Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials

Abstract

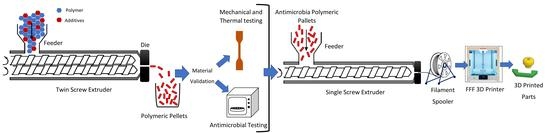

:1. Introduction

2. Techniques and Effectiveness of Developed Antibacterial 3D-Printed Materials

3. Applications Using 3D-Printed Antibacterial Materials

3.1. Biomedical Field

3.2. Use of Composite Materials in 3D Printing for Material Chemistry

3.3. Use of Metallic Fillers in Composites in 3D Printing Membrane Technology

3.4. Space Applications

4. Gaps, Challenges, Opportunities and Future Trends

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kudzin, M.H.; Mrozińska, Z. Biofunctionalization of Textile Materials. 2. Antimicrobial Modification of Poly(Lactide) (PLA) Nonwoven Fabricsby Fosfomycin. Polymers 2020, 12, 768. [Google Scholar] [CrossRef] [Green Version]

- Biniaś, D.; Biniaś, W.; Machnicka, A.; Hanus, M. Preparation of Antimicrobial Fibres from the EVOH/EPC Blend Containing Silver Nanoparticles. Polymers 2020, 12, 1827. [Google Scholar] [CrossRef]

- Fichou, D.; Morlock, G.E. Open-Source-Based 3D Printing of Thin Silica Gel Layers in Planar Chromatography. Anal. Chem. 2017, 89, 2116–2122. [Google Scholar] [CrossRef] [PubMed]

- Prikryl, J.; Foret, F. Fluorescence Detector for Capillary Separations Fabricated by 3D Printing. Anal. Chem. 2014, 86, 11951–11956. [Google Scholar] [CrossRef]

- Chauhan, I.; Chattopadhyay, S.; Mohanty, P. Fabrication of titania nanowires incorporated paper sheets and study of their optical properties. Mater. Express 2013, 3, 343–349. [Google Scholar] [CrossRef]

- Silva, C.; Bobillier, F.; Canales, D.; Sepúlveda, F.A.; Cament, A.; Amigo, N.; Rivas, L.M.; Ulloa, M.T.; Reyes, P.; Ortiz, J.A.; et al. Mechanical and Antimicrobial Polyethylene Composites with CaO Nanoparticles. Polymers 2020, 12, 2132. [Google Scholar] [CrossRef] [PubMed]

- Hwa, L.C.; Uday, M.; Ahmad, N.; Noor, A.M.; Rajoo, S.; Bin Zakaria, K. Integration and fabrication of the cheap ceramic membrane through 3D printing technology. Mater. Today Commun. 2018, 15, 134–142. [Google Scholar] [CrossRef]

- NASA. Space Tools on Demand NASA OK. Available online: https://www.nasa.gov/sites/default/files/files/3D_Printing-v3.pdf (accessed on 12 May 2020).

- Chou, Y.-C.; Lee, D.; Chang, T.-M.; Hsu, Y.-H.; Yu, Y.-H.; Chan, E.-C.; Liu, S.-J. Combination of a Biodegradable Three-Dimensional (3D)—Printed Cage for Mechanical Support and Nanofibrous Membranes for Sustainable Release of Antimicrobial Agents for Treating the Femoral Metaphyseal Comminuted Fracture. J. Mech. Behav. Biomed. Mater. 2017, 72, 209–218. [Google Scholar] [CrossRef] [PubMed]

- Snyder, M.; Dunn, J.; Gonzalez, E. The Effects of Microgravity on Extrusion Based Additive Manufacturing. In Proceedings of the Conference and Exposition, American Institute of Aeronautics and Astronautics, San Diego, CA, USA, 10 September 2013. [Google Scholar]

- Werkheiser, M.J.; Dunn, J.; Snyder, M.P.; Edmunson, J.; Cooper, K.; Johnston, M.M. 3D Printing in Zero-G ISS Technology Demonstration. In Proceedings of the Conference and Exposition, American Institute of Aeronautics and Astronautics, San Diego, CA, USA, 31 August 2014. [Google Scholar]

- Mills, D.K.; Jammalamadaka, U.; Tappa, K.; Weisman, J. Studies on the Cytocompatibility, Mechanical and Antimicrobial Properties of 3D Printed Poly(Methyl Methacrylate) Beads. Bioact. Mater. 2018, 3, 157–166. [Google Scholar] [CrossRef]

