The Use of New Waste-Based Plasticizer Made from Modified Used Palm Oil for Non-Glutinous Thermoplastic Starch Foam

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

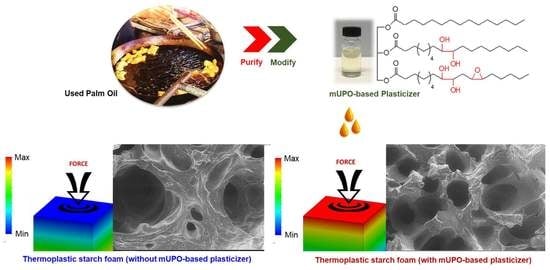

2.1.1. Preparation of Modified Used Palm Oil (mUPO)-Based Plasticizer

2.1.2. Preparation of Non-Glutinous Starch Foam

2.2. Characterizations

3. Results

3.1. Characteristic of Modified Used Palm Oil (mUPO)

3.2. Characteristic of Non-Glutinous Thermoplastic Starch Foam

3.2.1. The Shrinkage of Non-Glutinous Thermoplastic Starch Foam

3.2.2. The Moisture Absorption of Non-Glutinous Thermoplastic Starch Foam

3.2.3. The Mechanical Properties of Non-Glutinous Thermoplastic Starch Foam

Impact Strength

Flexural Test

3.2.4. The Morphology of Non-Glutinous Thermoplastic Starch Foam

3.2.5. The Thermal Properties of the Thermoplastic Starch Foam

DSC Analysis

TGA Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tomin, M.; Kmetty, Á. Polymer Foams as Advanced Energy Absorbing Materials for Sports Applications—A Review. J. Appl. Polym. Sci. 2022, 139, 51714. [Google Scholar] [CrossRef]

- Barbosa, J.V.; Martins, J.; Carvalho, L.; Bastos, M.M.S.M.; Magalhães, F.D. Effect of Peroxide Oxidation on the Expansion of Potato Starch Foam. Ind. Crops Prod. 2019, 137, 428–435. [Google Scholar] [CrossRef]

- Sun, Q.; Huang, G.; Ji, J.; Zhang, C. Preparation of Poly(Butylene Succinate)(PBS) Foaming Materials. Adv. Mater. Res. 2011, 287–290, 1805–1810. [Google Scholar] [CrossRef]

- Cruz-Tirado, J.P.; Barros Ferreira, R.S.; Lizárraga, E.; Tapia-Blácido, D.R.; Silva, N.C.C.; Angelats-Silva, L.; Siche, R. Bioactive Andean Sweet Potato Starch-Based Foam Incorporated with Oregano or Thyme Essential Oil. Food Packag. Shelf Life 2020, 23, 100457. [Google Scholar] [CrossRef]

- Bergel, B.F.; da Luz, L.M.; Santana, R.M.C. Comparative Study of the Influence of Chitosan as Coating of Thermoplastic Starch Foam from Potato, Cassava and Corn Starch. Prog. Org. Coat. 2017, 106, 27–32. [Google Scholar] [CrossRef]

- Zink, J.I.; Roth, A.; Junker, N.; Windhab, E.J. Native Corn and Potato Starch as CO2 Gas Bubble Nucleation Agent for Low-Temperature High-Pressure Foaming Applications. Chem. Eng. J. Adv. 2022, 9, 100211. [Google Scholar] [CrossRef]

- Bergel, B.F.; Araujo, L.L.; Santana, R.M.C. Effects of the Addition of Cotton Fibers and Cotton Microfibers on the Structure and Mechanical Properties of Starch Foams Made from Potato Starch. Carbohydr. Polym. Technol. Appl. 2021, 2, 100167. [Google Scholar] [CrossRef]

- Bergel, B.F.; Dias Osorio, S.; da Luz, L.M.; Santana, R.M.C. Effects of Hydrophobized Starches on Thermoplastic Starch Foams Made from Potato Starch. Carbohydr. Polym. 2018, 200, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Teng, Z.; Huang, R.; Catchmark, J.M. Biodegradable Starch/Chitosan Foam via Microwave Assisted Preparation: Morphology and Performance Properties. Polymers 2020, 12, 2612. [Google Scholar] [CrossRef] [PubMed]

- Tseng, W.J.; Wu, P.-S. Macroporous Gibbsite Foams Prepared from Particle-Stabilized Emulsions Using Corn Starch and Agar as Binders. Ceram. Int. 2012, 38, 4461–4465. [Google Scholar] [CrossRef]

- Polat, S.; Uslu, M.-K.; Aygün, A.; Certel, M. The Effects of the Addition of Corn Husk Fibre, Kaolin and Beeswax on Cross-Linked Corn Starch Foam. J. Food Eng. 2013, 116, 267–276. [Google Scholar] [CrossRef]

