Modified Polymeric Biosorbents from Rumex acetosella for the Removal of Heavy Metals in Wastewater

Abstract

:1. Introduction

2. Materials and Methods

2.1. Vegetal Material

2.2. Proximate Analysis of Vegetal Material

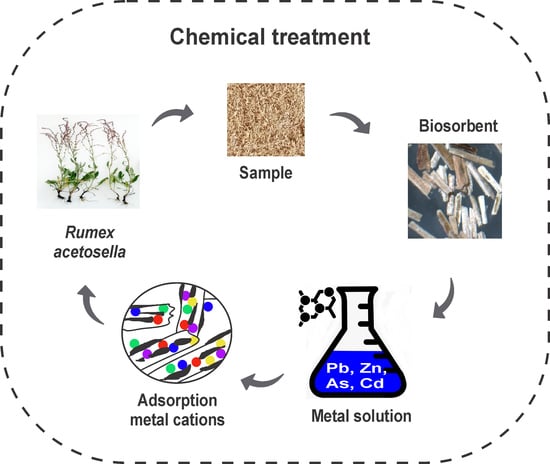

2.3. Getting Modified Biomass

2.4. Point of Zero Charge

2.5. Total Organic Carbon

2.6. Heavy Metal Biosorption

2.7. pH Influence

2.8. Adsorption Isotherms

2.9. Adsorption Kinetics

2.10. FTIR Analysis

2.11. Thermal Analysis

2.12. Morphological Analysis

2.13. Statistical Analysis

3. Results and Discussion

3.1. Characterizations of Bioadsorbents

3.1.1. Proximate Analysis of Vegetal Material

3.1.2. Point of Zero Charge

3.1.3. Total Organic Carbon

3.2. Application of Bioadsorbents

3.2.1. Heavy Metal Biosorption

3.2.2. pH Influence

3.2.3. Adsorption Isotherms

3.2.4. Adsorption Kinetics

3.3. Characterization before and after Adsorption

3.3.1. FTIR Analysis

3.3.2. Thermal Analysis

3.3.3. Morphological Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alawady, A.R.; Alshahrani, A.A.; Aouak, T.A.; Alandis, N.M. Polysulfone membranes with CNTs/Chitosan biopolymer nanocomposite as selective layer for remarkable heavy metal ions rejection capacity. Chem. Eng. J. 2020, 388, 124267. [Google Scholar] [CrossRef]

- Hoang, A.T.; Nižetić, S.; Cheng, C.K.; Luque, R.; Thomas, S.; Banh, T.L.; Nguyen, X.P. Heavy metal removal by biomass-derived carbon nanotubes as a greener environmental remediation: A comprehensive review. Chemosphere 2022, 287, 131959. [Google Scholar] [CrossRef] [PubMed]

- Qin, H.; Hu, T.; Zhai, Y.; Lu, N.; Aliyeva, J. The improved methods of heavy metals removal by biosorbents: A review. Environ. Pollut. 2020, 258, 113777. [Google Scholar] [CrossRef] [PubMed]

- Naseer, A.; Jamshaid, A.; Hamid, A.; Muhammad, N.; Ghauri, M.; Iqbal, J.; Rafiq, S.; Shah, N.S. Lignin and lignin based materials for the removal of heavy metals from waste water-an overview. Z. Phys. Chem. 2019, 233, 315–345. [Google Scholar] [CrossRef]

- Zamora-Ledezma, C.; Negrete-Bolagay, D.; Figueroa, F.; Zamora-Ledezma, E.; Ni, M.; Alexis, F.; Guerrero, V.H. Heavy metal water pollution: A fresh look about hazards, novel and conventional remediation methods. Environ. Technol. Innov. 2021, 22, 101504. [Google Scholar] [CrossRef]

- Jia, J.; Liu, C.; Wang, L.; Liang, X.; Chai, X. Double functional polymer brush-grafted cotton fiber for the fast visual detection and efficient adsorption of cadmium ions. Chem. Eng. J. 2018, 347, 631–639. [Google Scholar] [CrossRef]

- Asere, T.G.; Stevens, C.V.; Du Laing, G. Use of (modified) natural adsorbents for arsenic remediation: A review. Sci. Total Environ. 2019, 676, 706–720. [Google Scholar] [CrossRef]

- Bilal, M.; Ihsanullah, I.; Younas, M.; Shah, M.U.H. Recent advances in applications of low-cost adsorbents for the removal of heavy metals from water: A critical review. Sep. Purif. Technol. 2021, 278, 119510. [Google Scholar] [CrossRef]

- Vishan, I.; Saha, B.; Sivaprakasam, S.; Kalamdhad, A. Evaluation of Cd (II) biosorption in aqueous solution by using lyophilized biomass of novel bacterial strain Bacillus badius AK: Biosorption kinetics, thermodynamics and mechanism. Environ. Technol. Innov. 2019, 14, 100323. [Google Scholar] [CrossRef]

