Hydrothermal Ageing Effect on Reinforcement Efficiency of Nanofibrillated Cellulose/Biobased Poly(butylene succinate) Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Samples’ Processing

2.2. Nanocomposite Preparation

2.3. Water Absorption Studies

2.4. Tensile Tests

2.5. Differential Scanning Calorimetry

2.6. Dynamic Mechanical Thermal Analysis

3. Results

3.1. Water Absorption

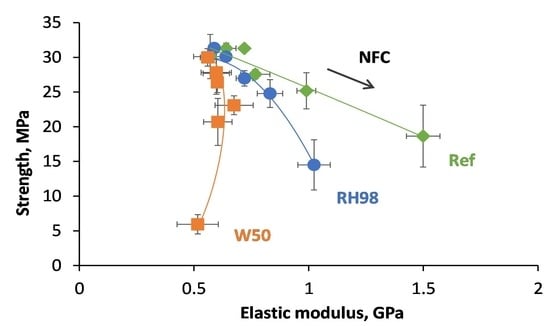

3.2. Tensile Properties

3.3. Calorimetric Properties

3.4. Thermomechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petru, M. Micro- and nanocellulose in polymer composite materials: A review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef]

- Helanto, L.; Matikainen, L.; Talja, R.; Rojas, O.J. Bio-based polymers for sustainable packaging and bio-barriers: A critical review. Bioresources 2019, 14, 4902–4951. [Google Scholar] [CrossRef]

- Kalia, S.; Boufi, S.; Celli, A. Nanofibrillated cellulose: Surface modification and potential applications. Colloid Polym. Sci. 2014, 292, 5–31. [Google Scholar] [CrossRef]

- Tan, Y.; Du, X.; Du, X.; Wang, H.; Cheng, X. Form-stable phase change composites based on nanofibrillated cellulose/polydopamine hybrid aerogels with extremely high energy storage density and improved photothermal conversion efficiency. RSC Adv. 2021, 11, 5712–5721. [Google Scholar] [CrossRef]

- Lee, K.Y.; Tammelin, T.; Schulfter, K.; Kiiskinen, H.; Samela, J.; Bismarck, A. High performance cellulose nanocomposites: Comparing the reinforcing ability of bacterial cellulose and nanofibrillated cellulose. ACS Appl. Mater. Interfaces 2012, 4, 4078–4086. [Google Scholar] [CrossRef] [Green Version]

- Naderi, A. Nanofibrillated cellulose: Properties reinvestigated. Cellulose 2017, 24, 1933–1945. [Google Scholar] [CrossRef]

- Platnieks, O.; Gaidukovs, S.; Thakur, V.K.; Barkane, A.; Beluns, S. Bio-based poly (butylene succinate): Recent progress, challenges and future opportunities. Eur. Polym. J. 2021, 161, 110855. [Google Scholar] [CrossRef]

- Gaidukovs, S.; Platnieks, O.; Gaidukova, G.; Starkova, O.; Barkane, A.; Beluns, S.; Thakur. Understanding the impact of microcrystalline cellulose modification on durability and biodegradation of highly loaded biocomposites for woody like materials applications. J. Polym. Environ. 2021, 1–6. [Google Scholar] [CrossRef]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly (butylene succinate)-based polyesters for biomedical applications: A review. Eur. Polym. J. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.N.; Lee, C.H. A review on properties and application of bio-based poly (butylene succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef]

- Terzopoulou, Z.N.; Papageorgiou, G.Z.; Papadopoulou, E.; Athanassiadou, E.; Reinders, M.; Bikiaris, D.N. Development and study of fully biodegradable composite materials based on poly (butylene succinate) and hemp fibers or hemp shives. Polym. Compos. 2016, 37, 407–421. [Google Scholar] [CrossRef]

- Huang, Z.; Qian, L.; Yin, Q.; Yu, N.; Liu, T.; Tian, D. Biodegradability studies of poly (butylene succinate) composites filled with sugarcane rind fiber. Polym. Test. 2018, 66, 319–326. [Google Scholar] [CrossRef]

