Characterisation of Hemp Fibres Reinforced Composites Using Thermoplastic Polymers as Matrices

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Variants

2.3. Composites Processing

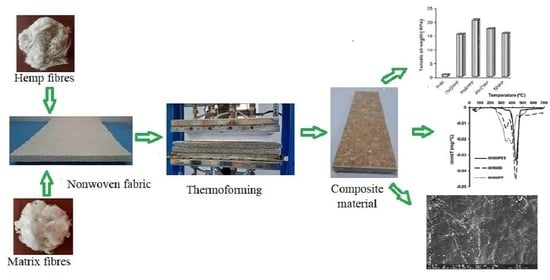

- Manufacturing of needle-punched nonwoven fabrics;

- Overlapping of nonwoven fabrics. Four samples of each nonwoven fabric variant have been overlaid alternatively in the longitudinal and transversal directions;

- Thermoforming. The overlaid nonwovens were placed in the mould of the thermoforming machine and then heated and pressed between the plates until the polymer matrix melted. The material was cooled in the rectangular mould (temperature—190–240 °C, pressure—735.46 MPa, pressing time—15 min and cooling time—15 min).

2.4. Characterisation

2.4.1. Mechanical Properties

2.4.2. Thermogravimetric Analysis (TG/DTG)

2.4.3. Differential Scanning Calorimetry (DSC)

2.4.4. Fourier Transform Infrared Spectroscopy

2.4.5. Scanning Electron Microscopy

2.4.6. Chromatic Measurements

3. Results and Discussions

3.1. Mechanical Properties

3.2. TGA and DTG Analysis

3.3. DSC Analysis

3.4. FTIR Analysis

3.5. SEM Analysis

3.6. Chromatic Measurements

4. Conclusions

- the highest tensile strengths were obtained for composites containing 30% to 50% hemp fibres;

- the elongation at break, which is about 71.5% for the sample consisting of 100% hemp, falls below 10% for the composites that contain 25% polymer matrix;

- thermal stability decreases as the amount of hemp in the composite increases (for the same mass losses, the decomposition temperature decreases significantly for composites containing quantities higher than 50% hemp), and with regard to the influence of the matrix, for the same mass losses, the decomposition temperature of the composites decreases in the order of 50H50PES > 50H50BI > 50H50PP;

- the SEM images indicate the presence of gaps in the composites that contain a quantity of hemp less than 50%, which could explain the better adhesiveness between the two components of these composites;

- the colour strength of the composite materials increased with the increase in the amount of hemp fibres, and decreased with the increase in the amount of polymeric fibres used as matrix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology-State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fibre and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Siengchin, S. Single-Polymer Composites: Concepts, Realization and Outlook: Review. KMUTNB Int. J. Appl. Sci. Technol. 2014, 7, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M.; Alothman, O.Y. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Const. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Meysam, T.; Nuruldiyanah, K.; Zahra, D.; Yee, E.; Ashen, G.; Chandima, G. Conventional and Advanced Composites in Aerospace Industry: Technologies Revisited. AJAE 2018, 5, 9–15. [Google Scholar]

- Thiruchitrambalam, M.; Athijayamani, A.; Sathiyamurthy, S.; Syed Abu Thaheer, S.A. A Review on the Natural Fibre-Reinforced Polymer Composites for the Development of Roselle Fibre Reinforced Polyester Composite. J. Nat. Fibers 2010, 7, 307–323. [Google Scholar] [CrossRef]

- Andrade, T.; Oliveira, G.; Altoéa, G.R.; Nettoa, P.A.; Muylaert, M.; Oliveira, B.; Neves, M.S. Evaluation of the Diameter Influence on the Tensile Strength of Pineapple Leaf Fibres (PALF) by Weibull Method. Mater. Res. 2015, 18, 185–192. [Google Scholar]

- Layth, M.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fibre Reinforced Polymer Composite and Its Applications, Hindawi Publishing Corporation. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar]

- Chika, E.M.; Chinedum, O.M. Recent Developments in Natural Fibre Composites: A Review. IJAREM 2017, 3, 28–42. [Google Scholar]

