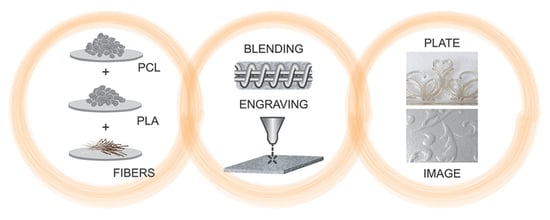

Blends Based on Poly(ε-Caprolactone) with Addition of Poly(Lactic Acid) and Coconut Fibers: Thermal Analysis, Ageing Behavior and Application for Embossing Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Biodegradable Blends

2.3. Ageing Process

2.4. Thermal Analysis

2.4.1. Differential Scanning Calorimetry Analysis

2.4.2. Thermogravimetric Analysis

2.5. Mechanical Measurements

2.6. Surface and Interfacial Characteristics

2.6.1. Surface Analysis

2.6.2. Fourier Transform Infrared Spectroscopy

2.6.3. Image Analysis of Engraved Printing Plates

3. Results and Discussion

3.1. Thermal Properties

3.2. Mechanical Measurements

3.3. Interfacial Interactions in PCL/PLA/CF Blends

3.4. Properties of UV Aged PCL Blends

3.4.1. Thermal Properties of UV Aged PCL Blends

3.4.2. Mechanical Properties of UV Aged PCL Blends

3.4.3. Results of the Surface and Structural Properties of Aged PCL Blends

3.5. Results of the Image Analysis of PCL/PLA/CF Blends

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Imre, B.; Pukánszky, B. Compatibilization in Bio-Based and Biodegradable Polymer Blends. Eur. Polym. J. 2013, 49, 1215–1233. [Google Scholar] [CrossRef] [Green Version]

- Yeh, J.-T.; Wu, C.-J.; Tsou, C.-H.; Chai, W.-L.; Chow, J.-D.; Huang, C.-Y.; Chen, K.-N.; Wu, C.-S. Study on the Crystallization, Miscibility, Morphology, Properties of Poly(Lactic Acid)/Poly(ϵ-Caprolactone) Blends. Polym. Plast. Technol. Eng. 2009, 48, 571–578. [Google Scholar] [CrossRef]

- Noroozi, N.; Schafer, L.L.; Hatzikiriakos, S.G. Thermorheological Properties of Poly (ϵ-Caprolactone)/Polylactide Blends. Polym. Eng. Sci. 2012, 52, 2348–2359. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Fouad, H.; Awad, S.; Saba, N.; Siengchin, S. Flexural and Dynamic Mechanical Properties of Alkali-Treated Coir/Pineapple Leaf Fibres Reinforced Polylactic Acid Hybrid Biocomposites. J. Bionic Eng. 2021, 18, 1430–1438. [Google Scholar] [CrossRef]

- Song, J.H.; Murphy, R.J.; Narayan, R.; Davies, G.B.H. Biodegradable and Compostable Alternatives to Conventional Plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2127–2139. [Google Scholar] [CrossRef] [PubMed]

- Tokiwa, Y.; Calabia, B.; Ugwu, C.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef]

- Przybysz-Romatowska, M.; Haponiuk, J.; Formela, K. Poly(ϵ-Caprolactone)/Poly(Lactic Acid) Blends Compatibilized by Peroxide Initiators: Comparison of Two Strategies. Polymers 2020, 12, 228. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Thomas, N.L. Preparation and Properties of Polyhydroxybutyrate Blended with Different Types of Starch. J. Appl. Polym. Sci. 2009, 116, 688–694. [Google Scholar] [CrossRef]

- Don, T.-M.; Chung, C.-Y.; Lai, S.-M.; Chiu, H.-J. Preparation and Properties of Blends from Poly(3-Hydroxybutyrate) with Poly(Vinyl Acetate)-Modified Starch. Polym. Eng. Sci. 2010, 50, 709–718. [Google Scholar] [CrossRef]