- Moreira, V.; Lebron, Y.; Lange, L.; Santos, L. Simultaneous biosorption of Cd (II), Ni (II) and Pb (II) onto a brown macroalgae Fucus vesiculosus: Mono-and multi-component isotherms, kinetics and thermodynamics. J. Environ. Manag. 2019, 251, 109587. [Google Scholar] [CrossRef]

- Modenes, A.N.; de Abreu Pietrobelli, J.M.T.; dos Santos, G.H.F.; Borba, C.E.; Ravagnani, M.A.d.S.S.; Espinoza-Quinones, F.R. Multi-component mathematical model based on mass transfer coefficients for prediction of the Zn and Cd ions biosorption data by E. densa in a continuous system. J. Environ. Chem. Eng. 2018, 6, 5141–5149. [Google Scholar] [CrossRef]

- Morales, B.L.; Cristiani, U.E. Equilibrium Biosorption of Zn2+ and Ni2+ Ions from Monometallic and Bimetallic Solutions by Crab Shell Biomass. Processes 2022, 10, 886. [Google Scholar] [CrossRef]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: A review. Sustain. Mater. Technol. 2016, 9, 10–40. [Google Scholar] [CrossRef] [Green Version]

- Gupta, V.; Pathania, D.; Agarwal, S.; Sharma, S. Removal of Cr (VI) onto Ficus carica biosorbent from water. Environ. Sci. Pollut. Res. 2013, 20, 2632–2644. [Google Scholar] [CrossRef] [PubMed]

- Kołodyńska, D.; Krukowska, J.; Thomas, P. Comparison of sorption and desorption studies of heavy metal ions from biochar and commercial active carbon. Chem. Eng. J. 2017, 307, 353–363. [Google Scholar] [CrossRef]

- Kwikima, M.M.; Mateso, S.; Chebude, Y. Potentials of Agricultural wastes as the ultimate alternative adsorbent for Cadmium removal from wastewater. A review. Sci. Afr. 2021, 13, e00934. [Google Scholar] [CrossRef]

- Okoli, C.P.; Diagboya, P.N.; Anigbogu, I.O.; Olu-Owolabi, B.I.; Adebowale, K.O. Competitive biosorption of Pb (II) and Cd (II) ions from aqueous solutions using chemically modified moss biomass (Barbula lambarenensis). Environ. Earth Sci. 2017, 76, 33. [Google Scholar] [CrossRef]

- Znad, H.; Awual, M.R.; Martini, S. The Utilization of Algae and Seaweed Biomass for Bioremediation of Heavy Metal-Contaminated Wastewater. Molecules 2022, 27, 1275. [Google Scholar] [CrossRef]

- Ngo, H.H.; Guo, W.; Zhang, J.; Liang, S.; Ton-That, C.; Zhang, X. Typical low cost biosorbents for adsorptive removal of specific organic pollutants from water. Bioresour. Technol. 2015, 182, 353–363. [Google Scholar] [CrossRef]

- Okoro, H.K.; Pandey, S.; Ogunkunle, C.O.; Ngila, C.J.; Zvinowanda, C.; Jimoh, I.; Lawal, I.A.; Orosun, M.M.; Adeniyi, A.G. Nanomaterial-based biosorbents: Adsorbent for efficient removal of selected organic pollutants from industrial wastewater. Emerg. Contam. 2022, 8, 46–58. [Google Scholar] [CrossRef]

- Vítězová, M.; Jančiková, S.; Dordević, D.; Vítěz, T.; Elbl, J.; Hanišáková, N.; Jampílek, J.; Kushkevych, I. The possibility of using spent coffee grounds to improve wastewater treatment due to respiration activity of microorganisms. Appl. Sci. 2019, 9, 3155. [Google Scholar] [CrossRef] [Green Version]

- Pan, Z.; Sheng, J.; Qiu, C.; Wei, H.; Yang, Q.; Pan, J.; Li, J. A Magic Filter Filled with Waste Plastic Shavings, Loofah, and Iron Shavings for Wastewater Treatment. Polymers 2022, 14, 1410. [Google Scholar] [CrossRef]

- Zuorro, A.; Maffei, G.; Lavecchia, R. Kinetic modeling of azo dye adsorption on non-living cells of Nannochloropsis oceanica. J. Environ. Chem. Eng. 2017, 5, 4121–4127. [Google Scholar] [CrossRef]

- Baiocco, D.; Lavecchia, R.; Natali, S.; Zuorro, A. Production of metal nanoparticles by agro-industrial wastes: A green opportunity for nanotechnology. Chem. Eng. Trans. 2016, 47, 67–72. [Google Scholar] [CrossRef]

- Choque, Q.D.; Ligarda, S.C.A.; Ramos, P.B.S.; Solano, R.A.M.; Choque, Q.Y.; Peralta, G.D.E.; Quispe, Q.Y. Optimization of the flocculating capacity of natural coagulants in water treatment. Dyna 2020, 87, 90–95. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Beckerman, J. Application of sustainable biosorbents from hemp for remediation copper (II)-containing wastewater. J. Environ. Chem. Eng. 2022, 10, 107494. [Google Scholar] [CrossRef]

