Computational Scale-Up for Flood Fed/Starve Fed Single Screw Extrusion of Polymers

Abstract

:1. Introduction

- -

- Parameters of the optimization task are processed in the coded form,

- -

- Searching the solution of the optimization task is performed from a randomly selected population, which avoids local extremes,

- -

- The rules of selection of population are probabilistic,

- -

- A new area of searching is determined using previous experiences,

- -

- Only the values of the objective function are required for searching the extremes, the derivatives are not needed.

- -

- Can tackle the single scale-up criteria only, e.g., plasticating rate or pumping rate and the single step of the process, e.g., polymer plasticating or melt flow;

- -

- Can take into account only a few geometry or process parameters, e.g., screw rotational speed, screw diameter, screw channel depth, screw length;

- -

- Use the simple mathematical models;

- -

- Are not flexible.

- -

- To consider simultaneously several criteria;

- -

- To select the single parameters or functions as the scale-up criteria;

- -

- To freely choose and define the criteria.

- -

- Simulating the process to have the response data of the reference extruder at a specific set of input data;

- -

- Defining the scale-up criteria;

- -

- Specifing the fixed parameters of the target extruder;

- -

- Performing the scaling-up by minimizing the differences between the selected parameters of the target and reference extruders.

- -

- Ratio of the total/drag flow rate;

- -

- Specific mechanical energy;

- -

- Pressure variation over the unit screw channel;

- -

- Ratio of the screw length required for melting/total screw length (relative melting length);

- -

- Average shear rate;

- -

- Average shear stress;

- -

- Overall vsicous dissipation;

- -

- Average total strain (WATS), which is the measure of mixing degree.

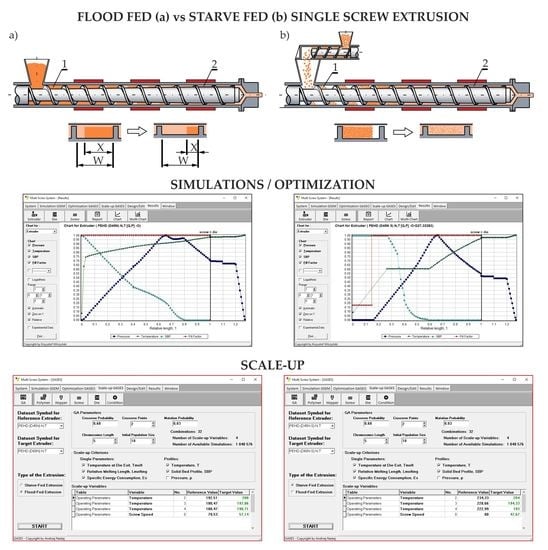

2. Extrusion with Flood Feeding and Metered Feeding

3. Scaling-Up Procedure

4. Scaling-Up

4.1. Research Program

4.2. Scale-Up of Flood Fed Extrusion

4.3. Scale-Up of Starve Fed Extrusion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mitchell, T.M. Machine Learning; McGraw-Hill Series in Computer Science; McGraw-Hill: New York, NY, USA, 1997; ISBN 9780070428072. [Google Scholar]

- Antoniou, A.; Murray, W.; Wright, M.H. Practical Optimization: Algorithms and Engineering Applications; Springer: New York, NY, USA, 2007; ISBN 9780387711065. [Google Scholar]

- Korte, B.; Vygen, J. Combinatorial Optimization; Algorithms and Combinatorics; Springer: Berlin/Heidelberg, Germany, 2012; Volume 21, ISBN 9783642244872. [Google Scholar]

- Ponce-Ortega, J.M.; Hernández-Pérez, L.G. Optimization of Process Flowsheets through Metaheuristic Techniques; Springer International Publishing: Cham, Switzerland, 2019; ISBN 9783319917214. [Google Scholar]

- Bianchi, L.; Dorigo, M.; Gambardella, L.M.; Gutjahr, W.J. A Survey on Metaheuristics for Stochastic Combinatorial Optimization. Nat. Comput. 2009, 8, 239–287. [Google Scholar] [CrossRef] [Green Version]