- Wu, C.-S. Improving Polylactide/Starch Biocomposites by Grafting Polylactide with Acrylic Acid—Characterization and Biodegradability Assessment. Macromol. Biosci. 2005, 5, 352–361. [Google Scholar] [CrossRef] [PubMed]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and Its Blends with Poly(Butylene Succinate) (PBS): A Brief Review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jimenez, A.; Yoon, K.; Ahn, J.; Kang, S.; et al. Processing and Characterization of Plasticized PLA/PHB Blends for Biodegradable Multiphase Systems. Express Polym. Lett. 2015, 9, 583–596. [Google Scholar] [CrossRef]

- Akos, N.I.; Wahit, M.U.; Mohamed, R.; Yussuf, A.A. Preparation, Characterization, and Mechanical Properties of Poly(ϵ-Caprolactone)/Polylactic Acid Blend Composites. Polym. Compos. 2013, 34, 763–768. [Google Scholar] [CrossRef]

- Yussuf, A.A.; Massoumi, I.; Hassan, A. Comparison of Polylactic Acid/Kenaf and Polylactic Acid/Rise Husk Composites: The Influence of the Natural Fibers on the Mechanical, Thermal and Biodegradability Properties. J. Polym. Environ. 2010, 18, 422–429. [Google Scholar] [CrossRef]

- Abedalwafa, M.; Wang, F.; Wang, L.; Li, C. Biodegradable Poly-Epsiloncaprolactone (PCL) for Tissue Engineering Applications: A Review. Rev. Adv. Mater. Sci. 2013, 34, 123–140. [Google Scholar]

- John, R.P.; Nampoothiri, K.M.; Pandey, A. Solid-State Fermentation for l-Lactic Acid Production from Agro Wastes Using Lactobacillus Delbrueckii. Process Biochem. 2006, 41, 759–763. [Google Scholar] [CrossRef]

- Tokić, I.; Fruk, G.; Jermić, T. Biodegradable Packaging for Storage of Fruit and Other Horticultural Products: Materials, Properties and Its Effect on Fruit Quality. J. Cent. Eur. Agric. 2011, 12, 226–238. [Google Scholar] [CrossRef] [Green Version]

- Chavalitpanya, K.; Phattanarudee, S. Poly(Lactic Acid)/Polycaprolactone Blends Compatibilized with Block Copolymer. Energy Procedia 2013, 34, 542–548. [Google Scholar] [CrossRef] [Green Version]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An Overview of the Recent Developments in Polylactide (PLA) Research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(Lactic Acid) Modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Piorkowska, E.; Kulinski, Z.; Galeski, A.; Masirek, R. Plasticization of Semicrystalline Poly(l-Lactide) with Poly(Propylene Glycol). Polymer 2006, 47, 7178–7188. [Google Scholar] [CrossRef]

- Wachirahuttapong, S.; Thongpin, C.; Sombatsompop, N. Effect of PCL and Compatibility Contents on the Morphology, Crystallization and Mechanical Properties of PLA/PCL Blends. Energy Procedia 2016, 89, 198–206. [Google Scholar] [CrossRef] [Green Version]

- Matta, A.K.; Rao, R.U.; Suman, K.N.S.; Rambabu, V. Preparation and Characterization of Biodegradable PLA/PCL Polymeric Blends. Procedia Mater. Sci. 2014, 6, 1266–1270. [Google Scholar] [CrossRef] [Green Version]

- Lv, H.; Song, S.; Sun, S.; Ren, L.; Zhang, H. Enhanced Properties of Poly(Lactic Acid) with Silica Nanoparticles. Polym. Adv. Technol. 2016, 27, 1156–1163. [Google Scholar] [CrossRef]

