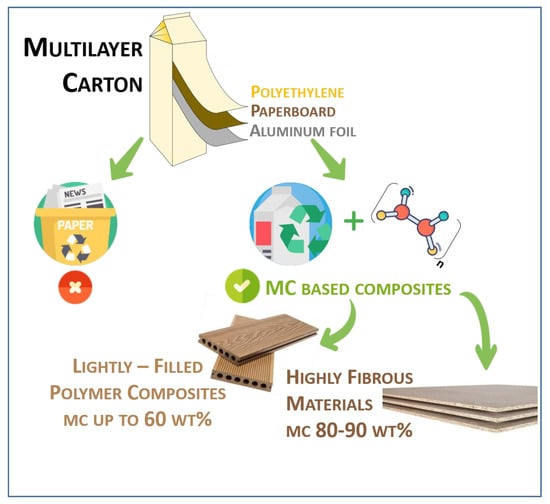

Sustainable Cellulose-Aluminum-Plastic Composites from Beverage Cartons Scraps and Recycled Polyethylene

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composites Preparation

2.3. Characterization

3. Results

3.1. Filler Size Distribution, Composites Preparation and Morphology

3.2. Thermal Analysis

3.3. Mechanical Analysis

3.4. Water Absorption

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ACE UK. What Is a Beverage Carton? Available online: http://www.ace-uk.co.uk/what-is-a-carton/ (accessed on 20 November 2021).

- Zero Waste Europe. Recycling of Multilayer Composite Packaging: The Beverage Carton; Available online: https://zerowasteeurope.eu/library/recycling-of-multilayer-composite-packaging-the-beverage-carton/ (accessed on 20 November 2021).

- Robertson, G. Recycling of Aseptic Beverage Cartons: A Review. Recycling 2021, 6, 20. [Google Scholar] [CrossRef]

- Gesellschaft für Verpackungsmarktforschung (GVM). Substitution of Plastic Packaging by Paper-Based Composites; Available online: https://newsroom.kunststoffverpackungen.de/wp-content/uploads/2021/03/2021_03_23_Bericht_Substitution-durch-Papierverbunde.pdf (accessed on 20 November 2021).

- Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment. Available online: https://www.legislation.gov.uk/eudr/2019/904 (accessed on 20 November 2021).

- Avella, M.; Avolio, R.; Bonadies, I.; Carfagna, C.; Errico, M.E.; Gentile, G. Recycled Multilayer Cartons as Cellulose Source in HDPE-Based Composites: Compatibilization and Structure-Properties Relationships. J. Appl. Polym. Sci. 2009, 114, 2978–2985. [Google Scholar] [CrossRef]

- Spear, M.J.; Eder, A.; Carus, M. Wood Polymer Composites. In Wood Composites; Ansell, M.P., Ed.; Woodhead Publishing Ltd.: Sawston, UK, 2015; pp. 195–249. [Google Scholar]

- Castaldo, R.; De Falco, F.; Avolio, R.; Bossanne, E.; Cicaroni Fernandes, F.; Cocca, M.; Di Pace, E.; Errico, M.E.; Gentile, G.; Jasiński, D.; et al. Critical Factors for the Recycling of Different End-of-Life Materials: Wood Wastes, Automotive Shredded Residues, and Dismantled Wind Turbine Blades. Polymers 2019, 11, 1604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rao, J.; Zhou, Y.; Fan, M. Revealing the Interface Structure and Bonding Mechanism of Coupling Agent Treated WPC. Polymers 2018, 10, 266. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Avella, M.; Cocca, M.; Errico, M.; Gentile, G. Biodegradable PVOH-Based Foams for Packaging Applications. J. Cell. Plast. 2011, 47, 271–281. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Avella, M.; Avolio, R.; Bonadies, I.; Carfagna, C.; Cocca, M.; Errico, M.E.; Gentile, G. Isothermal and Nonisothermal Crystallization of HDPE Composites Containing Multilayer Carton Scraps as Filler. J. Appl. Polym. Sci. 2012, 125, 3880–3887. [Google Scholar] [CrossRef]

- Wunderlich, B. Macromolecular Physics, Volume 3: Crystal Melting; Academic Press: London, UK, 1980. [Google Scholar]

- Woodhams, R.T.; Thomas, G.; Rodgers, D.K. Wood Fibers as Reinforcing Fillers for Polyolefins. Polym. Eng. Sci. 1984, 24, 1166–1171. [Google Scholar] [CrossRef]

- Cocca, M.; Avolio, R.; Gentile, G.; Di Pace, E.; Errico, M.E.; Avella, M. Amorphized Cellulose as Filler in Biocomposites Based on Poly(ɛ-Caprolactone). Carbohydr. Polym. 2015, 118, 170–182. [Google Scholar] [CrossRef]

