Effects of Accelerating the Ageing of 1D PLA Filaments after Fused Filament Fabrication

Abstract

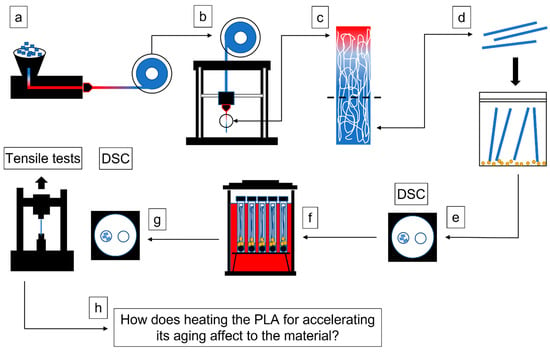

:1. Introduction

- Is it safe to effectively accelerate the ageing of the PLA by heating it? To answer this question, the degradation of the PLA was analysed with regard to the shifting of peaks in the DSC scans (decreased temperature in the crystallisation reactions, increase in the crystallisation enthalpies, a decrease in the melting point) and the decrease in both the elastic modulus and tensile strength. As the primary degradation mechanism is the hydrolytic degradation with the air humidity, the change in colour of a desiccant inside the ageing device was used to determine the low-humidity conditions during the ageing qualitatively.

- At which temperature can the PLA be effectively and safely accelerated? How long does the PLA need to be entirely aged at that temperature? Different temperatures were studied. The temperatures were chosen based on a DSC scan on the PLA right after it was printed after finding an optimal ageing temperature and forcing the degradation mechanism. The evolution of the thermal and mechanical properties was measured at different times to ensure that stable properties were reached and the minimum ageing time was set for the central ageing temperature of interest.

- What are the main differences between the PLA that was slowly aged at room temperature and the one aged at higher temperatures? The PLA aged at room temperature is compared with the material effectively aged at higher temperatures. This makes possible a better understanding of how future 3D-printed samples of PLA will be affected—at least for the thermal and mechanical properties of the 3D structures that are no longer slowly aged during 3 months at 20 °C but accelerated at a higher temperature.

- Has any other phenomenon of interest been detected? As different properties were studied, the results obtained during this research were analysed to determine other phenomena related to the PLA and, if something interesting is found, to share it with the research community.

- 5.

- Our main aim is to find and understand a reliable, safe, and effective method to accelerate the ageing of PLA 4043D-based materials (decoupled from the effects of the structure) to be sure of how the ageing method is affecting the PLA and reduce the research schedule from months (time required until the PLA is entirely aged at room temperature) to just a few days (as demonstrated in this study).

- 6.

- An emphasis on the importance of studying aged materials is essential for comparing results from different research with confidence.

- 7.

- It would allow us to understand and report how the thermal treatments affect the material decoupled from the variables related to the structure. Nonetheless, this study will have some limitations for extrapolation to 3D structures, as the thermal history of the PLA during the printing of 3D models is different depending on printed geometry, printer parameters, and ambient conditions [20]. However, studying the most fundamental building block of any 3D-printed structure, a 1D filament, will help unveil the phenomenon underlying the changes observed in a 3D-printed e-structure after thermal treatment, simplifying the multivariable problem of 3D-printed parts from a novel perspective not found in the literature.

2. Materials and Methods

2.1. Materials and FFF

2.2. Ageing Procedure

2.3. Differential Scanning Calorimetry

2.4. Tensile Test

- , the value of the property at an infinite time of ageing. It corresponds to the stabilised value. It has the units of the property (e.g., stress units such as MPa or GPa for the tensile strength or elastic modulus).

- A, the ageing potential (adimensional). It describes the gap between the property at zero days (on the material right after it was printed) and infinite days of ageing (stabilized).

- B, is the ageing rate in units of (1/time), which describes the speed at which the material evolves towards the steady state.This fitting was proven to properly define the evolution of the tensile strength, yield strength and elastic modulus with the natural ageing at room temperature by using just those 3 parameters. The objective was to increase the value of the B parameter, the ageing rate, by increasing the ageing temperature. B was used to quantify the extent to which the ageing rate varied at different ageing temperatures. The logistic fitting is impossible to apply if the material is not ageing, i.e., for the temperatures higher than Tg (51 °C and 65 °C). When the logistic fitting was not possible because the material did not evolve with the ageing temperature (51 °C in this study), the linear fitting y = mx + c was used. The 65 °C was not fitted to any curve as there were not enough points.

3. Results

3.1. Thermal Properties

3.2. Mechanical Properties

4. Conclusions

- Questions 1 and 2:

- Question 3:

- Question 4:

- Two glass transitions (Tg1 and Tg2) were found and characterised which had not been previously described in the literature. For these two glass transitions to be noticed, the printed PLA needed at least 2 h of ageing at 20 °C. This could induce possible mistakes in selecting the ageing temperature, as the 51 °C (below Tg2) was found to be too high for ageing the material.

