Thermal Degradation and Product Analysis of 3-iodo-2-propyl-butylcarbamate as a Wood Preservative

Abstract

:1. Introduction

2. Material and Methods

2.1. Materials

2.2. Test Method

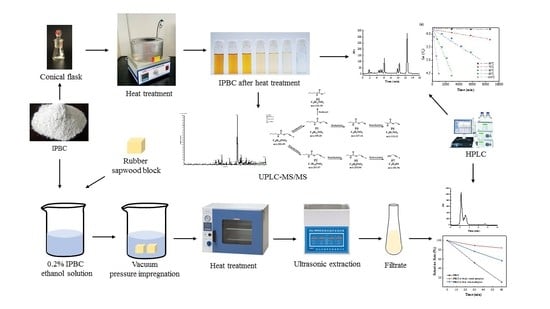

2.2.1. Thermal Treatment of IPBC

2.2.2. Determination of the Concentration of IPBC Solution

2.2.3. TG Analysis

2.2.4. Kinetic Modeling

2.2.5. Thermal Treatment of Wood Samples

2.2.6. Analysis of IPBC Content in Wood Samples

2.2.7. UPLC−MS/MS Analysis

3. Results and Discussion

3.1. Effect of Temperature on Degradation of IPBC

3.2. Thermal Degradation Kinetics of IPBC

3.2.1. Determination of the Thermal Degradation Reaction Order of IPBC

3.2.2. Arrhenius Equation for the Thermal Degradation of IPBC

3.2.3. Determination of the Half-Life of IPBC Degradation

3.2.4. The Application of the IPBC Thermal Degradation Kinetics in Wood/Bamboo

3.3. Effect of Temperature on Degradation of IPBC in Wood Samples

3.4. Degradation Products of IPBC

4. Conclusions

- (1)

- The effect of temperature on IPBC degradation is obvious. When IPBC was heated to 70 °C, thermal degradation occurred. Therefore, IPBC should choose a low-temperature environment for transportation and storage and during the use process and is not suitable for prolonged high-temperature heating.

- (2)

- The degradation of IPBC conformed to first-order kinetics and from 60 °C to 150 °C. The IPBC thermal degradation kinetic model could be used to predict the degradation loss of IPBC according to the parameters of the heat treatment process. An amount higher than the desired dosage of IPBC should be added in the production process to account for the loss of IPBC during thermal degradation to maintain the antifungal activity of IPBC in wood.

- (3)

- The thermal degradation products of IPBC detected by UPLC−MS/MS were: prop-2-yn-1-yl ethylcarbamate; methyl N-butylcarbamate; propargyl butylcarbamate; methylcarbamic acid prop-2-yn-1-ol; 2-propyn-1-ol, 3-iodo-, methylcarbamate; 3-iodoprop-2-yn-1-ol; and 3-iodoprop-2-ynyl N-propylcarbamate. A mechanism of IPBC thermal degradation was proposed, which involved deiodination, demethylation, deethynylation, deethylation, and hydroxylation processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pokhrel, G.; Gardner, D.J.; Han, Y. Properties of Wood–Plastic Composites Manufactured from Two Different Wood Feedstocks: Wood Flour and Wood Pellets. Polymers 2021, 13, 2769. [Google Scholar] [CrossRef] [PubMed]

- Renner, J.S.; Mensah, R.A.; Jiang, L.; Xu, Q.; Das, O.; Berto, F. Fire Behavior of Wood-Based Composite Materials. Polymers 2021, 13, 4352. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Zhang, S.; Fei, B.; Zhao, R. Mussel-Inspired Polydopamine Modification of Bamboo Flour for Superior Interfacial Compatibility of Bamboo Plastic Composites: Influence of Oxidant Type. Cellulose 2021, 28, 8567–8580. [Google Scholar] [CrossRef]

- Huang, Z.; Sun, Y.; Musso, F. Assessment of Bamboo Application in Building Envelope by Comparison with Reference Timber. Constr. Build. Mater. 2017, 156, 844–860. [Google Scholar] [CrossRef]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross Laminated Timber (CLT): Overview and Development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Scurlock, J.M.O.; Dayton, D.C.; Hames, B. Bamboo: An Overlooked Biomass Resource? Biomass Bioenergy 2000, 19, 229–244. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Luo, S.; Huang, A.; Luo, Y.; Li, D.; Wu, Y.; Ji, N. Mold Resistance of Bamboo Treated with Copper Complexes-Grafted Silica Gel and Its Microdistribution in Treated Bamboo. J. Wood Sci. 2019, 65, 62. [Google Scholar] [CrossRef] [Green Version]