- Montes-Zavala, I.; Pérez-González, M.J.; Castrejón-González, E.O.; Santamaría-Razo, D.A.; Almendárez-Camarillo, A.; Pérez, E.; Gonzalez-Calderon, J.A. Thermal and Mechanical Properties of Poly(Lactic Acid) Filled with Modified Silicon Dioxide: Importance of the Surface Area. Polym. Bull. 2022, 79, 1409–1435. [Google Scholar] [CrossRef]

- Vrsaljko, D.; Macut, D.; Kovačević, V. Potential Role of Nanofillers as Compatibilizers in Immiscible PLA/LDPE Blends. J. Appl. Polym. Sci. 2015, 132, 41414. [Google Scholar] [CrossRef]

- Wu, C.-S. Physical Properties and Biodegradability of Maleated-Polycaprolactone/Starch Composite. Polym. Degrad. Stab. 2003, 80, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Woodruff, M.A.; Hutmacher, D.W. The Return of a Forgotten Polymer—Polycaprolactone in the 21st Century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef] [Green Version]

- López-Rodríguez, N.; López-Arraiza, A.; Meaurio, E.; Sarasua, J.R. Crystallization, Morphology, and Mechanical Behavior of Polylactide/Poly(ɛ-Caprolactone) Blends. Polym. Eng. Sci. 2006, 46, 1299–1308. [Google Scholar] [CrossRef]

- Navarro-Baena, I.; Sessini, V.; Dominici, F.; Torre, L.; Kenny, J.M.; Peponi, L. Design of Biodegradable Blends Based on PLA and PCL: From Morphological, Thermal and Mechanical Studies to Shape Memory Behavior. Polym. Degrad. Stab. 2016, 132, 97–108. [Google Scholar] [CrossRef]

- Awad, S.A.; Jawaid, M.; Fouad, H.; Saba, N.; Dhakal, H.N.; Alothman, O.Y.; Khalaf, E.M. A Comparative Assessment of Chemical, Mechanical, and Thermal Characteristics of Treated Oil Palm/Pineapple Fiber/Bio Phenolic Composites. Polym. Compos. 2022, 43, 2115–2128. [Google Scholar] [CrossRef]

- Vruno, M. Hangin’ (with) Eco-Friendly Printing Plates. Available online: https://www.printingnews.com/trade-services/consumables-supplies/article/12173950/serving-up-the-latest-in-ecofriendly-printing-plates (accessed on 15 August 2020).

- Wilson, L. What Is Eco-Friendly Printing. Available online: https://www.helloprint.co.uk/blog/what-is-eco-friendly-printing/ (accessed on 15 April 2021).

- Priselac, D.; Tomašegović, T.; Mahović Poljaček, S.; Cigula, T.; Leskovac, M. Thermal, Surface and Mechanical Properties of PCL/PLA Composites with Coconut Fibres as an Alternative Material to Photopolymer Printing Plates. Teh. Glas. 2017, 11, 111–116. [Google Scholar]

- Mahović Poljaček, S.; Priselac, D.; Stanković Elesini, U.; Leskovšek, M.; Leskovac, M. Preparation, Properties, and Laser Processing of Poly(Ɛ-caprolactone)/Poly(Lactic Acid) Blends with Addition of Natural Fibers as a Potential for Printing Plates Application. Polym. Eng. Sci. 2021, 61, 2295–2310. [Google Scholar] [CrossRef]

- Izdebska, J.; Thomas, S. Printing on Polymers: Fundamentals and Applications, 1st ed.; Elsevier: Boston, MA, USA, 2016; pp. 397–411. [Google Scholar]

- Arsyad, M.; Wardana, I.N.G.; Pratikto; Irawan, Y.S. The Morphology of Coconut Fiber Surface under Chemical Treatment. Matéria 2015, 20, 169–177. [Google Scholar] [CrossRef] [Green Version]

- Coir. Available online: http://www.fao.org/economic/futurefibres/fibres/coir/en/ (accessed on 6 August 2020).

