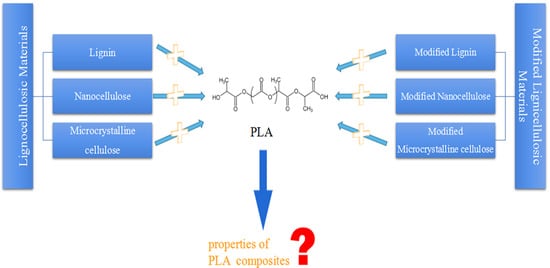

A Review: Research Progress in Modification of Poly (Lactic Acid) by Lignin and Cellulose

Abstract

:1. Introduction

2. Lignin/PLA Composite Materials

2.1. Lignin Modified PLA

2.2. Modified Lignin Modified PLA

2.2.1. Esterification

2.2.2. Sulfonation

2.2.3. Silanization

3. Cellulose/PLA Composite Materials

3.1. Nanocellulose

3.1.1. Nanocellulose Modified PLA

3.1.2. Modified Nanocellulose Modified PLA

Esterification

Graft Modification

3.2. Microcrystalline Cellulose

3.2.1. Microcrystalline Cellulose Modified PLA

3.2.2. Modified Microcrystalline Cellulose Modified PLA

Sulfonation

Graft Modification

4. Challenges and Commercial Value

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sirohi, R.; Pandey, J.P.; Tarafdar, A.; Sindhu, R.; Parameswaran, B.; Pandey, A. Applications of poly-3-hydroxybutyrate based composite in advanced applications of polysaccharides and their composites. Mater. Res. Found. 2020, 68, 45–59. [Google Scholar]

- Bhatia, S.K.; Gurav, R.; Choi, T.R.; Jung, H.R.; Yang, S.Y.; Moon, Y.M.; Song, H.S.; Jeon, J.M.; Choi, K.Y.; Yang, Y.H. Bioconversion of plant biomass hydrolysate into bioplastic (polyhydroxyalkanoates) using Ralstonia eutropha 5119. Bioresour. Technol. 2019, 271, 306–315. [Google Scholar] [CrossRef] [PubMed]

- Venkata Mohan, S.; Nikhil, G.N.; Chiranjeevi, P.; Nagendranatha Reddy, C.; Rohit, M.V.; Kumar, A.N.; Sarkar, O. Waste biorefinery models towards sustainable circular bioeconomy: Critical review and future perspectives. Bioresour. Technol. 2016, 215, 2–12. [Google Scholar] [CrossRef] [PubMed]

- Li, D.H.; Zhen, L.; Yu, P.; Muhammadlqbal, S.; Yu, F.Z.; Li, L. A review on biodegradable materials for cardiovascular stent application. Front. Mater. Sci. 2016, 10, 238–259. [Google Scholar]

- Serrano, R.H.; Martin, C.L.; Pelacho, A.M. Biodegradable plastic mulches: Impact on the agricultural biotic environment. Sci. Total Environ. 2021, 750, 141228. [Google Scholar] [CrossRef] [PubMed]

- Mangaraj, S.; Yadav, A.; Bal, L.M.; Dash, S.K.; Mahanti, N.K. Application of biodegradable polymers in food packaging industry: A comprehensive review. J. Packag. Technol. Res. 2019, 3, 77–96. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Maharana, T.; Mohanty, B.; Negi, Y.S. Melt–solid polycondensation of lactic acid and its biodegradability. Polym. Sci. 2009, 34, 99–124. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Ko, Y.G.; Deril, F. Biodegradable polymer blends and composites: An overview. Polym. Sci. Ser. A 2014, 56, 812–829. [Google Scholar] [CrossRef]

- Somerville, C.; Youngs, H.; Taylor, C.; Davis, S.C.; Long, S.P. Feedstocks for lignocellulosic biofuels. Science 2010, 329, 790–792. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Avérous, L. Polylactic acid: Synthesis, properties and applications. In Monomers, Polymers and Composites from Renewable Resources; Belgacem, M., Gandini, A., Eds.; Elsevier Ltd.: Oxford, UK, 2008; pp. 433–450. [Google Scholar]

