Conventional and Microcellular Injection Molding of a Highly Filled Polycarbonate Composite with Glass Fibers and Carbon Black

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Conventional and Microcellular Injection Molding of ASTM Tensile Test Bar Samples

2.2. Solid and Microcellular Injection Molding of Box-Shaped Samples

3. Results

3.1. Weight Reduction and Injection Pressure of Tensile Test Bar Samples

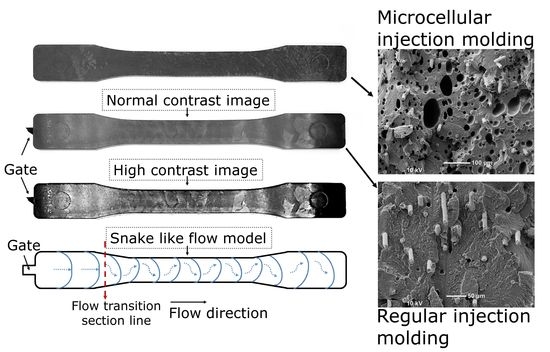

3.2. SEM Images of Tensile Test Bar Samples

3.3. Tensile Test Bar Sample Images

3.4. Mechanical Properties of Tensile Test Bar Samples

3.5. Comparison of Required Injection Pressure for the Box-Shaped Part

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, W.Y.; Jang, J.; Lee, H.S.; Kim, S.Y. Electrical Conductivity of Polymer Composites Based on Carbonized Wood Flour via Plasma Post-Treatment as an Effective and Economical Filler. Polym. Compos. 2021, 42, 4814–4821. [Google Scholar] [CrossRef]

- Qiu, J.; Wang, L.; Uchiya, K.; Sakai, E. Effects of Injection Molding Conditions on the Electrical Properties of Polycarbonate/Carbon Nanotube Nanocomposites. Polym. Compos. 2016, 37, 3245–3255. [Google Scholar] [CrossRef]

- Wang, Q.; Cheng, L.; Wang, J.; Qian, Z.; Wei, T.; Guo, W. High Performance Antistatic HDPE Composites with Bridging Effect of Hybrid Carbon Black and Multi-Walled Carbon Nanotubes Fillers. Adv. Eng. Mater. 2019, 21, 1800609. [Google Scholar] [CrossRef]

- Brunella, V.; Rossatto, B.G.; Mastropasqua, C.; Cesano, F.; Scarano, D. Thermal/Electrical Properties and Texture of Carbon Black Pc Polymer Composites near the Electrical Percolation Threshold. J. Compos. Sci. 2021, 5, 212. [Google Scholar] [CrossRef]

- Paasi, J. Assessment of ESD Threats to Electronic Components. J. Electrost. 2005, 63, 589–596. [Google Scholar] [CrossRef]

- Sadiku, M.N.O.; Akujuobi, C.M. Electrostatic Discharge (ESD). IEEE Potentials 2004, 23, 39–41. [Google Scholar] [CrossRef]

- Voldman, S. The ESD Handbook; Wiley: Hoboken, NJ, USA, 2021; ISBN 9781119233091. [Google Scholar]

- Bréchet, Y.; Cavaillé, J.-Y.; Chabert, E.; Chazeau, L.; Dendievel, R.; Flandin, L.; Gauthier, C. Polymer Based Nanocomposites: Effect of Filler-Filler and Filler-Matrix Interactions. Adv. Eng. Mater. 2001, 3, 571. [Google Scholar] [CrossRef]

- Ameli, A.; Nofar, M.; Park, C.B.; Pötschke, P.; Rizvi, G. Polypropylene/Carbon Nanotube Nano/Microcellular Structures with High Dielectric Permittivity, Low Dielectric Loss, and Low Percolation Threshold. Carbon 2014, 71, 206–217. [Google Scholar] [CrossRef]

- Chodák, I.; Omastová, M.; Pionteck, J. Relation between Electrical and Mechanical Properties of Conducting Polymer Composites. J. Appl. Polym. Sci. 2001, 82, 1903–1906. [Google Scholar] [CrossRef]

- Krupa, I.; Novák, I.; Chodák, I. Electrically and Thermally Conductive Polyethylene/Graphite Composites and Their Mechanical Properties. Synth. Met. 2004, 145, 245–252. [Google Scholar] [CrossRef]

