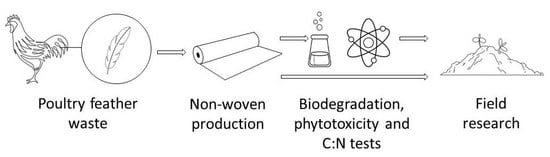

Biodegradable Nonwovens with Poultry Feather Addition as a Method for Recycling and Waste Management

Abstract

:1. Introduction

- They are safe for the environment and human health by ensuring a reduction in biomass waste, in the form of feathers, that is deposited and pollutes the environment;

- The developed innovative nonwovens are made of biodegradable raw materials of natural origin;

- We have the ability to control the time of microbial decomposition by adjusting the share of feather fractions in the nonwovens;

- They have high efficiency with low financial outlay (i.e., the market price of the developed products is much lower than that of fossil-based products due to the fact that they are made from waste materials);

- Nonwovens that are made from natural waste resources can be used soil improvement agents because they contain significant amounts of fertilising ingredients within their structure, which can then be used to meet the nutritional needs of crops.

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

6. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OECD. Glossary of Statistical Terms. 2021. Available online: https://stats.oecd.org/glossary/detail.asp?ID=203 (accessed on 17 February 2021).

- United Nations. Glossary of Environment Statistics. In Studies in Methods; Series F; United Nations: New York, NY, USA, 1997. [Google Scholar]

- Poznyak, T.I.; Chairez Oria, I.; Poznyak, A.S. Ozonation and Biodegradation in Environmental Engineering, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 353–388. [Google Scholar] [CrossRef]

- Rana, S.; Pichandi, S.; Parveen, S.; Fangueiro, R. Biodegradation Studies of Textiles and Clothing Products. In Roadmap to Sustainable Textiles and Clothing. Textile Science and Clothing Technology; Muthu, S., Ed.; Springer: Singapore, 2014. [Google Scholar]

- Urbanek, A.K.; Rymowicz, W.; Mirończuk, A.M. Degradation of plastics and plastic-degrading bacteria in cold marine habitats. Appl. Microbiol. Biotechnol. 2018, 102, 7669–7678. [Google Scholar] [CrossRef] [Green Version]

- Fernández, L. Chemical Fibers Global Production 2000–2019. Available online: https://www.statista.com/statistics/271651/global-production-of-the-chemical-fiber-industry/ (accessed on 17 February 2022).

- Shavandi, A.; Ali, M.A. Keratin based thermoplastic biocomposites: A review. Rev. Environ. Sci. Bio. 2019, 18, 299–316. [Google Scholar] [CrossRef] [Green Version]

- Shavandi, A.; Carne, A.; Bekhit, A.A.; Bekhit, A.E.-D.A. An improved method for solubilisation of wool keratin using peracetic acid. J. Environ. Chem. Eng. 2017, 5, 1977–1984. [Google Scholar] [CrossRef]

- Shavandi, A.; Silva, T.H.; Bekhit, A.A.; Bekhit, A.E.-D.A. Keratin: Dissolution, extraction and biomedical application. Biomater. Sci. 2017, 5, 1699–1735. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wrześniewska-Tosik, K.; Ryszkowska, J.; Mik, T.; Wesołowska, E.; Kowalewski, T.; Pałczyńska, M.; Sałasińska, K.; Walisiak, D.; Czajka, A. Composites of Semi-Rigid Polyurethane Foams with Keratin Fibers Derived from Poultry Feathers and Flame Retardant Additives. Polymers 2020, 12, 2943. [Google Scholar] [CrossRef] [PubMed]

- 2021/2004(INI); European Parliament Resolution of 11 March 2021 on the European Semester for Economic Policy Coordination: Annual Sustainable Growth Strategy. European Parliament: Brussels, Belgium, 2021.

