Polyurethane/Vermiculite Foam Composite as Sustainable Material for Vertical Flame Retardant

Abstract

:1. Introduction

2. Experimental

2.1. Reagents

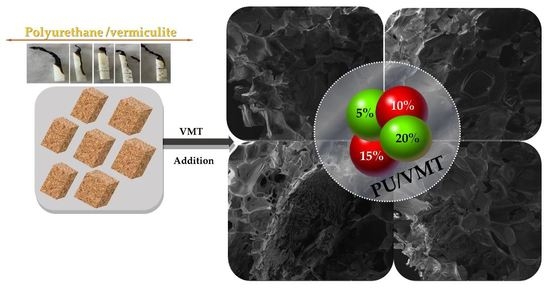

2.2. Preparation of Rigid Foam and Composites

2.3. Characterizations

2.4. Vertical Flammability Test

3. Results and Discussion

3.1. Analysis of TG/DTG, DRX, MEV, and EDS

3.2. Performance of Composites in Vertical Flame Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Gloc, M.; Kulesza, M.; Kowalski, M.; Krauze, S.; Lewandowska, M. Flammability, mechanical properties and structure of rigid polyurethane foams with different types of carbon reinforcing materials. Compos. Struct. 2016, 140, 67–76. [Google Scholar] [CrossRef]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Xu, C. (Charles) Depolymerization of lignins and their applications for the preparation of polyols and rigid polyurethane foams: A review. Renew. Sustain. Energy Rev. 2016, 60, 317–329. [Google Scholar] [CrossRef]

- Laufer, G.; Kirkland, C.; Cain, A.A.; Grunlan, J.C. Clay–Chitosan Nanobrick Walls: Completely Renewable Gas Barrier and Flame-Retardant Nanocoatings. ACS Appl. Mater. Interfaces 2012, 4, 1643–1649. [Google Scholar] [CrossRef]

- Estravís, S.; Tirado-Mediavilla, J.; Santiago-Calvo, M.; Ruiz-Herrero, J.L.; Villafañe, F.; Rodríguez-Pérez, M.Á. Rigid polyurethane foams with infused nanoclays: Relationship between cellular structure and thermal conductivity. Eur. Polym. J. 2016, 80, 1–15. [Google Scholar] [CrossRef]

- Wang, S.; Chen, H.; Liu, N. Ignition of expandable polystyrene foam by a hot particle: An experimental and numerical study. J. Hazard. Mater. 2015, 283, 536–543. [Google Scholar] [CrossRef] [PubMed]

- Slezak, F.B.; Stallings, J.P.; Rose, I. Chlorinated Xylene Derivatives for Flame-Retardant Rigid Polyurethane Foams. Ind. Eng. Chem. Prod. Res. 1964, 3, 292–294. [Google Scholar] [CrossRef]

- Ye, L.; Meng, X.-Y.; Ji, X.; Li, Z.-M.; Tang, J.-H. Synthesis and characterization of expandable graphite–poly(methyl methacrylate) composite particles and their application to flame retardation of rigid polyurethane foams. Polym. Degrad. Stab. 2009, 94, 971–979. [Google Scholar] [CrossRef]

- Shi, L.; Li, Z.-M.; Xie, B.-H.; Wang, J.-H.; Tian, C.-R.; Yang, M.-B. Flame retardancy of different-sized expandable graphite particles for high-density rigid polyurethane foams. Polym. Int. 2006, 55, 862–871. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.; Wang, W.; Qian, L. Preparation and characterization of surface-modified ammonium polyphosphate and its effect on the flame retardancy of rigid polyurethane foam. J. Appl. Polym. Sci. 2017, 134, 45369. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Nando, G.B.; Naik, Y.P.; Singha, N.K. Halogen-free flame retardant PUF: Effect of melamine compounds on mechanical, thermal, and flame retardant properties. Polym. Degrad. Stab. 2010, 95, 1138–1145. [Google Scholar] [CrossRef]

- Munschy, C.; Olivier, N.; Veyrand, B.; Marchand, P. Occurrence of legacy and emerging halogenated organic contaminants in marine shellfish along French coasts. Chemosphere 2015, 118, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Abe, F.R.; de Oliveira, A.Á.S.; Marino, R.V.; Rialto, T.C.R.; Oliveira, D.P.; Dorta, D.J. A comparison of the developmental toxicity of brominated and halogen-free flame retardant on zebrafish. Ecotoxicol. Environ. Saf. 2021, 208, 111745. [Google Scholar] [CrossRef] [PubMed]

