New Vegetable Oils with Different Fatty Acids on Natural Rubber Composite Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Compound Preparation and Testing

3. Results and Discussion

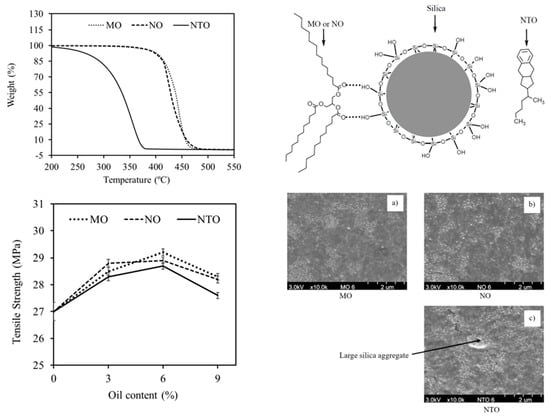

3.1. Thermal Stability of MO, NO and NTO

3.2. Effect of Oils on Viscosity and Cure Characteristics

3.3. Effect of Oils on Morphology and Storage Modulus

3.4. Effect of Oils on Physical and Dynamic Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, R.; Long, Y.; Feng, K.; Pan, Q.; Chen, Z. Fatty acid benzyl esters as bio-based plasticizers in silica-filled solution-polymerized styrene-butadiene rubber/butadiene rubber composites. J. Vinyl. Addit. Techn. 2021, 27, 68–76. [Google Scholar] [CrossRef]

- Sahakaro, K.; Beraheng, A. Epoxidized natural oils as the alternative safe process oils in rubber compounds. Rubber Chem. Technol. 2011, 84, 200–214. [Google Scholar] [CrossRef]

- Tarantini, A.; Maître, A.; Lefèbvre, E.; Marques, M.; Rajhi, A.; Douki, T. Polycyclic aromatic hydrocarbons in binary mixtures modulate the efficiency of benzo[a]pyrene to form DNA adducts in human cells. Toxicology 2011, 279, 36–44. [Google Scholar] [CrossRef] [PubMed]

- Niemczyk, J. Some ‘clean’-oils may contain carcinogens-Orgkhim. Eur. Rubber J. 2012, 194, 12. [Google Scholar]

- Kukreja, T.R.; Chauhan, R.C.; Choe, S.; Kundu, P.P. Effect of the doses and nature of vegetable oil on carbon black/rubber interactions: Studies on castor oil and other vegetable oils. J. Appl. Polym. Sci. 2003, 87, 1574–1578. [Google Scholar] [CrossRef]

- Hockensmith, L. Yokohama begins making eco-friendly E-Spec tire. Rubber Plast. News 2007, 37, 20. [Google Scholar]

- Raju, P.; Nandanan, V.; Sunil, K.N.K. A study on the use of coconut oil as plasticiser in natural rubber compounds. J. Rubber Res. 2007, 10, 1–16. [Google Scholar]

- Mishra, S.; Shimpi, N.G. Mechanical and flame-retarding properties of styrene-butadiene rubber filled with nano-CaCO3 as a filler and linseed oil as an extender. J. Appl. Polym. Sci. 2005, 98, 2563–2571. [Google Scholar] [CrossRef]

- Raju, P.; Nandanan, V.; Sunil, K.N.K. A study on the use of linseed oil as plasticiser in natural rubber compounds. J. Rubber Res. 2008, 11, 147–162. [Google Scholar]

- Kuriakose, A.P.; Rajendran, G. Use of rice-bran oil in the compounding of styrene butadiene rubber. J. Mater. Sci. 1995, 30, 2257–2262. [Google Scholar] [CrossRef]

- Kuriakose, A.P.; Varghese, M. Use of rice bran oil and epoxidized rice bran oil in carbon black-filled natural rubber-polychloroprene blends. J. Appl. Polym. Sci. 2003, 90, 4084–4092. [Google Scholar] [CrossRef]