- Poole, A.J.; Church, J.S.; Huson, M.G. Environmentally sustainable fibers from regenerated protein. Biomacromolecules 2009, 10, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Barone, J.R. Polyethylene/keratin fiber composites with varying polyethylene crystallinity. Compos. Part A Appl. Sci. 2005, 36, 1518–1524. [Google Scholar] [CrossRef]

- Barone, J.R.; Gregoire, N.T. Characterisation of fibre–polymer interactions and transcrystallinity in short keratin fibre–polypropylene composites. Plast. Rubber Compos. 2006, 35, 287–293. [Google Scholar] [CrossRef]

- Bertini, F.; Canetti, M.; Patrucco, A.; Zoccola, M. Wool keratin-polypropylene composites: Properties and thermal degradation. Polym. Degrad. Stab. 2013, 98, 980–987. [Google Scholar] [CrossRef]

- Cheng, S.; Lau, K.-t.; Liu, T.; Zhao, Y.; Lam, P.-M.; Yin, Y. Mechanical and thermal properties of chicken feather fiber/PLA green composites. Compos. B Eng. 2009, 40, 650–654. [Google Scholar] [CrossRef]

- Aranberri, I.; Montes, S.; Wesołowska, E.; Rekondo, A.; Wrześniewska-Tosik, K.; Grande, H.-J. Improved Thermal Insulating Properties of Renewable Polyol Based Polyurethane Foams Reinforced with Chicken Feathers. Polymers 2019, 11, 2002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Călin, M.; Constantinescu-Aruxandei, M.D.; Alexandrescu, E.; Răut, I.; Doni, M.B.; Arsene, M.-L.; Oancea, F.; Jecu, L.; Lazăr, V. Degradation of keratin substrates by keratinolytic fungi. Electron. J. Biotechnol. 2017, 28, 101–112. [Google Scholar] [CrossRef]

- European Standard EN 14995; Plastics—Evaluation of Compostability—Test Scheme and Specifications. CEN: Brussels, Belgium, 2009.

- Tesfaye, T.; Sithole, B.; Ramjugernath, D.; Chunilall, V. Valorisation of chicken feathers: Characterisation of physical properties and morphological structure. J. Clean. Prod. 2017, 149, 349–365. [Google Scholar] [CrossRef]

- Kakonke, G.; Tesfaye, T.; Sithole, B.; Ntunka, M. Production and characterization of cotton-chicken feather fibres blended absorbent fabrics. J. Clean. Prod. 2020, 243, 118508. [Google Scholar] [CrossRef]

- Marczak, D.; Lejcuś, K.; Misiewicz, J. Characteristics of biodegradable textiles used in environmental engineering: A comprehensive review. J. Clean. Prod. 2020, 268, 122129. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Nam, S.; Slopek, R.; Wolf, D.; Warnock, M.; Condon, B.D.; Sawhney, P.; Gbur, E.; Reynolds, M.; Allen, C. Comparison of biodegradation of low-weight hydroentangled raw cotton nonwoven fabric and that of commonly used disposable nonwoven fabrics in aerobic Captina silt loam soil. Text. Res. J. 2015, 86, 155–166. [Google Scholar] [CrossRef]

- Kumar, N.; Das, D. Nonwoven geotextiles from nettle and poly(lactic acid) fibers for slope stabilization using bioengineering approach. Geotext. Geomembr. 2018, 46, 206–213. [Google Scholar] [CrossRef]

- Montes-Zarazúa, E.; Colín-Cruz, A.; Pérez-Rea, M.d.L.L.; de Icaza, M.; Velasco-Santos, C.; Martínez-Hernández, A.L. Effect of Keratin Structures from Chicken Feathers on Expansive Soil Remediation. Adv. Mater. Sci. Eng. 2015, 2015, 1–10. [Google Scholar] [CrossRef] [Green Version]

- George, B.R.; Bockarie, A.; McBride, H. Utilization of Turkey Feather Fibers in Nonwoven Erosion Control Fabrics. Nonwoven Ind. 2003, 45–52. [Google Scholar] [CrossRef] [Green Version]

- Korniłłowicz-Kowalska, T.; Bohacz, J. Biodegradation of keratin waste: Theory and practical aspects. Waste Manag. 2011, 31, 1689–1701. [Google Scholar] [CrossRef] [PubMed]