- Lahtinen, E.; Precker, R.L.M.; Lahtinen, M.; Hey-Hawkins, E.; Haukka, M. Selective Laser Sintering of Metal-Organic Frameworks: Production of Highly Porous Filters by 3D Printing onto a Polymeric Matrix. ChemPlusChem 2019, 84, 222–225. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, W.; Siraj, S.; Alnajjar, F.; Al Marzouqi, A.H. 3D Printed Implants for Joint Replacement. In Applications of 3D Printing in Biomedical Engineering; Sharma, N.R., Subburaj, K., Sandhu, K., Sharma, V., Eds.; Springer: Singapore, 2021; pp. 97–119. [Google Scholar]

- Gutierrez, E.; Burdiles, P.A.; Quero, F.; Palma, P.; Olate-Moya, F.; Palza, H. 3D Printing of Antimicrobial Alginate/Bacterial-Cellulose Composite Hydrogels by Incorporating Copper Nanostructures. ACS Biomater. Sci. Eng. 2019, 5, 6290–6299. [Google Scholar] [CrossRef] [PubMed]

- Fielding, G.A.; Bandyopadhyay, A.; Bose, S. Effects of silica and zinc oxide doping on mechanical and biological properties of 3D printed tricalcium phosphate tissue engineering scaffolds. Dent. Mater. 2012, 28, 113–122. [Google Scholar] [CrossRef] [Green Version]

- Attaran, S.A.; Hassan, A.; Wahit, M.U. Materials for food packaging applications based on bio-based polymer nanocomposites. J. Thermoplast. Compos. Mater. 2017. [Google Scholar] [CrossRef]

- Mania, S.; Ryl, J.; Jinn, J.-R.; Wang, Y.-J.; Michałowska, A.; Tylingo, R. The Production Possibility of the Antimicrobial Filaments by Co-Extrusion of the PLA Pellet with Chitosan Powder for FDM 3D Printing Technology. Polymers 2019, 11, 1893. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.; Wang, C.; Qiu, W.; Liu, R. Antimicrobial Thiol–ene–acrylate Photosensitive Resins for DLP 3D Printing. Photochem. Photobiol. 2019, 95, 1219–1229. [Google Scholar] [CrossRef] [PubMed]

- Musić, S.; Filipović-Vinceković, N.; Sekovanić, L. Precipitation of amorphous SiO2 particles and their properties. Braz. J. Chem. Eng. 2011, 28, 89–94. [Google Scholar] [CrossRef]

- Falagas, M.; Kasiakou, S. Mesh-related infections after hernia repair surgery. Clin. Microbiol. Infect. 2005, 11, 3–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, G.; Sharma, S.; Sharma, P.; Chandola, D.; Dang, S.; Gupta, S.; Gabrani, R. Escherichia coli biofilm: Development and therapeutic strategies. J. Appl. Microbiol. 2016, 121, 309–319. [Google Scholar] [CrossRef] [Green Version]

- Galdbart, J.O.; Allignet, J.; Tung, H.S.; Rydèn, C.; El Solh, N. Screening for Staphylococcus Epidermidis Markers Discriminating between Skin-Flora Strains and Those Responsible for Infections of Joint Prostheses. J. Infect. Dis. 2000, 182, 351–355. [Google Scholar] [CrossRef] [Green Version]

- Aljohani, W.; Ullah, M.W.; Li, W.; Shi, L.; Zhang, X.; Yang, G. Three-dimensional printing of alginate-gelatin-agar scaffolds using free-form motor assisted microsyringe extrusion system. J. Polym. Res. 2018, 25, 62. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Hernandez, J.R. Antimicrobial Polymers for Additive Manufacturing. Int. J. Mol. Sci. 2019, 20, 1210. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Corrêa, A.C.; De Santi, C.R.; Manrich, S. Synthetic Paper from Plastic Waste: The Effect of CaCO3 on Physical, Surface Properties and Printability. Macromol. Symp. 2006, 245–246, 611–620. [Google Scholar] [CrossRef]

- Krupa, I.; Cecen, V.; Boudenne, A.; Prokeš, J.; Novák, I. The mechanical and adhesive properties of electrically and thermally conductive polymeric composites based on high density polyethylene filled with nickel powder. Mater. Des. 2013, 51, 620–628. [Google Scholar] [CrossRef]

- Lee, D.W.; Yoo, B.R. Advanced silica/polymer composites: Materials and applications. J. Ind. Eng. Chem. 2016, 38, 1–12. [Google Scholar] [CrossRef]

