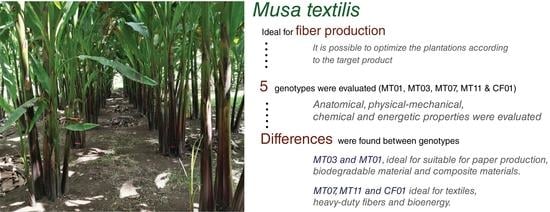

Evaluation of the Optimal Uses of Five Genotypes of Musa textilis Fiber Grown in the Tropical Region

Abstract

:1. Introduction

2. Materials and Methods

2.1. Genotypes and Study Site

2.2. Fiber Processing

2.3. Anatomical Properties

2.4. Physical-Mechanical Properties

2.5. Chemical and Energetic Properties

2.6. Genotype Differentiation and Optimal Use

2.7. Statistical Analysis

3. Results and Discussion

3.1. Anatomical Properties

3.2. Physical-Mechanical Properties

3.3. Chemical Properties

3.4. Energetic Properties

3.5. Genotypes Differentiation and Optimal Use

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pearson, P.J.; Foxon, T.J. A low carbon industrial revolution? Insights and challenges from past technological and economic transformations. Energy Policy 2012, 50, 117–127. [Google Scholar] [CrossRef] [Green Version]

- Valverde, J.C.; Arias, D.; Campos, R.; Jiménez, M.F.; Brenes, L. Forest and agro-industrial residues and bioeconomy: Perception of use in the energy market in Costa Rica. Energy Ecol. Environ. 2021, 6, 232–243. [Google Scholar] [CrossRef]

- Vasquez, J.Z.; Diaz, L.J.L. Unidirectional abaca fiber reinforced thermoplastic starch composite. In Materials Science Forum; Trans Tech Publications Ltd.: Zúrich, Swizerland, 2017; pp. 56–61. [Google Scholar]

- Oliver-Cervelló, L.; Martin-Gómez, H.; Mas-Moruno, C. New trends in the development of multifunctional peptides to functionalize biomaterials. J. Pept. Sci. 2022, 28, e3335. [Google Scholar] [CrossRef] [PubMed]

- Qin, D.; Bi, S.; You, X.; Wang, M.; Cong, X.; Yuan, C.; Yu, M.; Cheng, X.; Chen, X.-G. Development and application of fish scale wastes as versatile natural biomaterials. Chem. Eng. J. 2022, 428, 131102. [Google Scholar] [CrossRef]

- Dungani, R.; Aditiawati, P.; Aprilia, S.; Yuniarti, K.; Karliati, T.; Suwandhi, I.; Sumardi, I. Biomaterial from oil palm waste: Properties, characterization and applications. Palm Oil 2018, 31, 1–6. [Google Scholar]

- Petre, D.G.; Leeuwenburgh, S.C. The use of fibers in bone tissue engineering. Tissue Eng. Part B Rev. 2022, 28, 141–159. [Google Scholar] [CrossRef]

- Ilyas, R.; Zuhri, M.; Norrrahim, M.N.F.; Misenan, M.S.M.; Jenol, M.A.; Samsudin, S.A.; Nurazzi, N.; Asyraf, M.; Supian, A.; Bangar, S.P. Natural Fiber-Reinforced Polycaprolactone Green and Hybrid Biocomposites for Various Advanced Applications. Polymers 2022, 14, 182. [Google Scholar] [CrossRef]

- Bendigeri, C.; Jwalesh, H. Review on Fatigue Behaviour of Polymeric Biomaterials with Natural Fibers. Int. J. Adv. Res. Sci 2016, 3, 2349–6495. [Google Scholar]

- Kicińska-Jakubowska, A.; Bogacz, E.; Zimniewska, M. Review of natural fibers. Part I—Vegetable fibers. J. Nat. Fibers 2012, 9, 150–167. [Google Scholar] [CrossRef]

