Characteristics of the Waste Wood Biomass and Its Effect on the Properties of Wood Sanding Dust/Recycled PP Composite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Wood Processing Wastewater

2.1.2. Determination of Composition of the Model Wastewater

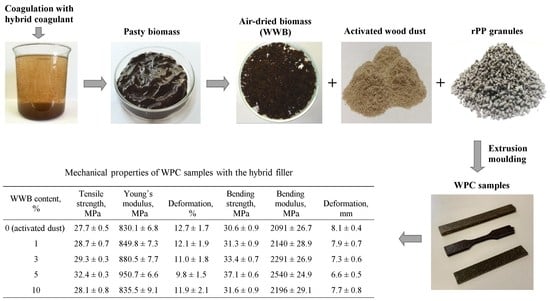

2.1.3. Separation of Waste Wood Biomass by the Coagulation/Flocculation Process

2.1.4. Activation of Wood Sanding Dust

2.1.5. Preparation of Wood–Plastic Samples

2.2. Methods

2.2.1. Elemental Analysis

2.2.2. Pyrolysis-Gas Chromatography-Mass Spectrometry (Py-GC/MS) Analysis

2.2.3. Fourier Transform Infrared (FT-IR) Spectroscopy

2.2.4. Thermogravimetric Analysis (TGA)

2.2.5. Particle Size

2.2.6. Surface Free Energy and Its Energetic Components

2.2.7. Water Uptake and Swelling

2.2.8. Mechanical Tests

2.2.9. Scanning Electron Microscopy (SEM)

2.2.10. Milling

3. Results and Discussion

3.1. Characterization of Waste Wood Biomass Samples

3.2. Effect of Biomass on the Properties of Wood–Plastic Composite

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Spear, M.J.; Eder, A.; Carus, M. Wood polymer composites. In Wood Composites; Ansell, M.P., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2015; pp. 195–249. [Google Scholar]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Moubarik, A.; Grimi, N.; Boussetta, N. Structural and thermal characterization of Moroccan sugar cane bagasse cellulose fibers and their applications as a reinforcing agent in low density polyethylene. Compos. B Eng. 2013, 52, 233–238. [Google Scholar] [CrossRef]

- Sain, M.; Park, S.H.; Suhara, F.; Law, S. Flame retardant and mechanical properties of natural fibre–PP composites containing magnesium hydroxide. Polym. Degrad. Stab. 2004, 83, 363–367. [Google Scholar] [CrossRef]

- Zampaloni, M.; Pourboghrat, F.; Yankovich, S.A.; Rodgers, B.N.; Moore, J.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Kenaf natural fiber reinforced polypropylene composites: A discussion on manufacturing problems and solutions. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1569–1580. [Google Scholar] [CrossRef]

- Renner, K.; Moczo, J.; Suba, P.; Pukanszky, B. Micromechanical deformations in PP/lignocellulosic filler composites: Effect of matrix properties. Compos. Sci. Technol. 2010, 70, 1141–1147. [Google Scholar] [CrossRef]

- Gupta, A.P.; Kumar, V. New emerging trends in synthetic biodegradable polymers—Polylactide: A critique. Eur. Polym. J. 2007, 43, 4053–4074. [Google Scholar] [CrossRef]

- Ebadi-Dehaghani, H.; Khonakdar, H.A.; Barikani, M.; Jafari, S.H. Experimental and theoretical analyses of mechanical properties of PP/PLA/clay nanocomposites. Compos. B. Eng. 2015, 69, 133–144. [Google Scholar] [CrossRef]

- Zheng, Y.T.; Cao, D.R.; Wang, D.S.; Chen, J. Study on the interface modification of bagasse fibre and the mechanical properties of its composite with PVC. Compos. Part A Appl. Sci. Manuf. 2007, 38, 20–25. [Google Scholar] [CrossRef]

- Najafi, S.K. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef]

- Shulga, G.; Neiberte, B.; Jaunslavietis, J.; Verovkins, A.; Vitolina, S.; Shakels, V.; Livcha, S. Lignin-containing adhesion enhancer for wood-plastic composites. BioResources 2021, 16, 2804–2823. [Google Scholar] [CrossRef]

- Turku, I.; Kärki, T.; Puurtinen, A. Durability of wood plastic composites manufactured from recycled plastic. Heliyon 2018, 4, e00559. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pączkowski, P.; Puszka, A.; Gawdzik, B. Green composites based on unsaturated polyester resin from recycled poly(ethyleneterephthalate) with wood flour as filler—Synthesis, characterization, and aging effect. Polymers 2020, 12, 2966. [Google Scholar] [CrossRef]