- Kunert, J. Thiosulphate esters in keratin attacked by dermatophytes in vitro. Sabouraudia 1972, 10, 6–13. [Google Scholar] [CrossRef] [PubMed]

- Broda, J.; Przybyło, S.; Kobiela-Mendrek, K.; Biniaś, D.; Rom, M.; Grzybowska-Pietras, M.J.; Laszczak, R. Biodegradation of sheep wool geotextiles. Int. Biodeter. Biodegr. 2016, 115, 31–38. [Google Scholar] [CrossRef]

- Casadesús, M.; Álvarez, M.D.; Garrido, N.; Molins, G.; Macanás, J.; Colom, X.; Cañavate, J.; Carrillo, F. Environmental impact assessment of sound absorbing nonwovens based on chicken feathers waste. Resour. Conserv. Recycl. 2019, 149, 489–499. [Google Scholar] [CrossRef]

- Vilchez, V.; Dieckmann, E.; Tammelin, E.; Cheeseman, C.; Lee, K.-Y. Upcycling poultry feathers with (nano)cellulose: Sustainable composites derived from non-woven whole feather preforms. ACS Sustain. Chem. Eng. 2020, 8, 14263–14267. [Google Scholar] [CrossRef]

- Yadav, S.; Khosla, B. Biodegradation of poultry feather waste by keratinase producing Bacillus cereus strain isolated from poultry farms waste disposal site. CSCEE 2021, 4, 100114. [Google Scholar] [CrossRef]

- Li, Q. Progress in Microbial Degradation of Feather Waste. Front. Microbiol. 2019, 10, 2717. [Google Scholar] [CrossRef] [Green Version]

- Kirwan, K.; Wood, B.M. Recycling of materials in automotive engineeringin. In Advanced Materials in Automotive Engineering; WMG, University of Warwick: Cambridge, UK, 2012; pp. 299–314. [Google Scholar]

- Bohacz, J.; Korniłłowicz-Kowalska, T. Nitrogen and sulfur transformations in composts containing chicken feathers. Compost Sci. Util. 2009, 17, 180–188. [Google Scholar] [CrossRef]

- Bohacz, J.; Korniłłowicz-Kowalska, T. Changes in enzymatic activity in composts containing chicken feathers. Biores. Technol. 2009, 100, 3604–3612. [Google Scholar] [CrossRef]

- Jin, X.; Lu, L.; Wu, H.; Ke, Q.; Wang, H. Duck Feather/Nonwoven Composite Fabrics for Removing Metals Present in Textile Dyeing Effluents. J. Eng. Fibers Fabr. 2013, 8, 155892501300800. [Google Scholar] [CrossRef] [Green Version]

- Soekoco, A.S.; Ichwan, M.; Hananto, A.; Mustafa, D. Application of Chicken Feather Waste as a Material of Nonwoven Insulator; AIP Publishing LLC: Melville, NY, USA, 2018. [Google Scholar]

- Mrajji, O.; Wazna, M.E.; Samouh, Z.; Bouari, A.E.; Cherkaoui, O.; El Moznine, R. The effect of nonwoven structure on thermomechanical properties of feather waste reinforced polyester composite. J. Ind. Text. 2020, 152808372094773. [Google Scholar] [CrossRef]

- Zhang, W.; Yangk, X.; Li, C.; Liang, M.; Lu, C.; Deng, Y. Mechanochemical activation of cellulose and its thermoplastic polyvinyl alcohol ecocomposites with enhanced physicochemical properties. Carbohydr. Polym. 2011, 83, 257–263. [Google Scholar] [CrossRef]