- Mohapatra, R.K.; Parhi, P.K.; Pandey, S.; Bindhani, B.K.; Thatoi, H.; Panda, C.R. Active and passive biosorption of Pb (II) using live and dead biomass of marine bacterium Bacillus xiamenensis PbRPSD202: Kinetics and isotherm studies. J. Environ. Manag. 2019, 247, 121–134. [Google Scholar] [CrossRef]

- Naik, B.R.; Suresh, C.; Kumar, N.S.; Seshaiah, K.; Reddy, A. Biosorption of Pb (II) and Ni (II) ions by chemically modified Eclipta alba stem powder: Kinetics and equilibrium studies. Sep. Sci. Technol. 2017, 52, 1717–1732. [Google Scholar] [CrossRef]

- Franzese, J.; Ghermandi, L. Early competition between the exotic herb Rumex acetosella and two native tussock grasses with different palatability and water stress tolerance. J. Arid Environ. 2014, 106, 58–62. [Google Scholar] [CrossRef]

- Agarwal, A.; Upadhyay, U.; Sreedhar, I.; Singh, S.A.; Patel, C.M. A review on valorization of biomass in heavy metal removal from wastewater. J. Water Process Eng. 2020, 38, 101602. [Google Scholar] [CrossRef]

- Syeda, H.I.; Sultan, I.; Razavi, K.S.; Yap, P.-S. Biosorption of heavy metals from aqueous solution by various chemically modified agricultural wastes: A review. J. Water Process Eng. 2022, 46, 102446. [Google Scholar] [CrossRef]

- Horwitz, W. Official Methods of Analysis of AOAC International. In Volume I, Agricultural Chemicals, Contaminants, Drugs; AOAC International: Gaithersburg, MD, USA, 2010. [Google Scholar]

- Robles, J.; Regalbuto, J. The Engineering of Pt/Carbon Catalyst Preparation: For Application on Proton Exchange Fuel Cell Membrane (PEFCM); Progress Report REU, University of Illinois: Chicago, IL, USA, 2004; Available online: http://amrel.bioe.uic.edu/NSFREU2004/Reports2004/Jaime%20Robles_Final%20Report.pdf (accessed on 1 May 2022).

- Adegoke, K.A.; Adesina, O.O.; Okon-Akan, O.A.; Adegoke, O.R.; Olabintan, A.B.; Ajala, O.A.; Olagoke, H.; Maxakato, N.W.; Bello, O.S. Sawdust-biomass based materials for sequestration of organic/inorganic pollutants and potential for engineering applications. Curr. Res. Green Sustain. Chem. 2022, 5, 100274. [Google Scholar] [CrossRef]

- Ahamed, M.I.; Lichtfouse, E. Water Pollution and Remediation: Heavy Metals; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Bortoluz, J.; Cemin, A.; Bonetto, L.R.; Ferrarini, F.; Esteves, V.I.; Giovanela, M. Isolation, characterization and valorization of lignin from Pinus elliottii sawdust as a low-cost biosorbent for zinc removal. Cellulose 2019, 26, 4895–4908. [Google Scholar] [CrossRef]

- Malik, D.; Jain, C.; Yadav, A.K. Removal of heavy metals from emerging cellulosic low-cost adsorbents: A review. Appl. Water Sci. 2017, 7, 2113–2136. [Google Scholar] [CrossRef] [Green Version]

- Peng, X.; Wu, Z.; Li, Z. A bowl-shaped biosorbent derived from sugarcane bagasse lignin for cadmium ion adsorption. Cellulose 2020, 27, 8757–8768. [Google Scholar] [CrossRef]

- Amar, M.B.; Walha, K.; Salvadó, V. Evaluation of olive stones for Cd (II), Cu (II), Pb (II) and Cr (VI) biosorption from aqueous solution: Equilibrium and kinetics. Int. J. Environ. Res. 2020, 14, 193–204. [Google Scholar] [CrossRef]

- Appel, C.; Ma, L.Q.; Rhue, R.D.; Kennelley, E. Point of zero charge determination in soils and minerals via traditional methods and detection of electroacoustic mobility. Geoderma 2003, 113, 77–93. [Google Scholar] [CrossRef] [Green Version]

- Schwantes, D.; Gonçalves, A.C., Jr.; Schiller, A.d.P.; Manfrin, J.; Bianco, L.A.V.; Rosenberger, A.G. Eco-friendly, renewable Crambe abyssinica Hochst-based adsorbents remove high quantities of Zn2+ in water. J. Environ. Health Sci. Eng. 2020, 18, 809–823. [Google Scholar] [CrossRef]

- Schwantes, D.; Junior, A.C.G.; Perina, H.A.; Tarley, C.R.T.; Dragunski, D.C.; Junior, E.C.; Zimmermann, J. Ecofriendly Biosorbents Produced from Cassava Solid Wastes: Sustainable Technology for the Removal of Cd2+, Pb2+, and Crtotal. Adsorpt. Sci. Technol. 2022, 2022, 5935712. [Google Scholar] [CrossRef]