- Borkow, G.; Sidwell, R.W.; Smee, D.F.; Barnard, D.L.; Morrey, J.D.; Lara-Villegas, H.H.; Shemer-Avni, Y.; Gabbay, J. Neutralizing Viruses in Suspensions by Copper Oxide-Based Filters. Antimicrob. Agents Chemother. 2007, 51, 2605–2607. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cevik, M.; Bamford, C.; Ho, A. COVID-19 pandemic—A focused review for clinicians. Clin. Microbiol. Infect. 2020, 26, 842–847. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Ko, Y.-S.; Jung, H.; Lee, C.; Woo, K.; Ko, G. Disinfection of Waterborne Viruses Using Silver Nanoparticle-Decorated Silica Hybrid Composites in Water Environments. Sci. Total Environ. 2018, 625, 477–485. [Google Scholar] [CrossRef] [PubMed]

- Trewyn, B.G.; Whitman, C.M.; Lin, V.S.-Y. Morphological Control of Room-Temperature Ionic Liquid Templated Mesoporous Silica Nanoparticles for Controlled Release of Antibacterial Agents. Nano Lett. 2004, 4, 2139–2143. [Google Scholar] [CrossRef]

- Ferraris, M.; Perero, S.; Miola, M.; Ferraris, S.; Verné, E.; Morgiel, J. Silver nanocluster–silica composite coatings with antibacterial properties. Mater. Chem. Phys. 2010, 120, 123–126. [Google Scholar] [CrossRef]

- Jiang, Z.; Demir, B.; Broughton, R.M.; Ren, X.; Huang, T.S.; Worley, S.D. Antimicrobial silica and sand particles functionalized with anN-halamine acrylamidesiloxane copolymer. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Zuniga, J.M.; Thompson, M. Applications of antimicrobial 3D printing materials in space. J. 3D Print. Med. 2019, 3, 5–9. [Google Scholar] [CrossRef]

- McCarthy, R.R.; Ullah, M.W.; Pei, E.; Yang, G. Antimicrobial Inks: The Anti-Infective Applications of Bioprinted Bacterial Polysaccharides. Trends Biotechnol. 2019, 37, 1155–1159. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, R.R.; Ullah, M.W.; Booth, P.; Pei, E.; Yang, G. The use of bacterial polysaccharides in bioprinting. Biotechnol. Adv. 2019, 37, 107448. [Google Scholar] [CrossRef]

- Ullah, M.W.; Manan, S.; Khattak, W.A.; Shahzad, A.; Ul-Islam, M.; Yang, G. Biotemplate-Mediated Green Synthesis and Applications of Nanomaterials. Curr. Pharm. Des. 2020, 26, 5819–5836. [Google Scholar] [CrossRef]

- Palza, H. Antimicrobial Polymers with Metal Nanoparticles. Int. J. Mol. Sci. 2015, 16, 2099–2116. [Google Scholar] [CrossRef] [Green Version]

- Kirsh, I.; Frolova, Y.; Beznaeva, O.; Bannikova, O.; Gubanova, M.; Tveritnikova, I.; Romanova, V.; Filinskaya, Y. Influence of the Ultrasonic Treatment on the Properties of Polybutylene Adipate Terephthalate, Modified by Antimicrobial Additive. Polymers 2020, 12, 2412. [Google Scholar] [CrossRef] [PubMed]

- Yue, J.; Zhao, P.; Gerasimov, J.Y.; Van De Lagemaat, M.; Grotenhuis, A.; Rustema-Abbing, M.; Van Der Mei, H.C.; Busscher, H.J.; Herrmann, A.; Ren, Y. 3D-Printable Antimicrobial Composite Resins. Adv. Funct. Mater. 2015, 25, 6756–6767. [Google Scholar] [CrossRef]

- Muwaffak, Z.; Goyanes, A.; Clark, V.; Basit, A.W.; Hilton, S.T.; Gaisford, S. Patient-specific 3D scanned and 3D printed antimicrobial polycaprolactone wound dressings. Int. J. Pharm. 2017, 527, 161–170. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Bártolo, P.J. Rheological characterization of polymer/ceramic blends for 3D printing of bone scaffolds. Polym. Test. 2018, 68, 365–378. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Wang, S.; Zhang, Y.; Mi, J.; Ding, X. Synthesis of Dimethyl Octyl Aminoethyl Ammonium Bromide and Preparation of Antibacterial ABS Composites for Fused Deposition Modeling. Polymers 2020, 12, 2229. [Google Scholar] [CrossRef]

- Yang, F.; Zeng, J.; Long, H.; Xiao, J.; Luo, Y.; Gu, J.; Zhou, W.; Wei, Y.; Dong, X. Micrometer Copper-Zinc Alloy Particles-Reinforced Wood Plastic Composites with High Gloss and Antibacterial Properties for 3D Printing. Polymers 2020, 12, 621. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brounstein, Z.; Yeager, C.M.; Labouriau, A. Development of Antimicrobial PLA Composites for Fused Filament Fabrication. Polymers 2021, 13, 580. [Google Scholar] [CrossRef] [PubMed]

