Modeling and Experimental Studies on Polymer Melting and Flow in Injection Molding

Abstract

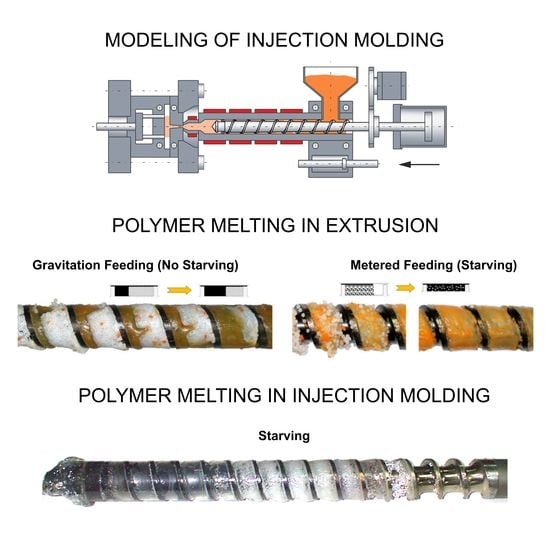

:1. Introduction

- The process is quasi-steady;

- The polymer melting contains two phases: the static melting at the stationary screw and the dynamic melting at the rotating screw with its axial backward movement;

- The screw retreat is computed by the equality of the calculated pressure in the front of the screw and the back pressure;

- Three zones of the plasticating system are distinguished: the feed port and the solid conveying zone, the delay zone, as well as the melting and melt conveying zone.

2. Experiment

2.1. Material and Process Data

2.2. Results

3. Future Concepts of Injection Molding Process Modeling

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wilczyński, K. Rheology in Polymer Processing. Modeling and Simulation; Carl Hanser Verlag: Munich, Germany, 2021; ISBN 978-1-56990-660-6. [Google Scholar]

- Rowell, H.S.; Finlayson, D. Screw Viscous Pumps. Engineering 1928, 126, 249. [Google Scholar]

- Carley, J.F.; Mallouk, R.S.; McKelvey, J.M. Simplified Flow Theory for Screw Extruders. Ind. Eng. Chem. 1953, 45, 974–978. [Google Scholar] [CrossRef]

- Carley, J.F.; Strub, R.A. Basic Concepts of Extrusion. Ind. Eng. Chem. 1953, 45, 970–974. [Google Scholar] [CrossRef]

- Darnell, W.H.; Mol, E.A.J. Solids Conveying in Extruders. SPE-J. 1956, 20, 20–29. [Google Scholar]

- Maddock, B.H. A Visual Analysis of Flow and Mixing in Extruder Screws. SPE ANTEC Tech. Pap. 1959, 15, 383. [Google Scholar]

- Street, L.F. Plastifying Extrusion. Intern. Plast. Eng. 1961, 1, 289–296. [Google Scholar]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental Study for Starve-Fed Single Screw Extrusion of Thermoplastics. Polym. Eng. Sci. 2012, 52, 1258–1270. [Google Scholar] [CrossRef]

- Tadmor, Z. Fundamentals of Plasticating Extrusion. I. A Theoretical Model for Melting. Polym. Eng. Sci. 1966, 6, 185–190. [Google Scholar] [CrossRef]

- Marshall, D.I.; Klein, I. Fundamentals of Plasticating Extrusion. II. Experiments. Polym. Eng. Sci. 1966, 6, 191–197. [Google Scholar] [CrossRef]

- Tadmor, Z.; Duvdevani, I.J.; Klein, I. Melting in Plasticating Extruders Theory and Experiments. Polym. Eng. Sci. 1967, 7, 198–217. [Google Scholar] [CrossRef]

- Tadmor, Z.; Klein, I. Computer Programs for Plastic Engineers; Reinhold Book Corporation: New York, NY, USA, 1968. [Google Scholar]

- Tadmor, Z.; Broyer, E. Solids Conveying in Screw Extruders—Part I: A Modified Isothermal Model. Polym. Eng. Sci. 1972, 12, 12–24. [Google Scholar] [CrossRef]

- Tadmor, Z.; Broyer, E. Solids Conveying in Screw Extruders—Part II: A Modified Non-Isothermal Model. Polym. Eng. Sci. 1972, 12, 376–378. [Google Scholar] [CrossRef]

- Kacir, L.; Tadmor, Z. Solids Conveying in Screw Extruders. Part III: The Delay Zone. Polym. Eng. Sci. 1972, 12, 387–395. [Google Scholar] [CrossRef]

- Fisher, E.G. Extrusion of Plastics, 1st ed.; Iliffe Books Ltd.: London, UK, 1958. [Google Scholar]

