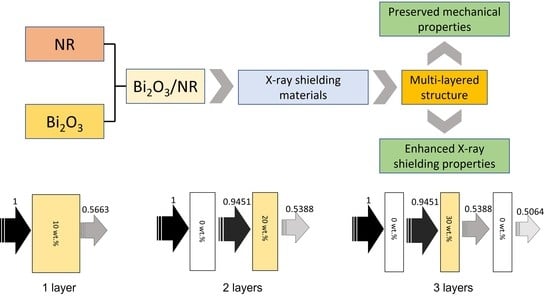

Figure 1.

Schemes showing single-layered and multi-layered structures and Bi2O3 contents for 11 distinct designs for determination of X-ray shielding properties in Bi2O3/NR composites, where thicknesses are in millimeters and the numbers enclosed in circles represent the sample#.

Figure 1.

Schemes showing single-layered and multi-layered structures and Bi2O3 contents for 11 distinct designs for determination of X-ray shielding properties in Bi2O3/NR composites, where thicknesses are in millimeters and the numbers enclosed in circles represent the sample#.

Figure 2.

Schemes showing relative X-ray intensities for each layer of sample#1, sample#2, sample#4, sample#5, sample#7, sample#9, sample#10, and sample#11, at the X-ray energy of 50 keV. The numbers enclosed in circles represent sample#.

Figure 2.

Schemes showing relative X-ray intensities for each layer of sample#1, sample#2, sample#4, sample#5, sample#7, sample#9, sample#10, and sample#11, at the X-ray energy of 50 keV. The numbers enclosed in circles represent sample#.

Figure 3.

(a) Final values of I/I0, (b) µeff, (c) µm,eff, and (d) HVLeff of three-layered Bi2O3/NR composites (sample#4) containing varying Bi2O3 contents from 10 to 90 wt.% in layer#2 (middle layer) and a fixed combined thickness of 6 mm, determined at X-ray energies of 50, 100, 150, and 200 keV.

Figure 3.

(a) Final values of I/I0, (b) µeff, (c) µm,eff, and (d) HVLeff of three-layered Bi2O3/NR composites (sample#4) containing varying Bi2O3 contents from 10 to 90 wt.% in layer#2 (middle layer) and a fixed combined thickness of 6 mm, determined at X-ray energies of 50, 100, 150, and 200 keV.

Figure 4.

Effective Pbeq of three-layered Bi2O3/NR composites (sample#4) with varying Bi2O3 contents from 10 to 90 wt.% in layer#2 (middle layer) and varying combined thicknesses of 6, 9, and 12 mm, determined at X-ray energies of (a) 50, (b) 100, (c) 150, and (d) 200 keV. The green dotted lines represent the common requirement of 0.5 mmPb used as a benchmark for this work and the blue, red, and black dotted lines represent the least Bi2O3 contents providing the composites with the Pbeq of the required 0.5 mmPb for varying thicknesses.

Figure 4.

Effective Pbeq of three-layered Bi2O3/NR composites (sample#4) with varying Bi2O3 contents from 10 to 90 wt.% in layer#2 (middle layer) and varying combined thicknesses of 6, 9, and 12 mm, determined at X-ray energies of (a) 50, (b) 100, (c) 150, and (d) 200 keV. The green dotted lines represent the common requirement of 0.5 mmPb used as a benchmark for this work and the blue, red, and black dotted lines represent the least Bi2O3 contents providing the composites with the Pbeq of the required 0.5 mmPb for varying thicknesses.

Table 1.

Sample codes with details of the number of layers, thickness of each layer, and Bi2O3 content in each layer for determination of X-ray shielding properties in Bi2O3/NR composites (Sample# and Layer# denote Sample Number and Layer Number, respectively).

Table 1.

Sample codes with details of the number of layers, thickness of each layer, and Bi2O3 content in each layer for determination of X-ray shielding properties in Bi2O3/NR composites (Sample# and Layer# denote Sample Number and Layer Number, respectively).

| Sample# | Number of Layers | Thickness of Each Layer (mm) | Bi2O3 Contents in Layer# (wt.%) |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| 1 | 1 | 6.0 | 10 | - | - | - | - |

| 2 | 2 | 3.0 | 0 | 20 | - | - | - |

| 3 | 2 | 3.0 | 20 | 0 | - | - | - |

| 4 | 3 | 2.0 | 0 | 30 | 0 | - | - |

| 5 | 3 | 2.0 | 15 | 0 | 15 | - | - |

| 6 | 4 | 1.5 | 20 | 0 | 20 | 0 | - |

| 7 | 4 | 1.5 | 0 | 20 | 0 | 20 | - |

| 8 | 4 | 1.5 | 0 | 20 | 20 | 0 | - |

| 9 | 4 | 1.5 | 20 | 0 | 0 | 20 | - |

| 10 | 5 | 1.2 | 16.7 | 0 | 16.7 | 0 | 16.7 |

| 11 | 5 | 1.2 | 0 | 25 | 0 | 25 | 0 |

Table 2.