- Rezić, I.; Majdak, M.; Bilić, V.L.; Pokrovac, I.; Martinaga, L.; Škoc, M.S.; Kosalec, I. Development of Antibacterial Protective Coatings Active against MSSA and MRSA on Biodegradable Polymers. Polymers 2021, 13, 659. [Google Scholar] [CrossRef] [PubMed]

- Bayarsaikhan, E.; Lim, J.-H.; Shin, S.-H.; Park, K.-H.; Park, Y.-B.; Lee, J.-H.; Kim, J.-E. Effects of Postcuring Temperature on the Mechanical Properties and Biocompatibility of Three-Dimensional Printed Dental Resin Material. Polymers 2021, 13, 1180. [Google Scholar] [CrossRef] [PubMed]

- Shaqour, B.; Reigada, I.; Górecka, Ż.; Choińska, E.; Verleije, B.; Beyers, K.; Święszkowski, W.; Fallarero, A.; Cos, P. 3D-Printed Drug Delivery Systems: The Effects of Drug Incorporation Methods on Their Release and Antibacterial Efficiency. Materials 2020, 13, 3364. [Google Scholar] [CrossRef]

- Ramos, M.; Fortunati, E.; Beltrán, A.; Peltzer, M.; Cristofaro, F.; Visai, L.; Valente, A.J.M.; Jiménez, A.; Kenny, J.M.; Garrigós, M.C. Controlled Release, Disintegration, Antioxidant, and Antimicrobial Properties of Poly (Lactic Acid)/Thymol/Nanoclay Composites. Polymers 2020, 12, 1878. [Google Scholar] [CrossRef] [PubMed]

- Puertas-Bartolomé, M.; Mora-Boza, A.; García-Fernández, L. Emerging Biofabrication Techniques: A Review on Natural Polymers for Biomedical Applications. Polymers 2021, 13, 1209. [Google Scholar] [CrossRef] [PubMed]

- Navaruckiene, A.; Bridziuviene, D.; Raudoniene, V.; Rainosalo, E.; Ostrauskaite, J. Influence of Vanillin Acrylate-Based Resin Composition on Resin Photocuring Kinetics and Antimicrobial Properties of the Resulting Polymers. Materials 2021, 14, 653. [Google Scholar] [CrossRef]

- Melo, S.F.; Neves, S.C.; Pereira, A.T.; Borges, I.; Granja, P.L.; Magalhães, F.D.; Gonçalves, I.C. Incorporation of Graphene Oxide into Poly(ε-Caprolactone) 3D Printed Fibrous Scaffolds Improves Their Antimicrobial Properties. Mater. Sci. Eng. C 2020, 109, 110537. [Google Scholar] [CrossRef] [PubMed]

- Guerra, A.J.; Lammel-Lindemann, J.; Katko, A.; Kleinfehn, A.; Rodriguez, C.A.; Catalani, L.H.; Becker, M.L.; Ciurana, J.; Dean, D. Optimization of Photocrosslinkable Resin Components and 3D Printing Process Parameters. Acta Biomater. 2019, 97, 154–161. [Google Scholar] [CrossRef]

- Sa, L.; Kaiwu, L.; Shenggui, C.; Junzhong, Y.; Yongguang, J.; Lin, W.; Li, R. 3D printing dental composite resins with sustaining antibacterial ability. J. Mater. Sci. 2019, 54, 3309–3318. [Google Scholar] [CrossRef]

- Liang, J.; Li, J.; Zhou, C.; Jia, W.; Song, H.; Zhang, L.; Zhao, F.; Lee, B.P.; Liu, B. In situ synthesis of biocompatible imidazolium salt hydrogels with antimicrobial activity. Acta Biomater. 2019, 99, 133–140. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Dai, G.; Hong, Y. Recent advances in high-strength and elastic hydrogels for 3d printing in biomedical applications. Acta Biomater. 2019, 95, 50–59. [Google Scholar] [CrossRef] [PubMed]

- Zuniga, J.M. 3D Printed Antibacterial Prostheses. Appl. Sci. 2018, 8, 1651. [Google Scholar] [CrossRef] [Green Version]

- Zuniga, J.M.; Carson, A.M.; Peck, J.M.; Kalina, T.; Srivastava, R.M.; Peck, K. The development of a low-cost three-dimensional printed shoulder, arm, and hand prostheses for children. Prosthetics Orthot. Int. 2017, 41, 205–209. [Google Scholar] [CrossRef]

- Ahmed, W.; Al-Douri, Y. Chapter 17: Three-Dimensional Printing of Ceramic Powder Technology. In Metal Oxide Powder Technologies: Fundamentals, Processing Methods and Applications; Al-Douri, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 351–383. [Google Scholar]