- Richardson, S.D.; Kimura, S.Y. Water Analysis: Emerging Contaminants and Current Issues. Anal. Chem. 2019, 77, 3807–3838. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Yu, B.; Song, P.; Maluk, C.; Wang, H. Surface-coating engineering for flame retardant flexible polyurethane foams: A critical review. Compos. Part B Eng. 2019, 176, 107185. [Google Scholar] [CrossRef]

- Zhu, M.; Ma, Z.; Liu, L.; Zhang, J.; Huo, S.; Song, P. Recent advances in fire-retardant rigid polyurethane foam. J. Mater. Sci. Technol. 2022, 112, 315–328. [Google Scholar] [CrossRef]

- Sapalidis, A.A.; Katsaros, F.K.; Kanellopoulos, N.K. PVA/Montmorillonite Nanocomposites: Development and Properties. In Nanocomposites and Polymers with Analytical Methods; InTech: London, UK, 2011. [Google Scholar]

- Bee, S.-L.; Abdullah, M.A.A.; Bee, S.-T.; Sin, L.T.; Rahmat, A.R. Polymer nanocomposites based on silylated-montmorillonite: A review. Prog. Polym. Sci. 2018, 85, 57–82. [Google Scholar] [CrossRef]

- Callister, W.D., Jr.; Rethwisch, D.G. Ciência e Engenharia de Materiais: Uma Introdução, 8th ed.; LTC: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- Ruiz-Hitzky, E.; Darder, M.; Fernandes, F.M.; Wicklein, B.; Alcântara, A.C.S.; Aranda, P. Fibrous clays based bionanocomposites. Prog. Polym. Sci. 2013, 38, 1392–1414. [Google Scholar] [CrossRef]

- Ruiz-Hitzky, E.; Aranda, P.; Álvarez, A.; Santarén, J.; Esteban-Cubillo, A. Advanced Materials and New Applications of Sepiolite and Palygorskite. In Developments in Clay Science; Elsevier: Amsterdam, The Netherlands, 2011; Volume 3, pp. 393–452. ISBN 9780444536075. [Google Scholar]

- Shmuradko, V.T.; Panteleenko, F.I.; Reut, O.P.; Panteleenko, E.F.; Kirshina, N.V. Composition, structure, and property formation of heat insulation fire- and heat-reflecting materials based on vermiculite for industrial power generation. Refract. Ind. Ceram. 2012, 53, 254–258. [Google Scholar] [CrossRef]

- Brindley, G.W.; Brown, G. Crystal Structures of Clay Minerals and their X-Ray Identification; Mineralogical Society of Great Britain and Ireland: London, UK, 1980. [Google Scholar]

- Hillier, S.; Marwa, E.M.M.; Rice, C.M. On the mechanism of exfoliation of ‘Vermiculite’. Clay Miner. 2013, 48, 563–582. [Google Scholar] [CrossRef]

- Beal, B.; Selby, A.; Atwater, C.; James, C.; Viens, C.; Almquist, C. A Comparison of Thermal and Mechanical Properties of Clay Bricks Prepared with Three Different Pore-Forming Additives: Vermiculite, Wood Ash, and Sawdust. Environ. Prog. Sustain. Energy 2019, 38, 13150. [Google Scholar] [CrossRef]

- Wang, S.; Gainey, L.; Marinelli, J.; Deer, B.; Wang, X.; Mackinnon, I.D.R.; Xi, Y. Effects of vermiculite on in-situ thermal behavior, microstructure, physical and mechanical properties of fired clay bricks. Constr. Build. Mater. 2022, 316, 125828. [Google Scholar] [CrossRef]

- Tjong, S.C. Structural and mechanical properties of polymer nanocomposites. Mater. Sci. Eng. R Rep. 2006, 53, 73–197. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-layered silicate nanocomposites: Preparation, properties and uses of a new class of materials. Mater. Sci. Eng. R Rep. 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Júnior, R.M.S.; de Oliveira, T.A.; Araque, L.M.; Alves, T.S.; de Carvalho, L.H.; Barbosa, R. Thermal behavior of biodegradable bionanocomposites: Influence of bentonite and vermiculite clays. J. Mater. Res. Technol. 2019, 8, 3234–3243. [Google Scholar] [CrossRef]