- Suteu, D.; Blaga, A.C.; Cimpoesu, R.; Puiţel, A.C.; Tataru-Farmus, R.-E. Composites Based on Natural Polymers and Microbial Biomass for Biosorption of Brilliant Red HE-3B Reactive Dye from Aqueous Solutions. Polymers 2021, 13, 4314. [Google Scholar] [CrossRef]

- Suteu, D.; Blaga, A.C.; Zaharia, C.; Cimpoesu, R.; Puițel, A.C.; Tataru-Farmus, R.-E.; Tanasă, A.M. Polysaccharides Used in Biosorbents Preparation for Organic Dyes Retaining from Aqueous Media. Polymers 2022, 14, 588. [Google Scholar] [CrossRef]

- Bellmann, C.; Caspari, A.; Albrecht, V.; Doan, T.L.; Mäder, E.; Luxbacher, T.; Kohl, R. Electrokinetic properties of natural fibres. Colloids Surf. A Physicochem. Eng. Asp. 2005, 267, 19–23. [Google Scholar] [CrossRef]

- Luxbacher, T. Electrokinetic properties of natural fibres. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 323–353. [Google Scholar]

- Choque, Q.D.; Ramos, P.B.S.; Ligarda, S.C.A.; Barboza, P.G.I.; Kari, F.A.; Taipe, P.F.; Choque, Q.Y. Heavy metal removal by biopolymers-based formulations with native potato starch/nopal mucilage. Rev. Fac. Ing. Univ. Antioq. 2022, 103, 44–50. [Google Scholar] [CrossRef]

- Mohd, S.R.; Khan, C.A.J.; Rayathulhan, R.; Yunus, K.; Sarkar, M.Z.I. Biosorption of Pb and Cu from aqueous solution using banana peel powder. Desalin. Water Treat. 2016, 57, 303–314. [Google Scholar] [CrossRef]

- Saravanan, A.; Kumar, P.S.; Yaashikaa, P.; Karishma, S.; Jeevanantham, S.; Swetha, S. Mixed biosorbent of agro waste and bacterial biomass for the separation of Pb (II) ions from water system. Chemosphere 2021, 277, 130236. [Google Scholar] [CrossRef]

- El-Wakeel, S.T.; Moghazy, R.; Labena, A.; Husien, S. Algal biosorbent as a basic tool for heavy metals removal; the first step for further applications. J. Mater. Environ. Sci 2019, 10, 75–87. [Google Scholar]

- Sia, G.B.; Vernasqui, L.G.; Consolin-Filho, N.; Gonçalves, M.S.; Medeiros, F.V.d.S. Zinc adsorption from aqueous solution on biosorbent from urban pruning waste. Environ. Technol. 2022, 43, 728–736. [Google Scholar] [CrossRef]

- Thaharah Ramadhani, F.A.; Indra, I.; Muslim, A.; Suhendrayatna, S.; Meilina, H.; Saiful, S. Adsorption of Cd (II) Ions From Aqueous Solution By A Low-Cost Biosorbent Prepared From Ipomea Pes-Caprae Stem. Aceh Int. J. Sci. Technol. 2020, 9, 197–206. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, T.-T.; Rao, Q.-Q.; Shui, S.-W.; Li, W.-W.; He, H.-B.; Yao, R.-S. Fabrication of mesoporous lignin-based biosorbent from rice straw and its application for heavy-metal-ion removal. J. Environ. Sci. 2017, 53, 132–140. [Google Scholar] [CrossRef] [Green Version]

- Choccata, D.Y.C. Evaluation of lead (II) biosorption capacity using inert plant biomass (rose stems) as adsorbent. Adv. Mech. 2021, 9, 868–907. Available online: https://www.advancesinmechanics.com/view-215.php (accessed on 2 May 2022).

- Tofan, L. Polymeric Biomass Derived Adsorbents for Co (II) Remediation, Recycling and Analysis. Polymers 2022, 14, 1647. [Google Scholar] [CrossRef]

- Nuithitikul, K.; Phromrak, R.; Saengngoen, W. Utilization of chemically treated cashew-nut shell as potential adsorbent for removal of Pb (II) ions from aqueous solution. Sci. Rep. 2020, 10, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Schwantes, D.; Gonçalves, A.C.; Coelho, G.F.; Campagnolo, M.A.; Dragunski, D.C.; Tarley, C.R.T.; Miola, A.J.; Leismann, E.A.V. Chemical modifications of cassava peel as adsorbent material for metals ions from wastewater. J. Chem. 2016, 2016, 3694174. [Google Scholar] [CrossRef]

- Schwantes, D.; Goncalves, A.C., Jr.; Campagnolo, M.A.; Tarley, C.R.T.; Dragunski, D.C.; de Varennes, A.; dos Santos Silva, A.K.; Junior, E.C. Chemical modifications on pinus bark for adsorption of toxic metals. J. Environ. Chem. Eng. 2018, 6, 1271–1278. [Google Scholar] [CrossRef]

