Effects of Filler Functionalization on Filler-Embedded Natural Rubber/Ethylene-Propylene-Diene Monomer Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Rubber Compounding

2.3. Surface Modification of Phlogopite Using Silane-Based Coupling Agents

2.4. Curing Characteristics

2.4.1. Cure Time (T90)

2.4.2. Mooney Viscosity

2.5. Mechanical Properties

2.5.1. Tensile Properties

2.5.2. Hardness

2.5.3. Abrasion Resistance

2.6. Elastic Properties

2.6.1. Rebound Resilience

2.6.2. Compression Set

2.7. Morphology

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghosh, A.K.; Debnath, S.C.; Naskar, N.; Basu, D.K. NR–EPDM Covulcanization: A Novel Approach. J. Appl. Polym. Sci. 2001, 81, 800–808. [Google Scholar] [CrossRef]

- Chang, Y.-W.; Shin, Y.-S.; Chun, H.; Nah, C. Effects of Trans-Polyoctylene Rubber (TOR) on the Properties of NR/EPDM Blends. J. Appl. Polym. Sci. 1999, 73, 749–756. [Google Scholar] [CrossRef]

- Rattanasom, N.; Poonsuk, A.; Makmoon, T. Effect of Curing System on the Mechanical Properties and Heat Aging Resistance of Natural Rubber/Tire Tread Reclaimed Rubber Blends. Polym. Test. 2005, 24, 728–732. [Google Scholar] [CrossRef]

- Phetphaisit, C.W.; Namahoot, J.; Saengkiettiyut, K.; Ruamcharoen, J.; Ruamcharoen, P. Green Metal Organic Coating from Recycled PETs and Modified Natural Rubber for the Automobile Industry. Prog. Org. Coat. 2015, 86, 181–189. [Google Scholar] [CrossRef]

- Fukahori, Y.; Yamazaki, H. Mechanism of Rubber Abrasion. Part I: Abrasion Pattern Formation in Natural Rubber Vulcanizate. Wear 1994, 171, 195–202. [Google Scholar] [CrossRef]

- Ryu, G.; Kim, D.; Song, S.; Hwang, K.; Kim, W. Effect of Molecular Weight of Epoxidized Liquid Isoprene Rubber as a Processing Aid on the Vulcanizate Structure of Silica Filled NR Compounds. Elastomers Compos. 2021, 56, 223–233. [Google Scholar] [CrossRef]

- Son, C.E.; Yang, S.R.; Choi, S.-S. Abrasion Behaviors of NR/BR Compounds Using Laboratory Abrasion Tester. Elastomers Compos. 2021, 56, 12–19. [Google Scholar] [CrossRef]

- Kim, I.J.; Kim, D.; Ahn, B.; Lee, H.J.; Kim, H.J.; Kim, W. Vulcanizate Structures of NR Compounds with Silica and Carbon Black Binary Filler Systems at Different Curing Temperatures. Elastomers Compos. 2021, 56, 20–31. [Google Scholar] [CrossRef]

- Fan, R.; Zhang, Y.; Huang, C.; Zhang, Y.; Fan, Y.; Sun, K. Effect of Crosslink Structures on Dynamic Mechanical Properties of Natural Rubber Vulcanizates under Different Aging Conditions. J. Appl. Polym. Sci. 2001, 81, 710–718. [Google Scholar] [CrossRef]

- Wu, W.; Zeng, X.; Li, H.; Lai, X.; Li, F.; Guo, J. Synthesis and Characterization of a Novel Macromolecular Hindered Phenol Antioxidant and Its Thermo-Oxidative Aging Resistance for Natural Rubber. J. Macromol. Sci. Part B 2014, 53, 1244–1257. [Google Scholar] [CrossRef]

- Varghese, S.; Kuriakose, B.; Thomas, S. Short Sisal Fibre Reinforced Natural Rubber Composites: High-Energy Radiation, Thermal and Ozone Degradation. Polym. Degrad. Stab. 1994, 44, 55–61. [Google Scholar] [CrossRef]

- Chae, E.; Choi, S.-S. Characterization of Chlorinated NR Using Pyrolytic Technique. Elastomers Compos. 2020, 55, 257–262. [Google Scholar] [CrossRef]

- Choi, E.Y.; Kim, C.K.; Park, C.B. Fabrication of MA-EPDM Grafted MWCNTs by Reactive Extrusion for Enhanced Interfacial Adhesion and Mechanical Properties of PP/MA-EPDM Composite. Compos. Part B Eng. 2022, 242, 110043. [Google Scholar] [CrossRef]