- Joseph, R.; Alex, R.; Vinod, V.S.; Premalatha, C.K.; Kuriakose, B. Studies on epoxidized rubber seed oil as plasticizer for acrylonitrile butadiene rubber. J. Appl. Polym. Sci. 2003, 89, 668–673. [Google Scholar] [CrossRef]

- Nandanan, V.; Joseph, R.; George, K.E. Rubber seed oil: A multipurpose additive in NR and SBR compounds. J. Appl. Polym. Sci. 1999, 72, 487–492. [Google Scholar] [CrossRef]

- Jayewardhana, W.G.D.; Perera, G.M.; Edirisinghe, D.G.; Karunanayake, L. Study on natural oils as alternative processing aids and activators in carbon black filled natural rubber. J. Natl. Sci. Found. Sri. 2009, 37, 187–193. [Google Scholar] [CrossRef]

- Chandrasekara, G.; Mahanama, M.K.; Edirisinghe, D.G.; Karunanayake, L. Epoxidized vegetable oils as processing aids and activators in carbon-black filled natural rubber compounds. J. Natl. Sci. Found. Sri. 2011, 39, 243–250. [Google Scholar] [CrossRef]

- Leone, A.; Spada, A.; Battezzati, A.; Schiraldi, A.; Aristil, J.; Bertoli, S. Cultivation, Genetic, Ethnopharmacology, Phytochemistry and Pharmacology of Moringa oleifera Leaves: An Overview. Int. J. Mol. Sci. 2015, 16, 12791–12835. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Gu, Y.; Cui, H. Moringa oil/chitosan nanoparticles embedded gelatin nanofibers for food packaging against Listeria monocytogenes and Staphylococcus aureus on cheese. Food Packag. 2019, 19, 86–93. [Google Scholar] [CrossRef]

- Athikomkulchai, S.; Tunit, P.; Tadtong, S.; Jantrawut, P.; Sommano, S.R.; Chittasupho, C. Moringa oleifera Seed Oil Formulation Physical Stability and Chemical Constituents for Enhancing Skin Hydration and Antioxidant Activity. Cosmetics 2021, 8, 2. [Google Scholar] [CrossRef]

- Zhong, J.; Wang, Y.; Yang, R.; Liu, X.; Yang, Q.; Qin, X. The application of ultrasound and microwave to increase oil extraction from Moringa oleifera seeds. Ind. Crop Prod. 2018, 120, 1–10. [Google Scholar] [CrossRef]

- Ayerza, R. Seed characteristics, oil content and fatty acid composition of moringa (Moringa oleifera Lam.) seeds from three arid land locations in Ecuador. Ind. Crop Prod. 2019, 140, 111575. [Google Scholar] [CrossRef]

- Boukandoul, S.; Casal, S.; Zaidi, F. The Potential of Some Moringa Species for Seed Oil Production. Agriculture 2018, 8, 150. [Google Scholar] [CrossRef] [Green Version]

- Geleta, M.; Stymne, S.; Bryngelsson, T. Variation and inheritance of oil content and fatty acid composition in niger (Guizotia abyssinica). J. Food Compost. Anal. 2011, 24, 995–1003. [Google Scholar] [CrossRef]

- Fatima, A.; Villani, T.S.; Komar, S.; Simon, J.E.; Juliani, H.R. Quality and chemistry of niger seeds (Guizotia abyssinica) grown in the United States. Ind. Crop Prod. 2015, 75, 40–42. [Google Scholar] [CrossRef]

- Neau, A.; Rangstedt, M. Naphthenic extender oils in natural rubber tire tread compounds. Rubber World 2009, 241, 21–26. [Google Scholar]

- Le, H.H.; Zia, Q.; Ilisch, S.; Radusch, H.J. Effect of extender oils on the stress relaxation behavior of thermoplastic vulcanizates. Express Polym. Lett. 2008, 2, 791–799. [Google Scholar] [CrossRef]