- Cheng, M.; Qin, Z.Y.; Chen, Y.Y.; Hu, S.; Ren, Z.C.; Zhu, M.F. Efficient extraction of cellulose nanocrystals through hydro-chloric acid hydrolysis catalyzed by inorganic chlorides under hydrothermal conditions. ACS Sustain. Chem. Eng. 2017, 5, 4656–4664. [Google Scholar] [CrossRef]

- Wu, Y.L.; Wang, H.; Qiu, Y.K.; Loh, X.J. PLA-based thermogel for the sustained delivery of chemotherapeutics in a mouse model of hepatocellular carcinoma. RSC Adv. 2016, 6, 44506–44513. [Google Scholar] [CrossRef]

- Tripathi, N.; Katiyar, V. Poly(lactic acid)/modified gum arabic based bionanocomposite films: Thermal degradation kinetics. Polym. Eng. Sci. 2017, 57, 1193–1206. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications: A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [Green Version]

- Haafiz, M.K.M.; Hassan, A.; Khalil, H.P.S.A.; Fazita, M.R.N.; Islam, M.S.; Inuwa, I.M.; Marliana, M.M.; Hussin, M.H. Exploring the effect of cellulose nanowhiskers isolated from oil palm biomass on polylactic acid properties. Int. J. Biol. Macromol. 2018, 85, 370–378. [Google Scholar] [CrossRef]

- Shaheen, T.I.; Emam, H.E. Sono-chemical synthesis of cellulose nanocrystals from wood sawdust using acid hydrolysis. Int. J. Biol. Macromol. 2018, 107, 1599–1606. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.H.; Yao, Z.J.; Zhou, J.T.; Zhang, Y. Reuse of waste cotton cloth for the extraction of cellulose nanocrystals. Carbohydr. Polym. 2017, 157, 945–952. [Google Scholar] [CrossRef]

- Smyth, M.; Garcia, A.; Rader, C.; Foster, E.J.; Bras, J. Extraction and process analysis of high aspect ratio cellulose nanocrystals from corn (Zea mays) agricultural residue. Ind. Crops Prod. 2017, 108, 257–266. [Google Scholar] [CrossRef]

- Gottermann, S.; Standau, T.; Weinmann, S.; Altstadt, V.; Bonten, C. Effect of chemical modification on the thermal and rheological properties of polylactide. Polym. Eng. Sci. 2017, 57, 1242–1251. [Google Scholar] [CrossRef]

- Saratale, R.G.; Saratale, G.D.; Ghodake, G.; Cho, S.K.; Kadam, A.; Kumar, G.; Jeon, B.H.; Pant, D.; Bhatnagar, A.; Shin, H.S. Wheat straw extracted lignin in silver nanoparticles synthesis: Expanding its prophecy towards antineoplastic potency and hydrogen peroxid sensig ability. J. Biol. Macromol. 2019, 128, 391–400. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.; Giri, V.P.; Tripathi, A.; Kumari, M.; Narayan, S.; Bhattacharya, A.; Srivastava, S.; Mishra, A. Early blight disease management by herbal nanoemulsion in solanum lycopersicum with bio-protective manner. Bioresour. Technol. 2021, 325, 124685. [Google Scholar] [CrossRef]

- Figueiredo, P.; Lintinen, K.; Hirvonen, J.T.; Kostiainen, M.A.; Santos, H.A. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog. Mater. Sci. 2018, 93, 233–269. [Google Scholar] [CrossRef]

- Gosselink, R.J.A.; Teunissen, W.; Van Dam, J.E.F.; de Jong, E.; Gellerstedt, G.; Scott, E.L.; Sanders, J.P.M. Lignin depolymerisation in supercritical carbon dioxide/acetone/water fluid for the production of aromatic chemicals. Bioresour. Technol. 2012, 106, 173–177. [Google Scholar] [CrossRef] [PubMed]

