef]

- Moussa, O.; Vassilopoulos, A.P.; Keller, T. Effects of low-temperature curing on physical behavior of cold-curing epoxy adhesives in bridge construction. Int. J. Adhes. Adhes. 2012, 32, 15–22. [Google Scholar] [CrossRef]

- Savvilotidou, M.; Vassilopoulos, A.P.; Frigione, M.; Keller., T. Development of physical and mechanical properties of a cold-curing structural adhesives in a wet bridge environment. Constr. Build. Mater. 2017, 144, 115–124. [Google Scholar] [CrossRef]

- AASHTO LRFD Bridge Design Specifications; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017.

- Zhou, J.M.; Lucas, J.P. Hygrothermal effects of epoxy resin. Part I: The nature of water in epoxy. Polymer 1999, 40, 5505–5512. [Google Scholar] [CrossRef]

- Zhou, J.M.; Lucas, J.P. Hygrothermal effects of epoxy resin. Part II: Variations of glass transition temperature. Polymer 1999, 40, 5513–5522. [Google Scholar] [CrossRef]

- Bockenheimer, C.; Fata, D.; Possart, W. New aspects of aging in epoxy networks. II. Hydrothermal aging. J. Appl. Polym. Sci. 2004, 91, 369–377. [Google Scholar] [CrossRef]

- Monney, L.; Belali, R.; Vebrel, J.; Dubois, C.; Chambaudet, A. Photochemical degradation study of an epoxy material by IR-ATR spectroscopy. Polym. Degrad. Stabil. 1998, 62, 353–359. [Google Scholar] [CrossRef]

- Noskov, A.M. Photochemistry of epoxy films. J. Appl. Spectrosc. 1975, 23, 1638–1642. [Google Scholar] [CrossRef]

- Jana, S.; Zhong, W.H. Effects of Hygrothermal Conditions and UV Radiation on UHMWPE Fibers/Nanofiber–Epoxy Composites. J. Compos. Mater 2007, 41, 2897. [Google Scholar] [CrossRef]

- Kim, H.; Urban, M.W. Molecular level chain scission mechanisms of epoxy and urethane polymeric films exposed to UV/H2O. Multidimensional spectroscopic studies. Langmuir 2000, 16, 5382–5390. [Google Scholar] [CrossRef]

- Li, J.; Xie, J.; Liu, F.; Lu, Z. A critical review and assessment for FRP-concrete bond systems with epoxy resin exposed to chloride environments. Compos. Struct. 2019, 229, 111372. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Durability of CFRP/steel joints under cyclic wet-dry and freeze-thaw conditions. Compos. Part B Eng. 2017, 126, 211–226. [Google Scholar] [CrossRef]

- Rudawska, A. The effect of the salt water aging on the mechanical properties of epoxy adhesives compounds. Polymers 2020, 12, 843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Q.; Xian, G.; Karbhari, V.M. Hygrothermal Ageing of an Epoxy Adhesive Used in FRP Strengthening of Concrete. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Shi, J.W.; Zhu, H.; Wu, G.; Wu, Z.S. Tensile behavior of FRP and hybrid FRP sheets in freeze-thaw cycling environments. Compos. Part B Eng. 2014, 60, 239–247. [Google Scholar] [CrossRef]

- Hadigheh, S.A.; Gravina, R.J.; Smith, S.T. Effect of acid attack on FRP-to-concrete bonded interfaces. Constr. Build. Mater. 2017, 152, 285–303. [Google Scholar] [CrossRef]

- Choi, S.; Phantu, A.; Douglas, E.P. Evaluation of the complex hygrothermal behaviors of epoxy-amine systems. J. Appl. Polym. Sci. 2012, 125, 3778–3787. [Google Scholar] [CrossRef]

- Saadatmanesh, H.; Tavakkolizadeh, M.; Mostofinejad, D. Environmental effects on mechanical properties of wet lay-up fiber-reinforced polymer. ACI Mater. J. 2010, 107, 267–274. [Google Scholar]

- Wang, J.; GangaRao, H.; Liang, R.; Liu, W. Durability and prediction models of fiber-reinforced polymer composites under various environmental conditions: A critical review. J. Reinf. Plast. Compos. 2016, 35, 179–211. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- ACI-440.1R Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars; American Concrete Institute: Farmington Hills, MI, USA, 2015.