- Chabros, A.; Gawdzik, B.; Podkościelna, B.; Goliszek, M.; Pączkowski, P. Composites of unsaturated polyester resins with cellulose and its derivatives. Materials 2020, 13, 62. [Google Scholar] [CrossRef] [Green Version]

- Basalp, D.; Tihminlioglu, F.; Sofuoglu, S.C.; Inal, F.; Sofuoglu, A. Utilization of municipal plastic and wood waste in industrial manufacturing of wood plastic composites. Waste Biomass Valorization 2020, 11, 5419–5430. [Google Scholar] [CrossRef] [Green Version]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2008; p. 728. [Google Scholar]

- Irfan, M.; Butt, T.; Imtiaz, N.; Abbas, N.; Khan, R.A.; Shafique, A. The removal of COD, TSS and colour of black liquor by coagulation–flocculation process at optimized pH, settling and dosing rate. Arab. J. Chem. 2017, 10, S2307–S2318. [Google Scholar] [CrossRef] [Green Version]

- Rahbar, M.S.; Alipour, E.; Sedighi, R.E. Color removal from industrial wastewater with a novel coagulant flocculant formulation. Int. J. Environ. Sci. Technol. 2006, 3, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Ahmada, A.L.; Wong, S.S.; Teng, T.T.; Zuhairi, A. Optimization of coagulation–flocculation process for pulp and paper mill effluent by response surface methodological analysis. J. Hazard. Mater. 2007, 145, 162–168. [Google Scholar] [CrossRef]

- Mayer, I.; Koch, G. Element content and pH value in American black cherry (Prunus serotina) with regard to colour changes during heartwood formation and hot water treatment. Wood Sci. Technol. 2007, 41, 537–547. [Google Scholar] [CrossRef]

- Yamamoto, A.; Rohumaa, A.; Kontturi, E.; Hughes, M.; Vuorinen, T. The effect of hydrothermal treatment on the color stability and chemical properties of birch veneer surfaces. BioResources 2015, 10, 6610–6623. [Google Scholar] [CrossRef]

- Mayer, I.; Koch, G.; Puls, J. Chemical investigations on boiling process waters in face veneer production. Eur. J. Wood Wood Prod. 2007, 65, 315–320. [Google Scholar] [CrossRef]

- Spinosa, L.; Ayol, A.; Baudez, J.C.; Canziani, R.; Jenicek, P.; Leonard, A.; Rulkens, W.; Xu, G.; Van Dijk, L. Sustainable and innovative solutions for sewage sludge management. Water 2011, 3, 702–717. [Google Scholar] [CrossRef]

- Sales, A.; De Souza, F.R.; Almeida, F.R. Mechanical properties of concrete produced with a composite of water treatment sludge and sawdust. Constr. Build. Mater. 2011, 25, 2793–2798. [Google Scholar] [CrossRef]

- Soucy, J.; Koubaa, A.; Migneault, S.; Riedl, B. The potential of paper mill sludge for wood–plastic composites. Ind. Crops Prod. 2014, 54, 248–256. [Google Scholar] [CrossRef]

- Brovkina, J.; Shulga, G.; Ozolins, J.; Neiberte, B.; Verovkins, A.; Lakevics, V. The advanced application of the wood-originated wastewater sludge. Agron. Res. 2020, 18, 729–741. [Google Scholar]

- Lin, L.; Xu, X.; Papelis, C.; Cath, T.Y.; Xu, P. Sorption of metals and metalloids from reverse osmosis concentrate on drinking water treatment solids. Sep. Purif. Technol. 2014, 134, 37–45. [Google Scholar] [CrossRef]

- Vitolina, S.; Shulga, G.; Neiberte, B.; Reihmane, S. Woodworking wastewater biomass effective separation and its recovery. Agron. Res. 2021, 19, 1659–1674. [Google Scholar]

- Lazdina, D.; Bardule, A.; Lazdins, A.; Stola, J. Use of wastewater sludge and wood ash as fertilizer for Salix cultivation in acid peat soils. Agron. Res. 2011, 9, 305–314. [Google Scholar]

- Kumar, V.; Chopra, A.K.; Kumar, A. A review on sewage sludge (Biosolids) a resource for sustainable agriculture. AAES 2017, 2, 340–347. [Google Scholar] [CrossRef]