- Cho, S.Y.; Lee, M.E.; Kwak, H.W.; Jin, H.J. Surface-modified cellulose nanocrystal-incorporated poly (butylene succinate) nanocomposites. Fibers Polym. 2018, 19, 1395–1402. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Ozola-Davidane, R.; Gagani, A.I.; Starkova, O. Modelling of environmental ageing of polymers and polymer composites—modular and multiscale methods. Polymers 2022, 14, 216. [Google Scholar] [CrossRef]

- Jithin, J.; Cintil, J.; Srirama, B.V.; Lovely, M.P.; Sabu, T.; Srikanth, P. Preparation and characterization of poly (butylene succinate) bionanocomposites reinforced with cellulose nanofiber extracted from helicteres isora plant. J. Renew. Mater. 2016, 4, 351–364. [Google Scholar] [CrossRef]

- Andersons, J.; Kirpluks, M.; Cabulis, U. Reinforcement efficiency of cellulose microfibers for the tensile stiffness and strength of rigid low-density polyurethane foams. Materials 2020, 13, 2725. [Google Scholar] [CrossRef]

- Beluns, S.; Gaidukovs, S.; Platnieks, O.; Gaidukova, G.; Mierina, I.; Grase, L.; Starkova, O.; Brazdausks, P.; Thakur, V.K. From wood and hemp biomass wastes to sustainable nanocellulose foams. Ind. Crop. Prod. 2021, 170, 113780. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syafiq, R.; Sherwani, S.F.K. Nanocellulose reinforced thermoplastic starch (TPS), polylactic acid (PLA), and polybutylene succinate (PBS) for food packaging applications. Front. Chem. 2020, 8, 213. [Google Scholar] [CrossRef]

- Zinge, C.; Kandasubramanian, B. Nanocellulose based biodegradable polymers. Eur. Polym. J. 2020, 133, 109758. [Google Scholar] [CrossRef]

- Platnieks, O.; Sereda, A.; Gaidukovs, S. Adding value to poly (butylene succinate) and nanofibrillated cellulose-based sustainable nanocomposites by applying masterbatch process. Ind. Crop. Prod. 2021, 169, 113669. [Google Scholar] [CrossRef]

- Platnieks, O. Highly Loaded cellulose/poly (butylene succinate) sustainable composites for woody-like advanced materials application. Molecules 2020, 25, 121. [Google Scholar] [CrossRef]

- Kim, T.; Jeon, H.; Jegal, J.; Kim, J.H.; Yang, H.; Park, J.; Oh, D.X.; Hwang, S.Y. Trans crystallization behavior and strong reinforcement effect of cellulose nanocrystals on reinforced poly (butylene succinate) nanocomposites. RSC Adv. 2018, 8, 15389–15398. [Google Scholar] [CrossRef] [Green Version]

- Spoljaric, S.; Salminen, A.; Luong, N.D.; Lahtinen, P.; Vartiainen, J.; Tammelin, T.; Seppälä, J. Nanofibrillated cellulose, poly (vinyl alcohol), montmorillonite clay hybrid nanocomposites with superior barrier and thermomechanical properties. Polym. Compos. 2014, 35, 1117–1131. [Google Scholar] [CrossRef]

- Alloin, F.; D’Aprea, A.; Dufresne, A.; El Kissi, N.; Bossard, F. Poly(oxyethylene) and ramie whiskers based nanocomposites: Influence of processing: Extrusion and casting/evaporation. Cellulose 2011, 18, 957–973. [Google Scholar] [CrossRef]

- Platnieks, O.; Gaidukovs, S.; Barkane, A.; Sereda, A.; Gaidukova, G.; Grase, L.; Thakur, V.K.; Filipova, I.; Fridrihsone, V.; Skute, M.; et al. Bio-based poly (butylene succinate)/microcrystalline cellulose/nanofibrillated cellulose-based sustainable polymer composites: Thermo-mechanical and biodegradation studies. Polymers 2020, 12, 1472. [Google Scholar] [CrossRef] [PubMed]

