Simulation of Motor Core Gluing Process with Fine Mesh Nets

Abstract

:1. Introduction

2. Theory

2.1. Theoretical Background

- Continuity Equation [16]

- Momentum Equation [1]

- Energy Equation [17]

- Volume of Fluid (VOF) [20]

2.2. Materials

3. Experiment

Equipment

4. Simulation

4.1. Mold Flow Analysis Software

4.2. Simulation Process

4.3. Mesh Generation

4.3.1. Filling Process

4.3.2. Dipping Process

4.4. Process Parameters

4.4.1. Filling Process

4.4.2. Dipping Process

5. Results and Discussion

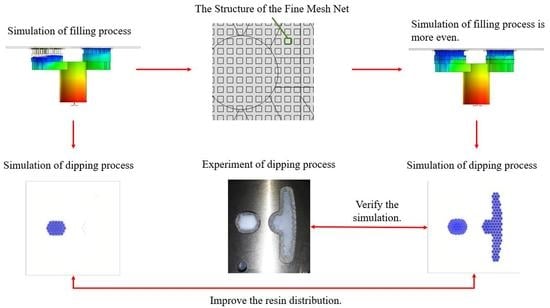

5.1. The Influence of Flow Front of The Runner with The Fine Mesh Net

5.2. The Resin Distribution on The Plate of Simulation and Experiment

5.3. Results of the Dipping Process

6. Conclusions

- Because the properties of the plastic in the filling simulation were the most important factors, defining the parameters of the material by Kamal’s reaction dynamic model and the Cross–Castro–Macosko viscosity model allowed the mold flow simulation to analyze more accurately.

- The results of the distribution of the resin filling showed that the distribution of the resin in Case 2 was more even than in Case 1. The important factor in Case 2 was the addition of more fine mesh net structures in the right side of the Teflon block.

- The flow front of the runner was more even, due to the fine mesh nets in the Teflon block, and the over-flow problem was further improved. Therefore, the fine mesh nets not only led to the flow trend being more even, but also could avoid bumps.

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Zeng, Y.J.; Hwang, S.J.; Liu, Y.D.; Huang, C.S. Mold Flow Analysis of Motor Core Gluing with Viscous Flow Channels and Dipping Module. Polymers 2021, 13, 2186. [Google Scholar] [CrossRef] [PubMed]

- Seo, U.J.; Kim, D.J.; Chun, Y.D.; Han, P.W. Mechanical cutting effect of electrical steel on the performance of induction motors. Energies 2020, 13, 6314. [Google Scholar] [CrossRef]

- Scapin, N.; Costa, P.; Brandt, L. A volume-of-fluid method for interface-resolved simulations of phase-changing two-fluid flows. J. Comput. Phys. 2020, 407, 109251. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Liu, D.Y.; Ou, C.Q. Simulation of flow transients in a water filling pipe containing entrapped air pocket with VOF model. Eng. Appl. Comput. Fluid Mech. 2011, 5, 127–140. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.K.; Wu, G.T.; Hwang, S.J.; Lee, H.H.; Hwang, D.Y. Molded underfill for flip chip package. In Proceedings of the 2013 8th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 22–25 October 2013; pp. 310–314. [Google Scholar]

- Khalil Abdullah, M.; Abdullah, M.Z.; Mujeebu, M.A.; Kamaruddin, S.; Ariff, Z.M. A Study on the Effect of Epoxy Molding Compound (EMC) Rheology During Encapsulation of Stacked-CHIP Scale Packages (S-CSP). J. Reinf. Plast. Compos. 2009, 28, 2527–2538. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Macosko, C.W. Kinetics and rheology characterization during curing of dicyanates. J. Appl. Polym. Sci. 1996, 62, 567–576. [Google Scholar] [CrossRef]

- Moon, J.Y.; Shin, Y.; Kim, S.; Hahn, S.H.; Lim, K.; Jung, J.W.; Rhee, M.D. Non Conductive Film Analysis Using Cure Kinetics and Rheokinetics for Gang Bonding Process for 3DIC TSV Packaging. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 1 June 2021–4 July 2021; pp. 706–710. [Google Scholar]

- Azmi, M.A.; Abdullah, M.K.; Abdullah, M.Z.; Ariff, Z.M.; Ismail, M.A.; Abdul Aziz, M.S. Flow Behavior Analysis of Emc in Molded Underfill (Muf) Encapsulation for Multi Flip-Chip Package. In Proceedings of the Regional Conference on Materials and ASEAN Micros-copy, Penang, Malaysia, 12–13 December 2017. [Google Scholar]

- Aniszewski, W.; Ménard, T.; Marek, M. Volume of Fluid (VOF) type advection methods in two-phase flow: A comparative study. Comput. Fluids 2014, 97, 52–73. [Google Scholar] [CrossRef] [Green Version]

- Lai, J.; Chen, T.; Wang, M.; Shih, M.; Tarng, D.; Hung, C. Characterization of Dual Side Molding SiP Module. In Proceedings of the 2017 IEEE 67th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May 2017–2 June 2017; pp. 1039–1044. [Google Scholar]

- Duan, Y.; Wang, X.; Yang, D.; Wang, J.; Ye, W.; Wu, Y. Mold Flow Analysis of a SiP Package for Power Management. In Proceedings of the 2020 21st International Conference on Electronic Packaging Technology (ICEPT), Guangzhou, China, 12–15 August 2020; pp. 1–4. [Google Scholar]