- Zanocco, M.; Boschetto, F.; Zhu, W.; Marin, E.; McEntire, B.J.; Bal, B.S.; Adachi, T.; Yamamoto, T.; Kanamura, N.; Ohgitani, E.; et al. 3D-additive deposition of an antibacterial and osteogenic silicon nitride coating on orthopaedic titanium substrate. J. Mech. Behav. Biomed. Mater. 2020, 103, 103557. [Google Scholar] [CrossRef]

- Zuniga, J.; Katsavelis, D.; Peck, J.; Stollberg, J.; Petrykowski, M.; Carson, A.; Fernandez, C. Cyborg beast: A low-cost 3d-printed prosthetic hand for children with upper-limb differences. BMC Res. Notes 2015, 8, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Young, K.J.; Pierce, J.E.; Zuniga, J.M. Assessment of body-powered 3D printed partial finger prostheses: A case study. 3D Print. Med. 2019, 5, 7–8. [Google Scholar] [CrossRef]

- Yamada, R.; Nozaki, K.; Horiuchi, N.; Yamashita, K.; Nemoto, R.; Miura, H.; Nagai, A. Ag Nanoparticle–Coated Zirconia for Antibacterial Prosthesis. Mater. Sci. Eng. C 2017, 78, 1054–1060. [Google Scholar] [CrossRef] [PubMed]

- Zahedi, P.; Rezaeian, I.; Ranaei-Siadat, S.-O.; Jafari, S.-H.; Supaphol, P. A review on wound dressings with an emphasis on electrospun nanofibrous polymeric bandages. Polym. Adv. Technol. 2009, 21, 77–95. [Google Scholar] [CrossRef]

- Thapa, R.K.; Diep, D.B.; Tønnesen, H.H. Topical antimicrobial peptide formulations for wound healing: Current developments and future prospects. Acta Biomater. 2020, 103, 52–67. [Google Scholar] [CrossRef]

- Long, J.; Etxeberria, A.E.; Nand, A.V.; Bunt, C.R.; Ray, S.; Seyfoddin, A. A 3D printed chitosan-pectin hydrogel wound dressing for lidocaine hydrochloride delivery. Mater. Sci. Eng. C 2019, 104, 109873. [Google Scholar] [CrossRef]

- Martínez-Jarquín, S.; Moreno-Pedraza, A.; Alonso, H.G.; Winkler, R. Template for 3D Printing a Low-Temperature Plasma Probe. Anal. Chem. 2016, 88, 6976–6980. [Google Scholar] [CrossRef] [PubMed]

- Dudukovic, N.A.; Wong, L.L.; Nguyen, D.T.; Destino, J.F.; Yee, T.D.; Ryerson, F.J.; Suratwala, T.; Duoss, E.B.; Dylla-Spears, R. Predicting Nanoparticle Suspension Viscoelasticity for Multimaterial 3D Printing of Silica–Titania Glass. ACS Appl. Nano Mater. 2018, 1, 4038–4044. [Google Scholar] [CrossRef]

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-dimensional printing of transparent fused silica glass. Nat. Cell Biol. 2017, 544, 337–339. [Google Scholar] [CrossRef] [PubMed]

- Arango, M.A.T.; Kwakye-Ackah, D.; Agarwal, S.; Gupta, R.K.; Sierros, K.A. Environmentally Friendly Engineering and Three-Dimensional Printing of TiO2 Hierarchical Mesoporous Cellular Architectures. ACS Sustain. Chem. Eng. 2017, 5, 10421–10429. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, X.; Guo, Z.; Volinsky, A.A. 3D gel-printing of Sr ferrite parts. Ceram. Int. 2018, 44, 22370–22377. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Zhao, T.; Han, W.; Duan, W.; Wang, L.; Dou, R.; Wang, G. Additive manufacturing of SiBCN/Si3N4w composites from preceramic polymers by digital light processing. RSC Adv. 2020, 10, 5681–5689. [Google Scholar] [CrossRef] [Green Version]

- Benito, J.; Ríos, G.; Ortea, E.; Fernández, E.; Cambiella, A.; Pazos, C.; Coca, J. Design and construction of a modular pilot plant for the treatment of oil-containing wastewaters. Desalination 2002, 147, 5–10. [Google Scholar] [CrossRef]

- Chen, W.; Su, Y.; Zheng, L.; Wang, L.; Jiang, Z. The Improved Oil/Water Separation Performance of Cellulose Acetate-Graft-Polyacrylonitrile Membranes. J. Membr. Sci. 2009, 337, 98–105. [Google Scholar] [CrossRef]

- Sciencedirect. Modification of a Novel Macroporous Silica-Based Crown Ether Impregnated Polymeric Composite with 1-Dodecanol and Its Adsorption for Some Fission and Non-Fission Products Contained in High Level Liquid Waste-Science Direct. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0014305708003625 (accessed on 1 April 2020).