- Arroyo, M.; López-Manchado, M.A.; Valentín, J.L.; Carretero, J. Morphology/Behaviour Relationship of Nanocomposites Based on Natural Rubber/Epoxidized Natural Rubber Blends. Compos. Sci. Technol. 2007, 67, 1330–1339. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Santoni, A.; Sbardella, F.; Calzolari, A.; Sarasini, F.; Mollica, F. Correlation between Mechanical Properties and Processing Conditions in Rubber-Toughened Wood Polymer Composites. Polymers 2020, 12, 1170. [Google Scholar] [CrossRef]

- Do, J.H.; Kim, D.Y.; Seo, K.H. Effect of Eco-Friendly Inorganic Flame Retardants on Mechanical and Flame-Retardant Properties of EPDM Compound. Elastomers Compos. 2020, 55, 40–45. [Google Scholar] [CrossRef]

- Ning, N.; Ma, Q.; Zhang, Y.; Zhang, L.; Wu, H.; Tian, M. Enhanced Thermo-Oxidative Aging Resistance of EPDM at High Temperature by Using Synergistic Antioxidants. Polym. Degrad. Stab. 2014, 102, 1–8. [Google Scholar] [CrossRef]

- Ha, K.-R.; Lee, J.-C.; Kim, T.-G.; Hwang, K.-S. Studies on the Ozone Resistance and Physical Properties of SBR/EPDM Blend Compound due to EPDM Content Variation. Elastomers Compos. 2008, 43, 8–17. [Google Scholar]

- Botros, S.H. Preparation and Characteristics of NR/EPDM Rubber Blends. Polym. Plast. Technol. Eng. 2002, 41, 341–359. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Peng, F.; Liu, M.; Zhao, Q.; Fu, P.-F. Morphology of Nylon 1212 Toughened with a Maleated EPDM Rubber. Polym. Int. 2009, 58, 190–197. [Google Scholar] [CrossRef]

- Hough, P.; van der Aar, N.; Qiu, Z. Compounding and Mixing Methodology for Good Performance of EPDM in Tire Sidewalls. Tire Sci. Technol. 2020, 48, 2–21. [Google Scholar] [CrossRef]

- Rezaeian, I.; Zahedi, P.; Loghmani, M.S. Formulation and Curing Characteristics of EPDM/NR and EPDM/SBR Polyblends Used in Metallic Surfaces Rubber Lining. J. Appl. Polym. Sci. 2009, 113, 849–854. [Google Scholar] [CrossRef]

- Lyu, L.; Hanada, T.; Yamahira, N.; Morita, J.; Yamamoto, R.; Itomi, K.; Adachi, T.; Kubouchi, S.; Horiuchi, S. Spatial Distribution of Silica Fillers in Phase-Separated Rubber Blends Investigated by Three-Dimensional Elemental Mapping. J. Appl. Polym. Sci. 2021, 138, 51443. [Google Scholar] [CrossRef]

- Šebenik, U.; Zupančič-Valant, A.; Krajnc, M. Investigation of Rubber–Rubber Blends Miscibility. Polym. Eng. Sci. 2006, 46, 1649–1659. [Google Scholar] [CrossRef]

- Corish, P.J. Fundamental Studies of Rubber Blends. Rubber Chem. Technol. 1967, 40, 324–340. [Google Scholar] [CrossRef]

- Coran, A.Y. Blends of Dissimilar Rubbers—Cure-Rate Incompatibility. Rubber Chem. Technol. 1988, 61, 281–292. [Google Scholar] [CrossRef]

- El-Sabbagh, S.H. Compatibility Study of Natural Rubber and Ethylene–Propylene Diene Rubber Blends. Polym. Test. 2003, 22, 93–100. [Google Scholar] [CrossRef]

- Mastromatteo, R.P.; Mitchell, J.M.; Brett, T.J., Jr. New Accelerators for Blends of EPDM. Rubber Chem. Technol. 1971, 44, 1065–1079. [Google Scholar] [CrossRef]

- Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Thapthong, P. Influence of Accelerator Type on Properties of NR/EPDM Blends. Polym. Test. 2007, 26, 1062–1067. [Google Scholar] [CrossRef]

- Suma, N.; Joseph, R.; George, K.E. Improved Mechanical Properties of NR/EPDM and NR/ Butyl Blends by Precuring EPDM and Butyl. J. Appl. Polym. Sci. 1993, 49, 549–557. [Google Scholar] [CrossRef]

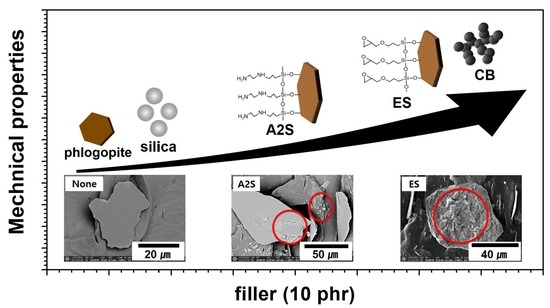

- Lee, S.-H.; Park, S.-Y.; Chung, K.-H.; Jang, K.-S. Phlogopite-Reinforced Natural Rubber (NR)/Ethylene-Propylene-Diene Monomer Rubber (EPDM) Composites with Aminosilane Compatibilizer. Polymers 2021, 13, 2318. [Google Scholar] [CrossRef] [PubMed]