- Coelho, G.F.; Gonçalves, A.C.; Schwantes, D.; Rodríguez, E.Á.; Tarley, C.R.T.; Dragunski, D.; Conradi Junior, É. Removal of Cd (II), Pb (II) and Cr (III) from water using modified residues of Anacardium occidentale L. Appl. Water Sci. 2018, 8, 96. [Google Scholar] [CrossRef] [Green Version]

- Villabona-Ortíz, Á.; Figueroa-Lopez, K.J.; Ortega-Toro, R. Kinetics and Adsorption Equilibrium in the Removal of Azo-Anionic Dyes by Modified Cellulose. Sustainability 2022, 14, 3640. [Google Scholar] [CrossRef]

- Gümüş, D.; Gümüş, F. The use of a wetland plant as a new biosorbent for treatment of water contaminated with heavy metals: Nonlinear analyses, modification, competitive effects. Environ. Technol. Innov. 2019, 16, 100483. [Google Scholar] [CrossRef]

- Kaur, S.; Rani, S.; Mahajan, R.; Asif, M.; Gupta, V.K. Synthesis and adsorption properties of mesoporous material for the removal of dye safranin: Kinetics, equilibrium, and thermodynamics. J. Ind. Eng. Chem. 2015, 22, 19–27. [Google Scholar] [CrossRef]

- Alorabi, A.Q.; Alharthi, F.A.; Azizi, M.; Al-Zaqri, N.; El-Marghany, A.; Abdelshafeek, K.A. Removal of lead (II) from synthetic wastewater by Lavandula pubescens decne biosorbent: Insight into composition–Adsorption relationship. Appl. Sci. 2020, 10, 7450. [Google Scholar] [CrossRef]

- Abdelfattah, I.; Ismail, A.A.; Al Sayed, F.; Almedolab, A.; Aboelghait, K. Biosorption of heavy metals ions in real industrial wastewater using peanut husk as efficient and cost effective adsorbent. Environ. Nanotechnol. Monit. Manag. 2016, 6, 176–183. [Google Scholar] [CrossRef]

- Baig, J.A.; Kazi, T.G.; Shah, A.Q.; Kandhro, G.A.; Afridi, H.I.; Khan, S.; Kolachi, N.F. Biosorption studies on powder of stem of Acacia nilotica: Removal of arsenic from surface water. J. Hazard. Mater. 2010, 178, 941–948. [Google Scholar] [CrossRef] [PubMed]

- Maity, S.; Nanda, S.; Sarkar, A. Colocasia esculenta stem as novel biosorbent for potentially toxic metals removal from aqueous system. Environ. Sci. Pollut. Res. 2021, 28, 58885–58901. [Google Scholar] [CrossRef] [PubMed]

- Jagung, P.T. Removal of Zn (II), Cd (II) and Mn (II) from aqueous solutions by adsorption on maize stalks. Malays. J. Anal. Sci. 2011, 15, 8–21. Available online: http://mjas.analis.com.my/wp-content/uploads/2018/11/El-Sayed.pdf (accessed on 3 May 2022).

- Yin, K.; Wang, J.; Zhai, S.; Xu, X.; Li, T.; Sun, S.; Xu, S.; Zhang, X.; Wang, C.; Hao, Y. Adsorption mechanisms for cadmium from aqueous solutions by oxidant-modified biochar derived from Platanus orientalis Linn leaves. J. Hazard. Mater. 2022, 428, 128261. [Google Scholar] [CrossRef]

- Mohan, D.; Dey, S.; Dwivedi, S.; Shukla, S. Adsorption of arsenic using low cost adsorbents: Guava leaf biomass, mango bark and bagasse. Curr. Sci. 2019, 117, 649–661. [Google Scholar] [CrossRef]

- Gomes, H.d.O.; Paulo de Tarso, C.F.; do Nascimento, R.F.; Teixeira, R.N.P. Removal of contaminants from water using Moringa oleifera Lam. as biosorbent: An overview of the last decade. J. Water Process Eng. 2022, 46, 102576. [Google Scholar] [CrossRef]

- Karimi, F.; Ayati, A.; Tanhaei, B.; Sanati, A.L.; Afshar, S.; Kardan, A.; Dabirifar, Z.; Karaman, C. Removal of metal ions using a new magnetic chitosan nano-bio-adsorbent; A powerful approach in water treatment. Environ. Res. 2022, 203, 111753. [Google Scholar] [CrossRef]

- Wang, F.; Pan, Y.; Cai, P.; Guo, T.; Xiao, H. Single and binary adsorption of heavy metal ions from aqueous solutions using sugarcane cellulose-based adsorbent. Bioresour. Technol. 2017, 241, 482–490. [Google Scholar] [CrossRef]

- Burakov, A.E.; Galunin, E.V.; Burakova, I.V.; Kucherova, A.E.; Agarwal, S.; Tkachev, A.G.; Gupta, V.K. Adsorption of heavy metals on conventional and nanostructured materials for wastewater treatment purposes: A review. Ecotoxicol. Environ. Saf. 2018, 148, 702–712. [Google Scholar] [CrossRef]