- McKelvey, J.M. Polymer Processing; John Wiley & Sons Inc: New York, NY, USA, 1962; ISBN 978-0471584438. [Google Scholar]

- Schenkel, G. Kunststoff-Extrudertechnik; Carl Hanser: Munich, Germany, 1963. [Google Scholar]

- Fenner, R.T. Extruder Screw Design; Iliffe Books Ltd.: London, UK, 1970. [Google Scholar]

- Tadmor, Z.; Klein, I. Engineering Principles of Plasticating Extrusion; Van Nostrand Reinhold Co.: New York, NY, USA, 1970; ISBN 978-0442156350. [Google Scholar]

- Hensen, F.; Knappe, W.; Potente, H. Handbuch der Kunststoff-Extrusiontechnik. Grundlagen; Carl Hanser: Munich, Germany, 1989; ISBN 978-3446143395. [Google Scholar]

- White, J.L. Rubber Processing; Hanser Publishers: Munich, Germany, 1995; ISBN 978-3446166004. [Google Scholar]

- White, J.L.; Potente, H. Screw Extrusion. Science and Technology; Hanser Publishers: Munich, Germany, 2003; ISBN 978-3-446-19624-7. [Google Scholar]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing, 2nd ed.; John Wiley & Sons Inc: New York, NY, USA, 2006; ISBN 978-0-471-38770-1. [Google Scholar]

- White, J.L.; Kim, E.K. Twin Screw Extrusion. Technology and Principles, 2nd ed.; Hanser Publishers: Munich, Germany, 2010; ISBN 978-1569904718. [Google Scholar]

- Rauwendaal, C. Polymer Extrusion, 5th ed.; Carl Hanser: Munich, Germany, 2014; ISBN 978-1-56990-516-6. [Google Scholar]

- Lafleur, P.G.; Vergnes, B. Polymer Extrusion; ISTE-Wiley: London, UK, 2014; ISBN 1848216505. [Google Scholar]

- Agassant, J.F.; Avenas, P.; Carreau, P.J.; Vergnes, B.; Vincent, M. Polymer Processing. Principles and Modeling, 2nd ed.; Carl Hanser: Munich, Germany, 2017; ISBN 978-1-56990-605-7. [Google Scholar]

- Chung, C.I. Extrusion of Polymers. Theory and Practice, 3rd ed.; Carl Hanser: Munich, Germany, 2020; ISBN 978-1-56990-609-5. [Google Scholar]

- Campbell, G.A.; Spalding, M.A. Analyzing and Troubleshooting Single-Screw Extruders; Carl Hanser: Munich, Germany, 2021; ISBN 978-1-56990-784-9. [Google Scholar]

- Vlachopoulos, J.; Polychronopoulos, N.D. Understanding Rheology and Technology of Polymer Extrusion; Polydynamic: Dundas, ON, Canada, 2019; ISBN 978-0-9952407-2-8. [Google Scholar]

- Ariffin, A.; Ahmad, M.S.B. Review: Single Screw Extruder in Particulate Filler Composite. Polym.-Plast. Technol. 2011, 50, 395–403. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J. Multipurpose Computer Model for Screw Processing of Plastics. Polym.-Plast. Technol. 2012, 51, 626–633. [Google Scholar] [CrossRef]

- Teixeira, C.; Gaspar-Cunha, A.; Covas, J.A. Flow and Heat Transfer Along the Length of a Co-rotating Twin Screw Extruder. Polym.-Plast. Technol. 2012, 51, 1567–1577. [Google Scholar] [CrossRef]

- Malik, M.; Kalyon, D.M.; Golba, J.C., Jr. Simulation of Co-Rotating Twin Screw Extrusion Process Subject to Pressure-Dependent Wall Slip at Barrel and Screw Surfaces: 3D FEM Analysis for Combinations of Forward- and Reverse-Conveying Screw Elements. Int. Polym. Proc. 2014, 29, 51–62. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Fundamentals of Global Modeling for Polymer Extrusion. Polymers 2019, 11, 2106. [Google Scholar] [CrossRef] [Green Version]

- Hyvärinen, M.; Jabeen, R.; Kärki, T. The Modeling of Extrusion Processes for Polymers—A Review. Polymers 2020, 12, 1306. [Google Scholar] [CrossRef]

- Lewandowski, A.; Wilczyński, K. Modeling of Twin Screw Extrusion of Polymeric Materials. Polymers 2022, 14, 274. [Google Scholar] [CrossRef]

- Marschik, C.; Roland, W.; Osswald, T.A. Melt Conveying in Single-Screw Extruders: Modeling and Simulation. Polymers 2022, 14, 875. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Latorre, L.; McKelvey, J.M. Melting and Pressurization in Starve Feed Extrusion. Adv. Polym. Technol. 1984, 3, 355–364. [Google Scholar] [CrossRef]