- Kılınç, A.C.; Durmuşkahya, C.; Seydibeyoğlu, M.Ö. Natural fibres. In Fibre Technology for Fibre-Reinforced Composites; Seydibeyoğlu, M.Ö., Mohanty, A.K., Misra, M., Eds.; Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2017; pp. 209–235. ISBN 9780081018712. [Google Scholar]

- Anuara, N.I.S.; Zakaria, S.; Gan, S.; Chia, C.H.; Wang, C.; Harun, J. Comparison of the morphological and mechanical properties of oil Palm EFB fibres and kenaf fibres in nonwoven reinforced composites. Ind. Crop. Prod. 2019, 127, 55–65. [Google Scholar] [CrossRef]

- Gowda, T.G.Y.; Sanjay, M.R.; Subrahmanya, B.K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer matrix-natural fibre composites: An overview. Cogent Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fibre reinforced polypropylene composites: The effects of material treatments. Compos. B Eng. 2017, 114, 15–22. [Google Scholar] [CrossRef] [Green Version]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural fiber reinforced composites: Sustainable the reference num materials for emerging applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Manaia, J.; Manaia, A.; Rodriges, L. Industrial Hemp Fibres: An Overview. Fibres 2019, 7, 106. [Google Scholar] [CrossRef] [Green Version]

- Trend Economy. Available online: https://trendeconomy.com/data/commodity_h2/530210 (accessed on 13 November 2021).

- European Commission. Available online: https://ec.europa.eu/info/food-farming-fisheries/plants-and-plant-products/plant-products/hemp_en, (accessed on 13 November 2021).

- Zwawi, M. A Review on Natural Fiber Bio-Composites, Surface Modifications and Applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef]

- Pracella, M.; Chionna, D.; Anguillesi, I.; Kulinski, Z.; Piorkowska, E. Functionalization, compatibilization and properties of polypropylene composites with Hemp fibres. Compos Sci Technol. 2006, 66, 2218–2230. [Google Scholar] [CrossRef]

- Shahzad, A. A Study in Physical and Mechanical Properties of Hemp Fibres. Adv. Mater. Sci. Eng. 2013, 2013, 325085. [Google Scholar] [CrossRef] [Green Version]

- Prasad, L.; Kumain, A.; Patel, R.V.; Yadav, A.; Winczek, J. Physical and Mechanical Behavior of Hemp and Nettle Fiber-Reinforced Polyester Resin-based Hybrid Composites. J. Nat. Fibers. 2020, 1–16. [Google Scholar] [CrossRef]

- Oza, S.; Wang, R.; Lu, N. Thermal and mechanical properties of recycled high density polyethylene/hemp fiber composites. Int. J. Appl. Sci. Technol. 2011, 1, 31–36. [Google Scholar]

- Lu, N.; Oza, S. A comparative study of the mechanical properties of hemp fiber with virgin and recycled high density polyethylene matrix. Compos. Part B Eng. 2013, 45, 1651–1656. [Google Scholar] [CrossRef]

- Lu, N.; Johnson, R.R. Hemp Fibre Reinforced Composite with Recycled High Density Polyethylene and Production Thereof. U.S. Patent 9187624B2, 23 February 2012. [Google Scholar]

- Zhijian, L.; Xungai, W.; Lijing, W. Properties of hemp fibre reinforced concrete composites. Compos. A Appl. Sci. Manuf. 2006, 37, 497–505. [Google Scholar]

- Cigasova, J.; Stevulova, N.; Sicakova, A. New Biocomposites Based on Hemp Hurds. JCEEA 2015, 62, 75–81. [Google Scholar] [CrossRef]

- Tina, H.; Ali, A.; Jalil, M. Hemp fibre reinforced thermoplastic polyurethane composite: An investigation in mechanical properties. Ind. Crop. Prod. 2017, 108, 853–863. [Google Scholar]

- Song, Y.S.; Lee, J.T.; Ji, D.S.; Kim, M.W.; Lee, S.H.; Youn, J.R. Viscoelastic and thermal behavior of woven hemp fiber reinforced poly(lactic acid) composites. Compos. Part B Eng. 2012, 43, 856–860. [Google Scholar] [CrossRef]