- Oladoye, P.O. Natural, low-cost adsorbents for toxic Pb (II) ion sequestration from (waste) water: A state-of-the-art review. Chemosphere 2022, 287, 132130. [Google Scholar] [CrossRef]

- Santos, V.D.; Tarley, C.; Caetano, J.; Dragunski, D. Assessment of chemically modified sugarcane bagasse for lead adsorption from aqueous medium. Water Sci. Technol. 2010, 62, 457–465. [Google Scholar] [CrossRef] [PubMed]

- Abdallah, M.M.; Ahmad, M.N.; Walker, G.; Leahy, J.J.; Kwapinski, W. Batch and continuous systems for Zn, Cu, and Pb metal ions adsorption on spent mushroom compost biochar. Ind. Eng. Chem. Res. 2019, 58, 7296–7307. [Google Scholar] [CrossRef]

- Díaz, M.L.; Bonilla, P.A.; Reynel, Á.H.; Mendoza, C.D. Sorption of heavy metal ions from aqueous solution using acid-treated avocado kernel seeds and its FTIR spectroscopy characterization. J. Mol. Liq. 2016, 215, 555–564. [Google Scholar] [CrossRef]

- Neto, C.P.; Rocha, J.; Gil, A.; Cordeiro, N.; Esculcas, A.; Rocha, S.; Delgadillo, I.; De Jesus, J.P.; Correia, A.F. 13C solid-state nuclear magnetic resonance and Fourier transform infrared studies of the thermal decomposition of cork. Solid State Nucl. Magn. Reson. 1995, 4, 143–151. [Google Scholar] [CrossRef]

- Akpomie, K.G.; Conradie, J. Banana peel as a biosorbent for the decontamination of water pollutants. A review. Environ. Chem. Lett. 2020, 18, 1085–1112. [Google Scholar] [CrossRef]

- Barka, N.; Abdennouri, M.; El Makhfouk, M.; Qourzal, S. Biosorption characteristics of cadmium and lead onto eco-friendly dried cactus (Opuntia ficus indica) cladodes. J. Environ. Chem. Eng. 2013, 1, 144–149. [Google Scholar] [CrossRef]

- Hussin, Z.M.; Talib, N.; Hussin, N.M.; Hanafiah, M.; Khalir, W. Methylene blue adsorption onto NaOH modified durian leaf powder: Isotherm and kinetic studies. Am. J. Environ. Eng. 2015, 5, 38–43. [Google Scholar]

- Wen, Y.; Ma, J.; Chen, J.; Shen, C.; Li, H.; Liu, W. Carbonaceous sulfur-containing chitosan–Fe (III): A novel adsorbent for efficient removal of copper (II) from water. Chem. Eng. J. 2015, 259, 372–380. [Google Scholar] [CrossRef]

- Demey, H.; Vincent, T.; Guibal, E. A novel algal-based sorbent for heavy metal removal. Chem. Eng. J. 2018, 332, 582–595. [Google Scholar] [CrossRef]

- Islam, A.; Ahmad, A.; Laskar, M.A. Flame atomic absorption spectrometric determination of trace metal ions in environmental and biological samples after preconcentration on a newly developed Amberlite XAD-16 chelating resin containing p-aminobenzene sulfonic acid. J. AOAC Int. 2015, 98, 165–175. [Google Scholar] [CrossRef]

- Kenawy, I.; Hafez, M.; Ismail, M.; Hashem, M. Adsorption of Cu (II), Cd (II), Hg (II), Pb (II) and Zn (II) from aqueous single metal solutions by guanyl-modified cellulose. Int. J. Biol. Macromol. 2018, 107, 1538–1549. [Google Scholar] [CrossRef] [PubMed]

- Mu, B.; Tang, W.; Liu, T.; Hao, X.; Wang, Q.; Ou, R. Comparative study of high-density polyethylene-based biocomposites reinforced with various agricultural residue fibers. Ind. Crops Prod. 2021, 172, 114053. [Google Scholar] [CrossRef]

- Rajesh, Y.; Jeeru, L.R. Synthesis and Characterization of Low-Cost Wood based Biosorbent. Mater. Today Proc. 2022, 57, 34–37. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Panayiotou, C. Novel biodegradable composites based on treated lignocellulosic waste flour as filler. Part II. Development of biodegradable composites using treated and compatibilized waste flour. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1231–1238. [Google Scholar] [CrossRef]

- Ou, R.; Xie, Y.; Wang, Q.; Sui, S.; Wolcott, M.P. Thermal, crystallization, and dynamic rheological behavior of wood particle/HDPE composites: Effect of removal of wood cell wall composition. J. Appl. Polym. Sci. 2014, 131, 40331. [Google Scholar] [CrossRef]

- Tokay, B.; Akpınar, I. A comparative study of heavy metals removal using agricultural waste biosorbents. Bioresour. Technol. Rep. 2021, 15, 100719. [Google Scholar] [CrossRef]

- Jawad, A.H.; Abdulhameed, A.S.; Mastuli, M.S. Acid-factionalized biomass material for methylene blue dye removal: A comprehensive adsorption and mechanism study. J. Taibah Univ. Sci. 2020, 14, 305–313. [Google Scholar] [CrossRef] [Green Version]