- Isherwood, D.P.; Pieris, R.N.; Kassatly, J. The Effect of Metered Starve Feeding on the Performance of a Small Extruder. J. Eng. Ind. 1984, 106, 132–136. [Google Scholar] [CrossRef]

- Strand, S.R.; Spalding, M.A.; Hyun, S.K. Modeling of the Solids-Conveying Section of a Starve Fed Single Screw Plasticating Extruder. SPE ANTEC Tech. Pap. 1992, 38, 2537–2541. [Google Scholar]

- Thompson, M.R.; Donoian, G.; Christiano, J.P. Melting Mechanism of a Starved-Fed Single-Screw Extruder for Calcium Carbonate Filled Polyethylene. Polym. Eng. Sci. 2000, 40, 2014–2026. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Wilczyński, K.J. Melting Model for Starve Fed Single Screw Extrusion of Thermoplastics. Int. Polym. Proc. 2013, 28, 34–42. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A.; Lewandowski, A.; Wilczyński, K. A Composite Model for Starve Fed Single Screw Extrusion of Thermoplastics. Polym. Eng. Sci. 2014, 54, 2362–2374. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. Modeling for Starve Fed/Flood Fed Mixing Single-Screw Extruders. Int. Polym. Proc. 2016, 31, 82–91. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. A Global Model for Starve-Fed Nonconventional Single-Screw Extrusion of Thermoplastics. Adv. Polym. Technol. 2017, 36, 23–35. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Wilczyński, K. Experimental Study of Melting of Polymer Blends in a Starve Fed Single Screw Extruder. Polym. Eng. Sci. 2016, 56, 1349–1356. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A.; Wilczyński, K. A Computer Model for Starve-Fed Single-Screw Extrusion of Polymer Blends. Adv. Polym. Technol. 2018, 37, 2142–2151. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Buziak, K. A Computer Model of Starve Fed Single Screw Extrusion of Wood Plastic Composites. Polymers 2021, 13, 1252. [Google Scholar] [CrossRef] [PubMed]

- Wilczyński, K.J. Experimental and Theoretical Study on Screw Filling in Starve Fed Single Screw Extruders. Int. Polym. Proc. 2018, 33, 171–179. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. Solids Conveying and Melting in a Starve Fed Self-wiping Co-Rotating Twin Screw Extruder. Int. Polym. Proc. 1995, 10, 105–110. [Google Scholar] [CrossRef]

- Todd, D.B. Melting of Plastics in Kneading Blocks. SPE ANTEC Tech. Papers 1992, 39, 2528–2536. [Google Scholar] [CrossRef]

- Sakai, T. The Development of On-line Techniques and Novel Processing Systems for the Monitoring and Handling of the Evolution of Microstructure in Nonreactive and Reactive Polymer Systems. Adv. Polym. Technol. 1995, 14, 277–290. [Google Scholar] [CrossRef]

- Gogos, C.G.; Tadmor, Z.; Kim, M.H. Melting Phenomena and Mechanisms in Polymer Processing Equipment. Adv. Polym. Technol. 1998, 17, 285–305. [Google Scholar] [CrossRef]

- Qian, B.; Gogos, C.G. The Importance of Plastic Energy Dissipation (PED) to the Heating and Melting of Polymer Particulates in Intermeshing Co-Rotating Twin-Screw Extruders. Adv. Polym. Technol. 2000, 19, 287–299. [Google Scholar] [CrossRef]

- Qian, B.; Todd, D.B.; Gogos, C.G. Plastic Energy Dissipation and its Role on Heating/Melting of Single-Component Polymers and Multi-Component Polymer Blends. Adv. Polym. Technol. 2003, 22, 85–95. [Google Scholar] [CrossRef]

- Potente, H.; Melisch, U. Theoretical and Experimental Investigations of the Melting of Pellets in Co-Rotating Twin-Screw Extruders. Int. Polym. Proc. 1996, 11, 101–108. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. Melting Model for Modular Self Wiping Co-Rotating Twin Screw Extruders. Polym. Eng. Sci. 1998, 38, 727–740. [Google Scholar] [CrossRef]

- Vergnes, B.; Delacour, M.L.; Souveton, G.; Bouvier, J.M. A Study of Polymer Melting in a Co-Rotating Twin Screw Extruder. In Proceedings of the International Polymer Processing Society 15th Annual Meeting (PPS-15), Hertogenbosch, The Netherlands, 31 May–4 June 1999. [Google Scholar]