- Becker, F.G.; Cleary, M.; Team, R.M.; Holtermann, H.; The, D.; Agenda, N.; Science, P.; Sk, S.K.; Hinnebusch, R.; Hinnebusch, A.R. Standard Test Method for Measuring the Comparative Burning Characteristics. Syria Stud. 2015, 7, 37–72. [Google Scholar]

- Wang, H.; Li, T.-T.; Ren, H.; Peng, H.; Huang, S.-Y.; Lin, Q.; Lin, J.-H.; Lou, C.-W. Expanded Vermiculite-Filled Polyurethane Foam-Core Bionic Composites: Preparation and Thermal, Compression, and Dynamic Cushion Properties. Polymers 2019, 11, 1028. [Google Scholar] [CrossRef]

- Meng, D.; Liu, X.; Wang, S.; Sun, J.; Li, H.; Wang, Z.; Gu, X.; Zhang, S. Self-healing polyelectrolyte complex coating for flame retardant flexible polyurethane foam with enhanced mechanical property. Compos. Part B Eng. 2021, 219, 108886. [Google Scholar] [CrossRef]

- Wang, W.; Pan, Y.; Pan, H.; Yang, W.; Liew, K.M.; Song, L.; Hu, Y. Synthesis and characterization of MnO2 nanosheets based multilayer coating and applications as a flame retardant for flexible polyurethane foam. Compos. Sci. Technol. 2016, 123, 212–221. [Google Scholar] [CrossRef]

- Kirbaş, İ. Investigation of the internal structure, combustion, and thermal resistance of the rigid polyurethane materials reinforced with vermiculite. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- Miedzińska, K.; Członka, S.; Strąkowska, A.; Strzelec, K. Vermiculite Filler Modified with Casein, Chitosan, and Potato Protein as a Flame Retardant for Polyurethane Foams. Int. J. Mol. Sci. 2021, 22, 10825. [Google Scholar] [CrossRef]

- Mahfuz, H.; Rangari, V.K.; Islam, M.S.; Jeelani, S. Fabrication, synthesis and mechanical characterization of nanoparticles infused polyurethane foams. Compos. Part A Appl. Sci. Manuf. 2004, 35, 453–460. [Google Scholar] [CrossRef]

- Xia, Z.; Wang, Z. Rigid polyurethane/expanded vermiculite/ melamine phenylphosphate composite foams with good flame retardant and mechanical properties. E-Polymers 2019, 19, 563–573. [Google Scholar] [CrossRef]

- Harikrishnan, G.; Umasankar Patro, T.; Khakhar, D.V. Reticulated vitreous carbon from polyurethane foam–clay composites. Carbon N. Y. 2007, 45, 531–535. [Google Scholar] [CrossRef]

- Han, S.; Zhu, X.; Chen, F.; Chen, S.; Liu, H. Flame-retardant system for rigid polyurethane foams based on diethyl bis(2-hydroxyethyl)aminomethyl phosphonate and in-situ exfoliated clay. Polym. Degrad. Stab. 2020, 177, 109178. [Google Scholar] [CrossRef]

- Cao, X.; James Lee, L.; Widya, T.; Macosko, C. Polyurethane/clay nanocomposites foams: Processing, structure and properties. Polymer 2005, 46, 775–783. [Google Scholar] [CrossRef]

- Zhang, X.-S.; Xia, Y.-Z.; Shi, M.-W.; Yan, X. The flame retardancy of alginate/flame retardant viscose fibers investigated by vertical burning test and cone calorimeter. Chin. Chem. Lett. 2018, 29, 489–492. [Google Scholar] [CrossRef]

- Rabello, L.G.; Carlos da Conceição Ribeiro, R. A novel vermiculite/ vegetable polyurethane resin-composite for thermal insulation eco-brick production. Compos. Part B Eng. 2021, 221, 109035. [Google Scholar] [CrossRef]

- Li, T.-T.; Liu, P.; Wang, H.; Dai, W.; Wang, J.; Wang, Z.; Shiu, B.-C.; Lou, C.-W.; Lin, J.-H. Preparation and characteristics of flexible polyurethane foam filled with expanded vermiculite powder and concave-convex structural panel. J. Mater. Res. Technol. 2021, 12, 1288–1302. [Google Scholar] [CrossRef]