- Mariana, M.; Mulana, F.; Juniar, L.; Fathira, D.; Safitri, R.; Muchtar, S.; Bilad, M.R.; Shariff, A.H.M.; Huda, N. Development of biosorbent derived from the endocarp waste of Gayo coffee for lead removal in liquid wastewater—effects of chemical activators. Sustainability 2021, 13, 3050. [Google Scholar] [CrossRef]

- Tee, G.T.; Gok, X.Y.; Yong, W.F. Adsorption of pollutants in wastewater via biosorbents, nanoparticles and magnetic biosorbents: A review. Environ. Res. 2022, 212, 113248. [Google Scholar] [CrossRef]

- Afroze, S.; Sen, T.K. A review on heavy metal ions and dye adsorption from water by agricultural solid waste adsorbents. Water Air Soil Pollut. 2018, 229, 225. [Google Scholar] [CrossRef]

- Hemavathy, R.; Saravanan, A.; Kumar, P.S.; Vo, D.-V.N.; Karishma, S.; Jeevanantham, S. Adsorptive removal of Pb (II) ions onto surface modified adsorbents derived from Cassia fistula seeds: Optimization and modelling study. Chemosphere 2021, 283, 131276. [Google Scholar] [CrossRef] [PubMed]

| Part of Plant | Moisture | Protein | Fat | Ash | Fiber | Carbohydrates | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| * | * | * | * | * | * | |||||||

| Stem | 7.80 ± 0.51 | a | 7.24 ± 0.73 | a | 1.59 ± 0.22 | a | 3.28 ± 0.32 | a | 62.28 ± 0.11 | a | 80.09 ± 0.64 | a |

| Leaf | 7.52 ± 0.43 | a | 9.85 ± 0.32 | b | 2.16 ± 0.41 | a | 5.25 ± 0.35 | b | 58.33 ± 0.61 | b | 80.47 ± 0.43 | a |

| Seeds | 7.39 ± 0.46 | a | 10.45 ± 0.12 | b | 3.90 ± 0.77 | b | 7.41 ± 0.54 | c | 30.85 ± 0.31 | c | 70.85 ± 0.63 | b |

| Treatments | Biosorbent (250 µm) | Biosorbent (500 µm) | ||

|---|---|---|---|---|

| * | * | |||

| T1 | 25.66 ± 1.23 | a | 24.08 ± 1.54 | a |

| T2 | 23.39 ± 0.11 | b | 23.49 ± 1.00 | a |

| T3 | 25.04 ± 0.20 | a | 23.83 ± 0.83 | a |

| T4 | 22.86 ± 0.38 | b | 22.59 ± 0.65 | a |

| Biosorbent. | Treatments | As | Cd | Pb | Zn | ||||

|---|---|---|---|---|---|---|---|---|---|

| * | * | * | * | ||||||

| 250 µm | T1 | 11.80 ± 1.25 | a | 11.17 ± 1.44 | a | 90.70 ± 1.22 | a | 12.23 ± 1.03 | a |

| T2 | 23.87 ± 2.03 | b | 21.03 ± 3.03 | b | 91.89 ± 0.84 | a | 27.73 ± 2.04 | b | |

| T3 | 30.10 ± 1.33 | c | 29.10 ± 1.63 | c | 92.65 ± 1.02 | a | 34.47 ± 1.01 | c | |

| T4 | 32.50 ± 2.14 | c | 34.10 ± 1.15 | d | 96.14 ± 1.12 | b | 36.30 ± 0.05 | c | |

| 500 µm | T1 | 10.73 ± 0.16 | a | 10.93 ± 0.65 | a | 86.90 ± 0.42 | a | 11.70 ± 0.37 | a |

| T2 | 23.30 ± 0.16 | b | 20.20 ± 0.57 | b | 90.91 ± 0.26 | b | 25.80 ± 0.27 | b | |

| T3 | 23.90 ± 0.65 | b | 23.97 ± 1.24 | c | 91.45 ± 0.31 | b | 26.63 ± 0.37 | c | |

| T4 | 25.97 ± 0.47 | c | 24.47 ± 0.75 | c | 94.38 ± 0.39 | c | 27.30 ± 0.54 | c | |

