Investigation of Efficient Alkali Treatment and the Effect of Flame Retardant on the Mechanical and Fire Performance of Frost-Retted Hemp Fiber Reinforced PLA

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Fiber Surface Treatment with Alkali

2.2.2. Fire Retardant (F1) Treatment

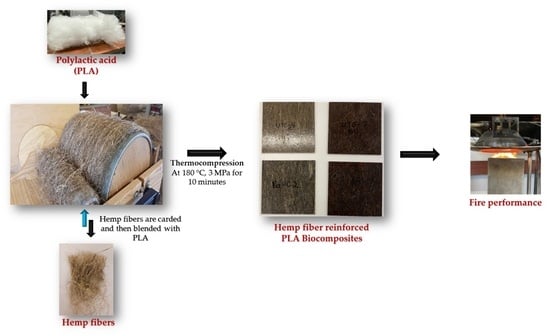

2.2.3. Composite Fabrication

2.2.4. Fiber Mass Loss

2.2.5. Fourier Transform Infrared (FTIR)

2.2.6. Mechanical Properties

2.2.7. Fire Protection Properties

3. Results and Discussion

3.1. Effect of Fiber Treatment on Weight Reduction

3.2. FTIR Analysis

3.3. Effect of Alkali and F1 Treatment on the Mechanical Properties of the Biocomposites

3.3.1. Tensile Properties

3.3.2. Flexural Properties

3.3.3. The Impact of FR Coating on Mechanical Performance

3.4. Fire Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Panaitescu, D.M.; Fierascu, R.C.; Gabor, A.R.; Nicolae, C.A. Effect of hemp fiber length on the mechanical and thermal properties of polypropylene/SEBS/hemp fiber composites. J. Mater. Res. Technol. 2020, 9, 10768–10781. [Google Scholar] [CrossRef]

- Beluns, S.; Gaidukovs, S.; Platnieks, O.; Gaidukova, G.; Mierina, I.; Grase, L.; Starkova, O.; Brazdausks, P.; Thakur, V.K. From Wood and Hemp Biomass Wastes to Sustainable Nanocellulose Foams. Ind. Crop. Prod. 2021, 170, 113780. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Réquilé, S.; Mazian, B.; Grégoire, M.; Musio, S.; Gautreau, M.; Nuez, L.; Day, A.; Thiébeau, P.; Philippe, F.; Chabbert, B.; et al. Exploring the dew retting feasibility of hemp in very contrasting European environments: Influence on the tensile mechanical properties of fibres and composites. Ind. Crop. Prod. 2021, 164, 113337. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Subasinghe, A.; Kim, N.K. Natural Fibers: Their Composites and Flammability Characterizations; Elsevier Inc.; William Andrew Publishing: Norwich, NY, USA, 2015; ISBN 9780323265034. [Google Scholar]

- Panaitescu, D.M.; Vuluga, Z.; Ghiurea, M.; Iorga, M.; Nicolae, C.-A.; Gabor, R. Influence of compatibilizing system on morphology, thermal and mechanical properties of high flow polypropylene reinforced with short hemp fibers. Compos. Part B Eng. 2015, 69, 286–295. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef] [Green Version]

- Väisänen, T.; Batello, P.; Lappalainen, R.; Tomppo, L. Modification of hemp fibers (Cannabis sativa L.) for composite applications. Ind. Crop. Prod. 2018, 111, 422–429. [Google Scholar] [CrossRef]

- Mohd Ishak, Z.A.; Mat Taib, R. Multifunctional Polymer Composites Using Natural Fiber Reinforcements; Elsevier Inc.; William Andrew Publishing: Norwich, NY, USA, 2015; ISBN 9780323265034. [Google Scholar]

- Marrot, L.; Alao, P.F.; Mikli, V.; Kers, J. Properties of Frost-Retted Hemp Fibers for the Reinforcement of Composites. J. Nat. Fibers 2021, 1–12. [Google Scholar] [CrossRef]