- Nesmachnow, S. An Overview of Metaheuristics: Accurate and Efficient Methods for Optimisation. Int. J. Metaheuristics 2014, 3, 320–347. [Google Scholar] [CrossRef]

- Juan, A.A.; Faulin, J.; Grasman, S.E.; Rabe, M.; Figueira, G. A Review of Simheuristics: Extending Metaheuristics to Deal with Stochastic Combinatorial Optimization Problems. Oper. Res. Perspect. 2015, 2, 62–72. [Google Scholar] [CrossRef] [Green Version]

- Abdmouleh, Z.; Gastli, A.; Ben-Brahim, L.; Haouari, M.; Al-Emadi, N.A. Review of Optimization Techniques Applied for the Integration of Distributed Generation from Renewable Energy Sources. Renew. Energy 2017, 113, 266–280. [Google Scholar] [CrossRef]

- Hussain, K.; Salleh, M.N.M.; Cheng, S.; Shi, Y. Metaheuristic Research: A Comprehensive Survey. Artif. Intell. Rev. 2019, 52, 2191–2233. [Google Scholar] [CrossRef] [Green Version]

- Peres, F.; Castelli, M. Combinatorial optimization problems and metaheuristics: Review, challenges, design, and development. Appl. Sci. 2021, 11, 6449. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization and Machine Learning; Addison-Wesley Longman Publishing Co.: Boston, MA, USA, 1989; ISBN 978-0-201-15767-3. [Google Scholar] [CrossRef]

- Yang, X.-S. Nature-Inspired Optimization Algorithms, 1st ed.; Elsevier: Amsterdam, The Netherland; Boston, MA, USA, 2014; ISBN 9780124167438. [Google Scholar]

- Fister, I., Jr.; Yang, X.-S.; Fister, I.; Brest, J.; Fister, D. A Brief Review of Nature-Inspired Algorithms for Optimization. arXiv 2013, arXiv:1307.4186. [Google Scholar]

- Li, M.; Yang, S.; Liu, X. Pareto or Non-Pareto: Bi-Criterion Evolution in Multiobjective Optimization. IEEE Trans. Evol. Comput. 2016, 20, 645–665. [Google Scholar] [CrossRef] [Green Version]

- Lones, M.A. Mitigating Metaphors: A Comprehensible Guide to Recent Nature-Inspired Algorithms. SN Comput. Sci. 2020, 1, 49. [Google Scholar] [CrossRef] [Green Version]

- Covas, J.A.; Cunha, A.G.; Oliveira, P. An Optimization Approach to Practical Problems in Plasticating Single Screw Extrusion. Polym. Eng. Sci. 1999, 39, 443–456. [Google Scholar] [CrossRef]

- Covas, J.A.; Gaspar-Cunha, A. The Use of an Optimization Approach to the Design of Extrusion Screw. In Proceedings of the Polymer Processing Society 16th Annual Meeting (PPS-16), Shanghai, China, 18–23 June 2000. [Google Scholar]

- Gaspar-Cunha, A.; Covas, J.A. The Design of Extrusion Screw: An Optimization Approach. Int. Polym. Proc. 2001, 16, 229–240. [Google Scholar] [CrossRef] [Green Version]

- Nastaj, A.; Wilczyński, K. Optimization for Single Screw Extrusion of Polymeric Materials—Experimental Studies. Polimery 2018, 1, 38–44. [Google Scholar] [CrossRef]

- Nastaj, A.; Wilczyński, K. Process Optimization for Single Screw Extrusion of Polymeric Materials—Simulation Studies. Polimery 2018, 4, 297–304. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Poulesquen, A.; Vergnes, B.; Covas, J.A. Optimization of Processing Conditions for Polymer Twin-Screw Extrusion. Int. Polym. Proc. 2002, 17, 201–213. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Covas, J.A.; Vergnes, B. An Optimisation Methodology for Setting the Operating Conditions in Twin-Screw Extrusion. In Materiały Konferencyjne; The Polymer Processing Society Eighteenth Annual Meeting (PPS-18): Guimaraes, Portugalia, 2002. [Google Scholar]