- Ciupan, E.; Lăzărescu, L.; Filip, I.; Ciupan, C.; Câmpean, E.; Cionca, I.; Pop, E. Characterization of a thermoforming composite material made from hemp fibres and polypropylene. In Proceedings of the Modern Technologies in Manufacturing (MTeM 2017—AMaTUC), Cluj-Napoca, Romania, 12–13 October 2017; pp. 537–544. [Google Scholar] [CrossRef] [Green Version]

- Etati, A.; Pather, S.; Fang, Z.; Wang, H. The study of fibre/matrix bond strength in short hemp polypropylene composites from dynamic mechanical analysis. Compos. Part B Eng. 2014, 62, 19–28. [Google Scholar] [CrossRef]

- Rachini, A.; Mougin, G.; Delalande, S.; Charmeau, J.Y.; Barres, C.; Fleury, E. Hemp fibers/polypropylene composites by reactive compounding: Improvement of physical properties promoted by selective coupling chemistry. Polym. Degrad. Stab. 2012, 97, 1988–1995. [Google Scholar] [CrossRef]

- Feng, D.; Caulfield, D.F.; Sanadi, A.R. Effect of Compatibilizer on the Structure-Property Relationships of Kenaf-Fiber/Polypropylene Composites. Polym. Compos. 2001, 22, 506–517. [Google Scholar] [CrossRef]

- Badji, C.; Beigbeder, J.; Garay, H.; Bergeret, A.; Bénézet, J.-C.; Desauziers, V. Natural weathering of hemp fibers reinforced polypropylene biocomposites: Relationships between visual and surface aspects, mechanical properties and microstructure based on statistical approach. Compos. Sci. Technol. 2018, 167, 440–447. [Google Scholar] [CrossRef] [Green Version]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Mutjé, A.; Lòpez, A.M.E.; Vallejos, A.M.E.; López, J.P.; Vilaseca, F. Full exploitation of Cannabis sativa as reinforcement/filler of thermoplastic composite materials. Compos. Part A Appl. Sci. 2007, 38, 369–377. [Google Scholar] [CrossRef]

- Ciupan, E.; Ciupan, M.; Jucan, D.-C. Determining the Mechanical Properties of a New Composite Material using Artificial Neural Networks. IJETT 2018, 66, 103–108. [Google Scholar] [CrossRef] [Green Version]

- Suardana, N.P.G.; Piao, Y.; Lim, J.K. Mechanical Properties of Hemp Fibres and Hemp/PP Composites: Effects of Chemical Surface Treatment. Mater. Phys. Mech. 2011, 11, 1–8. [Google Scholar]

- Zhang, X. Manufacturing of Hemp/PP Composites and Study of its Residual Stress and Aging Behavior. Ph.D. Thesis, Université de Technologie de Troyes, Troyes, France, 2016. [Google Scholar]

- Hargitai, H.; Rácz, I.; Anandjiwala, R. Development of Hemp Fibre Reinforced Polypropylene Composite. J. Thermoplast. Compos. Mater. 2008, 21, 165–174. [Google Scholar] [CrossRef]

- Souza, B.R.; Di Benedetto, R.M.; Hirayama, D.; de Andrade Raponi, O.; Barbosa, L.C.M.; Ancelotti Junior, A.C. Manufacturing and Characterization of Jute/PP Thermoplastic Commingled Composite. Mater. Res. 2017, 20, 458–465. [Google Scholar] [CrossRef] [Green Version]

- Susheel, K.; Kaith, B.S.; Inderjeet, K. Pretreatments of Natural Fibers and their Application as Reinforcing Material in Polymer Composites—A Review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Mehdi, T.; Nazanin, M. Mechanical Performance of Hemp Fibre Polypropylene Composites at Different Operating Temperatures. J. Reinf. Plast. Compos. 2010, 29, 664–667. [Google Scholar]