- Nkurunziza, G.; Debaiky, A.; Cousin, P.; Benmokrane, B. Durability of GFRP bars: A critical review of the literature. Prog. Struct. Engng Mater. 2005, 7, 194–209. [Google Scholar] [CrossRef]

- Belec, L.; Nguyen, T.H.; Nguyen, D.L.; Chailan, J.F. Comparative effects of humid tropical weathering and artificial ageing on a model composite properties from nano- to macro-scale. Compos. Part A Appl. Sci. Manuf. 2015, 68, 235–241. [Google Scholar] [CrossRef]

- Swit, G. Durability of stressed E-glass fibre in alkaline medium. In Recent Developments in Durability Analysis of Composite Systems; Reifsneider, K.L., Verchery, G., Eds.; Cardon, Fukuda, Balkema: Rotterdam, The Netherlands, 2000; pp. 473–476. [Google Scholar]

- Sen, R.; Mullins, G.; Salem, T. Durability of E-glass/vinylester reinforcement in alkaline solution. ACI Struct. J. 2002, 99, 369–375. [Google Scholar]

- Bashir, S.T.; Yang, L.; Liggat, J.J.; Thomason, L. Kinetics of dissolution of glass fibre in hot alkaline solution. J. Mater. Sci. Technol. 2018, 53, 1710–1722. [Google Scholar] [CrossRef] [Green Version]

- Fujii, Y.; Murakami, A.; Kato, K.; Yoshiki, T.; Maekawa, Z.; Hamada, H. Study of the stress corrosion cracking of GFRP: Effect of the toughness of the matrix resin on the fatigue damage and stress corrosion cracking of GFRP. J. Mater. Sci. 1994, 29, 4279–4285. [Google Scholar] [CrossRef]

- Schmitz, G.K.; Metcalfe, A.G. Stress Corrosion of E-Glass Fibers. Ind. Eng. Chem. Prod. Res. Dev. 1966, 5, 1–8. [Google Scholar] [CrossRef]

- Sheikh, S.A.; Tam, S. Effect of Freeze-Thaw Climatic Conditions on Long-Term Durability of FRP Strengthening Systems; Ministry of Transportation Ontario HIIFP-037; Ministry of Transportation Ontario: Toronto, ON, CA, 2007. [Google Scholar]

- Cromwell, J.R.; Harries, K.A.; Shahrooz, B.M. Environmental durability of externally bonded FRP materials intended for repair of concrete structures. Constr. Build. Mater. 2011, 25, 2528–2539. [Google Scholar] [CrossRef]

- Cao, S.; Wu, Z.; Wang, X. Tensile Properties of CFRP and Hybrid FRP Composites at Elevated Temperatures. J. Compos. Mater. 2009, 43, 315–330. [Google Scholar]

- Hawileh, R.A.; Obeidah, A.A.; Abdalla, J.A.; Al-Tamimia, A.R.A.; Hawileh, A.A.; Obeidah, J.A.; Abdalla, A. Al-Tamimia. Temperature effect on the mechanical properties of carbon, glass and carbon–glass FRP laminates. Constr. Build. Mater. 2015, 75, 342–348. [Google Scholar] [CrossRef]

- Li, H.; Xian, G.; Lin, Q.; Zhang, H. Freeze–thaw resistance of unidirectional-fiber-reinforced epoxy composites. J. Appl. Polym. Sci. 2011, 123, 3781–3788. [Google Scholar] [CrossRef]

- Bank, L.C.; Gentry, T.R.; Barkatt, A. Accelerated Test Methods to Determine the Long-Terma Behavior of FRP Composite Structures: Environmental Effects. J. Reinf. Plast. Compos. 1995, 14, 559–587. [Google Scholar] [CrossRef]

- Kafodya, I.; Xian, G.; Li, H. Durability study of pultruded CFRP plates immersed in water and seawater under sustained bending: Water uptake and effects on the mechanical properties. Compos. Part B Eng. 2015, 70, 138–148. [Google Scholar] [CrossRef]

- Au, C.; Büyüköztürk, O. Peel and shear fracture characterization of debonding in FRP plated concrete affected by moisture. J. Compos. Constr. 2006, 35, 35–47. [Google Scholar] [CrossRef]

- Leone, M.; Matthys, S.; Aiello, M.A. Effect of elevated service temperature on bond between FRP EBR systems and concrete. Compos. B Eng. 2009, 40, 85–93. [Google Scholar] [CrossRef]