- Avolio, R.; Graziano, V.; Pereira, Y.D.F.; Cocca, M.; Gentile, G.; Errico, M.E.; Ambrogi, V.; Avella, M. Effect of Cellulose Structure and Morphology on the Properties of Poly(Butylene Succinate-Co-Butylene Adipate) Biocomposites. Carbohydr. Polym. 2015, 133, 408–420. [Google Scholar] [CrossRef]

- Lin, J.-H.; Huang, C.-L.; Liu, C.-F.; Chen, C.-K.; Lin, Z.-I.; Lou, C.-W. Polypropylene/Short Glass Fibers Composites: Effects of Coupling Agents on Mechanical Properties, Thermal Behaviors, and Morphology. Materials 2015, 8, 8279–8291. [Google Scholar] [CrossRef] [Green Version]

- Avolio, R.; Gentile, G.; Avella, M.; Carfagna, C.; Errico, M.E. Polymer–Filler Interactions in PET/CaCO3 Nanocomposites: Chain Ordering at the Interface and Physical Properties. Eur. Polym. J. 2013, 49, 419–427. [Google Scholar] [CrossRef]

- Avolio, R.; Spina, F.; Gentile, G.; Cocca, M.; Avella, M.; Carfagna, C.; Tealdo, G.; Errico, M. Recycling Polyethylene-Rich Plastic Waste from Landfill Reclamation: Toward an Enhanced Landfill-Mining Approach. Polymers 2019, 11, 208. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hameed, T.; Hussein, I.A. Effect of Short Chain Branching of LDPE on Its Miscibility with Linear HDPE. Macromol. Mater. Eng. 2004, 289, 198–203. [Google Scholar] [CrossRef]

- Zhao, L.; Choi, P. A Review of the Miscibility of Polyethylene Blends. Mater. Manuf. Process. 2006, 21, 135–142. [Google Scholar] [CrossRef]

- Dányádi, L.; Renner, K.; Móczó, J.; Pukánszky, B. Wood Flour Filled Polypropylene Composites: Interfacial Adhesion and Micromechanical Deformations. Polym. Eng. Sci. 2007, 47, 1246–1255. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Dimensional stability and mechanical behaviour of wood–plastic composites based on recycled and virgin high-density polyethylene (HDPE). Compos. B Eng. 2008, 39, 807–815. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Strydom, M.J. Critical materials and processing challenges affecting the interface and functional performance of wood polymer composites (WPCs). Mater. Chem. Phys. 2016, 171, 290–302. [Google Scholar] [CrossRef]

- Müssig, J.; Graupner, N. Test Methods for Fibre/Matrix Adhesion in Cellulose Fibre--Reinforced Thermoplastic Composite Materials: A Critical Review. In Progress in Adhesion and Adhesives, Volume 6; Mittal, K.M., Ed.; Scrivener Publishing LLC: Beverly, MA, USA, 2021; pp. 69–130. [Google Scholar] [CrossRef]

- Cai, Z.; Ross, R.J. Mechanical Properties of Wood-Based Composite Materials. In Wood Handbook: Wood as an Engineering Material; General technical report FPL; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 12.1–12.12. [Google Scholar]

- Amazio, P.; Avella, M.; Emanuela Errico, M.; Gentile, G.; Balducci, F.; Gnaccarini, A.; Moratalla, J.; Belanche, M. Low Formaldehyde Emission Particleboard Panels Realized through a New Acrylic Binder. J. Appl. Polym. Sci. 2011, 122, 2779–2788. [Google Scholar] [CrossRef]

- Kibirkštis, E.; Kabelkaitė, A. Research of Paper/Paperboard Mechanical Characteristics. Mechanika 2006, 59, 34–41. [Google Scholar]

- Keener, T.; Stuart, R.; Brown, T. Maleated Coupling Agents for Natural Fibre Composites. Compos. A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Shi, S.Q. Diffusion Model Based on Fick’s Second Law for the Moisture Absorption Process in Wood Fiber-Based Composites: Is It Suitable or Not? Wood Sci. Technol. 2007, 41, 645–658. [Google Scholar] [CrossRef]