- Neoh, K.; Tan, K.; Goh, P.; Huang, S.; Kang, E. Electroactive polymer–SiO 2 nanocomposites for metal uptake. Polymers 1999, 40, 887–893. [Google Scholar] [CrossRef]

- Rezaei, F.; Lively, R.P.; Labreche, Y.; Chen, G.; Fan, Y.; Koros, W.J.; Jones, C.W. Aminosilane-Grafted Polymer/Silica Hollow Fiber Adsorbents for CO2Capture from Flue Gas. ACS Appl. Mater. Interfaces 2013, 5, 3921–3931. [Google Scholar] [CrossRef] [PubMed]

- Harbaugh, J. Space Station 3-D Printer Builds Ratchet Wrench to Complete First Phase. Available online: http://www.nasa.gov/mission_pages/station/research/news/3Dratchet_wrench (accessed on 26 May 2020).

- Cowley, A.; Perrin, J.; Meurisse, A.; Micallef, A.; Fateri, M.; Rinaldo, L.; Bamsey, N.; Sperl, M. Effects of variable gravity conditions on additive manufacture by fused filament fabrication using polylactic acid thermoplastic filament. Addit. Manuf. 2019, 28, 814–820. [Google Scholar] [CrossRef]

- Space Assembly Pushes 3D Printing Boundaries—ProQuest. Available online: https://search-proquest-com.uaeu.idm.oclc.org/docview/2102339029?accountid=62373 (accessed on 17 May 2020).

- Zocca, A.; Lüchtenborg, J.; Mühler, T.; Wilbig, J.; Mohr, G.; Villatte, T.; Léonard, F.; Nolze, G.; Sparenberg, M.; Melcher, J.; et al. Enabling the 3D Printing of Metal Components in Μ-Gravity. Adv. Mater. Technol. 2019, 4, 1900506. [Google Scholar] [CrossRef] [Green Version]

- Michelle, J. Zero Gravity Bioprinter: Ready for the International Space Station. Available online: https://www.3dnatives.com/en/zero-gravity-bioprinter220820184/ (accessed on 17 May 2020).

- Goulas, A.; Binner, J.G.; Harris, R.A.; Friel, R.J. Assessing extraterrestrial regolith material simulants for in-situ resource utilisation based 3D printing. Appl. Mater. Today 2017, 6, 54–61. [Google Scholar] [CrossRef]

- Johnson, M. Solving the Challenges of Long Duration Space Flight with 3D Printing. Available online: http://www.nasa.gov/mission_pages/station/research/news/3d-printing-in-space-long-duration-spaceflight-applications (accessed on 18 May 2020).

- Prater, T.J.; Bean, Q.A.; Beshears, R.D.; Rolin, T.D.; Werkheiser, N.J.; Ordonez, E.A.; Ryan, R.M.; Iii, F.E.L. Summary Report on Phase I Results From the 3D Printing in Zero-G Technology Demonstration Mission; NASA: Washington, WA, USA, 2016.

- Mathew, E.; Gilmore, B.F.; Larrañeta, E.; Lamprou, D.A. Antimicrobial 3D Printed Objects in the Fight Against Pandemics. 3D Print. Addit. Manuf. 2021, 8, 79–86. [Google Scholar] [CrossRef]

- Čech Barabaszová, K.; Holešová, S.; Hundáková, M.; Kalendová, A. Tribo-Mechanical Properties of the Antimicrobial Low-Density Polyethylene (LDPE) Nanocomposite with Hybrid ZnO–Vermiculite–Chlorhexidine Nanofillers. Polymers 2020, 12, 2811. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Ma, L.; Yang, X.; Fei, B.; Leung, P.H.M.; Tao, X. Mechanistic Study of Synergistic Antimicrobial Effects between Poly (3-hydroxybutyrate) Oligomer and Polyethylene Glycol. Polymers 2020, 12, 2735. [Google Scholar] [CrossRef]

- Strasakova, M.; Pummerova, M.; Filatova, K.; Sedlarik, V. Immobilization of Caraway Essential Oil in a Polypropylene Matrix for Antimicrobial Modification of a Polymeric Surface. Polymers 2021, 13, 906. [Google Scholar] [CrossRef]

