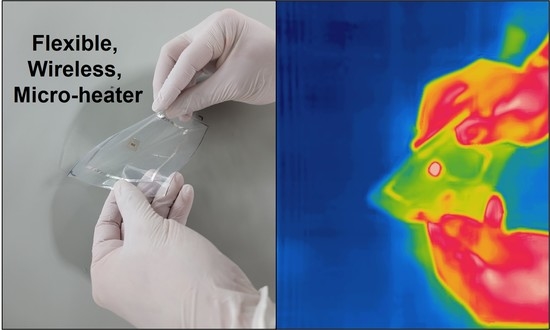

Fabrication of a Flexible, Wireless Micro-Heater on Elastomer for Wearable Gas Sensor Applications

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Wireless Micro-Heater and the Power Transfer System

3.2. Antenna Performance

3.3. Performances of Wireless Micro-Heaters

3.4. Wireless Micro-Heater for a Gas-Sensing Application

3.5. Flexible Properties of a Wireless Micro-Heater

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Han, S.; Kim, J.; Won, S.M.; Ma, Y.; Kang, D.; Xie, Z.; Lee, K.-T.; Chung, H.U.; Banks, A.; Min, S.; et al. Battery-free, wireless sensors for full-body pressure and temperature mapping. Sci. Transl. Med. 2018, 10, eaan4950. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jeong, W.; Song, J.; Bae, J.; Nandanapalli, K.R.; Lee, S. Breathable nanomesh humidity sensor for real-time skin humidity monitoring. ACS Appl. Mater. Interfaces 2019, 11, 44758–44763. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Zhang, X.; Tang, N.; Fang, Y.; Zhang, H.; Duan, X. Rapid response flexible humidity sensor for respiration monitoring using nano-confined strategy. Nanotechnology 2020, 31, 125302. [Google Scholar] [CrossRef] [PubMed]

- Pang, Y.; Jian, J.; Tu, T.; Yang, Z.; Ling, J.; Li, Y.; Wang, X.; Qiao, Y.; Tian, H.; Yang, Y.; et al. Wearable humidity sensor based on porous graphene network for respiration monitoring. Biosens. Bioelectron. 2018, 116, 123–129. [Google Scholar] [CrossRef]

- Park, Y.-G.; Lee, S.; Park, J.-U. Recent progress in wireless sensors for wearable electronics. Sensors 2019, 19, 4353. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.-K.; Murphy, R.K.J.; Hwang, S.-W.; Lee, S.M.; Harburg, D.V.; Krueger, N.A.; Shin, J.; Gamble, P.; Cheng, H.; Yu, S.; et al. Bioresorbable Silicon Electronic Sensors for the Brain. Nature 2016, 530, 71–76. [Google Scholar] [CrossRef]

- Shin, G. Soft, wirelessly powered humidity sensor based on SnO2 nanowires for wireless/wearable sensor application. Materials 2020, 13, 2176. [Google Scholar] [CrossRef]

- Yu, K.J.; Yan, Z.; Han, M.; Rogers, J.A. Inorganic semiconducting materials for flexible and stretchable electronics. NPJ Flexible Electronics 2017, 1, 4. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.; Ghaffari, R.; Baker, L.B.; Rogers, J.A. Skin-interfaced systems for sweat collection and analytics. Sci. Adv. 2018, 4, eaar3921. [Google Scholar] [CrossRef] [Green Version]

- Chung, H.U.; Kim, B.H.; Lee, J.Y.; Lee, J.; Xie, Z.; Ibler, E.M.; Lee, K.; Bank, A.; Jeong, J.Y.; Kim, J.; et al. Binodal, wireless epidermal electronic systems with in-sensor analytics for neonatal intensive care. Science 2019, 363, 947. [Google Scholar] [CrossRef] [Green Version]

- Oh, Y.S.; Kim, J.-H.; Xie, Z.; Cho, S.; Han, H.; Jeon, S.W.; Park, M.; Namkoong, M.; Avila, R.; Song, Z.; et al. Battery-free, wireless soft sensors for continuous multi-site measurements of pressure and temperature form patients at risk for pressure injuries. Nat. Comm. 2021, 12, 5008. [Google Scholar] [CrossRef] [PubMed]

- Heo, S.Y.; Kim, J.; Gutruf, P.; Banks, A.; Wei, P.; Pielak, R.; Balooch, G.; Shi, Y.; Araki, H.; Rollo, D.; et al. Wireless, battery-free, flexible, miniaturized dosimeters monitor exposure to solar radiation and to light for phototherapy. Sci. Transl. Med. 2018, 10, eaau1643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jeong, J.-W.; McCall, J.G.; Shin, G.; Zhang, Y.; Al-Hasani, R.; Kim, M.; Li, S.; Sim, J.Y.; Jang, K.-I.; Shi, Y.; et al. Wireless optofluidic systems for programmable in vivo pharmacology and optogenetics. Cell 2015, 162, 662–674. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Zhao, H.; Zhao, X.; Xu, C.; Franklin, D.; Vazquez-Guardado, A.; Bai, W.; Zhao, J.; Li, K.; Monti, G.; et al. Biocompatible light guide-assisted wearable devices for enhanced UV light delivery in deep skin. Adv. Funct. Mat. 2021, 31, 2100576. [Google Scholar] [CrossRef]