- Thuane, T.S.; Silva, P.H.P.M.D.; Matheus, P.R.; Maurício, F.L.; da Silva, A.P.; Monteiro, S.N.; Cassiano, L.F.N. Thermal and Chemical Characterization of Kenaf Fiber (Hibiscus cannabinus) Reinforced Epoxy Matrix Composites. Polymers 2021, 13, 2016. [Google Scholar]

- Jahangir, A.K.; Mubarak, A.K.; Rabiul, I.; Abdul, G. Mechanical, Thermal and Interfacial Properties of Jute Fabric-Reinforced Polypropylene Composites: Effect of Potassium Dichromate. Int. J. Mater. Sci. Appl. 2010, 1, 350–357. [Google Scholar]

- Tanvir, S.; Shahin, S.; Husna, P.N.; Wahab, K.M. Impact of Morphological, Physicomechanical of Polypropilene Composites Reinforced with Chemically Modified Betel Nut Husk fiber. IJAR 2019, 7, 1111–1119. [Google Scholar]

- Joseph, P.V.; Joseph, K.; Thomas, S.; Pillai, C.K.S.; Prasad, V.S.; Groeninckx, G.; Sarkissova, M. The Thermal and Crystallization Studies of Short Sisal Fiber Reinforced Polypropylene Composite. Mater. Sci. Eng. 2003, 34, 253–266. [Google Scholar]

- Ingamells, W. Colour for Textiles: A User’s Handbook; Society of Dyers and Colourists: Bradford, UK, 1993; p. 154. ISBN 0901956562/9780901956569. [Google Scholar]

- Sergio, N.M.; Calado, V.; Ruben, J.S.R.; Frederico, M.M. Thermogravimetric behavior of natural fibres reinforced polymer composites—An overview. Mater. Sci. Eng. A 2012, 557, 17–28. [Google Scholar]

- Anderson, K.S.; Hillmyer, M.A. Melt preparation and nucleation efficiency of polylactide stereocomplex crystallites. Polymer 2006, 47, 2030–2035. [Google Scholar] [CrossRef]

- Xu, H.; Liu, C.Y.; Chen, C.; Hsiao, B.S.; Zhong, G.J.; Li, Z.M. Easy alignment and effective nucleation activity of ramie fibers in injection-molded poly(lactic acid) biocomposites. Biopolymers 2012, 97, 825–839. [Google Scholar] [CrossRef] [PubMed]

- Zainal, M.; Santiagoo, R.; Ayob, A.; Ghani, A.A.; Mustafa, W.A.; Othman, N.S. Thermal and mechanical properties of chemical modification on sugarcane bagasse mixed with polypropylene and recycle acrylonitrile butadiene rubber composite. J. Thermoplast. Compos. Mater. 2019, 33, 1533–1554. [Google Scholar] [CrossRef]

- Franciszczak, P.; Wojnowski, J.; Kalniņš, K.; Piesowicz, E. The influence of matrix crystallinity on the mechanical performance of short-fibre composites—Based on homo-polypropylene and a random polypropylene copolymer reinforced with man-made cellulose and glass fibres. Compos. Part B Eng. 2019, 2019, 516–526. [Google Scholar] [CrossRef]

- Prabowo, I.; Pratama, J.N.; Chalid, M. The effect of modified ijuk fibers to crystallinity of polypropylene composite. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Medan, Indonesia, 7–10 November 2016; Volume 223, p. 012020. [Google Scholar] [CrossRef] [Green Version]

- Naruedee, P.; Amnouy, L. Wollastonite and talc reinforced polypropylene hybrid composites: Mechanical, morphological and thermal properties. J. Met. Mater. Miner. 2021, 31, 92–99. [Google Scholar]

- Noritake, A.; Mitsuo, H.; Mikiji, S.; Mitsuhiko, T. Recycling of Polyethylene Terephthalate Using High-pressure Steam Treatment. J. Polym. 2008, 40, 498–502. [Google Scholar] [CrossRef] [Green Version]

- Alessandro, P.; Amabile, P. Recycled poly(ethylene terephthalate) and its short glass fibres composites: Effects of hygrothermal aging on the thermo-mechanical behaviour. Polymer 2004, 45, 7995–8004. [Google Scholar]