Mass attenuation coefficients (µm; cm2/g) of Bi2O3/NR composites with varying Bi2O3 contents of 0, 10, 15, 16.7, 20, 25, and 30 wt.% at the X-ray energies of 50, 100, 150, and 200 keV.

Table 2.

Mass attenuation coefficients (µm; cm2/g) of Bi2O3/NR composites with varying Bi2O3 contents of 0, 10, 15, 16.7, 20, 25, and 30 wt.% at the X-ray energies of 50, 100, 150, and 200 keV.

| X-ray Energy (keV) | Bi2O3 Content (wt.%) |

|---|

| 0 | 10 | 15 | 16.7 | 20 | 25 | 30 |

|---|

| 50 | 0.2047 | 0.9379 | 1.3050 | 1.4290 | 1.6710 | 2.0380 | 2.4040 |

| 100 | 0.1683 | 0.6677 | 0.9174 | 1.0020 | 1.1670 | 1.4170 | 1.6670 |

| 150 | 0.1501 | 0.3233 | 0.4099 | 0.4393 | 0.4965 | 0.5831 | 0.6696 |

| 200 | 0.1371 | 0.2174 | 0.2575 | 0.2712 | 0.2976 | 0.3378 | 0.3779 |

Table 3.

Calculated densities (ρ) of Bi2O3/NR composites with varying Bi2O3 contents of 0, 10, 15, 16.7, 20, 25, and 30 wt.%.

Table 3.

Calculated densities (ρ) of Bi2O3/NR composites with varying Bi2O3 contents of 0, 10, 15, 16.7, 20, 25, and 30 wt.%.

| Bi2O3 Content (wt.%) | Density (g/cm3) |

|---|

| 0 | 0.920 |

| 10 | 1.011 |

| 15 | 1.063 |

| 16.7 | 1.082 |

| 20 | 1.121 |

| 25 | 1.186 |

| 30 | 1.259 |

Table 4.

Linear attenuation coefficients (µ; cm−1) of single-layered Bi2O3/NR composites with varying Bi2O3 contents of 0, 10, 15, 16.7, 20, 25, and 30 wt.% at X-ray energies of 50, 100, 150, and 200 keV.

Table 4.

Linear attenuation coefficients (µ; cm−1) of single-layered Bi2O3/NR composites with varying Bi2O3 contents of 0, 10, 15, 16.7, 20, 25, and 30 wt.% at X-ray energies of 50, 100, 150, and 200 keV.

| X-ray Energy (keV) | Bi2O3 Content (wt.%) |

|---|

| 0 | 10 | 15 | 16.7 | 20 | 25 | 30 |

|---|

| 50 | 0.1883 | 0.9478 | 1.3872 | 1.5457 | 1.8732 | 2.4167 | 3.0255 |

| 100 | 0.1548 | 0.6747 | 0.9751 | 1.0838 | 1.3082 | 1.6803 | 2.0979 |

| 150 | 0.1380 | 0.3267 | 0.4357 | 0.4751 | 0.5565 | 0.6914 | 0.8427 |

| 200 | 0.1261 | 0.2197 | 0.2737 | 0.2933 | 0.3336 | 0.4005 | 0.4755 |

Table 5.

Relative X-ray intensities for each layer of multi-layered Bi2O3/NR composites at an X-ray energy of 50 keV (Sample# and Layer# denote Sample Number and Layer Number, respectively).

Table 5.