- Matan, N.; Matan, N. Antifungal Activities of Anise Oil, Lime Oil, and Tangerine Oil against Molds on Rubberwood (Hevea Brasiliensis). Int. Biodeterior. Biodegrad. 2008, 62, 75–78. [Google Scholar] [CrossRef]

- Mousavi, B.; Hedayati, M.T.; Hedayati, N.; Ilkit, M.; Syedmousavi, S. Aspergillus Species in Indoor Environments and Their Possible Occupational and Public Health Hazards. Curr. Med. Mycol. 2016, 2, 36–42. [Google Scholar] [CrossRef] [Green Version]

- Dales, R.E.; Zwanenburg, H.; Burnett, R.; Franklin, C.A. Respiratory Health Effects of Home Dampness and Molds among Canadian Children. Am. J. Epidemiol. 1991, 134, 196–203. [Google Scholar] [CrossRef]

- Lee, C.L.; Chin, K.L.; Khoo, P.S.; Hafizuddin, M.S.; H’ng, P.S. Production and Potential Application of Pyroligneous Acids from Rubberwood and Oil Palm Trunk as Wood Preservatives through Vacuum-Pressure Impregnation Treatment. Polymers 2022, 14, 3863. [Google Scholar] [CrossRef]

- Hansen, J. A New Fungicide for Wood Protection. Mod. Paint Coatings 1984, 74, 50–54. [Google Scholar]

- Jin, X.; Zhang, R.; Su, M.; Li, H.; Yue, X.; Qin, D.; Jiang, Z. Functionalization of Halloysite Nanotubes by Enlargement and Layer-by-Layer Assembly for Controlled Release of the Fungicide Iodopropynyl Butylcarbamate. RSC Adv. 2019, 9, 42062–42070. [Google Scholar] [CrossRef] [Green Version]

- Chang, J.; Zhao, G.; Zhao, X.; He, C.; Pang, S.; Shreeve, J.M. New Promises from an Old Friend: Iodine-Rich Compounds as Prospective Energetic Biocidal Agents. Acc. Chem. Res. 2021, 54, 332–343. [Google Scholar] [CrossRef]

- Juergensen, L.; Busnarda, J.; Caux, P.Y.; Kent, R. Fate, Behavior, and Aquatic Toxicity of the Fungicide IPBC in the Canadian Environment. Environ. Toxicol. 2000, 15, 201–213. [Google Scholar] [CrossRef]

- Zhang, R.; Li, Y.; He, Y.; Qin, D. Preparation of Iodopropynyl Butycarbamate Loaded Halloysite and Its Anti-Mildew Activity. J. Mater. Res. Technol. 2020, 9, 10148–10156. [Google Scholar] [CrossRef]

- Freeman, M.H. Wood Preservative Formulation Development and Systems. In ACS Symposium Series; ACS Publications: New York, NY, USA, 2008; Volume 982, pp. 408–426. ISBN 978-0-84123-951-7. [Google Scholar]

- Kositchaiyong, A.; Rosarpitak, V.; Hamada, H.; Sombatsompop, N. Anti-Fungal Performance and Mechanical-Morphological Properties of PVC and Wood/PVC Composites under UV-Weathering Aging and Soil-Burial Exposure. Int. Biodeterior. Biodegrad. 2014, 91, 128–137. [Google Scholar] [CrossRef]

- Klement, I.; Vilkovský, P.; Vilkovská, T.; Orłowski, K.A.; Barański, J.; Chuchala, D.; Suchta, A. The Influence of Drying Temperature on Color Change of Hornbeam and Maple Wood Used as Surface and Inner Layers of Wood Composites. Appl. Sci. 2021, 11, 10673. [Google Scholar] [CrossRef]

- Kharaghani, A.; Le, K.H.; Tran, T.T.H.; Tsotsas, E. Reaction Engineering Approach for Modeling Single Wood Particle Drying at Elevated Air Temperature. Chem. Eng. Sci. 2019, 199, 602–612. [Google Scholar] [CrossRef]

- Volkmer, T.; Landmesser, H.; Genoud, A.; Schwarze, F.W.M.R. Penetration of 3-Iodo-2-Propynyl Butylcarbamate (IPBC) in Coniferous Wood Pre-Treated with Physisporinus Vitreus. J. Coatings Technol. Res. 2010, 7, 721–726. [Google Scholar] [CrossRef]