- Mrajji, O.; Wazna, M.E.; Boussoualem, Y.; Bouari, A.E.; Cherkaoui, O. Feather waste as a thermal insulation solution: Treatment, elaboration and characterization. J. Ind. Text. 2019, 50, 1674–1697. [Google Scholar] [CrossRef]

| Group | Nonwoven | Feather Amount (%) | Wool Amount (%) | Trevira Bico | |

|---|---|---|---|---|---|

| Amount (%) | Type | ||||

| I | Nonwoven I | 0 | 90 | 10 | 256 |

| 38.5 | 55 | 6 | |||

| Nonwoven II | 0 | 90 | 10 | ||

| 34.8 | 58 | 7 | |||

| Nonwoven III | 0 | 90 | 10 | ||

| 44.4 | 50 | 6 | |||

| II | DA I/1 | 30.0 | 63 | 7 | 453 |

| 0 | 90 | 10 | |||

| DA I/1 and 2 | 32.0 | 61 | 7 | ||

| 0 | 90 | 10 | |||

| DA I/2 | 40 | 54 | 6 | ||

| 0 | 90 | 10 | |||

| DA II/2 | 40.0 | 54 | 6 | ||

| 0 | 90 | 10 | |||

| Group | Nonwoven | Feather | Base Weight (g/m2) | Thickness (mm) | Tensile Strength in the Horizontal Direction (N) | Tensile Strength in the Vertical Direction (N) | Tear Resistance in the Horizontal Direction (N) | Tear Resistance in the Vertical Direction (N) |

|---|---|---|---|---|---|---|---|---|

| EN 29073-1:1994 | EN ISO 9073-2:2002 | EN 29073-3:1994 | EN 29073-3:1994 | EN ISO 9073-4:2002 | EN ISO 9073-4:2002 | |||

| I | Wool I | + | 78.2 ± 2.3 | 1.33 ± 0.06 | 1.11 ± 0.22 | 2.02 ± 0.43 | 1.80 ± 0.08 | 1.22 ± 0.04 |

| - | 48.1 ± 4.5 | 1.13 ± 0.05 | 1.18 ± 0.60 | 2.68 ± 0.57 | 2.26 ± 0.30 | 1.45 ± 0.36 | ||

| Wool II | + | 158.0 ± 7 | 2.04 ± 0.08 | 3.91 ± 1.07 | 10.20 ± 2.60 | 5.18 ± 0.39 | 4.94 ± 0.31 | |

| - | 103.0 ± 10.0 | 1.75 ± 0.08 | 4.89 ± 1.84 | 7.22 ± 1.09 | 5.89 ± 0.91 | 3.21 ± 0.35 | ||

| Wool III | + | 284.0 ± 8.0 | 2.83 ± 0.18 | 31.9 ± 12.1 | 27.20 ± 2.20 | 31.2 ± 6.3 | 15.4 ± 2.2 | |

| - | 158.0 ± 12.0 | 2.11 ± 0.07 | 14.90 ± 2.40 | 40.00 ± 5.1 | 18.90 ± 3.20 | 23.50 ± 6.1 | ||

| II | DA I/1 | + | 103.0 ± 6 | 1.62 ± 0.12 | 0.36 ± 0.11 | 0.70 ± 0.15 | 1.06 ± 0.56 | 0.52 ± 0.46 |

| - | 86.0 ± 4.00 | 1.76 ± 0.13 | 0.58 ± 0.05 | 1.14 ± 0.27 | 1.43 ± 0.51 | 0.65 ± 0.12 | ||

| DA I/1 and 2 | + | 116.0 ± 13.0 | 1.70 ± 0.14 | 0.44 ± 0.05 | 0.92 ± 0.16 | 1.17 ± 0.36 | 0.38 ± 0.20 | |

| - | 70.9 ± 3.80 | 1.56 ± 0.12 | 0.56 ± 0.10 | 1.01 ± 0.21 | 1.02 ± 0.30 | 0.64 ± 0.57 | ||

| DA I/2 | + | 101.0 ± 14.0 | 1.75 ± 0.15 | 0.34 ± 0.07 | 1.44 ± 1.29 | 1.38 ± 0.04 | 0.43 ± 0.12 | |

| - | 86.0 ± 4.00 | 1.76 ± 0.13 | 0.58 ± 0.05 | 1.14 ± 0.27 | 1.43 ± 0.51 | 0.65 ± 0.12 | ||

| DA II/2 | + | 144 ± 0.16 | 2.14 ± 0.13 | 0.69 ± 0.14 | 1.70 ± 0.46 | 1.94 ± 0.32 | 0.85 ± 0.34 | |

| - | 90.8 ± 5.00 | 1.93 ± 0.15 | 0.72 ± 0.12 | 2.42 ± 0.51 | 2.74 ± 0.68 | 0.67 ± 0.14 |