- Garcia, R.A.; Cloutier, A.; Riedl, B. Dimensional Stability of MDF Panels Produced from Fibres Treated with Maleated Polypropylene Wax. Wood Sci. Technol. 2005, 39, 630–650. [Google Scholar] [CrossRef]

| PE + MAPE | MAPE (% vs. PE) | MC (%) | Sample Codes | |

|---|---|---|---|---|

| Cartons without Al (C) | Cartons without Al (C-Al) | |||

| 100 | - | - | PE | - |

| 80 | - | 20 | M0 C20 | M0 CAl20 |

| 60 | - | 40 | M0 C40 | M0 CAl40 |

| 40 | - | 60 | M0 C60 | M0 CAl60 |

| 20 | - | 80 | M0 C80 | M0 CAl80 |

| 10 | - | 90 | M0 C90 | M0 CAl90 |

| 100 | 2.5 | - | M2.5 | - |

| 80 | 2.5 | 20 | M2.5 C20 | M2.5 CAl20 |

| 60 | 2.5 | 40 | M2.5 C40 | M2.5 CAl40 |

| 40 | 2.5 | 60 | M2.5 C60 | M2.5 CAl60 |

| 100 | 5 | - | M5 | - |

| 80 | 5 | 20 | M5 C20 | M5 CAl20 |

| 60 | 5 | 40 | M5 C40 | M5 CAl40 |

| 40 | 5 | 60 | M5 C60 | M5 CAl60 |

| 100 | 10 | - | M10 | - |

| 80 | 10 | 20 | M10 C20 | M10 CAl20 |

| 60 | 10 | 40 | M10 C40 | M10 CAl40 |

| 40 | 10 | 60 | M10 C60 | M10 CAl60 |

| 20 | 10 | 80 | M10 C80 | M10 CAl80 |

| 10 | 10 | 90 | M10 C90 | M10 CAl90 |

| Code | Tc (°C) | Tm (°C) | Xc (%) | Code | Tc (°C) | Tm (°C) | Xc (%) |

|---|---|---|---|---|---|---|---|

| PE | 116 | 138 | 71 | - | |||

| M0 C20 | 113 | 140 | 67 | M0 CAl20 | 113 | 140 | 66 |

| M0 C40 | 115 | 137 | 59 | M0 CAl40 | 115 | 137 | 59 |

| M0 C60 | 116 | 136 | 57 | M0 CAl60 | 116 | 136 | 56 |

| M0 C80 | 116 | 108–133 | 44 | M0 CAl80 | 115 | 108–132 | 54 |

| M0 C90 | 115 | 106–130 | 36 | M0 CAl90 | 114 | 106–128 | 48 |

| M2.5 | 116 | 137 | 71 | - | |||

| M2.5 C20 | 113 | 140 | 66 | M2.5 CAl20 | 116 | 137 | 71 |

| M2.5 C40 | 116 | 136 | 65 | M2.5 CAl40 | 113 | 140 | 62 |

| M2.5 C60 | 115 | 136 | 54 | M2.5 CAl60 | 116 | 135 | 59 |

| M5 | 116 | 137 | 68 | - | |||

| M5 C20 | 114 | 140 | 67 | M5 CAl20 | 115 | 138 | 69 |

| M5 C40 | 115 | 137 | 60 | M5 CAl40 | 114 | 138 | 54 |

| M5 C60 | 116 | 135 | 56 | M5 CAl60 | 115 | 136 | 63 |

| M10 | 115 | 137 | 71 | - | |||

| M10 C20 | 114 | 139 | 67 | M10 CAl20 | 115 | 138 | 64 |

| M10 C40 | 114 | 137 | 62 | M10 CAl40 | 114 | 138 | 63 |

| M10 C60 | 116 | 135 | 53 | M10 CAl60 | 115 | 136 | 59 |

| M10 C80 | 115 | 132 | 42 | M10 CAl80 | 116 | 109–132 | 54 |

| M10 C90 | 115 | 131 | 31 | M10 CAl90 | 116 | 106–128 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonadies, I.; Capuano, R.; Avolio, R.; Castaldo, R.; Cocca, M.; Gentile, G.; Errico, M.E. Sustainable Cellulose-Aluminum-Plastic Composites from Beverage Cartons Scraps and Recycled Polyethylene. Polymers 2022, 14, 807. https://doi.org/10.3390/polym14040807

Bonadies I, Capuano R, Avolio R, Castaldo R, Cocca M, Gentile G, Errico ME. Sustainable Cellulose-Aluminum-Plastic Composites from Beverage Cartons Scraps and Recycled Polyethylene. Polymers. 2022; 14(4):807. https://doi.org/10.3390/polym14040807

Chicago/Turabian StyleBonadies, Irene, Roberta Capuano, Roberto Avolio, Rachele Castaldo, Mariacristina Cocca, Gennaro Gentile, and Maria Emanuela Errico. 2022. "Sustainable Cellulose-Aluminum-Plastic Composites from Beverage Cartons Scraps and Recycled Polyethylene" Polymers 14, no. 4: 807. https://doi.org/10.3390/polym14040807

APA StyleBonadies, I., Capuano, R., Avolio, R., Castaldo, R., Cocca, M., Gentile, G., & Errico, M. E. (2022). Sustainable Cellulose-Aluminum-Plastic Composites from Beverage Cartons Scraps and Recycled Polyethylene. Polymers, 14(4), 807. https://doi.org/10.3390/polym14040807