Relative X-ray intensities for each layer of multi-layered Bi2O3/NR composites at an X-ray energy of 50 keV (Sample# and Layer# denote Sample Number and Layer Number, respectively).

| Sample# | Number of Layers | Thickness of Each Layer (mm) | Relative X-ray Intensities for Layer# |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| 1 | 1 | 6.0 | 0.5663 | - | - | - | - |

| 2 | 2 | 3.0 | 0.9451 | 0.5388 | - | - | - |

| 3 | 2 | 3.0 | 0.5701 | 0.5388 | - | - | - |

| 4 | 3 | 2.0 | 0.9630 | 0.5258 | 0.5064 | - | - |

| 5 | 3 | 2.0 | 0.7577 | 0.7298 | 0.5529 | - | - |

| 6 | 4 | 1.5 | 0.7550 | 0.7340 | 0.5542 | 0.5388 | - |

| 7 | 4 | 1.5 | 0.9722 | 0.7340 | 0.7136 | 0.5388 | - |

| 8 | 4 | 1.5 | 0.9722 | 0.7340 | 0.5542 | 0.5388 | - |

| 9 | 4 | 1.5 | 0.7550 | 0.7340 | 0.7136 | 0.5388 | - |

| 10 | 5 | 1.2 | 0.8307 | 0.8121 | 0.6746 | 0.6596 | 0.5479 |

| 11 | 5 | 1.2 | 0.9777 | 0.7315 | 0.7152 | 0.5352 | 0.5232 |

Table 6.

Relative X-ray intensities for each layer of multi-layered Bi2O3/NR composites at an X-ray energy of 100 keV (Sample# and Layer# denote Sample Number and Layer Number, respectively).

Table 6.

Relative X-ray intensities for each layer of multi-layered Bi2O3/NR composites at an X-ray energy of 100 keV (Sample# and Layer# denote Sample Number and Layer Number, respectively).

| Sample# | Number of Layers | Thickness of Each Layer (mm) | Relative X-ray Intensities for Layer# |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| 1 | 1 | 6.0 | 0.6671 | - | - | - | - |

| 2 | 2 | 3.0 | 0.9546 | 0.6447 | - | - | - |

| 3 | 2 | 3.0 | 0.6754 | 0.6447 | - | - | - |

| 4 | 3 | 2.0 | 0.9695 | 0.6373 | 0.6178 | - | - |

| 5 | 3 | 2.0 | 0.8228 | 0.7977 | 0.6564 | - | - |

| 6 | 4 | 1.5 | 0.8218 | 0.8030 | 0.6599 | 0.6447 | - |

| 7 | 4 | 1.5 | 0.9770 | 0.8030 | 0.7845 | 0.6447 | - |

| 8 | 4 | 1.5 | 0.9770 | 0.8030 | 0.6599 | 0.6447 | - |

| 9 | 4 | 1.5 | 0.8218 | 0.8030 | 0.7845 | 0.6447 | - |

| 10 | 5 | 1.2 | 0.8780 | 0.8619 | 0.7568 | 0.7428 | 0.6522 |

| 11 | 5 | 1.2 | 0.9816 | 0.8023 | 0.7876 | 0.6438 | 0.6319 |

Table 7.

Relative X-ray intensities for each layer of multi-layered Bi2O3/NR composites at an X-ray energy of 150 keV (Sample# and Layer# denote Sample Number and Layer Number, respectively).

Table 7.

Relative X-ray intensities for each layer of multi-layered Bi2O3/NR composites at an X-ray energy of 150 keV (Sample# and Layer# denote Sample Number and Layer Number, respectively).

| Sample# | Number of Layers | Thickness of Each Layer (mm) | Relative X-ray Intensities for Layer# |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| 1 | 1 | 6.0 | 0.8220 | - | - | - | - |

| 2 | 2 | 3.0 | 0.9594 | 0.8119 | - | - | - |

| 3 | 2 | 3.0 | 0.8462 | 0.8119 | - | - | - |

| 4 | 3 | 2.0 | 0.9728 | 0.8219 | 0.7995 | - | - |

| 5 | 3 | 2.0 | 0.9165 | 0.8916 | 0.8172 | - | - |

| 6 | 4 | 1.5 | 0.9199 | 0.9010 | 0.8289 | 0.8119 | - |

| 7 | 4 | 1.5 | 0.9795 | 0.9010 | 0.8826 | 0.8119 | - |

| 8 | 4 | 1.5 | 0.9795 | 0.9010 | 0.8289 | 0.8119 | - |

| 9 | 4 | 1.5 | 0.9199 | 0.9010 | 0.8826 | 0.8119 | - |

| 10 | 5 | 1.2 | 0.9446 | 0.9291 | 0.8776 | 0.8631 | 0.8153 |

| 11 | 5 | 1.2 | 0.9836 | 0.9052 | 0.8904 | 0.8195 | 0.8060 |

Table 8.