- Trache, D.; Hussin, M.H.; Chuin, C.T.H.; Sabar, S.; Fazita, M.N.; Taiwo, O.F.; Hassan, T.; Haafiz, M.M. Microcrystalline cellulose: Isolation, characterization and bio-composites application-a review. Int. J. Biol. Macromol. 2016, 93, 789–804. [Google Scholar] [CrossRef] [PubMed]

- Rinaldi, R.; Jastrzebski, R.; Clough, M.T.; Ralph, J.; Kennema, M.; Bruijnincx, P.C.A.; Weckhuysen, B.M. Paving the way for lignin valorisation: Recent advances in bioengineering, biorefining and catalysis. Angew. Chem. Int. Ed. 2016, 55, 8164–8215. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Cao, R.; Huang, K.; Xu, Y. Comparison of selective acidolysis of xylan and enzymatic hydrolysability of cellulose in various lignocellulosic materials by a novel xylonic acid catalysis method. Bioresour. Technol. 2020, 304, 122943. [Google Scholar] [CrossRef]

- Ufodike, C.O.; Eze, V.O.; Ahmed, M.F.; Oluwalowo, A.; Park, J.G.; Okoli, O.I.; Wang, H. Evaluation of the inter-particle interference of cellulose and lignin in lignocellulosic materials. Int. J. Biol. Macromol. 2020, 147, 762–767. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Othman, M.Z. A selective fractionation method of lignocellulosic materials using electro-assisted organosolv pretreatment. Bioresour. Technol. 2019, 288, 121421. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.P.; Zhang, W.W.; Li, Q.; Yang, G.S.; Zhang, H.H.; Shao, H.L. Structure and properties of lignin/polylactic acid composites. Polym. Mater. Sci. Eng. 2017, 33, 31–35. [Google Scholar]

- Singla, R.K.; Maiti, S.N.; Ghosh, A.K. Crystallization, morphological, and mechanical response of poly(lactic acid)/lignin-based biodegradable composites. Polym. -Plast. Technol. Eng. 2016, 55, 475–485. [Google Scholar] [CrossRef]

- Ma, A.L.; Xiao, X.Y.; Huang, D.M.; Zhang, J.T. Study on mechanical properties of lignin/PLA composites. Guangdong Chem.Eng. 2018, 45, 32–33. [Google Scholar]

- Mu, C.Y. Explorations for Processing and Properties of Lignin/Poly(l-Lactic) Acid Composites. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2014. [Google Scholar]

- Liang, X.L. Studies on Preparation and Properties of Poly(Lactic Acid)/Lignin Composites. Master’s Thesis, Jiangnan University, Wuxi, China, 2019. [Google Scholar]

- Zhang, J.B.; Ge, Y.Y.; Qin, L.; Huang, W.X.; Li, Z.L. Synthesis of a lignin-based surfactant through amination, sulfonation, and acylation. J. Dispers. Sci. Technol. 2018, 39, 1140–1143. [Google Scholar] [CrossRef]

- Buono, P.; Duval, A.; Verge, P.; Averous, L.; Habibi, Y. New insights on the chemical modification of lignin: Acetylation versus silylation. ACS Sustain. Chem. Eng. 2016, 4, 5212–5222. [Google Scholar] [CrossRef]

- Guo, J.; Chen, X.; Wang, J.; He, Y.; Xie, H.; Zheng, Q. The influence of compatibility on the structure and properties of PLA/lignin biocomposites by chemical modification. Polymers 2020, 12, 56. [Google Scholar] [CrossRef] [Green Version]

- Vila, C.; Santos, V.; Saake, B.; Parajo, J.C. Manufacture, characterization, and properties of poly-(lactic acid) and its blends with esterified pine lignin. BioResources 2016, 11, 5322–5332. [Google Scholar] [CrossRef]