- Green, M.F.; Bisby, L.A.; Fam, A.Z.; Kodur, V.K. FRP confined concrete columns: Behaviour under extreme conditions. Cem. Concr. Compos. 2006, 28, 928–937. [Google Scholar] [CrossRef]

- Silva, M.A.G.; Biscaia, H. Degradation of bond between FRP and RC beams. Compos. Struct 2008, 85, 164–174. [Google Scholar] [CrossRef]

- Chajes, M.J.; Thomson, T.A.; Farschman, C.A. Durability of concrete beams externally reinforced with composite fabrics. Constr. Build. Mater. 1995, 9, 141–148. [Google Scholar] [CrossRef]

- Dolan, C.W.; Tanner, J.; Mukai, D.; Hamilton III, H.; Douglas, E. Design Guidelines for Durability of Bonded CFRP Repair/Strengthening of Concrete Beams; National Cooperative Freight Research Program: Washington, DC, USA, 2010. [Google Scholar]

- Pan, Y.; Xian, G.; Silva, M.A.G. Effects of water immersion on the bond behavior between CFRP plates and concrete substrate. Constr. Build. Mater. 2015, 101, 326–337. [Google Scholar] [CrossRef]

- Shrestha, J.; Ueda, T.; Zhang, D. Durability of FRP Concrete Bonds and Its Constituent Properties under the Influence of Moisture Conditions. J. Mater. Civ. Eng. 2015, 27, 1–14. [Google Scholar] [CrossRef]

- Djouani, F.; Connan, C.; Delamar, M.; Chehimi, M.M.; Benzarti, K. Cement paste-epoxy adhesive interactions. Constr. Build. Mater. 2011, 25, 411–423. [Google Scholar] [CrossRef]

- Stewart, A.; Tatar, J.; Douglas, E.; Hamilton, H.R.; Nino, J. Highly Accelerated Lifetime for Externally Applied Bond Critical Fiber-Reinforced Polymer (FRP) Infrastructure Materials; Florida Department of Transportation Report No. BDK75-977-45; Florida Department of Transportation: Tallahassee, FL, USA, 2014. [Google Scholar]

- Callister, W.; Rethwisch, D. Fundamentals of Materials Science and Engineering; John Wiley Sons Inc.: New York, NY, UK, 2008. [Google Scholar]

- Guo, F.; Al-saadi, S.; Raman, R.K.S.; Zhao, X.L. Durability of fi ber reinforced polymer (FRP) in simulated seawater sea sand concrete (SWSSC) environment. Corros. Sci. 2018, 141, 1–13. [Google Scholar] [CrossRef]

- Amidi, S.; Wang, J. Subcritical debonding of FRP-to-concrete bonded interface under synergistic effect of load, moisture, and temperature. Mech. Mater. 2016, 92, 80–93. [Google Scholar] [CrossRef]

- Tatar, J.; Subhash, G.; Taylor, C.R.; Hamilton, H.R. Characterization of Adhesive Interphase Between Epoxy and Cement Paste Via Raman Spectroscopy and Mercury Intrusion Porosimetry. Cem. Concr. Compos. 2018, 88, 187–199. [Google Scholar] [CrossRef]

- Nishizaki, I.; Kato, Y. Durability of the adhesive bond between continuous fibre sheet reinforcements and concrete in an outdoor environment. Constr. Build. Mater. 2011, 25, 515–522. [Google Scholar] [CrossRef]

- Tatar, J.; Wagner, D.; Hamilton, H.R. Structural Testing and Dissection of Carbon Fiber-Reinforced Polymer-Repaired Bridge Girders Taken Out of Service. ACI Struct. J. 2016, 113, 1357–1367. [Google Scholar] [CrossRef]

- Colin, X.; Verdu, J. Mechanisms and Kinetics of Organic Matrix Thermal Oxidation; Springer: Berlin/Heidelberg, Germany, 2012; pp. 311–344. [Google Scholar]

- Aboubakr, S.H.; Kandil, U.F. Creep of epoxy–clay nanocomposite adhesive at the FRP interface: A multi-scale investigation. Int. J Adhes. Adhes. 2013, 54, 1–12. [Google Scholar] [CrossRef]