- Vallières, C.; Alexander, C.; Avery, S.V. Potentiated Inhibition of Trichoderma Virens and Other Environmental Fungi by New Biocide Combinations. Appl. Microbiol. Biotechnol. 2021, 105, 2867–2875. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Morén, T.; Sehlstedt-Persson, M.; Blom, Å. Effect of Oil Impregnation on Water Repellency, Dimensional Stability and Mold Susceptibility of Thermally Modified European Aspen and Downy Birch Wood. J. Wood Sci. 2017, 63, 74–82. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Li, J.; Liu, X. Novel Functionalized BN Nanosheets/Epoxy Composites with Advanced Thermal Conductivity and Mechanical Properties. ACS Appl. Mater. Interfaces 2020, 12, 6503–6515. [Google Scholar] [CrossRef]

- Liping, H.; Qingping, W.; Jingpeng, Z.; Mingliang, J.; Jinzhen, C. Analytical Method of IPBC by HPLC and Leachability in Treated Wood and Bamboo. J. Beijing For. Univ. 2021, 43, 140–146. [Google Scholar]

- Ordóñez-Santos, L.E.; Martínez-Girón, J. Thermal Degradation Kinetics of Carotenoids, Vitamin C and Provitamin A in Tree Tomato Juice. Int. J. Food Sci. Technol. 2020, 55, 201–210. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, M.J.; Wang, C.; Zhou, H.; Fan, L.; Huang, X. Thermolysis Kinetics and Thermal Degradation Compounds of Alliin. Food Chem. 2017, 223, 25–30. [Google Scholar] [CrossRef]

- Sørensen, G.; Nielsen, A.L.; Pedersen, M.M.; Poulsen, S.; Nissen, H.; Poulsen, M.; Nygaard, S.D. Controlled Release of Biocide from Silica Microparticles in Wood Paint. Prog. Org. Coatings. 2010, 68, 299–306. [Google Scholar] [CrossRef]

- Huang, Y.; Gram, A.; Fang, P. UV-Degradation of IPBC in Natural Water Sample; Roskilde University: Roskilde, Denmark, 2008; pp. 7–8. [Google Scholar]

- Hudson, J. The Foundation of Organic Chemistry. In The History of Chemistry; Springer: Berlin/Heidelberg, Germany, 1992; pp. 104–121. [Google Scholar]

- Eakins, P.M. CMIT/MIT–Isothiazolone Biocide Assessment; Hammonds Fuel Additives, Inc.: Houston, TX, USA, 2020. [Google Scholar]

- Jaiswal, A.K.; Abu-Ghannam, N. Degradation Kinetic Modelling of Color, Texture, Polyphenols and Antioxidant Capacity of York Cabbage after Microwave Processing. Food Res. Int. 2013, 53, 125–133. [Google Scholar] [CrossRef]

- Li, X.Y.; Liu, Y.B.; Hua, M.; Gao, B. Removal of U (VI) from Aqueous Solution by Nanoscale Zero-Valent Iron. Hedongli Gongcheng/Nuclear Power Eng. 2013, 34, 160–163. [Google Scholar]

- Kalawate, A.; Shahoo, S.C.; Khatua, P.K.; Das, H.S. Evaluation of Mechanical Properties of Plywood Treated with a New Wood Preservative (CEB) Chemical. J. Inst. Eng. Ser. D 2017, 98, 37–41. [Google Scholar] [CrossRef]

- Smith, W.R.; Wu, Q. Durability Improvement for Structural Wood Composites through Chemical Treatments: Current State of the Art. For. Prod. J. 2005, 55, 8–17. [Google Scholar]

- Kadivar, M.; Gauss, C.; Ghavami, K.; Savastano, H. Densification of Bamboo: State of the Art. Materials. 2020, 13, 4346. [Google Scholar] [CrossRef]

- Boneka, A.S.; Uyup, M.K.A.; Hua, L.S.; Siam, N.A.; Salim, S.; Ashaari, Z. Sorption Isotherm and Physico-Mechanical Properties of Kedondong (Canarium Spp.) Wood Treated with Phenolic Resin. Constr. Build. Mater. 2021, 288, 123060. [Google Scholar] [CrossRef]