- Kim, D.H.; Ahn, J.-H.; Choi, W.-M.; Kim, H.-S.; Kim, T.-H.; Song, J.; Huang, Y.Y.; Zhuangjian, L.; Chun, L.; Rogers, J.A. Stretchable and foldable silicon integrated circuits. Science 2008, 320, 507–511. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.H.; Xiao, J.; Song, J.; Huang, Y.; Rogers, J.A. Stretchable, curvilinear electronics based on inorganic materials. Adv. Mat. 2010, 22, 2108–2124. [Google Scholar] [CrossRef]

- Ko, H.C.; Shin, G.; Wang, S.; Stoykovich, M.P.; Lee, J.W.; Kim, D.-H.; Ha, J.S.; Huang, Y.; Rogers, J.A. Curvilinear electronics formed using silicon membrane circuits and elastomeric transfer elements. Small 2009, 5, 2703–2709. [Google Scholar] [CrossRef]

- Wang, D.; Chen, Y.; Liu, Z.; Li, L.; Shi, C.; Qin, H.; Hu, J. CO2-sensing properties and mechanism of nano-SnO2 thick-film sensor. Sens. Actuators 2016, B227, 73–84. [Google Scholar] [CrossRef]

- Hwang, W.-J.; Shin, K.-S.; Roh, J.-H.; Lee, D.-S.; Choa, S.-H. Development of micro-heaters with optimized temperature compensation design for gas sensors. Sensors 2011, 11, 2580–2591. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.-G.; Park, J.-S.; Park, K.-B.; Shin, J.; Lee, E.-A.; Noh, S.; Lee, H.-J. Temperature control of micro heater using Pt thin film temperature sensor embedded in micro gas sensor. Micro Nano Syst. Lett. 2017, 5, 26. [Google Scholar] [CrossRef] [Green Version]

- Toskov, S.; Glatz, R.; Miskovic, G.; Radosavljevic, G. Modeling and fabrication of Pt micro-heaters built on alumina substrate. In Proceedings of the 36th International Spring Seminar on Electronics Technology, Alba Iulia, Romania, 8–12 May 2013; pp. 47–52. [Google Scholar]

- Wang, C.-P.; Hsiao, M.-H.; Lee, G.-H.; Chang, T.-L.; Lee, Y.-W. The investigation of electrothermal response and reliability of flexible graphene micro-heaters. Microelectron. Eng. 2020, 228, 111334. [Google Scholar] [CrossRef]

- Lee, K.; Park, J.; Jung, S.I.; Hajra, S.; Kim, H.J. Direct integration of carbon nanotubes on a suspended Pt microheater for hydrogen gas sensing. J. Mater. Sci. Mater. Electron. 2021, 32, 19626–19634. [Google Scholar] [CrossRef]

- Zhang, T.-Y.; Zhao, H.-M.; Yang, Z.; Wang, Q.; Wang, D.-Y.; Deng, N.-Q.; Yang, Y.; Ren, T.-L. Improved electrothermal performance of custom-shaped micro heater based on anisotropic laser-reduced graphene oxide. Appl. Phys. Lett. 2016, 109, 151905. [Google Scholar] [CrossRef]

- Yeh, C.-C.; Yang, Y.-J. An rf-powered wireless micro-heater integrated with acrylate-composite-based temperature regulator for hyperthermia treatment. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020; pp. 357–360. [Google Scholar]

- Chung, G.-S.; Jeong, J.-M. Fabrication of micro heaters on polycrystalline 3C-SiC suspended membranes for gas sensors and their characteristics. Microelectron. Eng. 2010, 87, 2348–2352. [Google Scholar] [CrossRef]

- Choi, Y.J.; Hwang, I.S.; Park, J.G.; Choi, K.J.; Park, J.H.; Lee, J.H. Novel fabrication of an SnO(2) nanowire gas sensor with high sensitivity. Nanotechnology 2008, 19, 095508. [Google Scholar] [CrossRef] [PubMed]

- Shin, G. Studies of Parylene/Silicone-Coated Soft Bio-Implantable Optoelectronic Device. Coatings 2020, 10, 404. [Google Scholar] [CrossRef]

- Han, S.; Shin, G. Biodegradable optical fiber in a soft optoelectronic device for wireless optogenetic applications. Coatings 2020, 10, 1153. [Google Scholar] [CrossRef]