- Samples aged at temperatures above Tg1 did not age as expected as they increased their Tg values whilst remaining at a negligible enthalpic relaxation enthalpy. This makes it impossible to correlate the Tg values with those of a material that is or is not aged.

- The PLA 2003D from our previous studies and the PLA 4043D studied here were found to age similarly and to be relatively similar regarding their thermal and mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef] [Green Version]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Frohn-Sörensen, P.; Reuter, J.; Engel, B.; Reinicke, T. Fracture studies of 3D-printed continuous glass fiber reinforced composites. Theor. Appl. Fract. Mech. 2022, 119, 103317. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Ruli; Supriyanto, E.; Rasgianti; Prawara, B.; Martides, E.; Junianto, E.; Wibowo, A.; Sentanuhady, J.; Muflikhun, M.A. First-rate manufacturing process of primary air fan (PAF) coal power plant in Indonesia using laser powder bed fusion (LPBF) technology. J. Mater. Res. Technol. 2022, 18, 4075–4088. [Google Scholar] [CrossRef]

- Patmonoaji, A.; Mahardika, M.A.; Nasir, M.; She, Y.; Wang, W.; Muflikhun, M.A.; Suekane, T. Stereolithography 3D Printer for Micromodel Fabrications with Comprehensive Accuracy Evaluation by Using Microtomography. Geosciences 2022, 12, 183. [Google Scholar] [CrossRef]

- Masiuchok, O.; Iurzhenko, M.; Kolisnyk, R.; Mamunya, Y.; Godzierz, M.; Demchenko, V.; Yermolenko, D.; Shadrin, A. Polylactide/Carbon Black Segregated Composites for 3D Printing of Conductive Products. Polymers 2022, 14, 4022. [Google Scholar] [CrossRef] [PubMed]

- Arefin, A.M.E.; Khatri, N.; Kulkarni, N.; Egan, P.F. Polymer 3D Printing Review: Materials, Process, and Design Strategies for Medical Applications. Polymers 2021, 13, 1499. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Zayas-Figueras, E.E. Comparative study about dimensional accuracy and form errors of FFF printed spur gears using PLA and Nylon. Polym. Test. 2023, 117, 107862. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Sentanu, D.A. Characteristics and performance of carabiner remodeling using 3D printing with graded filler and different orientation methods. Eng. Fail. Anal. 2021, 130, 105795. [Google Scholar] [CrossRef]

- Nieto, D.M.; Alonso-García, M.; Pardo-Vicente, M.; Rodríguez-Parada, L. Product Design by Additive Manufacturing for Water Environments: Study of Degradation and Absorption Behavior of PLA and PETG. Polymers 2021, 13, 1036. [Google Scholar] [CrossRef]

- Khan, I.; Kumar, N. Fused deposition modelling process parameters influence on the mechanical properties of ABS: A review. Mater. Today Proc. 2021, 44, 4004–4008. [Google Scholar] [CrossRef]

- Selvamani, S.K.; Samykano, M.; Subramaniam, S.R.; Ngui, W.K.; Kadirgama, K.; Kanagaraj, G.; Idris, M.S. 3D printing: Overview of ABS evolvement. AIP Conf. Proc. 2019, 2059, 020041. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Corcione, C.E. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef] [PubMed]

- Pringle, A.M.; Rudnicki, M.; Pearce, J.M. Wood Furniture Waste–Based Recycled 3-D Printing Filament. For. Prod. J. 2018, 68, 86–95. [Google Scholar] [CrossRef] [Green Version]

- Pastor, J.Y.; Orellana-Barrasa, J.; Ferrández-Montero, A.; Ferrari, B.; Boccaccini, A.R. The Mechanical, Thermal, and Chemical Properties of PLA-Mg Filaments Produced via Colloidal Route for Fused Filament Fabrication. Polymers 2022, 14, 5414. [Google Scholar] [CrossRef]

- Cifuentes, S.C.; Lieblich, M.; López, F.; Benavente, R.; González-Carrasco, J.L. Effect of Mg content on the thermal stability and mechanical behaviour of PLLA/Mg composites processed by hot extrusion. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 72, 18–25. [Google Scholar] [CrossRef]

- Barrasa, J.O.; Ferrández-Montero, A.; Ferrari, B.; Pastor, J.Y. Characterisation and Modelling of PLA Filaments and Evolution with Time. Polymers 2021, 13, 2899. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Vidakis, N.; Petousis, M.; Mountakis, N. A multi-parametric process evaluation of the mechanical response of PLA in FFF 3D printing. Mater. Manuf. Process. 2022, 37, 1–13. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of Porosity and Crystallinity on 3D Printed PLA Properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef] [Green Version]