- Le, H.H.; Prodanova, I.; Ilisch, S.; Radusch, H.-J. Online electrical conductivity as a measure to characterize the carbon black dispersion in oil containing rubber compounds with a different polarity of rubber. Rubber Chem. Technol. 2004, 77, 815–829. [Google Scholar] [CrossRef]

- Hans-Detlef, L.; Frohlich, J.; Wehmeier, A. Influence of different silanes on the reinforcement of silica-filled rubber compounds. Rubber Chem. Technol. 2002, 75, 563–579. [Google Scholar]

- Das, S.; Chattopadhyay, S.; Dhanania, S.; Bhowmick, A.K. Improved dispersion and physico-mechanical properties of rubber/silica composites through new silane grafting. Polymer Eng. Sci. 2020, 60, 3115–3134. [Google Scholar] [CrossRef]

- Bernal-Ortega, P.; Anyszka, R.; Morishita, Y.; di Ronza, R.; Blume, A. Comparison between SBR Compounds Filled with In-Situ and Ex-Situ Silanized Silica. Polymers 2021, 13, 281. [Google Scholar] [CrossRef] [PubMed]

- Qian, M.; Huang, W.; Wang, J.; Wang, X.; Liu, W.; Zhu, Y. Surface Treatment Effects on the Mechanical Properties of Silica Carbon Black Reinforced Natural Rubber/Butadiene Rubber Composites. Polymers 2019, 11, 1763. [Google Scholar] [CrossRef] [Green Version]

- Adhikari, C.; Proctor, A.; Blyholder, G.D. Diffuse-reflectance fourier-transform infrared spectroscopy of vegetable oil triglyceride adsorption on silicic acid. J. Am. Oil Chem. Soc. 1994, 71, 589–594. [Google Scholar] [CrossRef]

- Proctor, A.; Adhikari, C.; Blyholder, G.D. Lipid adsorption on commercial silica hydrogels from hexane and changes in triglyceride complexes with time. J. Am. Oil Chem. Soc. 1996, 73, 693–698. [Google Scholar] [CrossRef]

- Siwarote, B.; Sae-Oui, P.; Wirasate, S.; Suchiva, K. Effects of Bio-based Oils on Processing Properties and Cure Characteristics of Silica-filled Natural Rubber Compounds. J. Rubber Res. 2017, 20, 1–19. [Google Scholar] [CrossRef]

- Prasertsri, S.; Rattanasom, N. Mechanical and damping properties of silica/natural rubber composites prepared from latex system. Polym. Test. 2011, 30, 515–526. [Google Scholar] [CrossRef]

- Hayichelaeh, C.; Reuvekamp, L.A.E.M.; Dierkes, W.K.; Blume, A.; Noordermeer, J.W.M.; Sahakaro, K. Enhancing the Silanization Reaction of the Silica-Silane System by Different Amines in Model and Practical Silica-Filled Natural Rubber Compounds. Polymers 2018, 10, 584. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- David, A.; Pasquini, M.; Tartaglino, U.; Raos, G. A Coarse-Grained Force Field for Silica–Polybutadiene Interfaces and Nanocomposites. Polymers 2020, 12, 1484. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Guo, M.; Zhai, X.; Ye, X.; Zhang, L. Using Epoxidized Solution Polymerized Styrene-Butadiene Rubbers (ESSBRs) as Coupling Agents to Modify Silica without Volatile Organic Compounds. Polymers 2020, 12, 1257. [Google Scholar] [CrossRef] [PubMed]

- Dasgupta, S.; Agrawal, S.L.; Bandyopadhyay, S.; Chakraborty, S.; Mukhopadhyay, R.; Malkani, R.K.; Ameta, S.C. Characterization of eco-friendly processing aids for rubber compound. Polym. Test. 2007, 26, 489–500. [Google Scholar] [CrossRef]