- Ramli, N.; Mazlan, N.; Ando, Y.; Leman, Z.; Abdan, K.; Aziz, A.; Sairy, N. Natural fiber for green technology in automotive industry: A brief review. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Selangor, Malaysia, 21–23 November 2017; p. 012012. [Google Scholar]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Batra, S.K. Other long vegetable fibres: Abaca, banana, sisal, henequen, flax, ramie, hemp, sunn, and coir. Handb. Fiber Sci. Technol. 1985, 4, 727–807. [Google Scholar]

- Yllano, O.B.; Diaz, M.G.Q.; Lalusin, A.G.; Laurena, A.C.; Tecson-Mendoza, E.M. Genetic Analyses of Abaca (Musa textilis Née) Germplasm from its Primary Center of Origin, the Philippines, Using Simple Sequence Repeat (SSR) Markers. Philipp. Agric. Sci. 2020, 103, 311–321. [Google Scholar]

- Moreno, L.; Gapasin, R. Participatory action research on comparison of growth performance of different abaca (Musa textilis Nee) planting materials for abaca industry rehabilitation. Philipp. J. Crop Sci. (Philipp.) 2017, 42, 82. [Google Scholar]

- Armecin, R.B.; Cosico, W.C.; Badayos, R.B. Characterization of the different abaca-based agro-ecosystems in Leyte, Philippines. J. Nat. Fibers 2011, 8, 111–125. [Google Scholar] [CrossRef]

- Göltenboth, F.; Mühlbauer, W. Abacá-cultivation, extraction and processing. Ind. Appl. Nat. Fibres 2010, 8, 163–179. [Google Scholar]

- Moreno, L.; Parac, A.; Ocon, F.; Gapasin, R. Fiber characteristics of promising abaca (Musa textilis Nee) accessions in NARC [National Abaca Research Center] germplasm suited for specific industry end uses. Philipp. J. Crop Sci. (Philipp.) 2010, 35, 113. [Google Scholar]

- Armecin, R.B.; Sinon, F.G.; Moreno, L.O. Abaca fiber: A renewable bio-resource for industrial uses and other applications. In Biomass and Bioenergy; Springer: Berlin/Heidelberg, Germany, 2014; pp. 107–118. [Google Scholar]

- Shahri, W.; Tahir, I.; Ahad, B. Abaca fiber: A renewable bio-resource for industrial uses and other applications. In Biomass and Bioenergy; Springer: Berlin/Heidelberg, Germany, 2014; pp. 47–61. [Google Scholar]

- Simbaña, E.A.; Ordóñez, P.E.; Ordóñez, Y.F.; Guerrero, V.H.; Mera, M.C.; Carvajal, E.A. Abaca: Cultivation, obtaining fibre and potential uses. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 197–218. [Google Scholar]

- Lalusin, A.G.; Villavicencio, M.L.H. Abaca (Musa textilis Nee) breeding in the Philippines. In Industrial Crops; Springer: Berlin/Heidelberg, Germany, 2015; pp. 265–289. [Google Scholar]

- Christelová, P.; Valárik, M.; Hřibová, E.; Channelière, S.; Roux, N.; Doležel, J. A platform for efficient genotyping in Musa using microsatellite markers. AoB Plants 2011, 2011, plr024. [Google Scholar] [CrossRef] [Green Version]

- De Souza, N.; d’Almeida, J. Tensile, thermal, morphological and structural characteristics of abaca (Musa textiles) fibers. Polym. Renew. Resour. 2014, 5, 47–60. [Google Scholar] [CrossRef]

- Bolton, A. Natural fibers for plastic reinforcement. Mater. Technol. 1994, 9, 12–20. [Google Scholar] [CrossRef]

- Piotrowski, S.; Carus, M. Natural fibres in technical applications: Market and trends. In Industrial Applications of Natural Fibers: Structure, Properties and Technical Applications; Wiley: Chichester, UK, 2010; pp. 73–86. [Google Scholar]