- Gaspar-Cunha, A.; Covas, J.; Vergnes, B. Defining the Configuration of Co-Rotating Twin-Screw Extruders with Multiobjective Evolutionary Algorithms. Polym. Eng. Sci. 2005, 45, 1159–1173. [Google Scholar] [CrossRef]

- Nastaj, A. Optimization for Starve Fed Single Screw Extrusion of Polymeric Materials—Experimental Studies. Polimery 2020, 5, 380–386. [Google Scholar] [CrossRef]

- Nastaj, A. Optimization for Starve Fed Single Screw Extrusion of Polymeric Materials—Simulations. Polimery 2020, 6, 468–477. [Google Scholar] [CrossRef]

- Nastaj, A.; Wilczyński, K. Optimization for Starve Fed/Flood Fed Single Screw Extrusion of Polymeric Materials. Polymers 2020, 12, 149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wilczyński, K.; Jiang, Q.; White, J.L. A Composite Model for Melting, Pressure and Fill Factor Profiles in a Metered Fed Closely Intermeshing Counter-Rotating Twin Screw Extruder. Int. Polym. Proc. 2007, 22, 198–203. [Google Scholar] [CrossRef]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental Study of Melting of LDPE/PS Polyblend in an Intermeshing Counter-Rotating Twin Screw Extruder. Polym. Eng. Sci. 2012, 52, 449–458. [Google Scholar] [CrossRef]

- Lewandowski, A.; Wilczyński, K.J.; Nastaj, A.; Wilczyński, K. A Composite Model for an Intermeshing Counter-Rotating Twin-Screw Extruder and its Experimental Verification. Polym. Eng. Sci. 2015, 55, 2838–2848. [Google Scholar] [CrossRef]

- Rauwendaal, C. Polymer Extrusion, 5th ed.; Carl Hanser Verlag: Munich, Germany, 2014; ISBN 978-1-56990-516-6. [Google Scholar]

- Hensen, F.; Knappe, W.; Potente, H. Handbuch der Kunststoff-Extrusiontechnik. Grundlagen; Carl Hanser Verlag: Munich, Germany, 1989; ISBN 978-3446143395. [Google Scholar]

- McKelvey, J.M. Polymer Processing; John Wiley & Sons Inc.: New York, NY, USA, 1962; ISBN 978-0471584438. [Google Scholar]

- Stevens, M.J.; Covas, J.A. Extruder Principles and Operation; Springer: Berlin/Heidelberg, Germany, 1995; ISBN 978-94-010-4247-5. [Google Scholar]

- Campbell, G.A.; Spalding, M.A. Analyzing and Troubleshooting Single-Screw Extruders; Carl Hanser Verlag: Munich, Germany, 2013; ISBN 978-3-446-41371-9. [Google Scholar]

- Chung, C.I. Extrusion of Polymers. Theory and Practice, 3rd ed.; Carl Hanser Verlag: Munich, Germany, 2019; ISBN 978-1-569-907375. [Google Scholar]

- Chen, B.; Zhu, L.; Zhang, F.; Qiu, Y. Process Development and Scale-Up. In Developing Solid Oral Dosage Forms; Elsevier: Amsterdam, The Netherlands, 2017; pp. 821–868. [Google Scholar] [CrossRef]

- Carley, J.F.; McKelvey, J.M. Extruder Scale-Up Theory and Experiments. Ind. Eng. Chem. 1953, 45, 989–992. [Google Scholar] [CrossRef]

- Maddock, B.H. A Visual Analysis of Flow and Mixing in Extruder Screws. Soc. Plast. Eng. J. 1959, 15, 383–389. [Google Scholar]

- Maddock, B.H. Extruder Scale-up by Computer. Polym. Eng. Sci. 1974, 14, 853–858. [Google Scholar] [CrossRef]