- Kargarzadeh, H.; Mariano, M.; Huang, J.; Lin, N.; Ahmad, I.; Dufresne, A.; Thomas, S. Recent developments on nanocellulose reinforced polymer nanocomposites: A review. Polymer 2017, 132, 368–393. [Google Scholar] [CrossRef]

- Ludueña, L.N.; Fortunati, E.; Morán, J.I.; Alvarez, V.A.; Cyras, V.P.; Puglia, D.; Manfredi, L.B.; Pracella, M. Preparation and characterization of polybutylene-succinate/poly(ethylene-glycol)/cellulose nanocrystals ternary composites. J. Appl. Polym. Sci. 2016, 133, 43302. [Google Scholar] [CrossRef]

- Peng, N.; Huang, D.; Gong, C.; Wang, J.; Zhou, J.; Chang, C. Controlled arrangement of nanocellulose in polymeric matrix: From reinforcement to functionality. ACS Nano 2020, 14, 16169–16179. [Google Scholar] [CrossRef] [PubMed]

- Lajarrige, A.; Gontard, N.; Gaucel, S.; Peyron, S. Evaluation of the food contact suitability of aged bio-nanocomposite materials dedicated to food packaging applications. Appl. Sci. 2020, 10, 877. [Google Scholar] [CrossRef] [Green Version]

- Bazan, P.; Mierzwiński, D.; Bogucki, R.; Kuciel, S. Bio-based polyethylene composites with natural fiber: Mechanical, thermal, and ageing properties. Materials 2020, 13, 2595. [Google Scholar] [CrossRef] [PubMed]

- Glaskova-Kuzmina, T.; Starkova, O.; Gaidukovs, S.; Platnieks, O.; Gaidukova, G. Durability of biodegradable polymer nanocomposites. Polymers 2021, 13, 3375. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Nakatani, H.; Kobayashi, S.; Song, J.I. Mechanical and thermal properties and water absorption of jute fiber reinforced poly (butylene succinate) biodegradable composites. Adv. Compos. Mater. 2012, 21, 241–258. [Google Scholar] [CrossRef]

- Kamau-Devers, K.; Kortum, Z.; Miller, S.A. Hydrothermal aging of bio-based poly(lactic acid) (PLA) wood polymer composites: Studies on sorption behavior, morphology, and heat conductance. Constr. Build. Mater. 2019, 214, 290–302. [Google Scholar] [CrossRef]

- Mazur, K.; Kuciel, S. Mechanical and hydrothermal aging behaviour of polyhydroxybutyrate-co-valerate (PHBV) composites reinforced by natural fibres. Molecules 2019, 24, 3538. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cosquer, R.; Pruvost, S.; Gouanvé, F. Improvement of barrier properties of biodegradable polybutylene succinate/graphene nanoplatelets nanocomposites prepared by melt process. Membranes 2021, 11, 151. [Google Scholar] [CrossRef] [PubMed]

- Petchwattana, N.; Sanetuntikul, J.; Sriromreun, P.; Narupai, B. Wood plastic composites prepared from biodegradable poly(butylenes succinate) and burma padauk sawdust (pterocarpus macrocarpus): Water absorption kinetics and sunlight exposure investigations. J. Bionic Eng. 2017, 14, 781–790. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion. Oxford; Clarendon Press: Oxford, UK, 1956. [Google Scholar]

- Starkova, O.; Gaidukovs, S.; Platnieks, O.; Barkane, A.; Garkusina, K.; Palitis, E.; Grase, L. Water absorption and hydrothermal ageing of epoxy adhesives reinforced with amino-functionalized graphene oxide nanoparticles. Polym. Degrad. Stab. 2021, 191, 109670. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Nanni, A.; Messori, M. Thermo-mechanical properties and creep modelling of wine lees filled polyamide 11 (PA11) and polybutylene succinate (PBS) bio-composites. Compos. Sci. Technol. 2020, 188, 107974. [Google Scholar] [CrossRef]

- Battegazzore, D.; Noori, A.; Frache, A. Natural wastes as particle filler for poly (lactic acid)-based composites. J. Compos. Mater. 2019, 53, 783–797. [Google Scholar] [CrossRef]