- Rathore, D.K.; Prusty, R.K.; Kumar, D.S.; Ray, B.C. Mechanical performance of CNT-filled glass fiber/epoxy composite in in-situ elevated temperature environments emphasizing the role of CNT content. Compos. Part A 2016, 84, 364–376. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H. Repair of heat-damaged RC columns using carbon nanotubes modified CFRP. Mater. Struct. 2017, 50, 1–11. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Prusty, R.K.; Rathore, D.K.; Ray, B.C. Creep behaviour of graphite oxide nanoplates embedded glass fiber/epoxy composites: Emphasizing the role of temperature and stress. Compos. Part A 2017, 102, 166–177. [Google Scholar] [CrossRef]

- Frigione, M.; Lionetto, F.; Mascia, L.; Antonacci, A. Novel epoxy-silica hybrid adhesives for concrete and structural materials: Properties and durability issues. Adv. Mat. Res. 2013, 687, 94–99. [Google Scholar] [CrossRef]

- Lettieri, M.; Lionetto, F.; Frigione, M.; Prezzi, L.; Mascia, L. Cold-cured epoxy-silica hybrids: Effects of large variation in specimen thickness on the evolution of the Tg and related properties. Polym. Eng. Sci. 2011, 51, 358–368. [Google Scholar] [CrossRef]

- Morshed, S.A.; Young, T.J.; Chirdon, W.M.; Zhang, Q.; Tatar, J. Durability of wet lay-up FRP bonded to concrete with nanomodified epoxy adhesives. J. Adhes. 2018, 96, 1141–1166. [Google Scholar] [CrossRef]

- Morshed, S.A.; Sinha, A.; Zhang, Q.; Tatar, J. Hygrothermal conditioning of wet-layup CFRP-concrete adhesive joints modified with silane coupling agent and core-shell rubber nanoparticles. Constr. Build. Mater. 2019, 227, 116531. [Google Scholar] [CrossRef]

- Gallo, G.J.; Thostenson, E.T. Electrical characterization and modeling of carbon nanotube and carbon fiber self-sensing composites for enhanced sensing of microcrack. Mater. Today Commun. 2015, 3, 17–26. [Google Scholar] [CrossRef]

- Al-Sabagh, A.; Taha, E.; Kandil, U.; Nasr, G.A.; Taha, M.R. Monitoring damage propagation in glass fiber composites using carbon nanofibers. Nanomaterials 2016, 6, 169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schumacher, T.; Thostenson, E.T. Development of structural carbon nanotube–based sensing composites for concrete structures. J. Intell. Mater. Syst. Struct. 2014, 25, 1331–1339. [Google Scholar] [CrossRef]

- Tatar, J.; Torrence, C.E.; Mecholsky, J.J.; Taylor, C.R.; Hamilton, H.R. Effects of Silane Surface Functionalization on Interfacial Fracture Energy and Durability of Adhesive Bond between Cement Paste and Epoxy. Int. J. Adhes. Adhes. 2018, 84, 132–142. [Google Scholar] [CrossRef]

- Stewart, A.; Scholsser, B.; Douglas, E.P. Surface modification of cured cement pastes by silane coupling agents. Appl. Mater. Interfaces 2013, 5, 1218–1225. [Google Scholar] [CrossRef]

- AASHTO-FRPS-1 Guide Specifications for Design of Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2010.

- ISIS Strengthening Reinforced Concrete Structures with Externally-Bonded Fibre Reinforced Polymers (FRPs); Man. No. 4, ISIS Canada; Neale, K.W. (Ed.) University Sherbrooke: Sherbrooke, QC, Canada, 2012. [Google Scholar]

- JSCE Recommendations for Upgrading of Concrete Structures with Use of Continuous Fiber Sheets; Concrete Engineering Service 41; Japan Society of Civil Engineers: Tokyo, Japan, 2001.

- Concrete Society TR55 Design Guidance for Strengthening Concrete Structures Using Fibre Composite Materials, 3rd ed.; Concrete Society Technical Reports 55; Camberley: Surrey, UK, 2012.

- CNR-DT200 Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures (CNR-DT200 R1/2012); National Research Council (NRC): Rome, Italy, 2013.

- ASTM D3039 Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017.