- Fenner, R.T.; Williams, J.G. Some Melt Flow and Mechanical Design Aspects of Large Extruders. Polym. Eng. Sci. 1971, 11, 474–483. [Google Scholar] [CrossRef]

- Yi, B.; Fenner, R.T. Scaling-up Plasticating Screw Extruders on the Basis of Similar Melting Performances. Plast. Rubber Process. 1976, 1, 119–123. [Google Scholar]

- Pearson, J.R.A. Scale-up of Single Screw Extruders for Polymer Processing. Plast. Rubber Process. 1976, 1, 113–118. [Google Scholar]

- Potente, H.; Fischer, P. Model Laws for the Design of Single Screw Plasticating Extruders. Kunststoffe 1977, 67, 242–247. [Google Scholar]

- Schenkel, G. Extruder Series with Variable L/D Ratios. Kunststoffe 1978, 68, 155–162. [Google Scholar]

- Chung, C.I. On the Scale-up of Plasticating Extruder Screws. Polym. Eng. Sci. 1984, 24, 626–632. [Google Scholar] [CrossRef]

- Rauwendaal, C. Scale-up of Single Screw Extruders. Polym. Eng. Sci. 1987, 27, 1059–1068. [Google Scholar] [CrossRef]

- Potente, H. Existing Scale-Up Rules for Single-Screw Plasticating Extruders. Int. Polym. Proc. 1991, 6, 267–278. [Google Scholar] [CrossRef]

- Potente, H. Scale-up of Mixing Equipments. In Mixing and Compounding of Polymers, 2nd ed.; Manas-Zloczower, I., Ed.; Carl Hanser Verlag: Munich, Germany, 2009; pp. 577–643. ISBN 978-1-56990-660-6. [Google Scholar]

- Covas, J.A.; Gaspar-Cunha, A. Extrusion Scale-up: An Optimization-based Methodology. Int. Polym. Proc. 2009, 24, 67–82. [Google Scholar] [CrossRef]

- Berzin, F.; David, C.; Vergnes, B. Optimization and Scale-Up of Twin-Screw Reactive Extrusion: The Case of EVA Transesterification. Int. Polym. Proc. 2020, 35, 422–428. [Google Scholar] [CrossRef]

- Covas, J.A.; Gaspar-Cunha, A. A Scaling-up Methodology for Co-rotating Twin-Extruders. In Proceedings of the 27th Annual Meeting of the Polymer Processing Society (PPS-27), Marrakesh, Morocco, 10–14 May 2011; pp. 1–6. [Google Scholar]

- Gaspar-Cunha, A.; Covas, J.A. An Engineering Scale-Up Approach Using Multi-Objective Optimization. Intern. J. Nat. Comp. Res. 2014, 4, 17–30. [Google Scholar] [CrossRef] [Green Version]

- Denysiuk, R.; Recio, G.; Covas, J.A.; Gaspar-Cunha, A. Using Multiobjective Optimization Algorithms and Decision Making Support to Solve Polymer Extrusion Problems. Polym. Eng. Sci. 2018, 58, 493–502. [Google Scholar] [CrossRef]

- Nastaj, A. Scale-up for Single Screw Extrusion of Polymeric Materials. Polimery 2021, 6, 331–340. [Google Scholar] [CrossRef]

- Nastaj, A.; Wilczyński, K. Optimization and Scale-Up for Polymer Extrusion. Polymers 2021, 13, 1547. [Google Scholar] [CrossRef]

- Nastaj, A. Scale-Up for Starve Fed Single Screw Extrusion of Polymeric Materials. Polimery 2021, 9, 400. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A.; Lewandowski, A.; Wilczyński, K. A Composite Model for Starve Fed Single Screw Extrusion of Thermoplastics. Polym. Eng. Sci. 2014, 54, 2362–2374. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. Modeling for Starve Fed/Flood Fed Mixing Single-Screw Extruders. Int. Polym. Proc. 2016, 31, 82–91. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. A Global Model for Starve-Fed Nonconventional Single-Screw Extrusion of Thermoplastics. Adv. Polym. Technol. 2017, 36, 23–35. [Google Scholar] [CrossRef]