- Machado, C.M.; Benelli, P.; Tessaro, I.C. Effect of Acetylated Starch on the Development of Peanut Skin-Cassava Starch Foams. Int. J. Biol. Macromol. 2020, 165, 1706–1716. [Google Scholar] [CrossRef]

- Engel, J.B.; Luchese, C.L.; Tessaro, I.C. How Are the Properties of Biocomposite Foams Influenced by the Substitution of Cassava Starch for Its Residual Sources? Food Hydrocoll. 2021, 118, 106790. [Google Scholar] [CrossRef]

- Kaisangsri, N.; Kowalski, R.J.; Kerdchoechuen, O.; Laohakunjit, N.; Ganjyal, G.M. Cellulose Fiber Enhances the Physical Characteristics of Extruded Biodegradable Cassava Starch Foams. Ind. Crops Prod. 2019, 142, 111810. [Google Scholar] [CrossRef]

- Cha, J.-Y. Effects of Different Plasticizers on Some Properties of Biodegradable Starch-Based Foams. J. Biosyst. Eng. 2003, 28, 143–150. [Google Scholar] [CrossRef]

- Machado, C.M.; Longhi, E.M.; Spada, J.C.; Tessaro, I.C. Effect of Broken Rice Flour Addition on Cassava Starch-Based Foams. Starch-Stärke 2018, 70, 1700191. [Google Scholar] [CrossRef]

- Williams, V.R.; Wu, W.-T.; Tsai, H.Y.; Bates, H.G. Rice Starch, Varietal Differences in Amylose Content of Rice Starch. J. Agric. Food Chem. 1958, 6, 47–48. [Google Scholar] [CrossRef]

- Khonakdar, H.A.; Morshedian, J.; Mehrabzadeh, M.; Wagenknecht, U.; Jafari, S.H. Thermal and Shrinkage Behaviour of Stretched Peroxide-Crosslinked High-Density Polyethylene. Eur. Polym. J. 2003, 39, 1729–1734. [Google Scholar] [CrossRef]

- Mali, S.; Grossmann, M.V.E.; García, M.A.; Martino, M.N.; Zaritzky, N.E. Effects of Controlled Storage on Thermal, Mechanical and Barrier Properties of Plasticized Films from Different Starch Sources. J. Food Eng. 2006, 75, 453–460. [Google Scholar] [CrossRef]

- Silva Nykänen, V.P.; Härkönen, O.; Nykänen, A.; Hiekkataipale, P.; Ruokolainen, J.; Ikkala, O. An Efficient and Stable Star-Shaped Plasticizer for Starch: Cyclic Phosphazene with Hydrogen Bonding Aminoethoxy Ethanol Side Chains. Green Chem. 2014, 16, 4339–4350. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Effect of Plasticizer Type and Concentration on Tensile, Thermal and Barrier Properties of Biodegradable Films Based on Sugar Palm (Arenga Pinnata) Starch. Polymers 2015, 7, 1106–1124. [Google Scholar] [CrossRef]

- Kahvand, F.; Fasihi, M. Microstructure and Physical Properties of Thermoplastic Corn Starch Foams as Influenced by Polyvinyl Alcohol and Plasticizer Contents. Int. J. Biol. Macromol. 2020, 157, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Tarique, J.; Sapuan, S.M.; Khalina, A. Effect of Glycerol Plasticizer Loading on the Physical, Mechanical, Thermal, and Barrier Properties of Arrowroot (Maranta Arundinacea) Starch Biopolymers. Sci. Rep. 2021, 11, 13900. [Google Scholar] [CrossRef] [PubMed]

- Prasertsan, S.; Prasertsan, P. Biomass Residues from Palm Oil Mills in Thailand: An Overview on Quantity and Potential Usage. Biomass Bioenergy 1996, 11, 387–395. [Google Scholar] [CrossRef]

- Saifuddin, N.M.; Wen, C.; Zhan, W.; Ning, X. Palm Oil Based Polyols for Polyurethane Foams Application. In Proceedings of the International Conference on Advances in Renewable Energy Technologies, Putrajaya, Malaysia, 6–7 July 2010. [Google Scholar]

- Kairytė, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vaitkus, S.; Pundienė, I. Cleaner Production of Polyurethane Foam: Replacement of Conventional Raw Materials, Assessment of Fire Resistance and Environmental Impact. J. Clean. Prod. 2018, 183, 760–771. [Google Scholar] [CrossRef]

- Sukhawipat, N.; Saengdee, L.; Pasetto, P.; Junthip, J.; Martwong, E. Sustainable Rigid Polyurethane Foam from Wasted Palm Oil and Water Hyacinth Fiber Composite—A Green Sound-Absorbing Material. Polymers 2022, 14, 201. [Google Scholar] [CrossRef]