- Richter, S.; Stromann, K.; Müssig, J. Abacá (Musa textilis) grades and their properties—A study of reproducible fibre characterization and a critical evaluation of existing grading systems. Ind. Crops Prod. 2013, 42, 601–612. [Google Scholar] [CrossRef]

- Moreno, L.; Ocon, F.; Gonzal, L.; Pono, G.; Borines, L.; Salamat, E.; Cardines, R. Collection conservation, maintenance and utilization of abaca (Musa textiles Nee) germplasm in the Philippines. Philipp. J. Crop Sci. (Philipp.) 2004, 29, 69. [Google Scholar]

- Debnath, S.; Bandvopadhvav, B.; Bauri, F.; Misra, D. A preliminary study on extraction of natural fibre from leaf sheath of some commercial genotypes of banana (Musa sp.) in West Bengal. Hortic. J. 2010, 23, 59–63. [Google Scholar]

- Diabor, E.; Funkenbusch, P.; Kaufmann, E.E. Characterization of cassava fiber of different genotypes as a potential reinforcement biomaterial for possible tissue engineering composite scaffold application. Fibers Polym. 2019, 20, 217–228. [Google Scholar] [CrossRef]

- Lundqvist, S.-O.; Grahn, T.; Olsson, L.; Seifert, T. Comparison of wood, fibre and vessel properties of drought-tolerant eucalypts in South Africa. South. For. A J. For. Sci. 2017, 79, 215–225. [Google Scholar] [CrossRef] [Green Version]

- Rennebaum, H.; Grimm, E.; Warnstorff, K.; Diepenbrock, W. Fibre quality of linseed (Linum usitatissimum L.) and the assessment of genotypes for use of fibres as a by-product. Ind. Crops Prod. 2002, 16, 201–215. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Ishak, M.R.; Sapuan, S.M.; Sharma, S.; Rashedi, A.; Razman, M.R.; Zakaria, S.Z.S. Product Development of Natural Fibre-Composites for Various Applications: Design for Sustainability. Polymers 2022, 14, 920. [Google Scholar] [CrossRef]

- Ferreira, T.; Rasband, W. ImageJ user guide. ImageJ/Fiji 2012, 1, 155–161. [Google Scholar]

- Valverde, J.C.; Arias, D.; Mata, E.; Figueroa, G.; Zamora, N. Determinación de las condiciones fotográficas óptimas para la caracterización anatómica de diez especies maderables de Costa Rica. Rev. Cuba. Cienc. For. 2020, 8, 439–455. [Google Scholar]

- Seifert, K. Zur frage der cellulose-schnellbestimmung nach der acetylaceton-methode. Das Pap. 1960, 14, 104–106. [Google Scholar]

- Sebio-Puñal, T.; Naya, S.; López-Beceiro, J.; Tarrío-Saavedra, J.; Artiaga, R. Thermogravimetric analysis of wood, holocellulose, and lignin from five wood species. J. Therm. Anal. Calorim. 2012, 109, 1163–1167. [Google Scholar] [CrossRef]

- del Río, J.C.; Gutiérrez, A. Chemical composition of abaca (Musa textilis) leaf fibers used for manufacturing of high quality paper pulps. J. Agric. Food Chem. 2006, 54, 4600–4610. [Google Scholar] [CrossRef] [Green Version]

- Narayana, V.L.; Rao, L.B. A brief review on the effect of alkali treatment on mechanical properties of various natural fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 1988–1994. [Google Scholar] [CrossRef]

- Muthu, S.S.; Gardetti, M.A. Sustainability in the Textile and Apparel Industries: Sourcing Synthetic and Novel Alternative Raw Materials; Springer Nature: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Gironès, J.; Lopez, J.; Vilaseca, F.; Herrera-Franco, P.; Mutje, P. Biocomposites from Musa textilis and polypropylene: Evaluation of flexural properties and impact strength. Compos. Sci. Technol. 2011, 71, 122–128. [Google Scholar] [CrossRef]