- Liang, X.L.; Liu, W.Y.; Zhang, F.K.; Yang, W.D.; Shi, D.J.; Chen, M.Q. Effect of maleic anhydride modified lignin on properties of polylactic acid/epoxy soybean oil. Polym. Mater. Sci. Eng. 2019, 35, 61–67. [Google Scholar]

- Guo, J.B.; Wang, J.; He, Y.; Sun, H.; Chen, X.L.; Zheng, Q.; Xie, H.B. Triply biobased thermoplastic composites of polylactide/succinylated lignin/epoxidized soybean oil. Polymers 2020, 12, 632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Natarelli, C.V.L.; Lemos, A.C.C.; de Assis, M.R.; Tonoli, G.H.D.; Trugilho, P.F.; Marconcini, J.M.; de Oliveira, J.E. Sulfonated kraft lignin addition in urea-formaldehyde resin: Thermokinetic analysis. J. Therm. Anal. Calorim. 2019, 137, 1537–1547. [Google Scholar] [CrossRef]

- Mimini, V.; Sykacek, E.; Syed Hashim, S.N.A.; Holzweber, J.; Hettegger, H.; Fackler, K.; Potthast, A.; Mundigler, N.; Rosenau, T. Compatibility of kraft lignin, organosolv lignin and lignosulfonate with PLA in 3D printing. J. Wood Chem. Technol. 2019, 39, 14–30. [Google Scholar] [CrossRef]

- Hu, J.P.; Guo, M.H. Influence of ammonium lignosulphonate on mechanical and thermal properties of polylactic acid/wood fiber biodegradable composites. Acta Mater. Compos. Sin. 2015, 32, 657–664. [Google Scholar]

- Wang, N.N.; Zhang, C.L.; Zhu, W.Q.; Weng, Y.X. Improving interfacial adhesion of PLA/lignin composites by one-step solvent-free modification method. J. Renew. Mater. 2020, 8, 1139–1149. [Google Scholar] [CrossRef]

- Yang, Q.; Yang, J.; Gao, Z.; Li, B.; Xiong, C. Carbonized cellulose nanofibril/graphene oxide composite aerogels for high-performance supercapacitors. ACS Appl. Energy Mater. 2019, 3, 1145–1151. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Chen, X.; Zhang, C.; Akbar, A.R.; Shi, Z.; Yang, Q.; Xiong, C. Transparent konjac glucomannan/cellulose nanofibril composite films with improved mechanical properties and thermal stability. Cellulose 2019, 26, 3155–3165. [Google Scholar] [CrossRef]

- Tiffany, A.; Amit, R.; Cao, Y.F.; Yuval, N.; Eldho, A.; Tal, B.; Shaul, L.; Oded, S. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar]

- Alana, G.; Rennan, F.S.; Derval, S. Nanocellulose from industrial and agricultural waste for further use in PLA composite. J. Polym. Environ. 2020, 28, 1851–1868. [Google Scholar]

- Huang, L.J.; Zhang, X.X.; Xu, M.Z.; Chen, J.; Shi, Y.H.; Huang, C.X.; Wang, S.F.; An, S.X.; Li, C.Y. Preparation and mechanical properties of modified nanocellulose / PLA composites from cassava residue. AIP Adv. 2018, 8, 025116. [Google Scholar] [CrossRef] [Green Version]

- Sullivan, E.; Moon, R.; Kalaitzidou, K. Processing and characterization of cellulose nanocrystals/polylactic acid nanocomposite films. Materials 2015, 8, 8106–8116. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.C.; Cui, L.; Xu, H.; Feng, X.L.; Wang, B.J.; Pukánszky, B.; Mao, Z.P.; Su, X.T. Poly(lactic acid)/cellulose nanocrystal composites via the pickering emulsion approach: Rheological, thermal and mechanical properties. Int. J. Biol. Macromol. 2019, 137, 197–204. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, W.J.; Shao, Z.Q.; Li, L. Preparation and characterization of nanocellulose/polylactide fully green nanocomposites. Chem. J. Chin. Univ. 2018, 39, 373–381. [Google Scholar]