- Alves, N.M.; Mano, J.F.; Balaguer, E.; Meseguer, J.M.D.; Gómez Ribelles, J.L. Glass transition and structural relaxation in semi-crystalline poly(ethylene terephthalate): A DSC study. Polymer 2002, 43, 4111–4122. [Google Scholar] [CrossRef]

- Huang, J.M.; Chu, P.P.; Chang, F.C. Conformational changes and molecular motion of poly(ethylene terephthalate) annealed above glass transition temperature. Polymer 2000, 41, 1741–1748. [Google Scholar] [CrossRef] [Green Version]

- Jung, M.R.; Horgen, F.D.; Orski, S.V.; Rodriguez, C.V.; Beers, K.L.; Balazs, G.H.; Jones, T.T.; Work, T.M.; Brignac, K.C.; Royer, S.J. Validation of ATR FT-IR to identify polymers of plastic marine debris, including those ingested by marine organisms. Mar. Pollut. Bull. 2018, 127, 704–716. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mat. 2011, 25, 927–948. [Google Scholar] [CrossRef]

- Luisa, A.; Ioana, D.P.; Rodica, S.; Zorita, D.; Alina, T.; Cristina, H.; Ancuta, R. Characterization of Flax and Hemp Using Spectrometric Methods. Appl. Sci. 2021, 11, 8341. [Google Scholar] [CrossRef]

- Célino, A.; Gonçalves, O.; Jacquemin, F.; Fréour, S. Qualitative and quantitative assessment of water sorption in natural fibres using ATR-FTIR spectroscopy. Carbohydr. Polym. 2014, 101, 163–170. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Xing, D.; Lia, J. FTIR Studies of the Changes in Wood Chemistry from Wood Forming Tissue under Inclined Treatment. Energy Procedia 2012, 16, 758–762. [Google Scholar] [CrossRef] [Green Version]

- Javier-Astete, R.; Jimenez-Davalos, J.; Zolla, G. Determination of hemicellulose, cellulose, holocellulose and lignin content using FTIR in Calycophyllum spruceanum (Benth.) K. Schum. and Guazuma crinita Lam. PLoS ONE 2021, 16, e0256559. [Google Scholar] [CrossRef]

- Ruth, C.; Asensio, M.S.A.M.; José, M.R.; Marisa, G. Analytical characterization of polymers used in conservation and restoration by ATR-FTIR spectroscopy. Anal. Bioanal. Chem. 2009, 395, 2081–2096. [Google Scholar] [CrossRef]