- Lomelí-Ramírez, M.G.; Anda, R.R.; Satyanarayana, K.G.; Bolzon de Muniz, G.I.; Iwakiri, S. Comparative Study of the Characteristics of Green and Brown Coconut Fibers for the Development of Green Composites. BioResources 2018, 13, 1637–1660. [Google Scholar] [CrossRef] [Green Version]

- Doi, Y.; Kanesawa, Y.; Tanahashi, N.; Kumagai, Y. Biodegradation of Microbial Polyesters in the Marine Environment. Polym. Degrad. Stab. 1992, 36, 173–177. [Google Scholar] [CrossRef]

- Hutmacher, D.; Hürzeler, M.B.; Schliephake, H. A Review of Material Properties of Biodegradable and Bioresorbable Polymers and Devices for GTR and GBR Applications. Int. J. Oral Maxillofac. Implant. 1996, 11, 667–678. [Google Scholar]

- Van Oss, C.J.; Giese, R.F.; Li, Z.; Murphy, K.; Norris, J.; Chaudhury, M.K.; Good, R.J. Contact Angle, Wettability and Adhesion; Mittal, K.L., Ed.; VSP: Utrecht, The Netherlands, 1993. [Google Scholar]

- Israelachvili, J. Intermolecular and Surface Forces; Elsevier: Boston, MA, USA, 2011; ISBN 978-0-12-391927-4. [Google Scholar]

- Tomašegović, T.; Mahović Poljaček, S.; Strižić Jakovljević, M.; Urbas, R. Effect of the Common Solvents on UV-Modified Photopolymer and EPDM Flexographic Printing Plates and Printed Ink Films. Coatings 2020, 10, 136. [Google Scholar] [CrossRef] [Green Version]

- Åkerlund, E. Development of Polymer Based Composite Filaments for 3D Printing. Ph.D. Thesis, Uppsala Universitet, Uppsala, Sweden, 2019. [Google Scholar]

- Sakai, F.; Nishikawa, K.; Inoue, Y.; Yazawa, K. Nucleation Enhancement Effect in Poly(L-Lactide) (PLLA)/Poly(ϵ-Caprolactone) (PCL) Blend Induced by Locally Activated Chain Mobility Resulting from Limited Miscibility. Macromolecules 2009, 42, 8335–8342. [Google Scholar] [CrossRef]

- Sivalingam, G.; Madras, G. Thermal Degradation of Ternary Blends of Poly(ϵ-Caprolactone)/Poly(Vinyl Acetate)/Poly(Vinyl Chloride). J. Appl. Polym. Sci. 2004, 93, 1378–1383. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J.M. PLA-PHB/Cellulose Based Films: Mechanical, Barrier and Disintegration Properties. Polym. Degrad. Stab. 2014, 107, 139–149. [Google Scholar] [CrossRef]

- Spiridon, U.; Darie Nita, R.N.; Kozlowski, M.; Nechita, A.; Ursu, R.G. Influence of Accelerated Weathering on the Performance of Polylactic Acid Based Materials. Cellul. Chem. Technol. 2016, 50, 629–635. [Google Scholar]

- Owens, D.K.; Wendt, R.C. Estimation of the Surface Free Energy of Polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Kovačević, V.; Lučić Blagojević, S.; Leskovac, M. Filler-Matrix Adhesion. In Handbook of Adhesion; John Wiley & Sons Ltd.: Chichester, UK, 2005. [Google Scholar]

- Patrício, T.; Bártolo, P. Thermal Stability of PCL/PLA Blends Produced by Physical Blending Process. Procedia Eng. 2013, 59, 292–297. [Google Scholar] [CrossRef]

- Ferri, J.M.; Fenollar, O.; Jorda-Vilaplana, A.; García-Sanoguera, D.; Balart, R. Effect of Miscibility on Mechanical and Thermal Properties of Poly(Lactic Acid)/Polycaprolactone Blends. Polym. Int. 2016, 65, 453–463. [Google Scholar] [CrossRef]