- Suwan, A.; Sukhawipat, N.; Uthaipan, N.; Saetung, A.; Saetung, N. Some Properties of Experimental Particleboard Manufactured from Waste Bamboo Using Modified Recycled Palm Oil as Adhesive. Prog. Org. Coat. 2020, 149, 105899. [Google Scholar] [CrossRef]

- Sukhawipat, N.; Yingshataporn-a-nan, T.; Minanandana, T.; Puksuwan, K.; Saengdee, L.; Nakaramontri, Y.; Sosa, N.; Saetung, N. Effects of Water Hyacinth Fiber Size on Sound Absorption Properties of Advanced Recycled Palm Oil-Based Polyurethane Foam Composite. Mater. Today Proc. 2021, 52, 2409–2413. [Google Scholar] [CrossRef]

- Riyapan, D.; Saetung, A.; Saetung, N. A Novel Rigid PU Foam Based on Modified Used Palm Oil as Sound Absorbing Material. J. Polym. Environ. 2019, 27, 1693–1708. [Google Scholar] [CrossRef]

- Boonchaisuriya, A.; Chungsiriporn, J. Biodegradable Foams Based on Cassava Starch by Compression Process. In Proceedings of the 5th PSU-UNS International Conference on Engineering and Technology, Phuket, Thailand, 2–3 May 2011; ICET: Songkhla, Thailand, 2011; pp. 71–74. [Google Scholar]

- Hadi, P.; Babaluo, A. Additives Effects on the Shrinkage Behavior of PVC Sheets. J. Appl. Polym. Sci. 2007, 106, 3967–3974. [Google Scholar] [CrossRef]

- Andreuccetti, C.; Carvalho, R.A.; Grosso, C.R.F. Effect of Hydrophobic Plasticizers on Functional Properties of Gelatin-Based Films. Food Res. Int. 2009, 42, 1113–1121. [Google Scholar] [CrossRef]

- Godwin, A.D. Plasticizers. In View on Science Direct Applied Polymer Science: 21st Century; Craver, C.D., Carraher, C.E.B.T., Eds.; Pergamon: Oxford, UK, 2000; pp. 157–175. ISBN 978-0-08-043417-9. [Google Scholar]

- Kormin, S.; Kormin, F.; Beg, M.D.H. Effect of Plasticizer on Physical and Mechanical Properties of Ldpe/Sago Starch Blend. J. Phys. Conf. Ser. 2019, 1150, 12032. [Google Scholar] [CrossRef]

- Tian, K.; Darvell, B.W. Determination of the Flexural Modulus of Elasticity of Orthodontic Archwires. Dent. Mater. 2010, 26, 821–829. [Google Scholar] [CrossRef]

- Wypych, G. 13—Testing Methods of Weathered Specimen. In Handbook of Material Weathering; Wypych, G.B.T.-H., Sixth, E., Eds.; ChemTec Publishing: Scarborough, ON, Canada, 2018; pp. 293–367. ISBN 978-1-927885-31-4. [Google Scholar]

- Watkinson, K.; Mohsen, R. Effect of Concentration and Type of Plasticizer on Some Physical Properties of Poly(Vinyl Chloride). J. Appl. Polym. Sci. 1982, 27, 3455–3460. [Google Scholar] [CrossRef]

- Schmitt, H.; Creton, N.; Prashantha, K.; Soulestin, J.; Lacrampe, M.-F.; Krawczak, P. Preparation and Characterization of Plasticized Starch/Halloysite Porous Nanocomposites Possibly Suitable for Biomedical Applications. J. Appl. Polym. Sci. 2015, 132, 41341. [Google Scholar] [CrossRef]

- Özeren, H.D.; Olsson, R.T.; Nilsson, F.; Hedenqvist, M.S. Prediction of Plasticization in a Real Biopolymer System (Starch) Using Molecular Dynamics Simulations. Mater. Des. 2020, 187, 108387. [Google Scholar] [CrossRef]

- Yin, D.; Xiang, A.; Li, Y.; Qi, H.; Tian, H.; Fan, G. Effect of Plasticizer on the Morphology and Foaming Properties of Poly(Vinyl Alcohol) Foams by Supercritical CO2 Foaming Agents. J. Polym. Environ. 2019, 27, 2878–2885. [Google Scholar] [CrossRef]

- Zhang, Y.; Rempel, C.; Liu, Q. Thermoplastic Starch Processing and Characteristics—A Review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1353–1370. [Google Scholar] [CrossRef]

- Sukhawipat, N.; Saetung, N.; Pasetto, P.; Pilard, J.-F.; Bistac, S.; Saetung, A. A Novel High Adhesion Cationic Waterborne Polyurethane for Green Coating Applications. Prog. Org. Coat. 2020, 148, 105854. [Google Scholar] [CrossRef]