- Yan, L.; Fu, L.; Chen, Y.; Tian, H.; Xiang, A.; Rajulu, A.V. Improved thermal stability and flame resistance of flexible polyimide foams by vermiculite reinforcement. J. Appl. Polym. Sci. 2017, 134, 2–8. [Google Scholar] [CrossRef]

| Samples | Polyol | Isocyanate | VMT |

|---|---|---|---|

| PU/VMT 0 | 476.19 g | 523.81 g | - |

| PU/VMT 5 | 476.19 g | 523.81 g | 5% |

| PU/VMT 10 | 476.19 g | 523.81 g | 10% |

| PU/VMT 15 | 476.19 g | 523.81 g | 15% |

| PU/VMT 20 | 476.19 g | 523.81 g | 20% |

| Sample | Weight Loss (%) | Temperature Range (°C) | Maximum Degradation Temperature (°C) | The Residue (%) |

|---|---|---|---|---|

| PU/VMT0% | 1.07% | 25–86 °C | 47 °C | 9.10% |

| 6.83% | 86–225 °C | 182 °C | ||

| 69.34% | 225–425 °C | 310 °C | ||

| 14.77% | 425–985 °C | 468 °C | ||

| PU/VMT5% | 3.02% | 25–99 °C | 47 °C | 9.93% |

| 4.42% | 99–188 °C | 157 °C | ||

| 64.76% | 188–422 °C | 312 °C | ||

| 17.88% | 422–988 °C | 459 °C | ||

| PU/VMT10% | 3.02% | 21–96 °C | 41 °C | 13.72% |

| 4.42% | 96–196 °C | 153 °C | ||

| 64.76% | 196–417 °C | 314 °C | ||

| 17.88% | 417–982 °C | 461 °C | ||

| PU/VMT15% | 3.02% | 24–85 °C | 46 °C | 22.53% |

| 4.42% | 85–195 °C | 164 °C | ||

| 64.76% | 195–421 °C | 311 °C | ||

| 17.88% | 421–987 °C | 458 °C | ||

| PU/VMT20% | 3.02% | 28–86 °C | 40 °C | 23.53% |

| 4.42% | 86–197 °C | 160 °C | ||

| 64.76% | 197–426 °C | 314 °C | ||

| 17.88% | 426–983 °C | 454 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, L.R.P.S.T.; Alves, M.D.T.C.; Honorio, L.M.C.; Moraes, A.I.; Silva-Filho, E.C.; Peña-Garcia, R.; Furtini, M.B.; da Silva, D.A.; Osajima, J.A. Polyurethane/Vermiculite Foam Composite as Sustainable Material for Vertical Flame Retardant. Polymers 2022, 14, 3777. https://doi.org/10.3390/polym14183777

Alves LRPST, Alves MDTC, Honorio LMC, Moraes AI, Silva-Filho EC, Peña-Garcia R, Furtini MB, da Silva DA, Osajima JA. Polyurethane/Vermiculite Foam Composite as Sustainable Material for Vertical Flame Retardant. Polymers. 2022; 14(18):3777. https://doi.org/10.3390/polym14183777

Chicago/Turabian StyleAlves, Lívia R. P. Silva Tenório, Márcio Davi Tenório C. Alves, Luzia M. Castro Honorio, Alan I. Moraes, Edson C. Silva-Filho, Ramón Peña-Garcia, Marcelo B. Furtini, Durcilene A. da Silva, and Josy A. Osajima. 2022. "Polyurethane/Vermiculite Foam Composite as Sustainable Material for Vertical Flame Retardant" Polymers 14, no. 18: 3777. https://doi.org/10.3390/polym14183777

APA StyleAlves, L. R. P. S. T., Alves, M. D. T. C., Honorio, L. M. C., Moraes, A. I., Silva-Filho, E. C., Peña-Garcia, R., Furtini, M. B., da Silva, D. A., & Osajima, J. A. (2022). Polyurethane/Vermiculite Foam Composite as Sustainable Material for Vertical Flame Retardant. Polymers, 14(18), 3777. https://doi.org/10.3390/polym14183777