- Meng, L.X.; Xu, S.Y.; Xie, Y.Z. Preparation and characterization of PLA/acetylated nanocellulose films. Sci. Technol. Food Ind. 2016, 37, 249–252,258. [Google Scholar]

- Xu, M.C.; Yang, R.; Huang, Q.T.; Zhao, X.; Ma, C.H.; Li, W.; Li, J.; Liu, S.X. Preparation and characterization of acetylated nanocrystalline cellulose-reinforced polylactide highly regular porous films. BioResources 2018, 13, 8432–8443. [Google Scholar] [CrossRef]

- Wang, Z.L. Preparation and Properties of Nanocellulose/Polylactic Acid Composites. Master’s Thesis, Central South University of Forestry and Technology, Changsha, China, 2014. [Google Scholar]

- Bhasney, S.M.; Bhagabati, P.; Kumar, A.; Katiyar, V. Morphology and crystalline characteristics of polylactic acid(PLA)/linear low density polyethylene(LLDPE)/microcrystalline cellulose(MCC) fiber composite. Compos. Sci. Technol. 2019, 171, 54–61. [Google Scholar] [CrossRef]

- Fernanda, A.; Gisele, C.V.; Maria, I.B.; Tavares. Effect of microcrystalline and nanocrystals cellulose fillers in materials based on PLA matrix. Polym. Test. 2017, 61, 280–288. [Google Scholar]

- Xian, X.J.; Wang, X.F.; Zhu, Y.C.; Guo, Y.T.; Tian, Y.M. Effects of MCC content on the structure and performance of PLA/MCC biocomposites. J. Polym. Environ. 2018, 26, 3484–3492. [Google Scholar] [CrossRef]

- Dong, F.; Yan, M.L.; Jin, C.D.; Li, S.J. Characterization of type-II acetylated cellulose nanocrystals with various degree of substitution and its compatibility in PLA films. Polymer 2017, 9, 346. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Cao, Z.; Wu, D.; Tao, G.; Zhong, W.; Zhu, H.; Qiu, P.; Liu, C. Crystallisation, mechanical properties and rheological behaviour of PLA composites reinforced by surface modified microcrystalline cellulose. Plast. Rubber Compos. 2016, 45, 181–187. [Google Scholar] [CrossRef]

- Pei, A.; Zhou, Q.; Berglund, L.A. Functionalized cellulose nanocrystals as biobased nucleation agents in poly(l-lactide) (PLLA)-crystallization and mechanical property effects. Compos. Sci. Technol. 2010, 70, 815–821. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.B.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, Y.; Ren, H.W. Effects of microcrystalline cellulose surface modification on the mechanical and thermal properties of polylactic acid composite films. Plast. Rubber Compos. 2020, 49, 7. [Google Scholar] [CrossRef]

- Frone, A.N.; Berlioz, S.; Chailan, J.F.; Denis, M.P. Morphology and thermal properties of PLA-cellulose nanofibers composites. Carbohydr. Polym. 2013, 91, 377–384. [Google Scholar] [CrossRef]

- Song, D.L.; Zhao, Y.L.; Dong, C.X.; Deng, Y.L. Surface modification of cellulose fibers by starch grafting with crosslinkers. Appl. Polym. Sci. 2009, 113, 3019–3026. [Google Scholar] [CrossRef]

- Zhu, T.; Guo, J.; Fei, B.; Feng, Z.Y.; Gu, X.Y. Preparation of methacrylic acid modified microcrystalline cellulose and their applications in polylactic acid: Flame retardancy, mechanical properties, thermal stability and crystallization behavior. Cellulose 2020, 27, 2309–2323. [Google Scholar] [CrossRef]

- Hu, Y.; Tang, L.; Lu, Q.; Wang, S.; Chen, X.; Huang, B. Preparation of cellulose nanocrystals and carboxylated cellulose nanocrystals from borer powder of bamboo. Cellulose 2014, 2, 1611–1618. [Google Scholar] [CrossRef]