- Prasad, S.V.; Pavithran, C.; Rohatgi, P.K. Alkali treatment of coir fibres for coir-polyester composites. J. Mater. Sci. 1983, 18, 1443–1454. [Google Scholar] [CrossRef]

- Zegaoui, A.; Ma, R.; Dayo, A.Q.; Derradji, M.; Wang, J.; Liu, W.; Xu, Y.; Cai, W. Morphological, mechanical and thermal properties of cyanate ester/benzoxazine resin composites reinforced by silane treated natural hemp fibers. Chin. J. Chem. Eng. 2018, 26, 1219–1228. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Alao, P.F.; Kallakas, H.; Poltimäe, T.; Kers, J. Effect of Hemp Fibre Length on the Properties of Polypropylene Composites. Agron. Res. 2019, 17, 1517–1531. [Google Scholar] [CrossRef]

- Sabarinathan, P.; Rajkumar, K.; Annamalai, V.E.; Vishal, K. Characterization on chemical and mechanical properties of silane treated fish tail palm fibres. Int. J. Biol. Macromol. 2020, 163, 2457–2464. [Google Scholar] [CrossRef]

- Alao, P.; Marrot, L.; Burnard, M.; Lavrič, G.; Saarna, M.; Kers, J. Impact of Alkali and Silane Treatment on Hemp/PLA Composites’ Performance: From Micro to Macro Scale. Polymers 2021, 13, 851. [Google Scholar] [CrossRef]

- Alao, P.; Marrot, L.; Kallakas, H.; Just, A.; Poltimäe, T.; Kers, J. Effect of Hemp Fiber Surface Treatment on the Moisture/Water Resistance and Reaction to Fire of Reinforced PLA Composites. Materials 2021, 14, 4332. [Google Scholar] [CrossRef]

- Demir, H.; Atikler, U.; Balkose, D.; Tıhmınlıoğlu, F. The effect of fiber surface treatments on the tensile and water sorption properties of polypropylene–luffa fiber composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 447–456. [Google Scholar] [CrossRef] [Green Version]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly(lactic acid) (PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Pejic, B.M.; Kostic, M.; Skundric, P.D.; Praskalo, J.Z. The effects of hemicelluloses and lignin removal on water uptake behavior of hemp fibers. Bioresour. Technol. 2008, 99, 7152–7159. [Google Scholar] [CrossRef] [PubMed]

- Sreekumar, P.; Thomas, S.P.; Saiter, J.M.; Joseph, K.; Unnikrishnan, G.; Thomas, S. Effect of fiber surface modification on the mechanical and water absorption characteristics of sisal/polyester composites fabricated by resin transfer molding. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1777–1784. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; Hassani, F.O.; Laachachi, A.; El Bouari, A. Effect of surface modification on morphological, mechanical and thermal conductivity of hemp fiber: Characterization of the interface of hemp –Polyurethane composite. Case Stud. Therm. Eng. 2017, 10, 550–559. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crop. Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef] [Green Version]

- Dayo, A.Q.; Zegaoui, A.; Nizamani, A.A.; Kiran, S.; Wang, J.; Derradji, M.; Cai, W.-A.; Liu, W.-B. The influence of different chemical treatments on the hemp fiber/polybenzoxazine based green composites: Mechanical, thermal and water absorption properties. Mater. Chem. Phys. 2018, 217, 270–277. [Google Scholar] [CrossRef]

- Naughton, A.; Fan, M.; Bregulla, J. Fire resistance characterisation of hemp fibre reinforced polyester composites for use in the construction industry. Compos. Part B Eng. 2014, 60, 546–554. [Google Scholar] [CrossRef]

- Hapuarachchi, T.D.; Ren, G.; Fan, M.; Hogg, P.J.; Peijs, T. Fire Retardancy of Natural Fibre Reinforced Sheet Moulding Compound. Appl. Compos. Mater. 2007, 14, 251–264. [Google Scholar] [CrossRef]

- Thiagamani, S.M.K.; Krishnasamy, S.; Muthukumar, C.; Tengsuthiwat, J.; Nagarajan, R.; Siengchin, S.; Ismail, S.O. Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 2019, 140, 637–646. [Google Scholar] [CrossRef]