- Vanaei, H.R.; Shirinbayan, M.; Costa, S.F.; Duarte, F.M.; Covas, J.A.; Deligant, M.; Khelladi, S.; Tcharkhtchi, A. Experimental study of PLA thermal behavior during fused filament fabrication. J. Appl. Polym. Sci. 2021, 138, 49747. [Google Scholar] [CrossRef]

- Kanakannavar, S.; Pitchaimani, J. Fracture toughness of flax braided yarn woven PLA composites. Int. J. Polym. Anal. Charact. 2021, 26, 364–379. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Orellana-Barrasa, J.; Ferrández-Montero, A.; Ferrari, B.; Pastor, J.Y. Natural Ageing of PLA Filaments, Can It Be Frozen? Polymers 2022, 14, 3361. [Google Scholar] [CrossRef]

- Deroiné, M.; Le Duigou, A.; Corre, Y.-M.; Le Gac, P.-Y.; Davies, P.; César, G.; Bruzaud, S. Accelerated ageing of polylactide in aqueous environments: Comparative study between distilled water and seawater. Polym. Degrad. Stab. 2014, 108, 319–329. [Google Scholar] [CrossRef] [Green Version]

- Saha, S.K.; Tsuji, H. Hydrolytic Degradation of Amorphous Films of L-Lactide Copolymers with Glycolide and D-Lactide. Macromol. Mater. Eng. 2006, 291, 357–368. [Google Scholar] [CrossRef]

- Polidar, M.; Metzsch-Zilligen, E.; Pfaendner, R. Controlled and Accelerated Hydrolysis of Polylactide (PLA) through Pentaerythritol Phosphites with Acid Scavengers. Polymers 2022, 14, 4237. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, E.J.; Marcos, B.; Huneault, M.A. Hydrolysis of polylactide in aqueous media. J. Appl. Polym. Sci. 2016, 133, 44152. [Google Scholar] [CrossRef]

- Agrawal, C.M.; Huang, D.; Schmitz, J.; Athanasiou, K.A. Elevated Temperature Degradation of a 50:50 Copolymer of PLA-PGA. Tissue Eng. 2007, 3, 345–352. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; McCarthy, S. Further investigations on the hydrolytic degradation of poly (DL-lactide). Biomaterials 1999, 20, 35–44. [Google Scholar] [CrossRef]

- Monnier, X.; Saiter, A.; Dargent, E. Physical aging in PLA through standard DSC and fast scanning calorimetry investigations. Thermochim. Acta 2017, 648, 13–22. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2011, 25, 927–948. [Google Scholar] [CrossRef]

- Cristea, M.; Ionita, D.; Iftime, M.M. Dynamic Mechanical Analysis Investigations of PLA-Based Renewable Materials: How Are They Useful? Materials 2020, 13, 5302. [Google Scholar] [CrossRef] [PubMed]

- Chalgham, A.; Ehrmann, A.; Wickenkamp, I. Mechanical Properties of FDM Printed PLA Parts before and after Thermal Treatment. Polymers 2021, 13, 1239. [Google Scholar] [CrossRef] [PubMed]

- Jayanth, N.; Jaswanthraj, K.; Sandeep, S.; Mallaya, N.; Siddharth, S.R. Effect of heat treatment on mechanical properties of 3D printed PLA. J. Mech. Behav. Biomed. Mater. 2021, 123, 104764. [Google Scholar] [CrossRef]

- Akhoundi, B.; Nabipour, M.; Hajami, F.; Shakoori, D. An Experimental Study of Nozzle Temperature and Heat Treatment (Annealing) Effects on Mechanical Properties of High-Temperature Polylactic Acid in Fused Deposition Modeling. Polym. Eng. Sci. 2020, 60, 979–987. [Google Scholar] [CrossRef]

- Backes, E.H.; Pires, L.D.N.; Costa, L.C.; Passador, F.R.; Pessan, L.A. Analysis of the Degradation During Melt Processing of PLA/Biosilicate® Composites. J. Compos. Sci. 2019, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- Bhagia, S.; Bornani, K.; Agrawal, R.; Satlewal, A.; Ďurkovič, J.; Lagaňa, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.; Kunc, V.; et al. Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries. Appl. Mater. Today 2021, 24, 101078. [Google Scholar] [CrossRef]

- Cao, X.; Mohamed, A.; Gordon, S.; Willett, J.; Sessa, D.J. DSC study of biodegradable poly(lactic acid) and poly(hydroxy ester ether) blends. Thermochim. Acta 2003, 406, 115–127. [Google Scholar] [CrossRef]

- Jia, S.; Yu, D.; Zhu, Y.; Wang, Z.; Chen, L.; Fu, L. Morphology, Crystallization and Thermal Behaviors of PLA-Based Composites: Wonderful Effects of Hybrid GO/PEG via Dynamic Impregnating. Polymers 2017, 9, 528. [Google Scholar] [CrossRef] [Green Version]