- Saragih, S.W.; Lubis, R.; Wirjosentono, B.; Eddyanto. Characteristic of abaca (Musa textilis) fiber from Aceh Timur as bioplastic. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018. [Google Scholar]

- Saragih, S.W.; Wirjosentono, B.; Meliana, Y. Thermal and Morphological Properties of Cellulose Nanofiber from Pseudo-Stem Fiber of Abaca (Musa textilis). In Macromolecular Symposia; Wiley Online Library: Hoboken, NJ, USA, 2020; p. 2000020. [Google Scholar]

- Reed, A.R.; Williams, P.T. Thermal processing of biomass natural fibre wastes by pyrolysis. Int. J. Energy Res. 2004, 28, 131–145. [Google Scholar] [CrossRef]

- Pinheiro, J.; Bates, D.; DebRoy, S.; Sarkar, D.; Heisterkamp, S.; Van Willigen, B.; Maintainer, R. Package ‘nlme’. Linear Nonlinear Mix. Eff. Models Version 2017, 3, 1–10. Available online: https://svn.r-project.org/R-packages/trunk/nlme/ (accessed on 6 March 2022).

- Makosso-Kallyth, S.; Diday, E. Principal Component Analysis of Distributional Data. In Analysis of Distributional Data; Chapman and Hall/CRC: London, UK, 2022; pp. 205–246. [Google Scholar]

- Bautista, M. Morpho-Anatomical Characterization of Some Banana (Musa spp. Linn.) Cultivars in Relation to Fiber Quality. Available online: https://agris.fao.org/agris-search/search.do?recordID=PH9411066 (accessed on 6 March 2022).

- Balakrishnan, S.; Wickramasinghe, G.D.; Wijayapala, U.S. A novel approach for banana (Musa) Pseudo-stem fibre grading Method: Extracted fibres from Sri Lankan Banana Cultivars. J. Eng. Fibers Fabr. 2020, 15, 1558925020971766. [Google Scholar] [CrossRef]

- Mukul, M. Elucidation of genotypic variability, character association, and genetic diversity for stem anatomy of twelve tossa jute (Corchorus olitorius L.) genotypes. BioMed Res. Int. 2020, 2020, 9424725. [Google Scholar] [CrossRef] [PubMed]

- Barba, B.J.D.; Madrid, J.F.; Penaloza, D.P., Jr. A review of abaca fiber-reinforced polymer composites: Different modes of preparation and their applications. J. Chil. Chem. Soc. 2020, 65, 4919–4924. [Google Scholar] [CrossRef]

- Campbell, B.; Jones, M. Assessment of genotype× environment interactions for yield and fiber quality in cotton performance trials. Euphytica 2005, 144, 69–78. [Google Scholar] [CrossRef]

- Hirondo, M.; Hirondo, L.L.; Mataya, K.J.; Francisco, E.; Mazon, A.; Natal, P.; Senoro, D.; Catajay-Mani, M. Abaca Fiber (Musa textilis Nee) and Plastic Post-Consumer Wastes (A/PCW) as Potential Building Material. J. Environ. Sci. Manag. 2020, 1, 8–17. [Google Scholar] [CrossRef]

- Chen, J.; Chang, H.; Chen, S.-R. Simulation study of a hybrid absorber–heat exchanger using hollow fiber membrane module for the ammonia–water absorption cycle. Int. J. Refrig. 2006, 29, 1043–1052. [Google Scholar] [CrossRef]

- Putra, A.; Abdullah, Y.; Efendy, H.; Farid, W.M.; Ayob, M.R.; Py, M.S. Utilizing sugarcane wasted fibers as a sustainable acoustic absorber. Procedia Eng. 2013, 53, 632–638. [Google Scholar] [CrossRef] [Green Version]