- Lopez-Latorre, L.; McKelvey, J.M. Melting and Pressurization in Starve Feed Extrusion. Adv. Polym. Technol. 1984, 3, 355–364. [Google Scholar] [CrossRef]

- Isherwood, D.P.; Pieris, R.N.; Kassatly, J. The Effect of Metered Starve Feeding on the Performance of a Small Extruder. J. Eng. Ind. 1984, 106, 132–136. [Google Scholar] [CrossRef]

- Strand, S.R.; Spalding, M.A.; Hyun, S.K. Modeling of the Solids-Conveying Section of a Starve Fed Single Screw Plasticating Extruder. SPE ANTEC Technol. Pap. 1992, 38, 2537–2541. [Google Scholar]

- Gale, M. Compounding with Single-Screw Extruders. Adv. Polym. Technol. 1997, 16, 251–262. [Google Scholar] [CrossRef]

- Thompson, M.R.; Donoian, G.; Christiano, J.P. Melting Mechanism of a Starved-Fed Single-Screw Extruder for Calcium Carbonate Filled Polyethylene. Polym. Eng. Sci. 2000, 40, 2014–2026. [Google Scholar] [CrossRef]

- Rathner, R.; Tranchida, D.; Roland, W.; Ruemer, F.; Buchmann, K.; Amsüss, P.; Steinbichler, G. Properties of Starve-Fed Extrusion on a Material Containing a VHMWPE Fraction. Polymers 2021, 13, 944. [Google Scholar] [CrossRef]

- White, J.L.; Potente, H. Screw Extrusion. Science and Technology; Hanser Publishers: Munich, Germany, 2003; ISBN 978-3-446-19624-7. [Google Scholar]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing, 2nd ed.; John Wiley & Sons Inc.: New York, NY, USA, 2006; ISBN 978-0-471-38770-1. [Google Scholar]

- Osswald, T.; Hernandez-Ortiz, J.P. Polymer Processing. Modeling and Simulation; Carl Hanser Verlag: Munich, Germany, 2006; ISBN 978-3-446-40381-9. [Google Scholar]

- Agassant, J.F.; Avenas, P.; Carreau, P.J.; Vergnes, B.; Vincent, M. Polymer Processing. Principles and Modelling, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2017; ISBN 978-1-56990-605-7. [Google Scholar]

- Altinkaynak, A.; Gupta, M.; Spalding, M.A.; Crabtree, S.L. Melting in a Single Screw Extruder: Experiments and 3D Finite Element Simulations. Int. Polym. Proc. 2011, 26, 182–196. [Google Scholar] [CrossRef]

- Ariffin, A.; Ahmad, M.S.B. Review: Single Screw Extruder in Particulate Filler Composite. Polym. Plast. Technol. 2011, 50, 395–403. [Google Scholar] [CrossRef]

- Teixeira, C.; Gaspar-Cunha, A.; Covas, J.A. Flow and Heat Transfer Along the Length of a Co-Rotating Twin Screw Extruder. Polym. Plast. Technol. 2012, 51, 1567–1577. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J. Multipurpose Computer Model for Screw Processing of Plastics. Polym. Plast. Technol. 2012, 51, 626–633. [Google Scholar] [CrossRef]