- Jiang, Y.P.; Wu, J.; Zhu, Y. A mesoscopic model for particle-filled composites with network microstructures. Mech. Compos. Mater. 2021, 57, 415–424. [Google Scholar] [CrossRef]

- Nair, S.S.; Zhu, J.Y.; Deng, Y.; Ragauskas, A.J. High performance green barriers based on nanocellulose. Sustain. Chem. Process. 2014, 2, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Lei, Y.; Luo, L.; Kang, Z.; Zhang, J.; Zhang, B. Modified Halpin–Tsai equation for predicting interfacial effect in water diffusion process. Sci. Eng. Compos. Mater. 2021, 28, 180–189. [Google Scholar] [CrossRef]

- Ansari, F.; Galland, S.; Johansson, M.; Plummer, C.J.G.; Berglund, L.A. Cellulose nanofiber network for moisture stable, strong and ductile biocomposites and increased epoxy curing rate. Compos. Part A Appl. Sci. Manuf. 2014, 63, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Nakajima, H.; Dijkstra, P.; Loos, K. The recent developments in biobased polymers toward general and engineering applications: Polymers that are upgraded from biodegradable polymers, analogous to petroleum-derived polymers, and newly developed. Polymers 2017, 9, 523. [Google Scholar] [CrossRef] [PubMed]

- Mysiukiewicz, O.; Kosmela, P.; Barczewski, M.; Hejna, A. Mechanical, thermal and rheological properties of polyethylene-based composites filled with micrometric aluminum powder. Materials 2020, 13, 1242. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bartos, A.; Kócs, J.; Anggono, J.; Móczó, J.; Pukánszky, B. Effect of fiber attrition, particle characteristics and interfacial adhesion on the properties of PP/sugarcane bagasse fiber composites. Polym. Test. 2021, 98, 107189. [Google Scholar] [CrossRef]

- Bhasney, S.M.; Kumar, A.; Katiyar, V. Microcrystalline cellulose, polylactic acid and polypropylene biocomposites and its morphological, mechanical, thermal and rheological properties. Compos. Part B-Eng. 2020, 184, 107717. [Google Scholar] [CrossRef]

- Andersons, J.; Filipova, I.; Kirpluks, M.; Cabulis, U. Evaluation of the apparent interfacial shear strength of nanocellulose/PVA composites. Key Eng. Mater. 2018, 774, 54–59. [Google Scholar] [CrossRef]

- Danyadi, L.; Janecska, T.; Szaboc, Z.; Nagy, G.; Moczo, J.; Pukanszky, B. Wood flour filled PP composites: Compatibilization and adhesion. Compos. Sci. Technol. 2007, 67, 2838–2846. [Google Scholar] [CrossRef] [Green Version]

- Sugiman, S.; Salman, S.; Maryudi, M. Effects of volume fraction on water uptake and tensile properties of epoxy filled with inorganic fillers having different reactivity to water. Mater. Today Commun. 2020, 24, 101360. [Google Scholar] [CrossRef]

- Yasuniwa, M.; Satou, T. Multiple melting behavior of poly (butylene succinate). I. Thermal analysis of melt-crystallized samples. J. Polym. Sci. Pol. Phys. 2002, 40, 2411–2420. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Zhuravlev, E.; Papageorgiou, G.Z.; Bikiaris, D.; Chrissafis, K.; Schick, C. Kinetics of nucleation and crystallization in poly(butylene succinate) nanocomposites. Polymer 2014, 55, 6725–6734. [Google Scholar] [CrossRef]

- Yao, S.F.; Chen, X.T.; Ye, H.M. Investigation of structure and crystallization behavior of poly(butylene succinate) by fourier transform infrared spectroscopy. J. Phys. Chem. B 2017, 121, 9476–9485. [Google Scholar] [CrossRef] [PubMed]

- Auad, M.L.; Contos, V.S.; Nutt, S.; Aranguren, M.I.; Marcovich, N.E. Characterization of nanocellulose- reinforced shape memory polyurethanes. Polym. Int. 2008, 57, 651–659. [Google Scholar] [CrossRef]