- Vergnes, B.; Souveton, G.; Delacour, M.L.; Ainser, A. Experimental and Theoretical Study of Polymer Melting in a Co-rotating Twin Screw Extruder. Int. Polym. Proc. 2001, 16, 351–362. [Google Scholar] [CrossRef]

- Zhu, L.; Narh, K.A.; Geng, X. Modeling of Particle-Dispersed Melting Mechanism and its Application in Corotating Twin-Screw Extrusion. J. Polym. Sci. B Polym. Phys. 2001, 39, 2461–2468. [Google Scholar] [CrossRef]

- Potente, H.; Ansalh, J.; Klarholz, B. Design of Tightly Intermeshing Co-Rotating Twin Screw Extruders. Int. Polym. Proc. 1994, 9, 11–25. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. A Composite Model for Solid Conveying, Melting, Pressure and Fill Factor Profiles in Modular Co-Rotating Twin Screw Extruders. Int. Polym. Proc. 1997, 12, 331–340. [Google Scholar] [CrossRef]

- Vergnes, B.; Valle, G.D.; Delamare, L. A Global Computer Software for Polymer Flows in Corotating Twin Screw Extruders. Polym. Eng. Sci. 1998, 38, 1781–1792. [Google Scholar] [CrossRef]

- Potente, H.; Bastian, M.; Flecke, J. Design of a Compounding Extruder by Means of the SIGMA Simulation Software. Adv. Polym. Technol. 1999, 18, 147–170. [Google Scholar] [CrossRef]

- White, J.L.; Kim, B.-J.; Bawiskar, S.; Keum, J.M. Development of a Global Computer Software for Modular Self-Wiping Corotating Twin Screw Extruders. Polym.-Plast. Technol. 2001, 40, 385–405. [Google Scholar] [CrossRef]

- White, J.L.; Keum, J.; Jung, H.; Ban, K.; Bumm, S. Corotating Twin-Screw Extrusion Reactive Extrusion-Devolatilization Model and Software. Polym.-Plast. Technol. 2006, 45, 539–548. [Google Scholar] [CrossRef]

- Teixeira, C.F. Designing Screws for Polymer Compounding in Twin-Screw Extruders. Ph.D. Thesis, University of Minho, Braga, Portugal, 2013. [Google Scholar]

- Janssen, L.P.B.M. Twin Screw Extrusion; Elsevier Scientific Pub. Co.: Amsterdam, The Netherlands, 1978; ISBN 978-0444416292. [Google Scholar]

- Lim, S.; White, J.L. Flow Mechanisms, Material Distributions and Phase Morphology Development in a Modular Intermeshing Counter-Rotating Twin Screw Extruder of Leistritz Design. Int. Polym. Proc. 1994, 9, 33–45. [Google Scholar] [CrossRef]

- Cho, J.W.; White, J.L. Melting and Blending in a Modular Co-Rotating/Counter-Rotating Twin Screw Extruder. Int. Polyrn Proc. 1996, 11, 21–28. [Google Scholar] [CrossRef]

- Wilczyński, K.; White, J.L. Experimental Study of Melting in an Intermeshing Counter-Rotating Twin Screw Extruder. Int. Polym. Proc. 2001, 16, 257–262. [Google Scholar] [CrossRef]

- Wilczyński, K.; White, J.L. Melting Model for Intermeshing Counter-Rotating Twin-Screw Extruders. Polym. Eng. Sci. 2003, 43, 1715–1726. [Google Scholar] [CrossRef]

- Wang, D.; Min, K. In-Line Monitoring and Analysis of Polymer Melting Behavior in an Intermeshing Counter-Rotating Twin-Screw Extruder by Ultrasound Waves. Polym. Eng. Sci. 2005, 45, 998–1010. [Google Scholar] [CrossRef]

- Wang, D.; Min, K. Experiments and Analysis of Effect of Calender Gaps on Melting of PVC Powders in an Intermeshing Counter-Rotating Twin-Screw Extruder. Int. Polym. Proc. 2006, 21, 17–23. [Google Scholar] [CrossRef]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental Study of Melting of LDPE/PS Polyblend in an Intermeshing Counter-Rotating Twin Screw Extruder. Polym. Eng. Sci. 2012, 52, 449–458. [Google Scholar] [CrossRef]

- Wilczynski, K.; Jiang, Q.; White, J.L. A Composite Model for Melting, Pressure and Fill Factor Profiles in a Metered Fed Closely Intermeshing Counter-Rotating Twin Screw Extruder. Int. Polym. Proc. 2007, 22, 198–203. [Google Scholar] [CrossRef]