- Malik, M.; Kalyon, D.M.; Golba, J.C., Jr. Simulation of Co-Rotating Twin Screw Extrusion Process Subject to Pressure-Dependent Wall Slip at Barrel and Screw Surfaces: 3D FEM Analysis for Combinations of Forward- and Reverse-Conveying Screw Elements. Int. Polym. Proc. 2014, 29, 51–62. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Jabeen, R.; Kärki, T. The Modeling of Extrusion Processes for Polymers—A Review. Polymers 2020, 12, 1306. [Google Scholar] [CrossRef] [PubMed]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Fundamentals of Global Modeling for Polymer Extrusion. Polymers 2019, 11, 2106. [Google Scholar] [CrossRef] [Green Version]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental Study for Starve-Fed Single Screw Extrusion of Thermoplastics. Polym. Eng. Sci. 2012, 52, 1258–1270. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Wilczyński, K.J. Melting Model for Starve Fed Single Screw Extrusion of Thermoplastics. Int. Polym. Proc. 2013, 28, 34–42. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Experimental Study for Extrusion of Polypropylene/Wood Flour Composites. Int. Polym. Proc. 2015, 30, 113–120. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Wilczyński, K. Experimental Study of Melting of Polymer Blends in a Starve Fed Single Screw Extruder. Polym. Eng. Sci. 2016, 56, 1349–1356. [Google Scholar] [CrossRef]

- Wilczyński, K.; Buziak, K.; Wilczyński, K.J.; Lewandowski, A.; Nastaj, A. Computer Modeling for Single-Screw Extrusion of Wood-Plastic Composites. Polymers 2018, 10, 295. [Google Scholar] [CrossRef] [Green Version]

- Wilczyński, K.J.; Nastaj, A.; Wilczyński, K. A Computer Model for Starve-Fed Single-Screw Extrusion of Polymer Blends. Adv. Polym. Technol. 2018, 37, 2142–2151. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F. A Review of Wood Polymer Composites Rheology and Its Implications for Processing. Polymers 2020, 12, 2304. [Google Scholar] [CrossRef]

- Agur, E.E.; Vlachopoulos, J. Numerical Simulation of a Single-Screw Plasticating Extruder. Polym. Eng. Sci. 1982, 22, 1084–1094. [Google Scholar] [CrossRef]

- Potente, H.; Hanhart, W.; Reski, T. Design and Processing Optimization of Extruder Screws. Polym. Eng. Sci. 1994, 34, 937–945. [Google Scholar] [CrossRef]

- Wilczyński, K. Single Screw Extrusion Model for Plasticating Extruders. Polym.-Plast. Technol. 1999, 38, 581–608. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. A Composite Model for Solid Conveying, Melting, Pressure and Fill Factor Profiles in Modular Co-Rotating Twin Screw Extruders. Int. Polym. Proc. 1997, 12, 331–340. [Google Scholar] [CrossRef]

- White, J.L.; Kim, B.-J.; Bawiskar, S.; Keum, J.M. Development of a Global Computer Software for Modular Self-Wiping Corotating Twin Screw Extruders. Polym.-Plast. Technol. 2001, 40, 385–405. [Google Scholar] [CrossRef]

- Potente, H.; Bastian, M.; Flecke, J. Design of a Compounding Extruder by Means of the SIGMA Simulation Software. Adv. Polym. Technol. 1999, 18, 147–170. [Google Scholar] [CrossRef]

- Vergnes, B.; Valle, G.D.; Delamare, L. A Global Computer Software for Polymer Flows in Corotating Twin Screw Extruders. Polym. Eng. Sci. 1998, 38, 1781–1792. [Google Scholar] [CrossRef]

- Wilczyński, K. Rheology in Polymer Processing. Modeling and Simulation; Carl Hanser Verlag: Munich, Germany, 2021; ISBN 978-1-56990-660-6. [Google Scholar]

| Screw Geometry | ||

|---|---|---|

| Reference | Target | |

| Length of feeding/compression/metering zone | 10.78; 7.11; 9.11 turns | 10.78; 7.11; 9.11 turns |