- Sahu, P.; Gupta, M. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Bande, M.M.; Grenz, J.; Asio, V.B.; Sauerborn, J. Fiber yield and quality of abaca (Musa textilis var. Laylay) grown under different shade conditions, water and nutrient management. Ind. Crops Prod. 2013, 42, 70–77. [Google Scholar] [CrossRef]

- Praveena, B.; Shetty, B.P.; Akshay, A.; Kalyan, B. Experimental study on mechanical properties of pineapple and banana leaf fiber reinforced hybrid composites. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2020. [Google Scholar]

- Valášek, P.; D’amato, R.; Müller, M.; Ruggiero, A. Musa textilis cellulose fibres in biocomposites—An investigation of mechanical properties and microstructure. BioResources 2018, 13, 3177–3194. [Google Scholar] [CrossRef]

- Moreno, L.O.; Protacio, C.M. Chemical composition and pulp properties of abaca (Musa textilis N’ee) cv. Inosa harvested at different stages of stalk maturity. Ann. Trop. Res. 2012, 34, 45–62. [Google Scholar] [CrossRef] [Green Version]

- Moreno, L.; Protacio, C. Fiber morphology and recovery chemical composition and pulp properties of abaca (Musa textilis Nee) cv. Inosa harvested at different stages of stalk maturity. Philipp. J. Crop Sci. (Philipp.) 2013, 38, 103. [Google Scholar]

- Alotaibi, F.; Tung, T.T.; Nine, M.J.; Kabiri, S.; Moussa, M.; Tran, D.N.; Losic, D. Scanning atmospheric plasma for ultrafast reduction of graphene oxide and fabrication of highly conductive graphene films and patterns. Carbon 2018, 127, 113–121. [Google Scholar] [CrossRef]

- Jiménez, L.; Ramos, E.; De la Torre, M.; Pérez, I.; Ferrer, J. Bleaching of soda pulp of fibres of Musa textilis nee (abaca) with peracetic acid. Bioresour. Technol. 2008, 99, 1474–1480. [Google Scholar] [CrossRef]

- Agung, E.; Sapuan, S.; Hamdan, M.; Zaman, H.; Mustofa, U. Study on abaca (Musa textilis Nee) fibre reinforced high impact polystyrene (HIPS) composites by thermogravimetric analysis (TGA). Int. J. Phys. Sci. 2011, 6, 2100–2106. [Google Scholar]

- Chegdani, F.; Mezghani, S.; El Mansori, M.; Mkaddem, A. Fiber type effect on tribological behavior when cutting natural fiber reinforced plastics. Wear 2015, 332, 772–779. [Google Scholar] [CrossRef] [Green Version]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Yang, H.-S.; Wolcott, M.; Kim, H.-S.; Kim, H.-J. Thermal properties of lignocellulosic filler-thermoplastic polymer bio-composites. J. Therm. Anal. Calorim. 2005, 82, 157–160. [Google Scholar] [CrossRef]

- Monzón, M.; Ortega, Z.; Benítez, A.; Ortega, F.; Díaz, N.; Marrero Alemán, M.D. Developments towards a more sustainable rotational moulding process. In Proceedings of the 15th European Conference on Composite Materials: Composites at Venice, ECCM 2012, Venezia, Italy, 24–28 June 2012. [Google Scholar]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Salvador, M.; Amigó, V.; Nuez, A.; Sahuquillo, O.; Llorens, R.; Martí, F. Caracterización de fibras vegetales utilizadas como refuerzo en matrices termoplásticos. J. Clean. Prod. 2017, 18, 573–580. [Google Scholar]

- Shibata, M.; Ozawa, K.; Teramoto, N.; Yosomiya, R.; Takeishi, H. Biocomposites Made from Short Abaca Fiber and Biodegradable Polyesters. Available online: http://www.upv.es/VALORES/Publicaciones/CNM08_Fibras_naturales.pdf (accessed on 6 March 2022).