- Rattanasupa, B.; Keawwattana, W. The Development of Rubber Compound Based on Natural Rubber (NR) and Ethylene-Propylene-Diene-Monomer (EPDM) Rubber for Playground Rubber Mat. Agric. Nat. Resour. 2007, 41, 239–247. [Google Scholar]

- Zeid, M.M.A. Radiation Effect on Properties of Carbon Black Filled NBR/EPDM Rubber Blends. Eur. Polym. J. 2007, 43, 4415–4422. [Google Scholar] [CrossRef]

- Fan, Y.; Fowler, G.D.; Zhao, M. The Past, Present and Future of Carbon Black as a Rubber Reinforcing Filler–A Review. J. Clean. Prod. 2020, 247, 119115. [Google Scholar] [CrossRef]

- O’Brien, J.; Cashell, E.; Wardell, G.E.; McBrierty, V.J. An NMR Investigation of the Interaction between Carbon Black and Cis-Polybutadiene. Available online: https://pubs.acs.org/doi/pdf/10.1021/ma60052a025 (accessed on 2 May 2022).

- Kapgate, B.P.; Das, C.; Basu, D.; Das, A.; Heinrich, G. Rubber Composites Based on Silane-Treated Stöber Silica and Nitrile Rubber: Interaction of Treated Silica with Rubber Matrix. J. Elastomers Plast. 2015, 47, 248–261. [Google Scholar] [CrossRef]

- Rattanasom, N.; Saowapark, T.; Deeprasertkul, C. Reinforcement of Natural Rubber with Silica/Carbon Black Hybrid Filler. Polym. Test. 2007, 26, 369–377. [Google Scholar] [CrossRef]

- Arroyo, M.; López-Manchado, M.A.; Herrero, B. Organo-Montmorillonite as Substitute of Carbon Black in Natural Rubber Compounds. Polymer 2003, 44, 2447–2453. [Google Scholar] [CrossRef]

- Greenough, S.; Dumont, M.-J.; Prasher, S. The Physicochemical Properties of Biochar and Its Applicability as a Filler in Rubber Composites: A Review. Mater. Today Commun. 2021, 29, 102912. [Google Scholar] [CrossRef]

- Castro, D.F.; Suarez, J.C.M.; Nunes, R.C.R.; Visconte, L.L.Y. Effect of Mica Addition on the Properties of Natural Rubber and Polybutadiene Rubber Vulcanizates. J. Appl. Polym. Sci. 2003, 90, 2156–2162. [Google Scholar] [CrossRef]

- Dananjaya, S.A.V.; Somarathna, Y.R.; Karunanayake, L.; Siriwardena, S. Waste Mica as Filler for Natural Rubber Latex Foam Composites. J. Polym. Res. 2022, 29, 71. [Google Scholar] [CrossRef]

- Verbeek, C.J.R. Highly Filled Polyethylene/Phlogopite Composites. Mater. Lett. 2002, 52, 453–457. [Google Scholar] [CrossRef]

- Cai, L.; Dou, Q. Effect of Filler Treatments on the Crystallization, Mechanical Properties, Morphologies and Heat Resistance of Polypropylene/Phlogopite Composites. Polym. Compos. 2019, 40, E795–E810. [Google Scholar] [CrossRef]

- Karian, H. Handbook of Polypropylene and Polypropylene Composites, Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2003; ISBN 978-0-203-91180-8. [Google Scholar]

- Jamel, M.M.; Khoshnoud, P.; Gunashekar, S.; Abu-Zahra, N. Mechanical Properties and Dimensional Stability of Rigid PVC Foam Composites Filled with High Aspect Ratio Phlogopite Mica. J. Miner. Mater. Charact. Eng. 2015, 3, 237. [Google Scholar] [CrossRef]

- Escócio, V.A.; Visconte, L.L.Y.; Nunes, R.C.R.; de Oliveira, M.G. Rheology and Processability of Natural Rubber Composites with Mica. Int. J. Polym. Mater. Polym. Biomater. 2008, 57, 374–382. [Google Scholar] [CrossRef]

- Roshanaei, H.; Khodkar, F.; Alimardani, M. Contribution of Filler–Filler Interaction and Filler Aspect Ratio in Rubber Reinforcement by Silica and Mica. Iran. Polym. J. 2020, 29, 901–909. [Google Scholar] [CrossRef]