- Kallakas, H.; Liblik, J.; Alao, P.F.; Poltimäe, T.; Just, A.; Kers, J. Fire and Mechanical Properties of Hemp and Clay Boards for Timber Structures. IOP Conf. Series Earth Environ. Sci. 2019, 290, 012019. [Google Scholar] [CrossRef]

- Petersson, L.; Kvien, I.; Oksman, K. Structure and thermal properties of poly(lactic acid)/cellulose whiskers nanocomposite materials. Compos. Sci. Technol. 2007, 67, 2535–2544. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Brounstein, Z.; Yeager, C.M.; Labouriau, A. Development of Antimicrobial PLA Composites for Fused Filament Fabrication. Polymers 2021, 13, 580. [Google Scholar] [CrossRef]

- Ruponen, J.; Kukkonen, J. Ionic Liquid (ILS) Based Fire Retardant for Wood-Based Panels. World Conf. Timber Eng. 2021, 2021, 2–5. [Google Scholar]

- Panaitescu, D.M.; Vuluga, Z.; Sanporean, C.-G.; Nicolae, C.A.; Gabor, A.R.; Trusca, R. High flow polypropylene/SEBS composites reinforced with differently treated hemp fibers for injection molded parts. Compos. Part B Eng. 2019, 174, 107062. [Google Scholar] [CrossRef]

- Zouari, M.; Devallance, D.B.; Marrot, L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials 2022, 15, 2271. [Google Scholar] [CrossRef]

- Pereira, P.H.F.; de Freitas Rosa, M.; Cioffi, M.O.H.; de Carvalho Benini, K.C.C.; Milanese, A.C.; Voorwald, H.J.C.; Mulinari, D.R. Vegetal fibers in polymeric composites: A review. Polímeros 2015, 25, 9–22. [Google Scholar] [CrossRef] [Green Version]

- Jiang, W.; Gu, J. Nanocrystalline cellulose isolated from different renewable sources to fabricate natural rubber composites with outstanding mechanical properties. Cellulose 2020, 27, 5801–5813. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Liu, K.; Takagi, H.; Osugi, R.; Yang, Z. Effect of physicochemical structure of natural fiber on transverse thermal conductivity of unidirectional abaca/bamboo fiber composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1234–1241. [Google Scholar] [CrossRef]

- Alix, S.; Philippe, E.; Bessadok, A.; Lebrun, L.; Morvan, C.; Marais, S. Effect of chemical treatments on water sorption and mechanical properties of flax fibres. Bioresour. Technol. 2009, 100, 4742–4749. [Google Scholar] [CrossRef] [PubMed]

- Ibraheem, S.A.; Ali, A.; Khalina, A. Development of Green Insulation Boards from Kenaf Fibres and Polyurethane. Polym. Technol. Eng. 2011, 50, 613–621. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of fibre treatments on interfacial shear strength of hemp fibre reinforced polylactide and unsaturated polyester composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1189–1196. [Google Scholar] [CrossRef] [Green Version]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Islam, M.; Pickering, K.; Foreman, N. Influence of alkali treatment on the interfacial and physico-mechanical properties of industrial hemp fibre reinforced polylactic acid composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 596–603. [Google Scholar] [CrossRef]

- Suardana, N.P.G.; Piao, Y.; Lim, J.K. Mechanical Properties of Hemp Fibers and Hemp/pp Composites: Effects of Chemical Surface Treatment. Mater. Phys. Mech. 2011, 11, 1–8. [Google Scholar]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanen, M.; Nousiainen, P. Novel aligned hemp fibre reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Hu, R.; Lim, J.-K. Fabrication and Mechanical Properties of Completely Biodegradable Hemp Fiber Reinforced Polylactic Acid Composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

| Cellulose (%) | Hemicellulose (%) | Lignin (%) | Other Components (%) | Tensile Strength (MPa) | Modulus (GPa) |