- Grelle, S.V.; Sneed, L.H. Review of Anchorage Systems for Externally Bonded FRP Laminates. Int. J. Conc. Struct. Mater. 2013, 7, 17–33. [Google Scholar] [CrossRef] [Green Version]

- Kalfat, R.; Gadd, J.; Al-Mahaidi, R.; Smith, S.T. An efficiency framework for anchorage devices used to enhance the performance of FRP strengthened RC members. Constr. Build. Mater. 2018, 191, 254–275. [Google Scholar] [CrossRef]

- Bae, S.W.; Belarbi, A. Behavior of Various Anchorage Systems Used for Shear Strengthening of Concrete Structures with Externally Bonded FRP Sheets. J. Bridg. Eng. 2013, 18, 837–847. [Google Scholar] [CrossRef]

- JSCE-E-543 Test Method for Bond Properties of Continuous Fiber Sheets to Concrete; Japan Society of Civil Engineers: Tokyo, Japan, 2000.

- Harries, K.A.; Hamilton, H.R.; Kassan, J.; Tatar, J. Development of Standard Bond Capacity Test for FRP Bonded to Concrete. In Proceedings of the 6th International Conference FRP Composites in Civil Engineering CICE, Rome, Italy, 13–15 June 2012. [Google Scholar]

- Gartner, A.L.; Douglas, E.P.; Dolan, C.W.; Hamilton, H.R. Small Beam Bond Test Method for CFRP Composites Applied to Concrete. ASCE J. Compos. Constr. 2011, 15, 52–61. [Google Scholar] [CrossRef]

- ASTM C78 Standard Test Method for Flexural Strength of Concrete Using Simple Beam with Third-Point Loading; ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D7958 Standard Test Method for Evaluation of Performance for FRP Composite Bonded to Concrete Substrate Using Beam Test; American Society for Testing Materials: West Conshohocken, PA, USA, 2017.

| Design Guideline | Environmental Reduction Factors | Maximum Usable Strain in FRP for Flexure ^ | ||

|---|---|---|---|---|

| ACI 440.2R | Exposure condition | Fiber | ^ | |

| Interior Exposure | Carbon | 0.95 | ||

| Glass | 0.75 | |||

| Aramid | 0.85 | |||

| Exterior Exposure (bridges, piers and unclosed parking garages) | Carbon | 0.85 | ||

| Glass | 0.65 | |||

| Aramid | 0.75 | |||

| Aggressive environment (chemical plants and wastewater treatment plants) | Carbon | 0.85 | ||

| Glass | 0.50 | |||

| Aramid | 0.70 | |||

| AASHTO FRPS-1 | No environmental reduction factors proposed. Specified that composite shall retain at least 85% of glass transition temperature (Tg) determined per ASTM E1640 and characteristic strain determined per ASTM D3039 following accelerated conditioning in four specified environments: (i) water, (ii) alternating ultraviolet light and condensation humidity, (iii) alkali, and (iv) freeze-thaw. | |||

| ISIS | No explicit environmental reduction factors proposed. Material safety factors that account for fiber type and composite manufacturing procedure are explicitly specified. The material safety factors make a differentiation between buildings and bridges to account for the environmental effects. | |||

| JSCE | Environmental reduction factors not explicitly specified. Suggested to use a protective layer (coating, mortar, or concrete) in outdoor applications, unless it can be demonstrated by suitable numerical simulation and accelerated conditioning tests that protection is not necessary. The designer is referred to JSCE “Standard Specifications for Design and Construction of Concrete Structures (Design)” for selection of material safety factors. | |||

| TR55 | Environmental reduction factors not explicitly proposed. Material safety factors depending on fiber type (carbon, aramid, and glass) and manufacturing procedure are specified. | |||

| CNR-DT 200 | Same as ACI 440.2R; however, it is stated that: “Designer shall use these values when more information on test evidence for the material in use and expected environmental condition are missing.” | (typical design case) | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tatar, J.; Milev, S. Durability of Externally Bonded Fiber-Reinforced Polymer Composites in Concrete Structures: A Critical Review. Polymers 2021, 13, 765. https://doi.org/10.3390/polym13050765

Tatar J, Milev S. Durability of Externally Bonded Fiber-Reinforced Polymer Composites in Concrete Structures: A Critical Review. Polymers. 2021; 13(5):765. https://doi.org/10.3390/polym13050765

Chicago/Turabian StyleTatar, Jovan, and Sandra Milev. 2021. "Durability of Externally Bonded Fiber-Reinforced Polymer Composites in Concrete Structures: A Critical Review" Polymers 13, no. 5: 765. https://doi.org/10.3390/polym13050765

APA StyleTatar, J., & Milev, S. (2021). Durability of Externally Bonded Fiber-Reinforced Polymer Composites in Concrete Structures: A Critical Review. Polymers, 13(5), 765. https://doi.org/10.3390/polym13050765