- Spirescu, V.; Chircov, C.; Grumezescu, A.; Andronescu, E. Polymeric Nanoparticles for Antimicrobial Therapies: An up-to-date Overview. Polymers 2021, 13, 724. [Google Scholar] [CrossRef] [PubMed]

- Kupnik, K.; Primožič, M.; Kokol, V.; Leitgeb, M. Nanocellulose in Drug Delivery and Antimicrobially Active Materials. Polymers 2020, 12, 2825. [Google Scholar] [CrossRef]

- Dong, P.; Feng, J.; Li, S.; Sun, T.; Shi, Q.; Xie, X. Synthesis, Characterization, and Antimicrobial Evaluation of Random Poly(ester-Carbonate)s Bearing Pendant Primary Amine in the Main Chain. Polymers 2020, 12, 2640. [Google Scholar] [CrossRef]

- Culbreath, C.J.; Gaerke, B.; Taylor, M.S.; McCullen, S.D.; Mefford, O.T. Effect of Infill on Resulting Mechanical Properties of Additive Manufactured Bioresorbable Polymers for Medical Devices. Materialia 2020, 12, 100732. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Alnajjar, F.; Alsaedi, N.F.N.; Ahmed, W.K. Robotic Gripping Assist. U.S. Patent Application No. 1049677B1, October 2019. [Google Scholar]

- Alnajjar, F.; Umari, H.; Ahmed, W.K.; Gochoo, M.; Vogan, A.A.; Aljumaily, A.; Mohamad, P.; Shimoda, S. CHAD: Compact Hand-Assistive Device for enhancement of function in hand impairments. Robot. Auton. Syst. 2021, 142, 103784. [Google Scholar] [CrossRef]

- Alnajjar, F.; Ahmed, W.; Gochoo, M. Touchless Elevator Keyboard System. U.S. Patent Application No. 10968073B1, April 2021. [Google Scholar]

- Ahmed, W.; Alabdouli, H.; Alqaydi, H.; Mansour, A.; Al, K.H.; Al, J.H. 3D printer: A case study. In Proceedings of the 10th Annual International IEOM Conference, Dubai, United Arab Emirates, 10–12 March 2020. [Google Scholar]

- Ahmed, W.; Alnajjar, F.; Zaneldin, E.; Al-Marzouqi, A.H.; Gochoo, M.; Khalid, S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials 2020, 13, 4065. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3D Printing PLA Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef] [PubMed]

- Mansour, A.; Alabdouli, H.; Alqaydi, H.; Al, K.H.; Ahmed, W.; Al, J.H. Evaluating the 3D printing capabilities. In Proceedings of the 10th Annual International IEOM Conference, Dubai, United Arab Emirates, 10–12 March 2020. [Google Scholar]

- Al Khawaja, H.; Alabdouli, H.; Alqaydi, H.; Mansour, A.; Ahmed, W.; Al Jassmi, H. Investigating the Mechanical Properties of 3D Printed Components. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 11–26 March 2020; pp. 1–7. [Google Scholar]

- Ahmed, W.; Zaneldin, E.; Kabbani, S. Fracture Mechanics Performance of Through-Thickness Crack of Polymeric 3D Printed Components; Metzler, J.B., Ed.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 269–279. [Google Scholar]

- Ahmed, W.; Al-Rifaie, W.; Zaneldin, E. Chapter 4—Mathematical modeling and simulation of interfaces between fiber and its matrix. In Micro and Nano Technologies, Fiber-Reinforced Nanocomposites: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 91–99. [Google Scholar]

- Ahmed, W.; Ahmed, S.; Alnajjar, F.; Zaneldin, E. Mechanical performance of three-dimensional printed sandwich composite with a high-flexible core. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 14644207211011729. [Google Scholar] [CrossRef]

- Ahmed, W. Product and method to manufacture multi-layered, multi-material composite sandwich structure with hyper elasticity rubber like core made by fusion deposition modeling. U.S. Patent Application No. US10974444B1, April 2021. [Google Scholar]

| Polymer Name | Particle Name | Particle Size | Weight/Volume % | Chemical Agent | Ref |

|---|---|---|---|---|---|

| PCL | Graphene oxide | Not specified | 0%, 5%, and 7.5%, | Not specified | [53] |

| Thiol-ene-acrylate | QUA, SH-QUA | Not specified | 2 wt%, 4 wt%, 6, wt%, 8 wt%, 10 wt% | phenylbis(2,4,6-trimethylbenzoyl), phosphineoxide photoinitiator, 1,2,3-benzenetriol | [19] |

| stereolithographic resins- UDMA | Ag-HNT | Nanoparticles | 1%, 2%, 5% | triethylene glycol dimethacrylate (TEGDMA), photosensitizer | [55] |