- Wang, X.; Wu, L.; Yu, H.; Xiao, T.; Li, H.; Yang, J. Analysis of Effect of Modification of Silica and Carbon Black Co-Filled Rubber Composite on Mechanical Properties. E Polym. 2021, 21, 279–288. [Google Scholar] [CrossRef]

- Sae-oui, P.; Thepsuwan, U.; Hatthapanit, K. Effect of Curing System on Reinforcing Efficiency of Silane Coupling Agent. Polym. Test. 2004, 23, 397–403. [Google Scholar] [CrossRef]

- Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Hatthapanit, K. Roles of Silane Coupling Agents on Properties of Silica-Filled Polychloroprene. Eur. Polym. J. 2006, 42, 479–486. [Google Scholar] [CrossRef]

- Surya, I.; Ismail, H.; Azura, A.R. The Comparison of Alkanolamide and Silane Coupling Agent on the Properties of Silica-Filled Natural Rubber (SMR-L) Compounds. Polym. Test. 2014, 40, 24–32. [Google Scholar] [CrossRef]

- Jang, K.-S.; Eom, Y.-S.; Choi, K.-S.; Bae, H.-C. Crosslinkable Deoxidizing Hybrid Adhesive of Epoxy–Diacid for Electrical Interconnections in Semiconductor Packaging. Polym. Int. 2018, 67, 1241–1247. [Google Scholar] [CrossRef]

- Jang, K.-S.; Eom, Y.-S.; Choi, K.-S.; Bae, H.-C. Synchronous Curable Deoxidizing Capability of Epoxy–Anhydride Adhesive: Deoxidation Quantification via Spectroscopic Analysis. J. Appl. Polym. Sci. 2018, 135, 46639. [Google Scholar] [CrossRef]

- Morancho, J.M.; Ramis, X.; Fernández-Francos, X.; Konuray, O.; Salla, J.M.; Serra, À. Dual Curing of an Epoxy Resin with Dicarboxylic Acids. J. Therm. Anal. Calorim. 2020, 142, 607–615. [Google Scholar] [CrossRef]

- Mirza-Aghayan, M.; Tavana, M.M.; Niazi, E.G.A.; Boukherroub, R. Efficient and Regioselective Ring-Opening of Epoxides with Carboxylic Acid Catalyzed by Graphite Oxide. Lett. Org. Chem. 2020, 17, 532–538. [Google Scholar] [CrossRef]

- Miao, K.; Hu, Y.; Zha, B.; Xu, L.; Miao, X.; Deng, W. Hydroxyl versus Carboxyl Substituent: Effects of Competitive and Cooperative Multiple Hydrogen Bonds on Concentration-Controlled Self-Assembly. J. Phys. Chem. C 2016, 120, 14187–14197. [Google Scholar] [CrossRef]

- Zhang, X.; He, J. Hydrogen-Bonding-Supported Self-Healing Antifogging Thin Films. Sci. Rep. 2015, 5, 9227. [Google Scholar] [CrossRef] [Green Version]

| Rubber Matrix (wt%) | |||||||

|---|---|---|---|---|---|---|---|

| NR | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

| EPDM | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Additive (phr) | |||||||

| Zinc oxide | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Stearic acid | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| CB | - | 10 | - | - | - | - | - |

| Silica | - | - | 10 | - | - | - | - |

| Phlogopite | - | - | - | 10 | - | - | - |

| A1S-phlogopite | - | - | - | - | 10 | - | - |

| A2S-phlogopite | - | - | - | - | - | 10 | - |

| ES-phlogopite | - | - | - | - | - | - | 10 |

| TMTD | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| CBS | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Sulfur | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-H.; Park, G.-W.; Kim, H.-J.; Chung, K.; Jang, K.-S. Effects of Filler Functionalization on Filler-Embedded Natural Rubber/Ethylene-Propylene-Diene Monomer Composites. Polymers 2022, 14, 3502. https://doi.org/10.3390/polym14173502

Lee S-H, Park G-W, Kim H-J, Chung K, Jang K-S. Effects of Filler Functionalization on Filler-Embedded Natural Rubber/Ethylene-Propylene-Diene Monomer Composites. Polymers. 2022; 14(17):3502. https://doi.org/10.3390/polym14173502

Chicago/Turabian StyleLee, Sung-Hun, Gun-Woo Park, Hee-Jun Kim, Kyungho Chung, and Keon-Soo Jang. 2022. "Effects of Filler Functionalization on Filler-Embedded Natural Rubber/Ethylene-Propylene-Diene Monomer Composites" Polymers 14, no. 17: 3502. https://doi.org/10.3390/polym14173502

APA StyleLee, S. -H., Park, G. -W., Kim, H. -J., Chung, K., & Jang, K. -S. (2022). Effects of Filler Functionalization on Filler-Embedded Natural Rubber/Ethylene-Propylene-Diene Monomer Composites. Polymers, 14(17), 3502. https://doi.org/10.3390/polym14173502