- Park, S.-I.; Brenner, D.S.; Shin, G.; Morgan, C.D.; Copits, B.A.; Chung, H.U.; Pullen, M.Y.; Noh, K.N.; Davidson, S.; Oh, S.J.; et al. Soft, stretchable, fully implantable miniaturized optoelectronic systems for wireless optogenetics. Nat. Biotechnol. 2015, 33, 1280–1286. [Google Scholar] [CrossRef] [Green Version]

- Shin, G.; Gomez, A.M.; Al-Hasani, R.; Jeong, Y.R.; Kim, J.; Xie, Z.; Banks, A.; Lee, S.M.; Han, S.Y.; Yoo, C.J.; et al. Flexible Near-Field Wireless Optoelectronics as Subdermal Implants for Broad Applications in Optogenetics. Neuron 2017, 93, 509–521. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.; Kim, Y.-K.; Park, S.C.; Ha, J.S.; Huh, J.; Na, J.; Kim, G.-T. Photoconductance of aligned SnO2 nanowire field effect transistors. Appl. Phys. Lett. 2009, 95, 043107. [Google Scholar] [CrossRef]

- Fan, Z.; Ho, J.C.; Jacobson, Z.A.; Yerushalmi, R.; Alley, R.L.; Razavi, H.; Javey, A. Wafer-scale assembly of highly ordered semiconductor nanowire arrays by contact printing. Nano Lett. 2008, 8, 20–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kuang, Q.; Lao, C.; Wang, Z.L.; Xie, Z.; Zheng, L. High-sensitivity humidity sensor based on a single SnO2 nanowire. J. Am. Chem. Soc. 2007, 129, 6070–6071. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.; Sinha, S.K.; Treich, G.M.; Wang, Y.; Yang, Q.; Deshmukh, A.A.; Sotzing, G.A.; Cao, Y. All-organic flexible fabric antenna for wearable electronics. J. Mater. Chem. C 2020, 8, 5662–5667. [Google Scholar] [CrossRef]

- Sidek, O.; Ishak, M.Z.; Khalid, M.A.; Abu Bakar, M.Z.; Miskam, M.A. Effect of heater geometry on the high temperature distribution on a MEMS micro-hotplate. In Proceedings of the 2011 3rd Asia Symposium on Quality Electronic Design (ASQED), Kuala Lumpur, Malaysia, 19–20 July 2011; pp. 100–104. [Google Scholar]

- Chang, J.F.; Kuo, H.H.; Leu, I.C. and Hon, M.H. The effects of thickness and operation temperature on ZnO:Al thin film CO gas sensor. Sens. Actuators B 2002, 84, 258–264. [Google Scholar] [CrossRef]

| Properties | This Work | Chang et al., 2002 [37] | Kang et al., 2017 [20] | Hwang et al., 2011 [19] | Yeh et al., 2020 [25] | Lee et al., 2021 [23] | Shin et al., 2020 [7] |

|---|---|---|---|---|---|---|---|

| Device | Heater and sensor | Heater and sensor | Heater and sensor | Heater and sensor | Heater | Heater and sensor | Sensor |

| Max. heating temperature | 102 °C | 500 °C | 210 °C | 460 °C | 45 °C | 420 °C | - |

| Sensor type | Resistive | Resistive | Resistive | Non dispersive IR | - | Resistive | Transistor |

| Sensing material | SnO2 nanowire (NW) | Al-doped ZnO film | SiNx membrane | SiNx | - | Carbon nanotube | SnO2 nanowire (NW) |

| Purpose | CO sensing | CO sensing | CO sensing | Gas sensing | Hyperthermia treatment | Gas sensing | Humidity alarm |

| Sensitivity 1 | ~10 | ~2 | 25 ppm | - | - | ~1.1 | ~104 |

| Recovery | ~30 s | ~130 s | - | - | - | ~39 s | Slow |

| Flexibility | Flexible | Rigid | Rigid | Rigid | Flexible | Rigid | Flexible |

| Substrate | PDMS | Silicon | Silicon | Silicon | PDMS | Silicon | PDMS |

| Wireless availability | NFC-based wireless | - | - | - | Wireless | - | NFC-based wireless |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, J.; Shin, G. Fabrication of a Flexible, Wireless Micro-Heater on Elastomer for Wearable Gas Sensor Applications. Polymers 2022, 14, 1557. https://doi.org/10.3390/polym14081557

Cho J, Shin G. Fabrication of a Flexible, Wireless Micro-Heater on Elastomer for Wearable Gas Sensor Applications. Polymers. 2022; 14(8):1557. https://doi.org/10.3390/polym14081557

Chicago/Turabian StyleCho, Jonam, and Gunchul Shin. 2022. "Fabrication of a Flexible, Wireless Micro-Heater on Elastomer for Wearable Gas Sensor Applications" Polymers 14, no. 8: 1557. https://doi.org/10.3390/polym14081557

APA StyleCho, J., & Shin, G. (2022). Fabrication of a Flexible, Wireless Micro-Heater on Elastomer for Wearable Gas Sensor Applications. Polymers, 14(8), 1557. https://doi.org/10.3390/polym14081557