- White, J.R. Polymer Ageing: Physics, Chemistry or Engineering? Time to Reflect. Comptes Rendus Chim. 2006, 9, 1396–1408. [Google Scholar] [CrossRef]

- Affolter, S. Long-Term Behaviour of Thermoplastic Materials; NTB Interstaatliche Hochschule Für Technik Buchs: Buchs, Switzerland, 2008. [Google Scholar]

- Phillipson, K. Ageing and Crystallisation of Polycaprolactone. PhD Thesis, University of Birmingham, Birmingham, UK, 2014. [Google Scholar]

- Lucas, N.; Bienaime, C.; Belloy, C.; Queneudec, M.; Silvestre, F.; Nava-Saucedo, J.-E. Polymer Biodegradation: Mechanisms and Estimation Techniques—A Review. Chemosphere 2008, 73, 429–442. [Google Scholar] [CrossRef]

- França, D.C.; Morais, D.D.; Bezerra, E.B.; Araújo, E.M.; Wellen, R.M.R. Photodegradation Mechanisms on Poly(ϵ-Caprolactone) (PCL). Mater. Res. 2018, 21, e20170837. [Google Scholar] [CrossRef]

- Sen, T.; Jagannatha Reddy, H.N. Application of Sisal, Bamboo, Coir and Jute Natural Composites in Structural Upgradation. Int. J. Innov. Manag. Technol. 2011, 2, 186–191. [Google Scholar]

- Ali, S.; Khatri, Z.; Oh, K.W.; Kim, I.-S.; Kim, S.H. Preparation and Characterization of Hybrid Polycaprolactone/Cellulose Ultrafine Fibers via Electrospinning. Macromol. Res. 2014, 22, 562–568. [Google Scholar] [CrossRef]

- Gómez-Lizárraga, K.K.; Flores-Morales, C.; Del Prado-Audelo, M.L.; Álvarez-Pérez, M.A.; Piña-Barba, M.C.; Escobedo, C. Polycaprolactone- and Polycaprolactone/Ceramic-Based 3D-Bioplotted Porous Scaffolds for Bone Regeneration: A Comparative Study. Mater. Sci. Eng. C 2017, 79, 326–335. [Google Scholar] [CrossRef] [PubMed]

- Rohindra, D.R.; Khurma, J.R. Miscibility, Melting and Crystallization of Poly(ϵ-Caprolactone) and Poly (Vinyl Formal) Blend. South Pac. J. Nat. Appl. Sci. 2007, 25, 53. [Google Scholar] [CrossRef] [Green Version]

- Yu, S.; Xiang, H.; Zhou, J.; Zhu, M. Enhanced Flame-Retardant Performance of Poly (Lactic Acid) (PLA) Composite by Using Intrinsically Phosphorus-Containing PLA. Prog. Nat. Sci. Mater. Int. 2018, 28, 590–597. [Google Scholar] [CrossRef]

- Mamidi, N.; Zuníga, A.E.; Villela-Castrejón, J. Engineering and Evaluation of Forcespun Functionalized Carbon Nano-Onions Reinforced Poly (ϵ-Caprolactone) Composite Nanofibers for PH-Responsive Drug Release. Mater. Sci. Eng. C 2020, 112, 110928. [Google Scholar] [CrossRef] [PubMed]

- Mamidi, N.; Martínez Gamero, M.R.; Velasco Delgadillo, R.M.; Castrejón, J.V.; Zúníga, A.E. Engineering of Functionalized Carbon Nano-Onions Reinforced Nanocomposites: Fabrication, Biocompatibility, and Mechanical Properties. J. Mater. Res. 2020, 35, 922–930. [Google Scholar] [CrossRef] [Green Version]

| Material | Physical Properties | Mechanical Properties | |||

|---|---|---|---|---|---|

| Density, ρ (g·cm−3) | Tm (°C) | Tg (°C) | Tensile Strength (MPa) | Tensile Elongation (%) | |