- Muñoz, F.; Ballerini, A.; Gacitúa, W. Variabilidad de las propiedades físicas, morfológicas y térmicas de la fibra de corteza de Eucalyptus nitens. Maderas. Cienc. Tecnol. 2013, 15, 17–30. [Google Scholar] [CrossRef] [Green Version]

- Hayajneh, M.; AL-Oqla, F.M.; Aldhirat, A. Physical and mechanical inherent characteristic investigations of various Jordanian natural fiber species to reveal their potential for green biomaterials. J. Nat. Fibers 2021, 1–14. [Google Scholar] [CrossRef]

- Roy, P.; Tadele, D.; Defersha, F.; Misra, M.; Mohanty, A.K. Environmental and economic prospects of biomaterials in the automotive industry. Clean Technol. Environ. Policy 2019, 21, 1535–1548. [Google Scholar] [CrossRef]

- Lakes, R.S. Composite Biomaterials; CRC Press: Boca Raton, FL, USA, 2003; pp. 79–80. [Google Scholar]

| Parameter | Genotype | |||||

|---|---|---|---|---|---|---|

| MT01 | MT03 | MT07 | MT11 | CF01 | ||

| Density (g cm−3) | 1.52 A (0.02) | 1.50 A (0.01) | 1.49 A (0.02) | 1.51 A (0.02) | 1.50 A (0.03) | |

| Green moisture content (%) | 42.5 A (1.50) | 45.80 A (3.33) | 35.56 B (4.01) | 41.22 A (4.21) | 43.45 A (4.99) | |

| Water absorption (%) | 24 h | 87.90 A (3.23) | 82.90 B (2.89) | 84.11 B (4.23) | 90.11 A (3.78) | 89.94 A (3.82) |

| 72 h | 94.56 A (3.02) | 93.38 A (2.11) | 91.11 A (3.46) | 95.99 A (2.87) | 96.89 B (3.11) | |

| 240 h | 98.99 A (3.00) | 99.02 A (2.34) | 98.88 A (3.56) | 99.50 A (3.17) | 98.93 A (2.87) | |

| Color (Green) | L* | 89.90 A (2.22) | 90.12 A (3.23) | 90.25 A (3.55) | 88.89 A (3.40) | 90.98 A (3.45) |

| a* | −0.09 A (1.33) | −2.89 B (3.09) | −0.90 A (2.67) | −0.34 A (0.23) | −2.90 B (3.02) | |

| b* | 1.45 A (1.90) | 2.89 B (2.88) | 1.12 (2.08) | 1.11 A (1.89) | 1.08 A (1.22) | |

| C* | 1.22 A (2.45) | 2.55 B (2.39) | 1.1 A (2.24) | 0.10 A (2.88) | 1.05 A (2.14) | |

| Color (Dry) | L* | 77.89 A (3.09) | 74.89 B (2.80) | 77.90 A (2.11) | 78.80 A (3.45) | 78.23 A (3.29) |

| a* | 1.18 A (1.22) | 1.89 A (1.30) | 1.44 A (1.24) | 1.00 A (1.99) | 1.34 A (2.04) | |

| b* | 3.99 A (2.34) | 4.50 A (1.33) | 3.89 A (2.89) | 3.99 A (2.09) | 3.80 A (2.80) | |

| C* | 3.56 A (2.33) | 4.45 A (2.11) | 4.30 A (2.90) | 3.87 A (2.87) | 4.11 A (2.33) | |

| Parameter | Genotype | |||||

|---|---|---|---|---|---|---|

| MT01 | MT03 | MT07 | MT11 | CF01 | ||

| Hollocelulose (%) | 89.62 A (0.95) | 87.91 B (0.46) | 89.38 A (0.98) | 93.06 A (0.37) | 90.65 A (90.56) | |