- Dasgupta, S.; Agrawal, S.L.; Bandyopadhyay, S.; Mukhopadhyay, R.; Malkani, R.K.; Ameta, S.C. Eco-friendly processing oils: A new tool to achieve the improved mileage in tyre tread. Polym. Test. 2009, 28, 251–263. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, K.; Fei, G.; Salzano de Luna, M.; Lavorgna, M.; Xia, H. High Silica Content Graphene/Natural Rubber Composites Prepared by a Wet Compounding and Latex Mixing Process. Polymers 2020, 12, 2549. [Google Scholar] [CrossRef] [PubMed]

- He, F.; Yuan, T.; Li, C.; Sun, L.; Liao, S. Interfacial interactions and properties of natural rubber–silica composites with liquid natural rubber as a compatibilizer and prepared by a wet-compounding method. J. Appl. Polym. Sci. 2018, 135, 46457. [Google Scholar] [CrossRef]

- Zheng, J.; Ye, X.; Han, D.; Zhao, S.; Wu, X.; Wu, Y.; Dong, D.; Wang, Y.; Zhang, L. Silica Modified by Alcohol Polyoxyethylene Ether and Silane Coupling Agent Together to Achieve High Performance Rubber Composites Using the Latex Compounding Method. Polymers 2018, 10, 1. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Composition | MO | NO | NTO |

|---|---|---|---|

| Palmitic acid (C16:0), % | 7 | 8 | - |

| Stearic acid (C18:0), % | 6 | 6 | - |

| Oleic acid (C18:1), % | 74 | 16 | - |

| Linoleic acid (C18:2), % | 1 | 70 | - |

| Other fatty acids, % | 12 | - | - |

| Aromatic content | - | - | 11 |

| Naphthenic content | - | - | 42 |

| Aliphatic content | - | - | 47 |

| Ingredients | Content, Part per Hundred of Rubber (Phr) |

|---|---|

| Natural rubber | 100 |

| ZnO | 5 |

| Stearic acid | 3 |

| Silica | 43 |

| TESPT | 3 |

| TBBS | 2 |

| Lowinox© CPL | 1.5 |

| Sulfur | 2.2 |

| Oil (MO, NO or NTO) | 0, 3, 6, 9 |

| Oil Type | Onset Temperature (Tonset, °C) | Maximum Decomposition Rate Temperature (Tmax, °C) | Final Decomposition Temperature (Tfinal, °C) | Decomposition Temperature Range (°C) | Residue at 700 °C (%) |

|---|---|---|---|---|---|

| MO | 401 | 444 | 480 | 79 | 0.0 |

| NO | 402 | 422 | 485 | 83 | 0.0 |

| NTO | 251 | 355 | 371 | 120 | 0.0 |

| Oil Type | Tg (°C) | |||

|---|---|---|---|---|

| 0 phr | 3 phr | 6 phr | 9 phr | |

| MO | −43.8 | −45.5 | −46.0 | −47.5 |

| NO | −43.8 | −45.4 | −46.5 | −47.3 |

| NTO | −43.8 | −45.2 | −45.9 | −46.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boonrasri, S.; Sae-Oui, P.; Reungsang, A.; Rachtanapun, P. New Vegetable Oils with Different Fatty Acids on Natural Rubber Composite Properties. Polymers 2021, 13, 1108. https://doi.org/10.3390/polym13071108

Boonrasri S, Sae-Oui P, Reungsang A, Rachtanapun P. New Vegetable Oils with Different Fatty Acids on Natural Rubber Composite Properties. Polymers. 2021; 13(7):1108. https://doi.org/10.3390/polym13071108

Chicago/Turabian StyleBoonrasri, Siwarote, Pongdhorn Sae-Oui, Alissara Reungsang, and Pornchai Rachtanapun. 2021. "New Vegetable Oils with Different Fatty Acids on Natural Rubber Composite Properties" Polymers 13, no. 7: 1108. https://doi.org/10.3390/polym13071108

APA StyleBoonrasri, S., Sae-Oui, P., Reungsang, A., & Rachtanapun, P. (2021). New Vegetable Oils with Different Fatty Acids on Natural Rubber Composite Properties. Polymers, 13(7), 1108. https://doi.org/10.3390/polym13071108