| Diameter of barrel, Db | 45 mm | 60 mm |

| Screw pitch | 45 mm | 60 mm |

| Depth of screw channel in feeding zone, HF | 8 mm | 12 mm |

| Depth of screw channel in metering zone, HM | 3 mm | 4.5 mm |

| Flight width | 5 mm | 5 mm |

| Material Properties | |

|---|---|

| Density—bulk | 595 kg/m3 |

| Density—solid | 951 kg/m3 |

| Density—melt | 721 kg/m3 |

| Polymer-barrel friction factor | 0.40 |

| Polymer-screw friction factor | 0.25 |

| Heat of fusion | 245,000 J/kg |

| Solid specific heat | 2250 J kg−1 deg−1 |

| Melt specific heat | 3000 J kg−1 deg−1 |

| Thermal conductivity | 0.27 W m−1 deg−1 |

| Melt flow rate (190 °C, 2.16 kg) | 7.6 g/10 min |

| Results of Scaling-Up the Extrusion Process | |||

|---|---|---|---|

| Extruder | |||

| Single Parameter | Reference | Target | Deviation |

| Specific energy consumption | 489.36 kJ/kg | 457.76 kJ/kg | 6.46% |

| Relative melting length | 0.769 | 0.793 | 3.12% |

| Polymer melt temperature | 254.88 °C | 254.93 °C | 0.02% |

| Extrusion throughput | 27.10 kg/h | 44.20 kg/h | 63.10% |

| Profile | |||

| Temperature profile | |||

| 1. | 20.00 °C | 20.00 °C | 0.00% |

| 2. | 128.55 °C | 159.16 °C | 21.48% |

| 3. | 176.15 °C | 184.41 °C | 4.69% |

| … | … | … | … |

| 141. | 254.48 °C | 254.21 °C | 0.11% |

| 142. | 254.84 °C | 254.82 °C | 0.00% |

| SBP profile | |||

| 1. | 1.00 | 1.00 | 0.00% |

| 2. | 0.99 | 0.99 | 0.00% |

| 3. | 0.96 | 0.97 | 1.04% |

| … | … | … | … |

| 75. | 0.01 | 0.01 | 0.00% |

| 76. | 0.00 | 0.00 | - |

| Results of Scaling-Up the Extrusion Process | |||

|---|---|---|---|

| Extruder | |||

| Single Parameters | Reference | Target | Deviation |

| Specific energy consumption | 453.84 kJ/kg | 360.32 kJ/kg | 20.61% |

| Relative melting length | 0.617 | 0.571 | 7.46% |

| Polymer melt temperature | 223.31 °C | 200.67 °C | 0.02% |

| Extrusion throughput/Feeding flow rate | 27.32 kg/h | 39.17 kg/h | 43.37% |

| Profiles | |||

| Temperature profile | |||

| 1. | 20.00 °C | 20.00 °C | 0.00% |

| … | … | … | … |

| 21. | 132.12 °C | 135.00 °C | 2.18% |

| 22. | 135.00 °C | 135.00 °C | 0.00% |

| … | … | … | … |

| 126. | 223.26 °C | 200.67 °C | 10.12% |

| SBP profile | |||

| 1. | 1.00 | 1.00 | 0.00% |

| … | … | … | … |

| 21. | 0.98 | 0.97 | 1.02% |

| 22. | 0.95 | 0.94 | 1.05% |

| … | … | … | … |

| 46. | 0.00 | 0.00 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nastaj, A.; Wilczyński, K. Computational Scale-Up for Flood Fed/Starve Fed Single Screw Extrusion of Polymers. Polymers 2022, 14, 240. https://doi.org/10.3390/polym14020240

Nastaj A, Wilczyński K. Computational Scale-Up for Flood Fed/Starve Fed Single Screw Extrusion of Polymers. Polymers. 2022; 14(2):240. https://doi.org/10.3390/polym14020240

Chicago/Turabian StyleNastaj, Andrzej, and Krzysztof Wilczyński. 2022. "Computational Scale-Up for Flood Fed/Starve Fed Single Screw Extrusion of Polymers" Polymers 14, no. 2: 240. https://doi.org/10.3390/polym14020240

APA StyleNastaj, A., & Wilczyński, K. (2022). Computational Scale-Up for Flood Fed/Starve Fed Single Screw Extrusion of Polymers. Polymers, 14(2), 240. https://doi.org/10.3390/polym14020240