Relative X-ray intensities for each layer of multi-layered Bi2O3/NR composites at an X-ray energy of 200 keV (Sample# and Layer# denote Sample Number and Layer Number, respectively).

Table 8.

Relative X-ray intensities for each layer of multi-layered Bi2O3/NR composites at an X-ray energy of 200 keV (Sample# and Layer# denote Sample Number and Layer Number, respectively).

| Sample# | Number of Layers | Thickness of Each Layer (mm) | Relative X-ray intensities for Layer# |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| 1 | 1 | 6.0 | 0.8765 | - | - | - | - |

| 2 | 2 | 3.0 | 0.9629 | 0.8712 | - | - | - |

| 3 | 2 | 3.0 | 0.9048 | 0.8712 | - | - | - |

| 4 | 3 | 2.0 | 0.9751 | 0.8866 | 0.8645 | - | - |

| 5 | 3 | 2.0 | 0.9467 | 0.9231 | 0.8740 | - | - |

| 6 | 4 | 1.5 | 0.9512 | 0.9334 | 0.8878 | 0.8712 | - |

| 7 | 4 | 1.5 | 0.9813 | 0.9334 | 0.9159 | 0.8712 | - |

| 8 | 4 | 1.5 | 0.9813 | 0.9334 | 0.8878 | 0.8712 | - |

| 9 | 4 | 1.5 | 0.9512 | 0.9334 | 0.9159 | 0.8712 | - |

| 10 | 5 | 1.2 | 0.9654 | 0.9509 | 0.9180 | 0.9042 | 0.8729 |

| 11 | 5 | 1.2 | 0.9850 | 0.9388 | 0.9247 | 0.8813 | 0.8680 |

Table 9.

Effective densities and effective percentages by weight of Bi2O3 for all 11 multi-layered Bi2O3/NR composites (Sample# denotes Sample Number).

Table 9.

Effective densities and effective percentages by weight of Bi2O3 for all 11 multi-layered Bi2O3/NR composites (Sample# denotes Sample Number).

| Sample# | Effective Density (g/cm3) | Effective Percentage by Weight (wt.%) |

|---|

| 1 | 1.011 | 10.00 |

| 2 | 1.021 | 10.98 |

| 3 | 1.021 | 10.98 |

| 4 | 1.033 | 12.19 |

| 5 | 1.015 | 10.47 |

| 6 | 1.021 | 10.98 |

| 7 | 1.021 | 10.98 |

| 8 | 1.021 | 10.98 |

| 9 | 1.021 | 10.98 |

| 10 | 1.017 | 10.64 |

| 11 | 1.026 | 11.55 |

Table 10.

Comparative final transmission factors (I/I0) of 11 multi-layered structures of Bi2O3/NR composites at X-ray energies of 50, 100, 150, and 200 keV using XCOM and PHITS and their corresponding percentage differences (Sample# denotes Sample Number).

Table 10.

Comparative final transmission factors (I/I0) of 11 multi-layered structures of Bi2O3/NR composites at X-ray energies of 50, 100, 150, and 200 keV using XCOM and PHITS and their corresponding percentage differences (Sample# denotes Sample Number).

| Sample# | XCOM | PHITS | %Difference |

|---|

| Final Transmission Factor (I/I0) at X-ray Energy (keV) |

|---|

| 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

|---|

| 1 | 0.5663 | 0.6671 | 0.8220 | 0.8765 | 0.5732 | 0.6681 | 0.8258 | 0.8785 | 1.22 | 0.15 | 0.46 | 0.23 |

| 2 | 0.5388 | 0.6447 | 0.8119 | 0.8712 | 0.5518 | 0.6483 | 0.8498 | 0.8964 | 2.42 | 0.55 | 4.67 | 2.89 |

| 3 | 0.5388 | 0.6447 | 0.8119 | 0.8712 | 0.5578 | 0.6756 | 0.8196 | 0.8946 | 3.54 | 4.78 | 0.95 | 2.69 |

| 4 | 0.5064 | 0.6178 | 0.7995 | 0.8645 | 0.5289 | 0.6371 | 0.8255 | 0.8865 | 4.44 | 3.11 | 3.25 | 2.54 |

| 5 | 0.5529 | 0.6564 | 0.8172 | 0.8740 | 0.5766 | 0.6589 | 0.8443 | 0.8871 | 4.27 | 0.38 | 3.32 | 1.50 |