- Sohail, M.; Nazir, U.; El-Zahar, E.R.; Park, C.; Jamshed, W.; Mukdasai, K.; Galal, A.M. Galerkin finite element analysis for the augmentation in thermal transport of ternary-hybrid nanoparticles by engaging non-Fourier’s law. Sci. Rep. 2022, 12, 13497. [Google Scholar] [CrossRef] [PubMed]

- Nazir, U.; Sohail, M.; Kumam, P.; Sitthithakerngkiet, K.; Mousa, A.A.A.; Khan, M.J.; Galal, A.M. A dynamic assessment of various non-Newtonian models for ternary hybrid nanomaterial involving partially ionized mechanism. Sci. Rep. 2022, 12, 10306. [Google Scholar] [CrossRef] [PubMed]

- Nazir, U.; Saleem, S.; Al-Zubaidi, A.; Shahzadi, I.; Feroz, N. Thermal and mass species transportation in tri-hybridized Sisko martial with heat source over vertical heated cylinder. Int. Commun. Heat Mass Transf. 2022, 134, 106003. [Google Scholar] [CrossRef]

- Ouyang, E.; Jeong, Y.; Kim, J.; Kim, J.; Kwon, O.; Liu, M.; Lin, S.; Wang, J.A.; Yang, A.; Yang, E. Warpage of Compression Molded SiP Strips. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 1 June 2021–4 July 2021. [Google Scholar]

- Yen, F.; Kao, N.; Lai, D.; Wang, Y.P. FCCSP (MUF) Mold-flow Void Risk Prediction with Different Substrate Surface and Bump Height Design. In Proceedings of the 2021 22nd International Conference on Electronic Packaging Technology (ICEPT), Xiamen, China, 14–17 September 2021. [Google Scholar]

- Castro, J.M.; Mascosko, C.W. Studies of mold filling and curing in the reaction injection molding process. AICHE J. 1982, 28, 250–260. [Google Scholar] [CrossRef]

- Kamal, M.R. Thermoset characterization for moldability analysis. Polym. Eng. Sci. 1974, 14, 231–239. [Google Scholar] [CrossRef]

- Scardovelli, R.; Zaleski, S. Direct Numerical Simulation of Free-Surface and Interfacial Flow. Annu. Rev. Fluid Mech. 1999, 31, 567–603. [Google Scholar] [CrossRef] [Green Version]

- Lo, D.C.; Young, D.L. Numerical Simulation of Solitary Waves Using Velocity–Vorticity Formulation of Navier–Stokes Equations. J. Eng. Mech. 2006, 132, 211–219. [Google Scholar] [CrossRef]

| Process Parameters | Parameter Values | Unit |

|---|---|---|

| 0.3 | - | |

| 5.3193 | - | |

| −10 | - | |

| g/(cms) | ||

| 7996 | K | |

| 0.8 | - | |

| 10 | dyne/cm2 |

| Process Parameters | Parameter Values | Unit |

|---|---|---|

| m | 0.75648 | - |

| n | 2.0614 | - |

| 228.29 | 1/s | |

| 1/s | ||

| 14,586 | K | |

| 8619 | K |

| Process Parameters | Parameter Values |

|---|---|

| Injection pressure (MPa) | 0.8 |

| Melt temperature (°C) | 45 |

| Mold temperature (°C) | 45 |

| Initial conversion (%) | 0 |

| Filling time (s) | 138 |

| Process Parameters | Parameter Values |

|---|---|

| Injection pressure (MPa) | 0.8 |

| Melt temperature (°C) | 45 |

| Mold temperature (°C) | 45 |

| Initial conversion (%) | 0 |

| Filling time (s) | 30 |

| Process Parameters | Parameter Values |

|---|---|

| Compression time (s) | 0.273 |

| Compression gap (mm) | 0.5 |

| Compression speed (mm/sec) | 1.83 |

| Compression force (tf) | 0.022 |

| Resin temperature (°C) | 45 |

| Mold temperature (°C) | 45 |

| Initial conversion (%) | 0 |

| Experiment | Simulation | Experiment (Δt) | Simulation (Δt) |

|---|---|---|---|

40 s |  96 s | - | - |

43 s |  99 s | 3 s | 3 s |

45 s |  102 s | 2 s | 3 s |

| Simulation | Filling Percentage |

|---|---|

| 70% |

| 70.5% |

| 71% |

| 71.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Y.-J.; Liang, C.-W.; Hwang, S.-J.; Liu, Y.-D.; Huang, C.-S. Simulation of Motor Core Gluing Process with Fine Mesh Nets. Polymers 2022, 14, 4596. https://doi.org/10.3390/polym14214596

Zeng Y-J, Liang C-W, Hwang S-J, Liu Y-D, Huang C-S. Simulation of Motor Core Gluing Process with Fine Mesh Nets. Polymers. 2022; 14(21):4596. https://doi.org/10.3390/polym14214596

Chicago/Turabian StyleZeng, Yong-Jie, Chia-Wei Liang, Sheng-Jye Hwang, Yu-Da Liu, and Chien-Sheng Huang. 2022. "Simulation of Motor Core Gluing Process with Fine Mesh Nets" Polymers 14, no. 21: 4596. https://doi.org/10.3390/polym14214596

APA StyleZeng, Y. -J., Liang, C. -W., Hwang, S. -J., Liu, Y. -D., & Huang, C. -S. (2022). Simulation of Motor Core Gluing Process with Fine Mesh Nets. Polymers, 14(21), 4596. https://doi.org/10.3390/polym14214596