- Bilal, S.; Gul, S.; Shah, A.-H.A. Calculation of Activation Energy of Degradation of Polyaniline-Dodecylbenzene Sulfonic Acid Salts via TGA. J. Sci. Innov. Res. 2013, 2, 673–684. [Google Scholar]

- Sukhawipat, N.; Raksanak, W.; Kalkornsurapranee, E.; Saetung, A.; Saetung, N. A New Hybrid Waterborne Polyurethane Coating Synthesized from Natural Rubber and Rubber Seed Oil with Grafted Acrylate. Prog. Org. Coat. 2020, 141, 105554. [Google Scholar] [CrossRef]

- Sukhawipat, N.; Saengdee, L.; Pasetto, P. Caesalpinia Sappan, L. Wood Fiber: Bio-Reinforcement for Polybutylene Succinate-Based Biocomposite Film. Cellulose 2022, 29, 3375–3387. [Google Scholar] [CrossRef]

| Code Name. | Starch (wt%) | PVOH (wt%) | Baking Powder (phr) | mUPO (phr) |

|---|---|---|---|---|

| SF_mUPO_0phr | 92.5 | 7.5 | 7.5 | 0 |

| SF_mUPO_3phr | 92.5 | 7.5 | 7.5 | 3 |

| SF_mUPO_6phr | 92.5 | 7.5 | 7.5 | 6 |

| SF_mUPO_9phr * | 92.5 | 7.5 | 7.5 | 9 |

| Code Name | Physical Appearance | Properties | Results |

|---|---|---|---|

| UPO |  | Iodine number | 40.1 |

| OH value (mgKOH/g) | 0 | ||

| Acid number (mgKOH/g) | 1.41 | ||

| a* Mn (g/mol) | 2841 | ||

| a* Mw (g/mol) | 3074 | ||

| a* PDI | 1.08 | ||

| mUPO |  | Iodine number | 0.51 |

| OH value (mgKOH/g) | 192.19 | ||

| Acid number (mgKOH/g) | 1.76 | ||

| a* Mn (g/mol) | 3073 | ||

| a* Mw (g/mol) | 3150 | ||

| a* PDI | 1.02 |

| Code Name | TGA/DTG | DSC | |||

|---|---|---|---|---|---|

| Main Thermal Decomposition | Residual Mass (%) | Tg (°C) | |||

| Tmax (°C) | Decomposition (%) | Ea of Degradation (kJ/mol) | |||

| SF_mUPO_0phr | 294.17 | 49.03 | 0.88 | 23.86 | 70.83 |

| SF_mUPO_3phr | 294.67 | 48.38 | 1.05 | 23.85 | 66.83 |

| SF_mUPO_6phr | 295.00 | 48.02 | 7.88 | 23.65 | 66.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junthip, J.; Chaipalee, N.; Sangsorn, Y.; Maspornpat, C.; Jitcharoen, J.; Limrungruengrat, S.; Chotchuangchutchaval, T.; Martwong, E.; Sukhawipat, N. The Use of New Waste-Based Plasticizer Made from Modified Used Palm Oil for Non-Glutinous Thermoplastic Starch Foam. Polymers 2022, 14, 3997. https://doi.org/10.3390/polym14193997

Junthip J, Chaipalee N, Sangsorn Y, Maspornpat C, Jitcharoen J, Limrungruengrat S, Chotchuangchutchaval T, Martwong E, Sukhawipat N. The Use of New Waste-Based Plasticizer Made from Modified Used Palm Oil for Non-Glutinous Thermoplastic Starch Foam. Polymers. 2022; 14(19):3997. https://doi.org/10.3390/polym14193997

Chicago/Turabian StyleJunthip, Jatupol, Natchapat Chaipalee, Yada Sangsorn, Chanannat Maspornpat, Juthamas Jitcharoen, Sittichai Limrungruengrat, Thana Chotchuangchutchaval, Ekkachai Martwong, and Nathapong Sukhawipat. 2022. "The Use of New Waste-Based Plasticizer Made from Modified Used Palm Oil for Non-Glutinous Thermoplastic Starch Foam" Polymers 14, no. 19: 3997. https://doi.org/10.3390/polym14193997

APA StyleJunthip, J., Chaipalee, N., Sangsorn, Y., Maspornpat, C., Jitcharoen, J., Limrungruengrat, S., Chotchuangchutchaval, T., Martwong, E., & Sukhawipat, N. (2022). The Use of New Waste-Based Plasticizer Made from Modified Used Palm Oil for Non-Glutinous Thermoplastic Starch Foam. Polymers, 14(19), 3997. https://doi.org/10.3390/polym14193997