| PCL | 1.145 | 58–60 | −60 | 20 | 800 |

| PLA | 1.24 | 150–160 | 55–60 | 60 | 3.5 |

| Sample Name | Ratio (%) | Sample Name | Ratio (%) |

|---|---|---|---|

| PCL/PLA/CF | 100/0/0 | PCL/PLA/CF | 80/20/3.0 |

| PCL/PLA/CF | 100/0/0.5 | PCL/PLA/CF | 70/30/0 |

| PCL/PLA/CF | 100/0/3.0 | PCL/PLA/CF | 70/30/0.5 |

| PCL/PLA/CF | 80/20/0 | PCL/PLA/CF | 70/30/3.0 |

| PCL/PLA/CF | 80/20/0.5 |

| PCL/PLA/CF (wt%) | PCL | PLA | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tg (°C) | Tm (°C) | ΔHm (J·g−1) | Tc (°C) | ΔHc (J·g−1) | Xc (PCL) (%) | Tcc (°C) | ΔHcc (J·g−1) | Tm (°C) | ΔHm (J·g−1) | Xc(PLA) (%) | |

| 100/0/0 | −63.6 | 56.3 | 74.0 | 32.9 | 70.1 | 53.1 | - | - | - | - | - |

| 100/0/0.5 | −64.5 | 55.7 | 73.4 | 26.5 | 64.5 | 52.7 | - | - | - | - | - |

| 100/0/3.0 | −63.9 | 56.2 | 77.0 | 27.8 | 64.8 | 55.2 | - | - | - | - | - |

| 80/20/0 | −63.7 | 57.4 | 48.8 | 32.2 | 47.2 | 43.8 | 98.1 | 4.6 | 168.2 | 8.1 | 17.1 |

| 80/20/0.5 | −63.9 | 56.3 | 65.3 | 33.2 | 60.0 | 58.6 | 94.2 | 3.3 | 166.8 | 9.5 | 29.3 |

| 80/20/3.0 | −64.5 | 56.3 | 65.9 | 33.2 | 58.2 | 59.2 | 94.1 | 5.1 | 166.8 | 9.9 | 23.0 |

| 70/30/0 | −63.0 | 56.4 | 46.2 | 31.1 | 40.9 | 47.4 | 99.5 | 8.9 | 167.6 | 12.5 | 11.4 |

| 70/30/0.5 | −63.2 | 56.6 | 46.0 | 31.2 | 38.9 | 47.2 | 95.9 | 6.9 | 167.3 | 12.4 | 17.2 |

| 70/30/3.0 | −64.0 | 56.4 | 37.7 | 30.7 | 39.9 | 38.3 | 93.8 | 5.8 | 166.4 | 12.4 | 20.8 |

| PCL/PLA/CF (wt%) | ° Sh D | SD |

|---|---|---|

| 100/0/0 | 53.3 | 1.0 |

| 100/0/0.5 | 54.2 | 0.7 |

| 100/0/3.0 | 54.4 | 0.9 |

| 80/20/0 | 55.0 | 1.1 |

| 80/20/0.5 | 58.7 | 1.3 |

| 80/20/3.0 | 58.9 | 1.4 |

| 70/30/0 | 58.7 | 1.3 |

| 70/30/0.5 | 60.0 | 1.1 |

| 70/30/3.0 | 60.1 | 1.9 |

| SFE | γtotal | γD | γP | Adhesion Parameters | γmf | Wmf | Smf |

|---|---|---|---|---|---|---|---|

| CF | 33.1 | 31.9 | 1.1 | PLA/CF | 1.4 | 77.4 | 11.3 |

| PCL | 36.8 | 30.3 | 6.4 | PCL/CF | 2.2 | 67.6 | 1.5 |

| PLA | 45.7 | 39.8 | 7.7 | PCL/PLA | 0.5 | 82.0 | −9.5 |

| Ageing (Weeks) | PCL/PLA/CF (wt%) | PCL | PLA | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tg (°C) | Tm (°C) | ΔHm (J·g−1) | Tc (°C) | ΔHc (J·g−1) | Xc(PCL) (%) | Tcc (°C) | ΔHcc (J·g−1) | Tm (°C) | ΔHm (J·g−1) | Xc(PLA) (%) | ||