| alginate beads | Copper nanoparticles | Nanoparticles | 4 wt% alginate concentration; 50-mM copper salt concentration | Bacterial cellulose | [15] |

| PLA | Copper nanoparticles | Nanoparticles | 1% antibacterial nanoparticle additive | - | [58] |

| PCL | Metal ions (Ag, Cu, Zn) | Not specified | Ag-10% w/w Cu-10% and 25% w/w Zn-10% w/w | Tetrahydrofuran (THF) dichloromethane (DCM) - | [42] |

| UDMA | QA_Cn (n=2 to n=16)pQA_C12 | Not specified | Nitrogen (N%) linearly related to alkyl chain pQA-C12–25 wt% | camphorquinone (CQ); ethyl 4-(dimethylamino)benzoate (EDMAB); glycerol dimethacrylate (GDMA); 2-hydroxyethyl methacrylate (HEMA) for pQA_Cn12 | 2015 [41] |

| Polymer Name | Nozzle Diameter | Filament Diameter/Printer Settings | Printing Temperature | Filament Process | Tests Done | Reference |

|---|---|---|---|---|---|---|

| PCL | xy distances ranged from 200 μm to 400 μm, z-steps from 20 μm to 80 μm, and staggering between layers from 50 μm to 200 μm | Not specified | Not specified | internal diameter of 184 μm (28G) for scaffold plotting | 1,4,6,12,16 | [53] |

| Thiol-ene-acrylate | Not specified | Not specified | Not specified | Not specified | 1,2,9,14 | [19] |

| stereolithographic resins | Not specified | Resolution of the device = 50 lm in the Z-direction; exposure time of each layer = 12 s | Not specified | Not specified | 1,2,8,5,14,15,18 | [55] |

| alginate beads | 1.75 mm | 3D structures of 30 × 30 × 1 mm3 (length × width × height) 1.5 mm of thread spacing; dispensing head temperature of 25 °C; ink extruded with 23-G needle tip at 25 °C; printing speed of 50 mm s−1; extrusion pressure of 1 bar | 25 °C | Not specified | 1,5,18 | [15] |

| PLA | Not specified | 40% infill (hexagon pattern); 50-mm/s print speed; 150–200-mm/s travel speed; 50 °C heated bed; 0.15-mm layer height; 1-mm shell thickness | 200 °C | Not specified | 1,13 | [58] |

| PCL | 1.75 mm | - square dressings (20 _ 20-1 mm) for antimicrobial studies and circular dressings (10-mm diameter; 1-mm thickness) −0.1 (mm layer height), with two shells, 100% infill and speed while extruding and while traveling was set to 50 mm/s | 170 °C | Extruded/Single screw Ag-80 °C Cu-60 °C Zn-75 °C | 1,2,3,4,7,11,17 | [41] |

| UDMA | Not specified | z-stage with the substrate moved upward by 200 μm; resolution of the device ~300 μm in the XY-plane and 25 μm in the Z-direction | Not specified | Not specified | 1,7,12,14,15,19 | [41] |

| Reinforcement Material | Antimicrobial Synthesis Method | Printing Method | Antimicrobial Activity (%) | Application | Reference |

|---|---|---|---|---|---|

| Graphene oxide | Dissolution | Wet spinning + AM | 80% | Fibrous scaffolds | [53] |

| QUA, SH-QUA | Dissolution (Copolymerization) | DLP | 100% | Dental tooth | [19] |

| Ag-HNT | Dissolution in SLR | DLP | 99% | Dental composite resin | [55] |

| Copper nanoparticles | Ionic cross-linking | FFF | Not specified | Composite hydrogel | [15] |

| Copper nanoparticles | Purchased PLACTIVE© | Extrusion + FFF | 99% | Finger prosthesis | [58] |

| Metal ions (Ag, Cu, Zn) | Hot-melt extrusion | FFF | Not specified | Wound dressing | [41] |

| QA_Cn (n=2 to n=16) pQA_C12 | Dissolution (Copolymerization) | SLA | 99% | Dental composite resin | [41] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials. Polymers 2021, 13, 1523. https://doi.org/10.3390/polym13091523

Ahmed W, Siraj S, Al-Marzouqi AH. Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials. Polymers. 2021; 13(9):1523. https://doi.org/10.3390/polym13091523

Chicago/Turabian StyleAhmed, Waleed, Sidra Siraj, and Ali H. Al-Marzouqi. 2021. "Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials" Polymers 13, no. 9: 1523. https://doi.org/10.3390/polym13091523

APA StyleAhmed, W., Siraj, S., & Al-Marzouqi, A. H. (2021). Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials. Polymers, 13(9), 1523. https://doi.org/10.3390/polym13091523