- Wilczyński, K.; White, J.L. Modelowanie procesu wytłaczania dwuślimakowego (Modeling of Twin Screw Extrusion). Polimery 2008, 53, 754–759. [Google Scholar]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J. Modelowanie przepływu tworzyw w procesie wytłaczania dwuślimakowego przeciwbieżnego. Badania symulacyjne i doświadczalne—weryfikacja modelu (Modeling of the Polymer Melt Flow in a Twin-Screw Counter Rotating Extrusion Process. Simulation and Experimental Studies—Verification of the Adopted Mode). Polimery 2011, 56, 45–50. [Google Scholar] [CrossRef]

- Lewandowski, A.; Wilczyński, K.J.; Nastaj, A.; Wilczyński, K. A Composite Model for an Intermeshing Counter-Rotating Twin-Screw Extruder and its Experimental Verification. Polym. Eng. Sci. 2015, 55, 2838–2848. [Google Scholar] [CrossRef]

- Manzione, L.T. (Ed.) Applications of Computer Aided Engineering in Injection Molding; Carl Hanser: Munich, Germany, 1992; ISBN 978-0-195-20752-1. [Google Scholar]

- Kennedy, P.; Zheng, R. Flow Analysis of Injection Molds; Carl Hanser: Munich, Germany, 1992; ISBN 978-1-569-90512-8. [Google Scholar]

- Kamal, M.R.; Isayev, A.I.; Liu, S.J. Injection Molding. Technology and Fundamentals; Carl Hanser: Munich, Germany, 2009; ISBN 978-3-446-41685-7. [Google Scholar]

- Osswald, T.; Turng, L.S.; Gramman, P. Injection Molding Handbook; Carl Hanser: Munich, Germany, 2009; ISBN 978-3-446-40781-7. [Google Scholar]

- Wang, M.; Chang, R.; Hsu, C. Molding Simulation. Theory and Practice; Carl Hanser: Munich, Germany, 2018; ISBN 978-1-569-90619-4. [Google Scholar]

- Menges, G.; Michaeli, W.; Mohren, P. How to Make Injection Molds, 3rd ed.; Carl Hanser: Munich, Germany, 2001; ISBN 978-1-569-90282-0. [Google Scholar]

- Rees, H. Mold Engineering, 2nd ed.; Carl Hanser: Munich, Germany, 2002; ISBN 978-1-569-90322-3. [Google Scholar]

- Unger, P. Gastrow Injection Molds, 4th ed.; Carl Hanser: Munich, Germany, 2006; ISBN 978-1-569-90402-2. [Google Scholar]

- Mennig, G.; Stoeckhert, K. Mold-Making Handbook, 3rd ed.; Carl Hanser: Munich, Germany, 2006; ISBN 978-1-569-90446-6. [Google Scholar]

- Kazmer, D. Injection Mold Design Engineering, 2nd ed.; Carl Hanser: Munich, Germany, 2016; ISBN 978-1-569-90570-8. [Google Scholar]

- Turng, L.; Chen, S. Advanced Injection Molding Technologies; Carl Hanser: Munich, Germany, 2019; ISBN 978-1-569-90603-3. [Google Scholar]

- Beaumont, J. Runner and Gating Design Handbook, 3rd ed.; Carl Hanser: Munich, Germany, 2020; ISBN 978-1-569-90590-6. [Google Scholar]

- Catoen, B.; Rees, H. Injection Mold Design Handbook; Carl Hanser: Munich, Germany, 2021; ISBN 978-1-569-90815-0. [Google Scholar]

- Johannaber, F. Injection Molding Machines, 4th ed.; Carl Hanser: Munich, Germany, 2007; ISBN 978-1-569-90418-3. [Google Scholar]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Modeling and Optimization of the Injection-Molding Process: A Review. Adv. Polym. Technol. 2016, 37, 429–449. [Google Scholar] [CrossRef]

- MOLDFLOW Plastic Injection and Compression Mold Simulation. Available online: www.autodesk.com/products/moldflow (accessed on 7 March 2021).

- Wilczyński, K.; Narowski, P. Simulation Studies on the Effect of Material Characteristics and Runners Layout Geometry on the Filling Imbalance in Geometrically Balanced Injection Molds. Polymers 2019, 11, 639. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moldex3D Plastic Injection Molding Simulation Software. Available online: www.moldex3d.com (accessed on 7 March 2021).

- Wilczyński, K.; Narowski, P. A Strategy for Problem Solving of Filling Imbalance in Geometrically Balanced Injection Molds. Polymers 2020, 12, 805. [Google Scholar] [CrossRef] [Green Version]

- CADMOULD Plastic Injection Molding Simulation. Available online: www.simcon.com/cadmould (accessed on 7 March 2021).