| 0 | 100/0/0 | −63.6 | 56.3 | 74.0 | 70.1 | 53.1 | - | - | - | - | - | |

| 1 | −64.9 | 56.2 | 75.5 | 28.6 | 69.6 | 54.2 | ||||||

| 2 | −63.8 | 55.3 | 80.6 | 30.5 | 76.5 | 57.9 | ||||||

| 3 | −64.5 | 55.4 | 75.6 | 29.6 | 73.3 | 54.3 | ||||||

| 0 | 100/0/0.5 | −64.5 | 55.7 | 73.4 | 26.5 | 64.5 | 52.7 | - | - | - | - | - |

| 1 | −64.1 | 56.0 | 77.4 | 27.6 | 65.9 | 55.6 | ||||||

| 2 | −64.1 | 55.9 | 78.0 | 29.3 | 67.2 | 56.0 | ||||||

| 3 | −63.2 | 56.5 | 79.7 | 29.8 | 68.9 | 57.0 | ||||||

| 0 | 100/0/3.0 | −63.9 | 56.2 | 77.0 | 27.8 | 64.8 | 55.2 | - | - | - | - | - |

| 1 | −65.1 | 56.0 | 76.3 | 29.2 | 66.3 | 54.8 | ||||||

| 2 | −63.6 | 57.0 | 73.8 | 30.4 | 63.8 | 53.0 | ||||||

| 3 | −64.8 | 55.8 | 78.4 | 30.8 | 69.5 | 56.3 | ||||||

| 0 | 80/20/0 | −63.7 | 57.4 | 48.8 | 32.2 | 47.2 | 43.8 | 98.1 | 4.6 | 168.2 | 8.1 | 16.1 |

| 1 | −63.8 | 55.5 | 59.9 | 33.6 | 58.7 | 53.8 | 90.9 | 4.5 | 166.0 | 9.7 | 24.5 | |

| 2 | −63.7 | 56.4 | 58.8 | 33.2 | 56.0 | 52.8 | 92.9 | 5.1 | 166.7 | 9.5 | 20.9 | |

| 3 | −63.4 | 55.1 | 61.4 | 33.6 | 61.4 | 55.1 | 90.9 | 4.8 | 166.1 | 9.2 | 20.7 | |

| 0 | 80/20/0.5 | −63.9 | 56.3 | 65.3 | 33.2 | 60.0 | 58.6 | 94.2 | 3.3 | 166.8 | 9.5 | 29.3 |

| 1 | −62.6 | 55.5 | 64.9 | 33.6 | 60.2 | 58.3 | 90.4 | 4.0 | 165.8 | 9.5 | 25.8 | |

| 2 | −63.4 | 56.6 | 62.1 | 34.1 | 58.7 | 55.7 | 92.5 | 2.7 | 167.3 | 7.5 | 22.9 | |

| 3 | −61.2 | 55.5 | 56.9 | 33.4 | 61.7 | 51.0 | 89.7 | 1.4 | 165.4 | 8.5 | 33.2 | |

| 0 | 80/20/3.0 | −64.5 | 56.3 | 65.9 | 33.2 | 58.2 | 59.2 | 94.1 | 5.1 | 166.8 | 9.9 | 22.8 |

| 1 | −64.8 | 55.9 | 56.2 | 33.1 | 56.4 | 50.4 | 90.4 | 4.6 | 165.5 | 9.8 | 24.5 | |

| 2 | −63.9 | 57.0 | 53.9 | 33.5 | 51.8 | 48.4 | 93.2 | 4.5 | 166.8 | 9.4 | 23.4 | |