- Moreno, G.; Ramirez, K.; Esquivel, M.; Jimenez, G. Bio-composite films of polylactic acid reinforced with micro-crystalline cellulose from pineapple leaf fibers. J. Renew. Mater. 2019, 7, 9–20. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Pu, Y.; Ragauskas, A.; Yang, B. From lignin to valuable products–strategies, challenges, and prospects. Bioresour. Technol. 2019, 271, 449–461. [Google Scholar] [CrossRef] [PubMed]

- Thakur, V.K.; Thakur, M.K.; Raghavan, P.; Kessler, M.R. Progress in green polymer composites from lignin for multifunctional applications: A review. ACS Sustain. Chem. Eng. 2014, 2, 1072–1092. [Google Scholar] [CrossRef]

| Sample | Tensile Strength (MPa) | Elongation at Break (%) | Elastic Modulus (GPa) | References |

|---|---|---|---|---|

| Pure PLA | 64.21 | 7.01 | 2.84 | [30] |

| PLA/20%Lignin | 43.71 | 1.79 | 3.13 | [30] |

| Pure PLA | 56 | 10.4 | 0.4462 | [30] |

| PLA/50% Lignin | 53.3 | 9.1 | 0.5221 | [32] |

| PLA/60%Lignin | 47.7 | 7.1 | 0.5161 | [32] |

| PLA/70%Lignin | 51.8 | 8.3 | 0.4695 | [32] |

| Sample | Onset Thermal Degradation Temperature (Tonset)/°C | Maximum Thermal Degradation Temperature (Tmax/°C) |

|---|---|---|

| Pure Lignin | 266 | 346 |

| Pure PLA | 328 | 359 |

| PLA/5%Lignin | 326 | 351 |

| PLA/10%Lignin | 324 | 346 |

| PLA/20%Lignin | 319 | 345 |

| PLA/30%Lignin | 315 | 337 |

| Sample | Yield Strength/MPa | Crystallinity (Xc)/% | Crystallinity Time/min |

|---|---|---|---|

| PLA | 36.5 ± 0.3 | 13 | 14.2 |

| PLA/1.0%ANC | 38.0 ± 0.5 | 16.3 | 8 |

| PLA/1.5%ANC | 43.1 ± 0.8 | 21.2 | 7.2 |

| Sample | Applications |

|---|---|

| Pure PLA | Medical devices, Food packaging, Agriculture |

| Lignin/PLA | Food packaging, Sutures |

| Modified lignin/PLA | 3D printing |

| Cellulose/PLA | Medical devices, Packaging |

| Modified cellulose/PLA | Plastic bags, Disposable cups, Liquid stuff container |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, S.; Liu, Q.; Zhao, Y.; Sun, H.; Yang, B.; Weng, Y. A Review: Research Progress in Modification of Poly (Lactic Acid) by Lignin and Cellulose. Polymers 2021, 13, 776. https://doi.org/10.3390/polym13050776

Zhai S, Liu Q, Zhao Y, Sun H, Yang B, Weng Y. A Review: Research Progress in Modification of Poly (Lactic Acid) by Lignin and Cellulose. Polymers. 2021; 13(5):776. https://doi.org/10.3390/polym13050776

Chicago/Turabian StyleZhai, Sixiang, Qingying Liu, Yuelong Zhao, Hui Sun, Biao Yang, and Yunxuan Weng. 2021. "A Review: Research Progress in Modification of Poly (Lactic Acid) by Lignin and Cellulose" Polymers 13, no. 5: 776. https://doi.org/10.3390/polym13050776

APA StyleZhai, S., Liu, Q., Zhao, Y., Sun, H., Yang, B., & Weng, Y. (2021). A Review: Research Progress in Modification of Poly (Lactic Acid) by Lignin and Cellulose. Polymers, 13(5), 776. https://doi.org/10.3390/polym13050776