| Fibres | Characteristics | |||

|---|---|---|---|---|

| Title (dtex) | Tenacity (cN/tex) | Elongation (%) | Fibre Length (mm) | |

| Hemp | 102 | 39.5 | 1.8 | 50–250; 50/60 |

| Polypropylene | 6.7 | 27 | 100 | 60 |

| Polyester | 19 | 28.5 | 50.80 | 38/64 |

| Bicomponent | 6.7 | 28 | 52 | 51 |

| Variant | Blend | Variant | Blend | Variant | Blend |

|---|---|---|---|---|---|

| V 1.1 | 100H | V 2.1 | 100H | V 3.1 | 100H |

| V 1.2 | 75H25PP | V 2.2 | 75H25BI | V 3.2 | 75H25PES |

| V 1.3 | 50H50PP | V 2.3 | 50H50BI | V 3.3 | 50H50PES |

| V 1.4 | 25H75PP | V 2.4 | 25H75BI | V 3.4 | 25H75PES |

| V 1.5 | 100PP | V 2.5 | 100BI | V.3.5 | 100PES |

| Sample | Stage | Tonse °C | Tpeak °C | Tendset °C | Mass Loss % |

|---|---|---|---|---|---|

| 100H | I | 303 | 359 | 377 | 57.74 |

| II | 377 | 446 | 499 | 11.31 | |

| 100PES | I | 399 | 435 | 461 | 89.33 |

| 100BI | I | 396 | 436 | 462 | 84.98 |

| II | 462 | 601 | 664 | 14.81 | |

| 100PP | I | 358 | 437 | 453 | 99.39 |

| 50H50BI | I | 283 | 343 | 357 | 21.43 |

| II | 357 | 432 | 454 | 50.38 | |

| III | 454 | 546 | 654 | 23.95 | |

| 50H50PES | I | 328 | 345 | 401 | 9.68 |

| II | 401 | 435 | 458 | 79.97 | |

| 25H75PP | I | 261 | 280 | 321 | 7.46 |

| II | 321 | 340 | 384 | 15.69 | |

| III | 384 | 440 | 463 | 74.10 | |

| 50H50PP | I | 266 | 342 | 362 | 43.20 |

| II | 362 | 394 | 424 | 42.61 | |

| III | 424 | 465 | 535 | 14.55 | |

| 75H25PP | I | 261 | 339 | 361 | 44.59 |

| II | 361 | 467 | 483 | 31.18 |

| Mass Loss % | 100H | 75H25PP | 50H50PP | 25H75PP | 100PP | 100BI | 50H50BI | 50H50PES | 100PES |

|---|---|---|---|---|---|---|---|---|---|

| 10 | 275 | 276 | 279 | 315 | 386 | 405 | 322 | 403 | 413 |

| 15 | 307 | 296 | 296 | 335 | 396 | 411 | 340 | 411 | 417 |

| 25 | 331 | 321 | 320 | 373 | 411 | 420 | 385 | 422 | 424 |

| 50 | 356 | 346 | 360 | 411 | 434 | 436 | 429 | 437 | 438 |

| First Heating | Cooling | Second Heating | ||||||

|---|---|---|---|---|---|---|---|---|

| Sample | Tm (°C) | ΔHm (J/g) * | Tc (°C) | ΔHc (J/g) | Χc (%) | Tm (°C) | ΔHm (J/g) ** | Χc (%) |

| 100H | – | – | – | – | – | |||

| 75H25PP | 161.58 | 32.35 | 115.55 | 39.97 | 77,23 | 161.58 | 35.68 | 68.94 |

| 50H50PP | 163.28 | 41.96 | 115.30 | 54.33 | 52.49 | 162.25 | 46.86 | 45,27 |

| 25H75PP | 164.26 | 59.19 | 115.20 | 72.33 | 46,58 | 163.20 | 63.42 | 40,85 |

| 100PP | 167.54 | 74.40 | 112.5 | 93.56 | 45,19 | 164.74 | 81.67 | 39.45 |

| Sample | ΔHm (J/g) * | ΔHc (J/g) | ΔHm (J/g) ** | Tg (°C) *** |

|---|---|---|---|---|

| 50H50BI | 2.26 | 3.40 | 2.34 | 61.91 |

| 100BI | 31.16 | 18.10 | 26.83 | 70.38 |

| 50H50PES | 42.72 | 36.32 | 31.25 | 74.58 |

| 100PES | 50.70 | 39.68 | 33.81 | 77.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stelea, L.; Filip, I.; Lisa, G.; Ichim, M.; Drobotă, M.; Sava, C.; Mureșan, A. Characterisation of Hemp Fibres Reinforced Composites Using Thermoplastic Polymers as Matrices. Polymers 2022, 14, 481. https://doi.org/10.3390/polym14030481

Stelea L, Filip I, Lisa G, Ichim M, Drobotă M, Sava C, Mureșan A. Characterisation of Hemp Fibres Reinforced Composites Using Thermoplastic Polymers as Matrices. Polymers. 2022; 14(3):481. https://doi.org/10.3390/polym14030481

Chicago/Turabian StyleStelea, Lucia, Ioan Filip, Gabriela Lisa, Mariana Ichim, Mioara Drobotă, Costică Sava, and Augustin Mureșan. 2022. "Characterisation of Hemp Fibres Reinforced Composites Using Thermoplastic Polymers as Matrices" Polymers 14, no. 3: 481. https://doi.org/10.3390/polym14030481

APA StyleStelea, L., Filip, I., Lisa, G., Ichim, M., Drobotă, M., Sava, C., & Mureșan, A. (2022). Characterisation of Hemp Fibres Reinforced Composites Using Thermoplastic Polymers as Matrices. Polymers, 14(3), 481. https://doi.org/10.3390/polym14030481