| Biosorbent | Heavy Metal | Langmuir Isotherm | Freundlich Isotherm | |||||

|---|---|---|---|---|---|---|---|---|

| qm (mg/g) | KL (L/mg) | R2 | KF | 1/n | n | R2 | ||

| 250T4 | As | 95.24 | 0.21 | 0.976 | 13.25 | 0.575 | 1.74 | 0.951 |

| Cd | 109.89 | 0.25 | 0.975 | 16.93 | 0.581 | 1.71 | 0.930 | |

| Pb | 156.25 | 0.06 | 0.981 | 8.04 | 0.840 | 1.19 | 0.946 | |

| Zn | 119.05 | 0.23 | 0.955 | 17.96 | 0.591 | 1.69 | 0.907 | |

| 500T4 | As | 97.09 | 0.27 | 0.979 | 15.46 | 0.557 | 1.79 | 0.934 |

| Cd | 112.36 | 0.26 | 0.974 | 17.78 | 0.580 | 1.72 | 0.936 | |

| Pb | 140.85 | 0.09 | 0.964 | 9.92 | 0.783 | 1.19 | 0.956 | |

| Zn | 117.65 | 0.26 | 0.957 | 19.06 | 0.575 | 1.74 | 0.915 | |

| Biosorbent | Heavy Metal | Pseudo First Order | Pseudo Second Order | ||||

|---|---|---|---|---|---|---|---|

| qe (mg/g) | K (min−1) | R2 | qe (mg/g) | K2 (g mg−1 min−1) | R2 | ||

| 250T4 | As | 6.17 | 0.0122 | 0.873 | 23.47 | 0.282 | 0.998 |

| Cd | 5.96 | 0.0133 | 0.886 | 22.12 | 0.273 | 0.998 | |

| Pb | 14.11 | 0.0149 | 0.966 | 17.24 | 0.038 | 0.986 | |

| Zn | 6.68 | 0.0105 | 0.849 | 21.93 | 0.242 | 0.996 | |

| 500T4 | As | 5.47 | 0.0179 | 0.929 | 23.36 | 0.325 | 0.999 |

| Cd | 5.52 | 0.0172 | 0.923 | 22.42 | 0.305 | 0.999 | |

| Pb | 13.97 | 0.0158 | 0.985 | 17.33 | 0.040 | 0.988 | |

| Zn | 6.04 | 0.0128 | 0.880 | 22.17 | 0.270 | 0.998 | |

| Treatments | Biosorbents of the Fraction of 250 µm | Biosorbents of the Fraction of 500 µm | ||||

|---|---|---|---|---|---|---|

| Length (µm) ± s | Diameter (µm) | L/D | Length (µm) | Diameter (µm) | L/D | |

| T1 | 340.03 ± 58.65 | 69.11 ± 8.02 | 4.99 ± 1.04 | 750.01 ± 33.42 | 152.74 ± 7.26 | 4.92 ± 0.34 |

| T2 | 256.38 ± 57.21 | 38.21 ± 8.17 | 6.79 ± 1.25 | 464.48 ± 61.65 | 84.18 ± 19.99 | 5.76 ± 1.29 |

| T3 | 267.11 ± 61.20 | 54.90 ± 10.18 | 4.96 ± 1.16 | 685.67 ± 81.29 | 105.23 ± 18.97 | 6.63 ± 1.30 |

| T4 | 194.83 ± 38.20 | 31.72 ± 8.42 | 6.38 ± 1.47 | 405.64 ± 57.36 | 74.82 ± 9.18 | 5.50 ± 1.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ligarda-Samanez, C.A.; Choque-Quispe, D.; Palomino-Rincón, H.; Ramos-Pacheco, B.S.; Moscoso-Moscoso, E.; Huamán-Carrión, M.L.; Peralta-Guevara, D.E.; Obregón-Yupanqui, M.E.; Aroni-Huamán, J.; Bravo-Franco, E.Y.; et al. Modified Polymeric Biosorbents from Rumex acetosella for the Removal of Heavy Metals in Wastewater. Polymers 2022, 14, 2191. https://doi.org/10.3390/polym14112191

Ligarda-Samanez CA, Choque-Quispe D, Palomino-Rincón H, Ramos-Pacheco BS, Moscoso-Moscoso E, Huamán-Carrión ML, Peralta-Guevara DE, Obregón-Yupanqui ME, Aroni-Huamán J, Bravo-Franco EY, et al. Modified Polymeric Biosorbents from Rumex acetosella for the Removal of Heavy Metals in Wastewater. Polymers. 2022; 14(11):2191. https://doi.org/10.3390/polym14112191

Chicago/Turabian StyleLigarda-Samanez, Carlos A., David Choque-Quispe, Henry Palomino-Rincón, Betsy S. Ramos-Pacheco, Elibet Moscoso-Moscoso, Mary L. Huamán-Carrión, Diego E. Peralta-Guevara, Mirian E. Obregón-Yupanqui, Jimmy Aroni-Huamán, Eyner Y. Bravo-Franco, and et al. 2022. "Modified Polymeric Biosorbents from Rumex acetosella for the Removal of Heavy Metals in Wastewater" Polymers 14, no. 11: 2191. https://doi.org/10.3390/polym14112191

APA StyleLigarda-Samanez, C. A., Choque-Quispe, D., Palomino-Rincón, H., Ramos-Pacheco, B. S., Moscoso-Moscoso, E., Huamán-Carrión, M. L., Peralta-Guevara, D. E., Obregón-Yupanqui, M. E., Aroni-Huamán, J., Bravo-Franco, E. Y., Palomino-Rincón, W., & De la Cruz, G. (2022). Modified Polymeric Biosorbents from Rumex acetosella for the Removal of Heavy Metals in Wastewater. Polymers, 14(11), 2191. https://doi.org/10.3390/polym14112191