| 6 | 0.5388 | 0.6447 | 0.8119 | 0.8712 | 0.5428 | 0.6480 | 0.8226 | 0.8735 | 0.75 | 0.50 | 1.32 | 0.27 |

| 7 | 0.5388 | 0.6447 | 0.8119 | 0.8712 | 0.5494 | 0.6547 | 0.8432 | 0.8898 | 1.97 | 1.54 | 3.85 | 2.14 |

| 8 | 0.5388 | 0.6447 | 0.8119 | 0.8712 | 0.5471 | 0.6452 | 0.8461 | 0.8917 | 1.55 | 0.08 | 4.22 | 2.36 |

| 9 | 0.5388 | 0.6447 | 0.8119 | 0.8712 | 0.5596 | 0.6522 | 0.8480 | 0.8789 | 3.87 | 1.15 | 4.45 | 0.89 |

| 10 | 0.5479 | 0.6522 | 0.8153 | 0.8729 | 0.5550 | 0.6723 | 0.8523 | 0.8861 | 1.30 | 3.08 | 4.54 | 1.50 |

| 11 | 0.5232 | 0.6319 | 0.8060 | 0.8680 | 0.5297 | 0.6384 | 0.8343 | 0.9039 | 1.24 | 1.03 | 3.51 | 4.13 |

Table 11.

Values for µeff, µm,eff, and HVLeff of 11 multi-layered Bi2O3/NR composites at X-ray energies of 50, 100, 150, and 200 keV (Sample# denotes Sample Number).

Table 11.

Values for µeff, µm,eff, and HVLeff of 11 multi-layered Bi2O3/NR composites at X-ray energies of 50, 100, 150, and 200 keV (Sample# denotes Sample Number).

| Sample# | µeff (cm−1) | µm,eff (cm2/g) | HVLeff (cm) |

|---|

| 50 keV | 100 keV | 150 keV | 200 keV | 50 keV | 100 keV | 150 keV | 200 keV | 50 keV | 100 keV | 150 keV | 200 keV |

|---|

| 1 | 0.9479 | 0.6748 | 0.3267 | 0.2197 | 0.9379 | 0.7195 | 0.4541 | 0.4838 | 0.7313 | 1.0272 | 2.1215 | 3.1549 |

| 2 | 1.0308 | 0.7315 | 0.3473 | 0.2299 | 1.0101 | 0.7243 | 0.4796 | 0.4793 | 0.6724 | 0.9475 | 1.9956 | 3.0153 |

| 3 | 1.0308 | 0.7315 | 0.3473 | 0.2299 | 1.0101 | 0.7243 | 0.4796 | 0.4793 | 0.6724 | 0.9475 | 1.9956 | 3.0153 |

| 4 | 1.1341 | 0.8025 | 0.3730 | 0.2426 | 1.0980 | 0.7309 | 0.5103 | 0.4755 | 0.6112 | 0.8637 | 1.8585 | 2.8569 |

| 5 | 0.9876 | 0.7017 | 0.3365 | 0.2245 | 0.9727 | 0.7214 | 0.4664 | 0.4814 | 0.7019 | 0.9878 | 2.0599 | 3.0873 |

| 6 | 1.0308 | 0.7315 | 0.3473 | 0.2299 | 1.0101 | 0.7243 | 0.4796 | 0.4793 | 0.6724 | 0.9475 | 1.9956 | 3.0153 |

| 7 | 1.0308 | 0.7315 | 0.3473 | 0.2299 | 1.0101 | 0.7243 | 0.4796 | 0.4793 | 0.6724 | 0.9475 | 1.9956 | 3.0153 |

| 8 | 1.0308 | 0.7315 | 0.3473 | 0.2299 | 1.0101 | 0.7243 | 0.4796 | 0.4793 | 0.6724 | 0.9475 | 1.9956 | 3.0153 |

| 9 | 1.0308 | 0.7315 | 0.3473 | 0.2299 | 1.0101 | 0.7243 | 0.4796 | 0.4793 | 0.6724 | 0.9475 | 1.9956 | 3.0153 |

| 10 | 1.0028 | 0.7122 | 0.3403 | 0.2265 | 0.9860 | 0.7224 | 0.4712 | 0.4807 | 0.6912 | 0.9732 | 2.0366 | 3.0608 |

| 11 | 1.0797 | 0.7650 | 0.3594 | 0.2359 | 1.0520 | 0.7272 | 0.4943 | 0.4773 | 0.6420 | 0.9061 | 1.9284 | 2.9382 |