|---|---|---|---|---|---|

| 77.4 ± 0.3 | 8.3 ± 0.3 | 1.4 ± 0.0 | 12.9 ± 0.4 | 500 ± 239 | 16.6 ± 8.5 |

| Concentration | Durations, Hour(s) | |||

|---|---|---|---|---|

| 1 wt.% | - | 1 | 2 | 4 |

| 3 wt.% | 0.5 | 1 | 2 | 4 |

| 5 wt.% | 0.5 | 1 | 2 | 4 |

| Composites | Strain at Break under Tensile Loading, % | Strain at Break under Flexural Loading, % |

|---|---|---|

| UH | 1.2 ± 0.2 | 1.9 ± 0.3 |

| UHp | 0.6 ± 0.1 | 0.8 ± 0.1 |

| AH | 1.1 ± 0.2 | 2.0 ± 0.4 |

| AHp | 0.5 ± 0.1 | 0.7 ± 0.1 |

| Sample | Mloss, % | tig, s | Igtemp, °C | tprop, s | tch, s |

|---|---|---|---|---|---|

| PLA | 100 ± 0.0 | 27 ± 2.5 | 155 ± 18 | 45 ± 7.9 | 51 ± 10.8 |

| UH | 84 ± 1.8 | 13 ± 2.3 | 138 ± 26 | 194 ± 18.1 | 210 ± 21.0 |

| AH5 | 84 ± 2.4 | 14 ± 1.7 | 150 ± 19 | 177 ± 27.5 | 192 ± 27.5 |

| Sample | F1 Deposition, % | mloss, % | tig, s | igtemp, °C | tprop, s | tch, s |

|---|---|---|---|---|---|---|

| UHp1 | 21.46 | 50.56 | 40 | 281.60 | - | - |

| UHp2 | 22.35 | 49.74 | 35 | 390.46 | 261 | - |

| UHp3 | 20.58 | 47.11 | 30 | 339.20 | - | - |

| Average | 21.46 | 49.14 | 35 | 337.09 | - | - |

| Std. | 0.89 | 1.80 | 5.0 | 54.46 | - | - |

| AH5p1 | 22.53 | 47.91 | 96 | 577.09 | - | - |

| AH5p2 | 22.02 | 44.63 | - | - | - | - |

| AH5P3 | 23.95 | 39.58 | 252 | 735.99 | - | - |

| Average | 22.77 | 44.04 | - | - | - | - |

| Std. | 0.83 | 4.19 | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alao, P.F.; Press, R.; Kallakas, H.; Ruponen, J.; Poltimäe, T.; Kers, J. Investigation of Efficient Alkali Treatment and the Effect of Flame Retardant on the Mechanical and Fire Performance of Frost-Retted Hemp Fiber Reinforced PLA. Polymers 2022, 14, 2280. https://doi.org/10.3390/polym14112280

Alao PF, Press R, Kallakas H, Ruponen J, Poltimäe T, Kers J. Investigation of Efficient Alkali Treatment and the Effect of Flame Retardant on the Mechanical and Fire Performance of Frost-Retted Hemp Fiber Reinforced PLA. Polymers. 2022; 14(11):2280. https://doi.org/10.3390/polym14112280

Chicago/Turabian StyleAlao, Percy Festus, Raimond Press, Heikko Kallakas, Jussi Ruponen, Triinu Poltimäe, and Jaan Kers. 2022. "Investigation of Efficient Alkali Treatment and the Effect of Flame Retardant on the Mechanical and Fire Performance of Frost-Retted Hemp Fiber Reinforced PLA" Polymers 14, no. 11: 2280. https://doi.org/10.3390/polym14112280

APA StyleAlao, P. F., Press, R., Kallakas, H., Ruponen, J., Poltimäe, T., & Kers, J. (2022). Investigation of Efficient Alkali Treatment and the Effect of Flame Retardant on the Mechanical and Fire Performance of Frost-Retted Hemp Fiber Reinforced PLA. Polymers, 14(11), 2280. https://doi.org/10.3390/polym14112280