- Blutmager, A.; Varga, M.; Schmidt, T.; Pock, A.; Friesenbichler, W. Abrasive/Erosive Wear on MMCs in Plastic Molds as a Function of Volumetric Flow Rates and Glass Fiber Distribution. Polym. Eng. Sci. 2019, 59, E302–E311. [Google Scholar] [CrossRef] [Green Version]

- Bendler, J.T. Handbook of Polycarbonate Science and Technology; Bendler, J.T., Ed.; CRC Press: Boca Raton, FL, USA, 1999; ISBN 9781482273694. [Google Scholar]

- Osswald, T.A.; Turng, L.-S.; Gramann, P.J. Injection Molding Handbook, 2nd ed.; Hanser: München, Germany, 2008; ISBN 9781569904206. [Google Scholar]

- Yang, H.; Yilmaz, G.; Han, G.; Eriten, M.; Zhang, Z.; Yu, S.; Shi, M.; Yan, H.; Yang, W.; Xie, P.; et al. A Quick Response and Tribologically Durable Graphene Heater for Rapid Heat Cycle Molding and Its Applications in Injection Molding. Appl. Therm. Eng. 2020, 167, 114791. [Google Scholar] [CrossRef]

- Li, S.; Xu, Y.; Jing, X.; Yilmaz, G.; Li, D.; Turng, L.-S. Effect of Carbonization Temperature on Mechanical Properties and Biocompatibility of Biochar/Ultra-High Molecular Weight Polyethylene Composites. Compos. Part B Eng. 2020, 196, 108120. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, T.; Zhang, Y.; Huang, Z.; Gao, H.; Han, W.; Turng, L.S.; Zhou, H. Intelligent Setting of Process Parameters for Injection Molding Based on Case-Based Reasoning of Molding Features. J. Intell. Manuf. 2020, 33, 77–89. [Google Scholar] [CrossRef]

- Okamoto, K.T. Microcellular Processing; Hanser: Munich, Germany, 2003; ISBN 9781569903445. [Google Scholar]

- Ellingham, T.; Kharbas, H.; Manitiu, M.; Scholz, G.; Turng, L.-S. Microcellular Injection Molding Process for Producing Lightweight Thermoplastic Polyurethane with Customizable Properties. Front. Mech. Eng. 2018, 13, 96–106. [Google Scholar] [CrossRef]

- Sun, X.; Turng, L.S. Novel Injection Molding Foaming Approaches Using Gas-Laden Pellets with N2, CO2, and N2 + CO2 as the Blowing Agents. Polym. Eng. Sci. 2014, 54, 899–913. [Google Scholar] [CrossRef]

- Kramschuster, A.; Cavitt, R.; Ermer, D.; Chen, Z.B.; Turng, L.-S. Effect of Processing Conditions on Shrinkage and Warpage and Morphology of Injection Moulded Parts Using Microcellular Injection Moulding. Plast. Rubber Compos. 2006, 35, 198–209. [Google Scholar] [CrossRef]

- Yilmaz, G.; Ellingham, T.; Turng, L.-S. Improved Processability and the Processing-Structure-Properties Relationship of Ultra-High Molecular Weight Polyethylene via Supercritical Nitrogen and Carbon Dioxide in Injection Molding. Polymers 2017, 10, 36. [Google Scholar] [CrossRef] [Green Version]

- Xu, J. Microcellular Injection Molding; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; ISBN 9780470642818. [Google Scholar]

- Wang, G.; Zhao, G.; Dong, G.; Mu, Y.; Park, C.B. Lightweight and Strong Microcellular Injection Molded PP/Talc Nanocomposite. Compos. Sci. Technol. 2018, 168, 38–46. [Google Scholar] [CrossRef]

- Osorio, A.; Turng, L.-S. Mathematical Modeling and Numerical Simulation of Cell Growth in Injection Molding of Microcellular Plastics. Polym. Eng. Sci. 2004, 44, 2274–2287. [Google Scholar] [CrossRef]

- Antunes, M.; Mudarra, M.; Velasco, J.I. Broad-Band Electrical Conductivity of Carbon Nanofibre-Reinforced Polypropylene Foams. Carbon 2011, 49, 708–717. [Google Scholar] [CrossRef]

- Kim, H.K.; Sohn, J.S.; Ryu, Y.; Kim, S.W.; Cha, S.W. Warpage Reduction of Glass Fiber Reinforced Plastic Using Microcellular Foaming Process Applied Injection Molding. Polymers 2019, 11, 360. [Google Scholar] [CrossRef] [Green Version]

- Xi, Z.; Sha, X.; Liu, T.; Zhao, L. Microcellular Injection Molding of Polypropylene and Glass Fiber Composites with Supercritical Nitrogen. J. Cell. Plast. 2014, 50, 489–505. [Google Scholar] [CrossRef]

- Carbo-Rite™ Conductive Compounds and Sheet Products—Lubrizol. Available online: https://www.lubrizol.com/Engineered-Polymers/Products/Carbo-Rite (accessed on 16 September 2021).