| Lignin (%) | 11.43 A (0.28) | 11.46 A (0.23) | 15.49 B (0.39) | 14.13 B (0.26) | 11.66 B (0.10) | |

| Extracts | Hot water (%) | 11.01 A (0.18) | 10.17 A (0.41) | 7.75 B (0.24) | 10.88 A (0.15) | 3.90 C (0.20) |

| Cool water (%) | 11.27 A (0.24) | 10.35 A (0.22) | 6.76 B (0.20) | 7.33 B (0.31) | 3.67 C (0.16) | |

| Ethanol-toluene (%) | 11.07 A (0.11) | 10.43 A (0.23) | 5.93 B (0.15) | 7.19 B (0.16) | 2.14 C (0.13) | |

| Sodium hidroxide (%) | 1.33 A (0.10) | 1.33 A (0.11) | 1.30 A (0.09) | 1.32 A (0.10) | 1.31 A (0.09) | |

| Dichloromethane (%) | 9.23 A (0.11) | 9.44 A (0.09) | 4.56 B (0.10) | 5.01 B (0.09) | 4.89 B (0.10) | |

| Nitrogen (%) | 0.14 A (0.02) | 0.11 B (0.01) | 0.09 B (0.02) | 0.10 B (0.02) | 0.10 B (0.02) | |

| Carbon (%) | 62.21 A (1.15) | 66.44 B (0.74) | 66.11 B (0.50) | 66.49 B (0.45) | 66.57 B (0.41) | |

| Hydrogen (%) | 6.44 A (0.02) | 6.72 A (0.10) | 6.61 A (0.12) | 6.78 A (0.43) | 6.90 A (0.29) | |

| Sulfur (%) | 1.55 A (0.09) | 1.50 A (0.07) | 1.32 B (0.03) | 1.33 B (0.02) | 0.33 B (0.03) | |

| Potential Use | Genotype | References | ||||

|---|---|---|---|---|---|---|

| MT01 | MT03 | MT07 | MT11 | CF01 | ||

| Paper | High | High | Medium | Medium | Medium | [38] |

| Materials with high degradation | High | High | Medium | Medium | Medium | [39] |

| Textile | Medium | Medium | High | High | High | [40] |

| Rope, heavy use | Medium | Medium | High | High | High | [41] |

| Composite materials (Low use) | High | High | Medium | Medium | Medium | [42] |

| Composite materials (High use) | Medium | Medium | High | High | High | [21,42] |

| Thermal exposition | Low | Medium | High | High | High | [43] |

| Energy | Low | Low | High | High | Medium | [44] |

| Electronic | High | High | High | High | High | [21] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valverde, J.C.; Araya, M.; Arias-Aguilar, D.; Masís, C.; Muñoz, F. Evaluation of the Optimal Uses of Five Genotypes of Musa textilis Fiber Grown in the Tropical Region. Polymers 2022, 14, 1772. https://doi.org/10.3390/polym14091772

Valverde JC, Araya M, Arias-Aguilar D, Masís C, Muñoz F. Evaluation of the Optimal Uses of Five Genotypes of Musa textilis Fiber Grown in the Tropical Region. Polymers. 2022; 14(9):1772. https://doi.org/10.3390/polym14091772

Chicago/Turabian StyleValverde, Juan Carlos, Mónica Araya, Dagoberto Arias-Aguilar, Charlyn Masís, and Freddy Muñoz. 2022. "Evaluation of the Optimal Uses of Five Genotypes of Musa textilis Fiber Grown in the Tropical Region" Polymers 14, no. 9: 1772. https://doi.org/10.3390/polym14091772

APA StyleValverde, J. C., Araya, M., Arias-Aguilar, D., Masís, C., & Muñoz, F. (2022). Evaluation of the Optimal Uses of Five Genotypes of Musa textilis Fiber Grown in the Tropical Region. Polymers, 14(9), 1772. https://doi.org/10.3390/polym14091772