- Zapałowska, A.; Puchalski, C.; Stankowski, S.; Gibczyńska, M. Fertilisation with ash from wood and with sewage sludge versus contents of macro-and microelements in the soil following cultivation of Helianthus tuberosus L. Agron. Res. 2020, 18, 650–661. [Google Scholar]

- Chaharmahali, M.; Mirbagheri, J.; Tajvidi, M. Mechanical and physical properties of wood-plastic composite panels. J. Reinforc. Plast. Compos. 2010, 29, 310–319. [Google Scholar] [CrossRef]

- Komal, U.K.; Lila, M.K.; Chaitanya, S.; Singh, I. Fabrication of short fiber reinforced polymer composites. In Reinforced Polymer Composites: Processing, Characterization and Post Life Cycle Assessment; Bajpai, P.K., Singh, I., Eds.; Wiley-VCH: Weinheim, Germany, 2020; pp. 21–38. [Google Scholar]

- Biswas, S.; Anurag, J. Fabrication of composite laminates. In Reinforced Polymer Composites: Processing, Characterization and Post Life Cycle Assessment; Bajpai, P.K., Singh, I., Eds.; Wiley-VCH: Weinheim, Germany, 2020; pp. 39–53. [Google Scholar]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. B. Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Farsi, M. Effect of fiber surface modification on the thermo-mechanical behavior of wood-polymer composite. Asian J. Chem. 2012, 24, 2775–2779. [Google Scholar]

- De la Orden, M.U.; Sánchez, C.G.; Quesada, M.G.; Urreaga, J.M. Effect of different coupling agents on the browning of cellulose–polypropylene composites during melt processing. Polym. Degrad. Stabil. 2010, 95, 201–206. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Saba, N.; Md Tahir, P.; Jawaid, M. A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Lette, M.J.; Ly, E.B.; Ndiaye, D.; Takasaki, A.; Okabe, T. Evaluation of sawdust and rice husks as fillers for phenolic resin based wood-polymer composites. Open J. Compos. Mater. 2018, 8, 124–137. [Google Scholar] [CrossRef] [Green Version]

- Saxena, M.; Gupta, M.K. Hybrid mango/shorea robusta wood reinforced epoxy composite: Crystalline behavior and dynamic mechanical analysis. Mater. Today Proc. 2018, 5, 19359–19366. [Google Scholar] [CrossRef]

- Khan, M.Z.R.; Srivastava, S.K.; Gupta, M.K. Hybrid wood particulates composites: Mechanical and thermal properties. Mater. Res. Express 2019, 6, 105323. [Google Scholar] [CrossRef]

- Pérez-Fonseca, A.A.; Robledo-Ortíz, J.R.; Ramirez-Arreola, D.E.; Ortega-Gudiño, P.; Rodrigue, D.; González-Núñez, R. Effect of hybridization on the physical and mechanical properties of high density polyethylene–(pine/agave) composites. Mater. Des. 2014, 64, 35–43. [Google Scholar] [CrossRef]

- Technical Association of the Pulp and Paper Industry. Method T 222 om-02. Acid-Insoluble Lignin in Wood and Pulp. In TAPPI Test Methods; TAPPI Press: Atlanta, GA, USA, 2002. [Google Scholar]

- Technical Association of the Pulp and Paper Industry. Method T 203 cm-99. Alpha-, Beta- and Gamma-Cellulose in Pulp. In TAPPI Test Methods; TAPPI Press: Atlanta, GA, USA, 1999. [Google Scholar]

- Technical Association of the Pulp and Paper Industry. Method T 264 om-97. Preparation of Wood for Chemical Analysis. In TAPPI Test Methods; TAPPI Press: Atlanta, GA, USA, 1997. [Google Scholar]

- Liu, Z.; Ni, Y.; Fatehi, P.; Saeed, A. Isolation and cationization of hemicelluloses from pre-hydrolysis liquor of kraft-based dissolving pulp production process. Biomass Bioenergy 2011, 35, 1789–1796. [Google Scholar] [CrossRef]

- Vitolina, S. Efficient Separation of Biomass from Veneer Production Hydrothermal Treatment Wastewater, Its Characterization and Application Possibility. Ph.D. Thesis, Riga Technical University, Riga, Latvia, 2018. [Google Scholar]

- Shulga, G.; Brovkina, J.; Neiberte, B.; Ozolins, J.; Neilands, R. A Method for Wastewater Treating from Lignin and Hemicellulose Substances at Wood Processing Plants. Patent LR 14789 B, 20 January 2014. [Google Scholar]

- ISO 15586:2003; Water Quality—Determination of Trace Elements Using Atomic Absorption Spectrometry with Graphite Furnace. International Organization for Standardization: Geneva, Switzerland, 2003.