- Lee, J.; Turng, L.S. Improving Surface Quality of Microcellular Injection Molded Parts through Mold Surface Temperature Manipulation with Thin Film Insulation. Polym. Eng. Sci. 2010, 50, 1281–1289. [Google Scholar] [CrossRef]

- Owada, S.; Yokoi, H. Visualization Analysis of Tiger-Striped Flow Mark Generation Phenomena in Injection Molding. AIP Conf. Proc. 2016, 1713, 040001–040003. [Google Scholar] [CrossRef] [Green Version]

- Hirano, K.; Suetsugu, Y.; Kanai, T. Morphological Analysis of the Tiger Stripe on Injection Molding of Polypropylene/Ethylene-Propylene Rubber/Talc Blends Dependent on Based Polypropylene Design. J. Appl. Polym. Sci. 2007, 104, 192–199. [Google Scholar] [CrossRef]

| Parameters | Unit | Solid | MIM-1 | MIM-2 | MIM-3 |

|---|---|---|---|---|---|

| Injection speed | cm3/s | 30 | 30 | ↑50 | ↑40 |

| Shot volume | cm3 | 21 | 21 | 21 | ↓18 |

| Packing pressure | MPa | 80 | N/A | N/A | N/A |

| Packing time | s | 8 | N/A | N/A | N/A |

| Back pressure | MPa | 0.2 | 5.0 | 5.0 | 5.0 |

| Melt temperature | °C | 300 | 300 | ↓285 | ↑310 |

| Mold temperature | °C | 80 | 80 | ↓60 | ↑90 |

| Cooling time | s | 20 | 20 | 20 | ↑25 |

| SCF (N2) dosage 1 | wt% | N/A | 0.50 | ↑0.55 | ↑0.61 |

| Actual weight reduction | wt% | N/A | 5.1 | ↓4.0 | ↑11.4 |

| Sample Name | Solid | MIM | |

|---|---|---|---|

| Parameters | Unit | Value | Value |

| Injection speed | cm3/s | 30 | 30 |

| Injection volume | cm3 | 52.0 | 51.8 |

| Packing pressure | MPa | 80 | N/A |

| Packing time | s | 8 | N/A |

| Back pressure | MPa | 0.2 | 5.0 |

| Melt temperature | °C | 320 | 320 |

| Mold temperature | °C | 80 | 80 |

| Cooling time | s | 30 | 30 |

| SCF (N2) dosage 1 | wt% | N/A | 0.50 |

| Nominal weight Reduction | wt% | N/A | 5 |

| Sample Name | Solid | MIM | Solid and MIM Comparison | |

|---|---|---|---|---|

| Parameters | Unit | Value | Value | % Change |

| Average weight | g | 59.41 ± 0.10 | 56.30 ± 0.24 | 5.23 |

| Injection pressure at 90% of filling | MPa | 102.6 ± 2.2 | 76.2 ± 2.4 | 25.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yilmaz, G.; Devahastin, A.; Turng, L.-S. Conventional and Microcellular Injection Molding of a Highly Filled Polycarbonate Composite with Glass Fibers and Carbon Black. Polymers 2022, 14, 1193. https://doi.org/10.3390/polym14061193

Yilmaz G, Devahastin A, Turng L-S. Conventional and Microcellular Injection Molding of a Highly Filled Polycarbonate Composite with Glass Fibers and Carbon Black. Polymers. 2022; 14(6):1193. https://doi.org/10.3390/polym14061193

Chicago/Turabian StyleYilmaz, Galip, Apichart Devahastin, and Lih-Sheng Turng. 2022. "Conventional and Microcellular Injection Molding of a Highly Filled Polycarbonate Composite with Glass Fibers and Carbon Black" Polymers 14, no. 6: 1193. https://doi.org/10.3390/polym14061193

APA StyleYilmaz, G., Devahastin, A., & Turng, L. -S. (2022). Conventional and Microcellular Injection Molding of a Highly Filled Polycarbonate Composite with Glass Fibers and Carbon Black. Polymers, 14(6), 1193. https://doi.org/10.3390/polym14061193