- COMSOL Multiphysics Simulation Software. Available online: www.comsol.com/comsol-multiphysics (accessed on 9 May 2022).

- Sullivan, A.; Saigal, A.; Zimmerman, M.A. Practical Simulation and Experimental Measurement of Liquid Crystal Polymer Directionality during Injection Molding. Polym. Eng. Sci. 2019, 59, E414–E424. [Google Scholar] [CrossRef]

- Donovan, R.C.; Thomas, D.E.; Leversen, L.D. An Experimental Study of Plasticating in a Reciprocating-Screw Injection Molding Machine. Polym. Eng. Sci. 1971, 11, 353–360. [Google Scholar] [CrossRef]

- Gao, F.; Jin, Z.; Chen, X. A Visual Barrel System for Study of Reciprocating Screw Injection Molding. Polym. Eng. Sci. 2000, 40, 1334–1343. [Google Scholar] [CrossRef]

- Jin, Z.; Gao, F.; Zhu, F. An Experimental Study of Solid-Bed Break-up in Plasticization of a Reciprocating-Screw Injection Molding. Polym. Eng. Sci. 2004, 44, 1313–1318. [Google Scholar] [CrossRef]

- Pham, T.L.; Balcaen, J.; Charmeau, J.Y.; Bereaux, Y. In-Line Visualisation of Polymer Plastication in an Injection Molding Screw. Key Eng. Mater. 2013, 554, 1683–1691. [Google Scholar] [CrossRef]

- Donovan, R.C. A Theoretical Melting Model for a Reciprocating-Screw Injection Molding Machine. Polym. Eng. Sci. 1971, 11, 361–368. [Google Scholar] [CrossRef]

- Donovan, R.C. The Plasticating Process in Injection Molding. Polym. Eng. Sci. 1974, 14, 101–111. [Google Scholar] [CrossRef]

- Donovan, R.C. A Theoretical Melting Model for Plasticating Extruders. Polym. Eng. Sci. 1971, 11, 247–257. [Google Scholar] [CrossRef]

- Lipshitz, S.D.; Lavie, R.; Tadmor, Z. A Melting Model for Reciprocating Screw Injection-Molding Machines. Polym. Eng. Sci. 1974, 14, 553–559. [Google Scholar] [CrossRef]

- Rauwendaal, C. Melt Conveying in Reciprocating extruders. SPE-ANTEC Tech. Pap. 1991, 36, 433–435. [Google Scholar]

- Rauwendaal, C. Conveying and Melting in Screw Extruders with Axial Movement. Int. Polym. Process. 1992, 7, 26–31. [Google Scholar] [CrossRef]

- Dormeier, S.; Panreck, K. Dynamic behavior of temperature during extrusion. Kunststoffe 1990, 11, 32–33. [Google Scholar]

- Rao, N.S.; Schumacher, G.; Schott, N.R.; Edwards, R. Calculations of Melting Performance of Injection Molding Screws by an Easily Applicable Model. SPE-ANTEC Tech. Pap. 2001, 46, 5. [Google Scholar]

- Potente, H.; Schulte, H.; Effen, N. Simulation of Injection Molding and Comparison with Experimental Values. Int. Polym. Process. 1993, 8, 224–235. [Google Scholar] [CrossRef]

- Potente, H.; Bornemann, M. Non-isothermal Model for the Drive Power Calculation of Single-Screw Plasticating Units. Int. Polym. Process. 2008, 23, 345–350. [Google Scholar] [CrossRef]

- Bereaux, Y.; Charmeau, J.-Y.; Moguedet, M. A simple model of throughput and pressure development for single screw. J. Mater. Process. Technol. 2009, 209, 611–618. [Google Scholar] [CrossRef]

- Yung, K.L.; Yan, X. Analysis of a melting model for an extruder with reciprocation. J. Mater. Process. Technol. 2001, 117, 21–27. [Google Scholar] [CrossRef]

- Yung, K.L.; Yan, X.; Lau, K.H. Simulation of transient process in melting section of reciprocating extruder. Polymer 2002, 3, 983–988. [Google Scholar] [CrossRef]

- Yung, K.L.; Yan, X. Transient melting models for the three stages of reciprocating extrusion. J. Mater. Process. Technol. 2003, 139, 170–177. [Google Scholar] [CrossRef]

- Steller, R.; Iwko, J. Polymer Plastication during Injection Molding. Part 1. Mathematical model. Int. Polym. Process. 2008, 23, 252–262. [Google Scholar] [CrossRef]

- Iwko, J.; Steller, R. Polymer Plastication during Injection Molding. Part 2. Simulations and Experiments. Int. Polym. Process. 2008, 23, 263–269. [Google Scholar] [CrossRef]