- Adamson, A.W.; Gast, A.P. Physical Chemistry of Surfaces, 6th ed.; John Wiley & Sons: Hoboken, NJ, USA, 1997; p. 808. [Google Scholar]

- ASTM D 570-98; Standard Test Method for Water Absorption of Plastics. American Society for Testing and Materials Information Handling Services: West Conshohocken, PA, USA, 2000.

- Faix, O. Fourier Transform Infrared Spectroscopy. In Methods in Lignin Chemistry; Lin, S.Y., Dence, C.W., Eds.; Springer: Berlin/Heidelberg, Germany, 1992; pp. 233–241. [Google Scholar]

- Fang, J.M.; Sun, R.C.; Tomkinson, J. Isolation and characterization of hemicelluloses and cellulose from rye straw by alkaline peroxide extraction. Cellulose 2000, 7, 87–107. [Google Scholar] [CrossRef]

- Kačuráková, M.; Capek, P.; Sasinkova, V.; Wellner, N.; Ebringerova, A. FT-IR study of plant cell wall model compounds: Pectic polysaccharides and hemicelluloses. Carbohyd. Polym. 2000, 43, 195–203. [Google Scholar] [CrossRef]

- Lin, J.; Yang, Z.; Hu, X.; Hong, G.; Zhang, S.; Song, W. The Effect of Alkali Treatment on Properties of Dopamine Modification of Bamboo Fiber/Polylactic Acid Composites. Polymers 2018, 10, 403. [Google Scholar] [CrossRef] [Green Version]

- Rajesh, G.; Prasad, L.S.R. Effect of fiber loading and successive alkali treatments on Tensile properties of short jute fiber rein-forced polypropylene composites. Int. J. Adv. Mater. Manuf. Charact. 2013, 3, 528–535. [Google Scholar]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Kim, S.K.; Jang, R.; Kim, W.N. Effects of compatibilizer on the mechanical, rheological, and shape memory behaviors of poly(lactic acid) and poly(MnBM) blends. J. Appl. Polym. Sci. 2020, 137, 48591. [Google Scholar] [CrossRef]

- Mat Taib, R.; Mohd Ishak, Z.A.; Rozman, H.D.; Glasser, W.G. Effect of moisture absorption on the tensile properties of steam-exploded Acacia mangium fiber-polypropylene composites. J. Thermoplast. Compos. Mater. 2006, 19, 475–489. [Google Scholar] [CrossRef]

- Fortini, A.; Mazzanti, V. Combined effect of water uptake and temperature on wood polymer composites: Research Article. J. Appl. Polym. Sci. 2018, 135, 46674. [Google Scholar] [CrossRef]

- Segerholm, B.K.; Ibach, R.E.; Westin, M. Moisture sorption, biological durability, and mechanical performance of WPC containing modified wood and polylactates. BioResources 2012, 7, 4575–4585. [Google Scholar] [CrossRef] [Green Version]

- Good, R.J.; van Oss, C.J. The modern theory of contact angle and the hydrogen bond components of surface energies. In Modern Approaches to Wettability; Schrader, M.E., Loeb, G.I., Eds.; Springer: Boston, MA, USA, 1992; pp. 1–27. [Google Scholar]

- Gindl, M.; Sinn, G.; Reiterer, A.; Tschegg, S. Wood surface energy and time dependence of wettability: A comparison of different wood surfaces using an acid-base approach. Holzforschung 2001, 55, 433–440. [Google Scholar] [CrossRef]

| pH | Biomass Content, mg L−1 | Density, g cm−3 | Chemical Oxygen Demand, mg L−1 | Permanganate Index, mg L−1 | Color, mgPt L−1 |

|---|---|---|---|---|---|

| 9.0–9.1 | 1400 ± 67 | 0.998 | 1285 ± 30 | 320 ± 10 | 746 ± 19 |

| Nr | Activated Wood Dust, % | Waste Wood Biomass, % | Recycled Polypropylene, % |