- Ashori, A.; Matini Behzad, H.; Tarmian, A. Effects of Chemical Preservative Treatments on Durability of Wood Flour/HDPE Composites. Compos. Part B Eng. 2013, 47, 308–313. [Google Scholar] [CrossRef]

| Temperature (°C) | Reaction Order | |||||

|---|---|---|---|---|---|---|

| Zero-Order | First-Order | |||||

| k | R2 | ∑R2 | k | R2 | ∑R2 | |

| 60 | 0.0460 | 0.7439 | 5.7171 × 10−6 | 0.9999 | ||

| 70 | 0.0186 | 0.9957 | 4.3852 × 10−5 | 0.9999 | ||

| 80 | 0.0492 | 0.9959 | 4.6867 | 1.6218 × 10−4 | 0.9998 | 4.9992 |

| 90 | 0.1370 | 0.9770 | 5.8235 × 10−4 | 0.9997 | ||

| 100 | 0.4274 | 0.9742 | 0.0018 | 0.9999 | ||

| Temperature (°C) | Reaction Order | |||||

|---|---|---|---|---|---|---|

| Zero-Order | First-Order | |||||

| k | R2 | ∑R2 | k | R2 | ∑R2 | |

| 110 | 0.7522 | 0.9865 | 0.0026 | 0.9999 | ||

| 120 | 1.7306 | 0.9937 | 0.0068 | 0.9995 | ||

| 130 | 4.4019 | 0.9879 | 4.9500 | 0.0159 | 0.9993 | 4.9959 |

| 140 | 7.9918 | 0.9901 | 0.0358 | 0.9991 | ||

| 150 | 11.3843 | 0.9918 | 0.0447 | 0.9981 | ||

| Temperature (°C) | t1/2 (min) | Ea (kJ/mol) | A |

|---|---|---|---|

| 60 | 121,240 | ||

| 70 | 15,806 | ||

| 80 | 4273.9 | ||

| 90 | 1190.3 | ||

| 100 | 385.1 | 111.13 | 3.47 × 1012 |

| 110 | 266.6 | ||

| 120 | 101.9 | ||

| 130 | 43.59 | ||

| 140 | 19.36 | ||

| 150 | 15.51 |

| No. | Retention Time (min) | Formula | Measured Molecular Mass | Theoretical Molecular Mass | Molecular Mass of Secondary Ion(s) | Compound Name |

|---|---|---|---|---|---|---|

| I-1 | 11.05 | C6H9NO2 | 128.1065 | 127.14 | 111.0759 | prop-2-yn-1-yl ethylcarbamate |

| I-2 | 13.50 | C6H13NO2 | 132.1010 | 131.18 | 102.1019 | methyl N-butylcarbamate |

| I-3 | 14.72 | C8H13NO2 | 156.1011 | 155.20 | 114.0368, 100.0375 | Propargyl butylcarbamate |

| I-4 | 16.06 | C5H7NO2 | 114.0545 | 113.12 | 104.4309 | methylcarbamic acid,prop-2-yn-1-ol |

| I-5 | 16.58 | C6H8INO2 | 254.0029 | 253.04 | 235.9530, 226.0085 | 2-Propyn-1-ol, 3-iodo-, methylcarbamate |

| I-6 | 22.60 | C3H3IO | 182.9299 | 181.96 | 154.9200, 105.0229 | 3-iodoprop-2-yn-1-ol |

| I-7 | 23.76 | C14H20I2N2O4 | 535.8060 | 267.07 (diploid) | 418.7085, 436.6701 | 3-iodoprop-2-ynyl N-propylcarbamate |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, L.; Jiang, M.; Zhang, J.; Shao, C.; Zhang, Q. Thermal Degradation and Product Analysis of 3-iodo-2-propyl-butylcarbamate as a Wood Preservative. Polymers 2022, 14, 4531. https://doi.org/10.3390/polym14214531

Han L, Jiang M, Zhang J, Shao C, Zhang Q. Thermal Degradation and Product Analysis of 3-iodo-2-propyl-butylcarbamate as a Wood Preservative. Polymers. 2022; 14(21):4531. https://doi.org/10.3390/polym14214531

Chicago/Turabian StyleHan, Liping, Mingliang Jiang, Jingpeng Zhang, Chuang Shao, and Qingshuo Zhang. 2022. "Thermal Degradation and Product Analysis of 3-iodo-2-propyl-butylcarbamate as a Wood Preservative" Polymers 14, no. 21: 4531. https://doi.org/10.3390/polym14214531

APA StyleHan, L., Jiang, M., Zhang, J., Shao, C., & Zhang, Q. (2022). Thermal Degradation and Product Analysis of 3-iodo-2-propyl-butylcarbamate as a Wood Preservative. Polymers, 14(21), 4531. https://doi.org/10.3390/polym14214531