| DA II/2 “0” | DA II/2 | |

|---|---|---|

| 1 Week |  |  |

| 4 Weeks |  |  |

| 8 Weeks |  |  |

| 12 Weeks |  | Biodegradation 100% |

| 16 Weeks |  | |

| 20 Weeks |  | |

| 24 Weeks | Biodegradation 100% |

| Feather | |||

|---|---|---|---|

| No | Yes | ||

| Week of Biodegradation | Mean | 14 | 9 |

| SD * | 6.93 | 2.00 | |

| Min. | 8 | 8 | |

| Max. | 24 | 12 | |

| Median | 12 | 8 | |

| Tensile Strength in the Horizontal Direction | Mean | 0.61 | 0.46 |

| SD * | 0.07 | 0.16 | |

| Min. | 0.56 | 0.34 | |

| Max. | 0.72 | 0.69 | |

| Median | 0.58 | 0.40 | |

| Tensile Strength in the Vertical Direction | Mean | 1.42 | 1.19 |

| SD * | 0.66 | 0.46 | |

| Min. | 1.01 | 0.70 | |

| Max. | 2.42 | 1.70 | |

| Median | 1.14 | 1.18 | |

| Tear Resistance in the Horizontal Direction | Mean | 1.65 | 1.39 |

| SD * | 0.75 | 0.39 | |

| Min. | 1.02 | 1.06 | |

| Max. | 2.74 | 1.94 | |

| Median | 1.43 | 1.28 | |

| Tear Resistance in the Vertical Direction | Mean | 0.65 | 0.54 |

| SD * | 0.01 | 0.21 | |

| Min. | 0.64 | 0.38 | |

| Max. | 0.67 | 0.85 | |

| Median | 0.65 | 0.47 | |

| Group | Feather Addition | Thickness | Tensile Strength in the Horizontal Direction | Tensile Strength in the Vertical Direction | Tear Resistance in the Horizontal Direction | Tear Resistance in the Vertical Direction | |

|---|---|---|---|---|---|---|---|

| Biodegradability (%) | I | 0.24 | −0.16 | 0.12 | −0.10 | 0.19 | −0.05 |

| Weeks of Biodegradation | II | −0.62 | 0.54 | 0.74 | 0.87 | 0.94 | 0.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jóźwik-Pruska, J.; Wrześniewska-Tosik, K.; Mik, T.; Wesołowska, E.; Kowalewski, T.; Pałczyńska, M.; Walisiak, D.; Szalczyńska, M. Biodegradable Nonwovens with Poultry Feather Addition as a Method for Recycling and Waste Management. Polymers 2022, 14, 2370. https://doi.org/10.3390/polym14122370

Jóźwik-Pruska J, Wrześniewska-Tosik K, Mik T, Wesołowska E, Kowalewski T, Pałczyńska M, Walisiak D, Szalczyńska M. Biodegradable Nonwovens with Poultry Feather Addition as a Method for Recycling and Waste Management. Polymers. 2022; 14(12):2370. https://doi.org/10.3390/polym14122370

Chicago/Turabian StyleJóźwik-Pruska, Jagoda, Krystyna Wrześniewska-Tosik, Tomasz Mik, Ewa Wesołowska, Tomasz Kowalewski, Michalina Pałczyńska, Damian Walisiak, and Magdalena Szalczyńska. 2022. "Biodegradable Nonwovens with Poultry Feather Addition as a Method for Recycling and Waste Management" Polymers 14, no. 12: 2370. https://doi.org/10.3390/polym14122370

APA StyleJóźwik-Pruska, J., Wrześniewska-Tosik, K., Mik, T., Wesołowska, E., Kowalewski, T., Pałczyńska, M., Walisiak, D., & Szalczyńska, M. (2022). Biodegradable Nonwovens with Poultry Feather Addition as a Method for Recycling and Waste Management. Polymers, 14(12), 2370. https://doi.org/10.3390/polym14122370