|---|---|---|---|

| 1. | 30 | 0 | 70 |

| 2. | 29 | 1 | 70 |

| 3. | 27 | 3 | 70 |

| 4. | 25 | 5 | 70 |

| 5. | 23 | 7 | 70 |

| 6. | 20 | 10 | 70 |

| C, % | H, % | O, % | N, % | Al, % | Cl, % | |

|---|---|---|---|---|---|---|

| evaporated (a) | 37.8 | 4.8 | 56.7 | 0.3 | - | - |

| coagulated (b) | 32.9 | 4.7 | 54.3 | 4.2 | 2.7 | 0.8 |

| Peak Positions (cm−1) | Peak Assignments | |

|---|---|---|

| Evaporated | Coagulated | |

| 3433 | Phenolic and aliphatic OH stretching | Phenolic and aliphatic OH stretching, N–H stretching |

| 3289, 3186 | C–H stretching in the low-molecular wood thermal hydrolysis products | |

| 2937, 2860 | C–H stretching in methoxyl, methyl and methylene groups | |

| 1700, 1640, 1559 | C=O stretching in ketones, carbonyls and ester groups | |

| 1596 | complex vibrations of C=O stretching bonded with N–H bending | |

| 1416 | aromatic skeleton vibrations | |

| 1331 | syringyl ring breathing with C=O stretching | |

| 1125–800 | Vibration typical for hemicelluloses (C–C ring vibrations, overlapped with the stretching vibrations of C–OH side groups and the C–O–C glycosidic band vibrations) | |

| Waste Wood Biomass Content, % | Tensile Strength, MPa | Young’s Modulus, MPa | Tensile Deformation, % | Bending Strength, MPa | Bending Modulus, MPa | Bending Deformation, mm |

|---|---|---|---|---|---|---|

| 0 (initial dust) | 20.9 ± 0.4 | 670.2 ± 6.5 | 15.6 ± 1.5 | 21.5 ± 0.7 | 1395 ± 25.5 | 9.6 ± 0.5 |

| 0 (activated dust) | 27.7 ± 0.5 | 830.1 ± 6.8 | 12.7 ± 1.7 | 30.6 ± 0.9 | 2091 ± 26.7 | 8.1 ± 0.4 |

| 1 | 28.7 ± 0.7 | 849.8 ± 7.3 | 12.1 ± 1.9 | 31.3 ± 0.9 | 2140 ± 28.9 | 7.9 ± 0.7 |

| 3 | 29.3 ± 0.3 | 880.5 ± 7.7 | 11.0 ± 1.8 | 33.4 ± 0.7 | 2291 ± 26.9 | 7.3 ± 0.6 |

| 5 | 32.4 ± 0.3 | 950.7 ± 6.6 | 9.8 ± 1.5 | 37.1 ± 0.6 | 2540 ± 24.9 | 6.6 ± 0.5 |

| 10 | 28.1 ± 0.8 | 835.5 ± 9.1 | 11.9 ± 2.1 | 31.6 ± 0.9 | 2196 ± 29.1 | 7.7 ± 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vitolina, S.; Shulga, G.; Neiberte, B.; Jaunslavietis, J.; Verovkins, A.; Betkers, T. Characteristics of the Waste Wood Biomass and Its Effect on the Properties of Wood Sanding Dust/Recycled PP Composite. Polymers 2022, 14, 468. https://doi.org/10.3390/polym14030468

Vitolina S, Shulga G, Neiberte B, Jaunslavietis J, Verovkins A, Betkers T. Characteristics of the Waste Wood Biomass and Its Effect on the Properties of Wood Sanding Dust/Recycled PP Composite. Polymers. 2022; 14(3):468. https://doi.org/10.3390/polym14030468

Chicago/Turabian StyleVitolina, Sanita, Galia Shulga, Brigita Neiberte, Jevgenijs Jaunslavietis, Anrijs Verovkins, and Talrits Betkers. 2022. "Characteristics of the Waste Wood Biomass and Its Effect on the Properties of Wood Sanding Dust/Recycled PP Composite" Polymers 14, no. 3: 468. https://doi.org/10.3390/polym14030468

APA StyleVitolina, S., Shulga, G., Neiberte, B., Jaunslavietis, J., Verovkins, A., & Betkers, T. (2022). Characteristics of the Waste Wood Biomass and Its Effect on the Properties of Wood Sanding Dust/Recycled PP Composite. Polymers, 14(3), 468. https://doi.org/10.3390/polym14030468