| 3 | −64.6 | 55.6 | 56.4 | 32.8 | 55.7 | 50.6 | 89.2 | 3.7 | 166.0 | 9.1 | 25.1 | |

| 0 | 70/30/0 | −63.0 | 56.4 | 46.2 | 31.1 | 40.9 | 47.4 | 99.5 | 8.9 | 167.6 | 12.5 | 11.4 |

| 1 | −63.6 | 55.7 | 55.9 | 33.6 | 53.3 | 57.3 | 95.8 | 9.1 | 166.5 | 14.1 | 15.4 | |

| 2 | −63.2 | 55.1 | 55.8 | 33.5 | 57.5 | 57.2 | 96.2 | 9.4 | 166.1 | 12.2 | 8.9 | |

| 3 | −63.6 | 55.9 | 55.7 | 33.9 | 52.9 | 57.2 | 98.4 | 9.9 | 166.9 | 12.9 | 9.7 | |

| 0 | 70/30/0.5 | −63.2 | 56.6 | 46.0 | 31.2 | 38.9 | 47.2 | 95.8 | 6.9 | 167.3 | 12.4 | 17.2 |

| 1 | −64.0 | 55.1 | 55.6 | 33.5 | 55.5 | 57.0 | 90.6 | 3.7 | 165.5 | 12.3 | 27.2 | |

| 2 | −63.4 | 55.6 | 54.4 | 33.6 | 53.9 | 55.8 | 92.4 | 4.6 | 166.1 | 13.6 | 28.4 | |

| 3 | −63.0 | 55.7 | 55.2 | 33.9 | 55.2 | 56.6 | 92.9 | 4.8 | 166.1 | 13.9 | 28.6 | |

| 0 | 70/30/3.0 | −64.0 | 56.4 | 37.7 | 30.7 | 39.2 | 38.3 | 93.8 | 5.8 | 166.4 | 12.4 | 20.8 |

| 1 | −65.3 | 55.8 | 47.4 | 32.4 | 49.8 | 48.6 | 91.4 | 5.1 | 165.8 | 13.3 | 26.0 | |

| 2 | −65.1 | 55.6 | 51.4 | 33.3 | 50.5 | 52.7 | 92.4 | 5.6 | 165.8 | 13.6 | 25.2 | |

| 3 | −63.4 | 56.4 | 48.8 | 32.7 | 48.6 | 50.0 | 92.1 | 4.0 | 166.2 | 12.7 | 27.6 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Priselac, D.; Mahović Poljaček, S.; Tomašegović, T.; Leskovac, M. Blends Based on Poly(ε-Caprolactone) with Addition of Poly(Lactic Acid) and Coconut Fibers: Thermal Analysis, Ageing Behavior and Application for Embossing Process. Polymers 2022, 14, 1792. https://doi.org/10.3390/polym14091792

Priselac D, Mahović Poljaček S, Tomašegović T, Leskovac M. Blends Based on Poly(ε-Caprolactone) with Addition of Poly(Lactic Acid) and Coconut Fibers: Thermal Analysis, Ageing Behavior and Application for Embossing Process. Polymers. 2022; 14(9):1792. https://doi.org/10.3390/polym14091792

Chicago/Turabian StylePriselac, Dino, Sanja Mahović Poljaček, Tamara Tomašegović, and Mirela Leskovac. 2022. "Blends Based on Poly(ε-Caprolactone) with Addition of Poly(Lactic Acid) and Coconut Fibers: Thermal Analysis, Ageing Behavior and Application for Embossing Process" Polymers 14, no. 9: 1792. https://doi.org/10.3390/polym14091792

APA StylePriselac, D., Mahović Poljaček, S., Tomašegović, T., & Leskovac, M. (2022). Blends Based on Poly(ε-Caprolactone) with Addition of Poly(Lactic Acid) and Coconut Fibers: Thermal Analysis, Ageing Behavior and Application for Embossing Process. Polymers, 14(9), 1792. https://doi.org/10.3390/polym14091792