- Steller, R.; Iwko, J. Modeling of the process of polymers plasticization during injection molding. Part 1. Model assumptions and solid polymer transport. Polimery 2008, 53, 836–840. (In Polish) [Google Scholar] [CrossRef] [Green Version]

- Steller, R.; Iwko, J. Modeling of the process of polymers plasticization during injection molding. Part 2. The melting zone. Polimery 2011, 56, 51–57. (In Polish) [Google Scholar] [CrossRef]

- Iwko, J.; Steller, R.; Wróblewski, R.; Kaczmar, J. Experimental verification of computer model for polymer plastication process in injection molding. Polimery 2015, 60, 644–656. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Nóbrega, J.M.; Gaspar-Cunha, A. Modeling of Plasticating Injection Molding-Experimental Assessment. Int. Polym. Process. 2014, 29, 558–569. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A. Modeling and Optimization of Single Screw Extrusion. Ph.D. Thesis, University of Minho, Braga, Portugal, 2000. [Google Scholar]

- Iwko, J.; Steller, R.; Wróblewski, R. Experimentally Verified Mathematical Model of Polymer Plasticization Process in Injection Molding. Polymers 2018, 10, 968. [Google Scholar] [CrossRef] [Green Version]

- Klein, I.; Klein, R.J. The SPR System of CAE Software. In Computer Modeling for Extrusion and Other Continuous Polymer Processes; O’Brien, K.T., Ed.; Hanser Publishers: New York, NY, USA, 1992; Chapter 5; pp. 103–252. ISBN 978-1569900680. [Google Scholar]

- Agur, E.E.; Vlachopoulos, J. Numerical Simulation of a Single-Screw Plasticating Extruder. Polym. Eng. Sci. 1982, 22, 1084–1094. [Google Scholar] [CrossRef]

- Potente, H.; Hanhart, W.; Schöppner, V. Potential Applications for Computer-aided Extruder Design. Int. Polym. Proc. 1993, 8, 335–344. [Google Scholar] [CrossRef]

- Potente, H.; Hanhart, W.; Reski, T. Design and Processing Optimization of Extruder Screws. Polym. Eng. Sci. 1994, 34, 937–945. [Google Scholar] [CrossRef]

- Sebastian, D.H.; Rakos, R. Extrusion Process Analysis with PASS. In Computer Modeling for Extrusion and Other Continuous Polymer Processes; O’Brien, K.T., Ed.; Hanser Publishers: New York, NY, USA, 1992; Chapter 7; pp. 331–448. ISBN 978-1569900680. [Google Scholar]

- Wilczyński, K. A Computer Model for Single-Screw Plasticating Extrusion. Polym.-Plast. Technol. 1996, 35, 449–477. [Google Scholar] [CrossRef]

- Wilczyński, K. Single Screw Extrusion Model for Plasticating Extruders. Polym.-Plast. Technol. 1999, 38, 581–608. [Google Scholar] [CrossRef]

- Wilczyński, K.; Buziak, K.; Wilczyński, K.J.; Lewandowski, A.; Nastaj, A. Computer Modeling for Single-Screw Extrusion of Wood-Plastic Composites. Polymers 2018, 10, 295. [Google Scholar] [CrossRef] [Green Version]

- Fukase, H.; Kunio, T.; Shinya, S.; Nomura, A. A Plasticating Model for Single-Screw Extruders. Polym. Eng. Sci. 1982, 22, 578–586. [Google Scholar] [CrossRef]

- Zawadsky, E.; Karnis, J. Mathematical Model of a Single-Screw Plasticating Extruder. J. Rheol. Acta 1985, 24, 556–565. [Google Scholar] [CrossRef]

- Vincelette, A.R.; Guerrero, C.S.; Carreau, P.J.; Lafleur, P.G. A Model for Single-Screw Plasticating Extruders. Int. Polym. Proc. 1989, 4, 232–241. [Google Scholar] [CrossRef]

- Amellal, K.; Lafleur, P.G. Computer Simulation of Conventional and Barrier Screw Extruders. Plast. Rub. Compos. Pro. 1993, 19, 227–239. [Google Scholar]

- PSI—Paderborner Spritzgießsimulation. Available online: www.ktp.uni-paderborn.de/en/foerderverein/software/psi (accessed on 7 March 2021).