- Camarero-Espinosa, S.; Boday, D.J.; Weder, C.; Foster, E.J. Cellulose nanocrystal driven crystallization of poly(d,l-lactide) and improvement of the thermomechanical properties. J. Appl. Polym. Sci. 2015, 132, 41607. [Google Scholar] [CrossRef]

- Rastogi, V.K.; Samyn, P. Novel processing of polyhydroxybutyrate with micro- to nanofibrillated cellulose and effect of fiber morphology on crystallization behaviour of composites. eXPRESS Polym. Lett. 2020, 14, 115–133. [Google Scholar] [CrossRef]

- Jyoti, J.; Singh, P.B.; Arya, A.K.; Dhakate, S.R. Dynamic mechanical properties of multiwall carbon nanotube reinforced ABS composites and their correlation with entanglement density, adhesion, reinforcement and C factor. RSC Adv. 2016, 6, 3997–4006. [Google Scholar] [CrossRef]

- Perotto, G.; Simonutti, R.; Ceseracciu, L.; Mauri, M.; Besghini, D.; Athanassiou, A. Water-induced plasticization in vegetable-based bioplastic films: A structural and thermo-mechanical study. Polymer 2020, 200, 122598. [Google Scholar] [CrossRef]

- Kubat, J.; Rigdhal, M.; Welander, M. Characterization of interfacial interaction in high density polyethylene filled with glass spheres using dynamic mechanical analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

| Sample | NFC wt.% | NFC vol.% | ρ 1, g/cm3 |

|---|---|---|---|

| PBS | 0 | 0 | 1.260 ± 0.0018 |

| 5NFC | 5 | 4.8 | 1.266 ± 0.0025 |

| 10NFC | 10 | 8.0 | 1.273 ± 0.0082 |

| 20NFC | 20 | 16.4 | 1.296 ± 0.0039 |

| 30NFC | 30 | 25.2 | 1.307 ± 0.0164 |

| 50NFC | 50 | 44.1 | 1.326 ± 0.0072 |

| Sample | χ (%) | Tm (°C) | ||||

|---|---|---|---|---|---|---|

| Ref | RH98 | W50 | Ref | RH98 | W50 | |

| PBS | 54.6 | 38.0 | 37.6 | 118 | 118 | 111 |

| 5NFC | 54.7 | 36.8 | 37.5 | 116 | 116 | 113 |

| 10NFC | 49.6 | 36.7 | 34.4 | 115 | 114 | 111 |

| 20NFC | 50.5 | 33.9 | 35.8 | 113 | 114 | 110 |

| 30NFC | 53.6 | 34.3 | 36.3 | 114 | 115 | 110 |

| 50NFC | 43.1 | 32.4 | 39.7 | 117 | 117 | 114 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Starkova, O.; Platnieks, O.; Sabalina, A.; Gaidukovs, S. Hydrothermal Ageing Effect on Reinforcement Efficiency of Nanofibrillated Cellulose/Biobased Poly(butylene succinate) Composites. Polymers 2022, 14, 221. https://doi.org/10.3390/polym14020221

Starkova O, Platnieks O, Sabalina A, Gaidukovs S. Hydrothermal Ageing Effect on Reinforcement Efficiency of Nanofibrillated Cellulose/Biobased Poly(butylene succinate) Composites. Polymers. 2022; 14(2):221. https://doi.org/10.3390/polym14020221

Chicago/Turabian StyleStarkova, Olesja, Oskars Platnieks, Alisa Sabalina, and Sergejs Gaidukovs. 2022. "Hydrothermal Ageing Effect on Reinforcement Efficiency of Nanofibrillated Cellulose/Biobased Poly(butylene succinate) Composites" Polymers 14, no. 2: 221. https://doi.org/10.3390/polym14020221

APA StyleStarkova, O., Platnieks, O., Sabalina, A., & Gaidukovs, S. (2022). Hydrothermal Ageing Effect on Reinforcement Efficiency of Nanofibrillated Cellulose/Biobased Poly(butylene succinate) Composites. Polymers, 14(2), 221. https://doi.org/10.3390/polym14020221