- Kontopoulou, M.; Vlachopoulos, J. Melting and Densification of Thermoplastic Powders. Polym. Eng. Sci. 2001, 41, 62–73. [Google Scholar] [CrossRef]

- Demirci, A.; Teke, I.; Goger, A.; Canbaz, E.; Vlachopoulos, J. Gelation of Poly (vinyl chloride) Inside a Single Screw Extruder and its Effect on Product Properties. J. Vinyl. Addit. Technol. 2019, 25, E174–E180. [Google Scholar] [CrossRef] [Green Version]

- Fang, S.; Chen, L.; Zhu, F. Studies on the Theory of Single Screw Plasticating Extrusion. Part II: Non-Plug Flow Solid Conveying. Polym. Eng. Sci. 1991, 31, 1117–1122. [Google Scholar] [CrossRef]

- Pohl, T.C.; Potente, H. Simulation and Analyses of the Polymer-Pellet-Flow into the First Section of a Single Screw. SPE ANTEC Tech. Pap. 2001, 46, 185–189. [Google Scholar]

- Moysey, P.A.; Thompson, M.R. Investigation of Solids Transport in a Single-Screw Extruder Using a 3-D Discrete Particle Simulation. Polym. Eng. Sci. 2004, 44, 2203–2215. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Modelling the Solids Inflow and Solids Conveying of Single-Screw Extruders Using the Discrete Element Method. Powder Technol. 2005, 153, 95–107. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Determining the Collision Properties of Semi-Crystalline and Amorphous Thermoplastics for DEM Simulations of Solids Transport in an Extruder. Chem. Eng. Sci. 2007, 62, 3699–3709. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Discrete Particle Simulations of Solids Compaction and Conveying in a Single-Screw Extruder. Polym. Eng. Sci. 2008, 48, 62–73. [Google Scholar] [CrossRef]

- Leßmann, J.-S.; Weddige, R.; Schöppner, V.; Porsch, A. Modelling the Solids Throughput of Single Screw Smooth Barrel Extruders as a Function of the Feed Section Parameters. Int. Polym. Proc. 2012, 27, 469–477. [Google Scholar] [CrossRef]

- Trippe, J.; Schöppner, V. Modeling of Solid Conveying Pressure Throughput Behavior of Single Screw Smooth Barrel Extruders under Consideration of Backpressure and High Screw Speeds. Int. Polym. Process. 2018, 33, 486–496. [Google Scholar] [CrossRef]

- Altair EDEM Discrete Element Method (DEM) Software. Available online: www.altair.com/edem (accessed on 7 March 2022).

- Viriyayuthakorn, M.; Kassahun, B. A Three Dimensional Model for Plasticating Extrusion Screw Design. SPE ANTEC Tech. Pap. 1985, 33, 81–84. [Google Scholar]

- Syrjala, S. A New Approach for the Simulation of Melting in Extruders. Int. Commun. Heat Mass 2000, 27, 623–634. [Google Scholar] [CrossRef]

- Altinkaynak, A.; Gupta, M.; Spalding, M.A.; Crabtree, S.L. Melting in a Single Screw Extruder: Experiments and 3D Finite Element Simulations. Int. Polym. Proc. 2011, 26, 182–196. [Google Scholar] [CrossRef]

- Hopmann, C.; Kremer, C.; Grammel, S. Predicting the Melting Behavior within a Single Screw Extruder Using 3D FVM simulation. In Proceedings of the Polymer Processing Society 28th Annual Meeting (PPS-28), Pattaya, Thailand, 11–15 December 2012. [Google Scholar]

- Kazmer, D.O.; Grosskopf, C.M.; Venoor, V. Vortical Fountain Flows in Plasticating Screws. Polymers 2018, 10, 823. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lewandowski, A.; Wilczyński, K. General Model of Polymer Melting in Extrusion Process. Polimery 2018, 63, 444–452. [Google Scholar] [CrossRef]

- Ansys Polyflow Polymer Processing Simulation Software. Available online: www.ansys.com/products/fluids/ansys-polyflow (accessed on 7 March 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilczyński, K.; Wilczyński, K.J.; Buziak, K. Modeling and Experimental Studies on Polymer Melting and Flow in Injection Molding. Polymers 2022, 14, 2106. https://doi.org/10.3390/polym14102106

Wilczyński K, Wilczyński KJ, Buziak K. Modeling and Experimental Studies on Polymer Melting and Flow in Injection Molding. Polymers. 2022; 14(10):2106. https://doi.org/10.3390/polym14102106

Chicago/Turabian StyleWilczyński, Krzysztof, Krzysztof J. Wilczyński, and Kamila Buziak. 2022. "Modeling and Experimental Studies on Polymer Melting and Flow in Injection Molding" Polymers 14, no. 10: 2106. https://doi.org/10.3390/polym14102106

APA StyleWilczyński, K., Wilczyński, K. J., & Buziak, K. (2022). Modeling and Experimental Studies on Polymer Melting and Flow in Injection Molding. Polymers, 14(10), 2106. https://doi.org/10.3390/polym14102106