- Leonés, A.; Peponi, L.; Lieblich, M.; Benavente, R.; Fiori, S. In Vitro Degradation of Plasticized PLA Electrospun Fiber Mats: Morphological, Thermal and Crystalline Evolution. Polymers 2020, 12, 2975. [Google Scholar] [CrossRef]

- Kaavessina, M.; Ali, I.; Al-Zahrani, S.M. The Influences of Elastomer toward Crystallization of Poly(lactic acid). Procedia Chem. 2012, 4, 164–171. [Google Scholar] [CrossRef] [Green Version]

- Murariu, M.; Paint, Y.; Murariu, O.; Laoutid, F.; Dubois, P. Tailoring and Long-Term Preservation of the Properties of PLA Composites with ‘Green’ Plasticizers. Polymers 2022, 14, 4836. [Google Scholar] [CrossRef] [PubMed]

- De Bortoli, L.S.; De Farias, R.; Mezalira, D.; Schabbach, L.; Fredel, M.C. Functionalized carbon nanotubes for 3D-printed PLA-nanocomposites: Effects on thermal and mechanical properties. Mater. Today Commun. 2022, 31, 103402. [Google Scholar] [CrossRef]

- Da Silva Barbosa Ferreira, E.; Luna, C.; Siqueira, D.; Araújo, E.; De França, D.; Wellen, R.M.R. Annealing Effect on Pla/Eva Blends Performance. J. Polym. Environ. 2022, 30, 541–554. [Google Scholar] [CrossRef]

- Coxon, L.D.; White, J.R. Residual stresses and aging in injection molded polypropylene. Polym. Eng. Sci. 1980, 20, 230–236. [Google Scholar] [CrossRef]

- Chan, T.W.D.; Lee, L.J. Analysis of molecular orientation and internal stresses in extruded plastic sheets. Polym. Eng. Sci. 1989, 29, 163–170. [Google Scholar] [CrossRef]

- White, J.R. Origins and measurements of internal stress in plastics. Polym. Test. 1984, 4, 165–191. [Google Scholar] [CrossRef]

- Niaounakis, M.; Kontou, E.; Xanthis, M. Effects of aging on the thermomechanical properties of poly(lactic acid). J. Appl. Polym. Sci. 2011, 119, 472–481. [Google Scholar] [CrossRef]

| Ageing | Ageing Temperature | Tg.1 | TER.1 | ΔHER.1 | Tg.2 | TCC | ΔHCC | Tm | ΔHm | χ% |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 h | 20 ± 0.1 | - | - | - | 54.4 | 123 | −15.2 | 152 | 15.2 | <3 |

| 2 h 1 | 45.5 | - | - | 57.5 | 123 | −15.2 | 152 | 15.2 | <3 | |

| 3 h | 46.4 | - | - | 57.6 | 123 | −14.7 | 151 | 16.4 | <3 | |

| 1 d | 51.5 | - | - | 59.9 | 124 | −17.0 | 154 | 17.2 | <3 | |

| 4 d | 54.8 | - | - | 61.1 | 121 | −16.8 | 152 | 16.4 | <3 | |

| 7 d | 56.1 | 58.6 | 0.15 | 62.6 | 122 | −15.6 | 152 | 15.9 | <3 | |

| 14 d | 56.6 | 58.9 | 0.79 | - | 121 | −15.8 | 152 | 16.3 | <3 | |

| 24 d | 56.9 | 60.0 | 1.61 | - | 122 | −16.2 | 152 | 16.5 | <3 | |

| 49 d | 57.2 | 60.6 | 2.5 | - | 122 | −15.9 | 152 | 16.3 | <3 | |

| 91 d | 57.5 | 61.0 | 3.7 | - | 123 | −15.7 | 153 | 16.5 | <3 | |

| 1 d | 39 ± 0.1 | 58.4 | 61.4 | 2.0 | - | 125 | −14.4 | 153 | 15.2 | <3 |

| 2 d | 59.0 | 61.7 | 3.3 | - | 124 | −17.8 | 152 | 18.6 | <3 | |

| 4 d | 59.4 | 62.2 | 4.0 | - | 125 | −14.5 | 152 | 15.7 | <3 | |

| 7 d | 60.7 | 63.2 | 4.4 | - | 125 | −14.7 | 152 | 15.5 | <3 | |

| 14 d | 61.0 | 63.5 | 4.7 | - | 124 | −15.0 | 152 | 15.7 | <3 | |

| 24 d | 61.2 | 63.5 | 5.0 | - | 124 | −15.9 | 152 | 17.2 | <3 | |

| 1 d | 42 ± 0.1 | 59.5 | 62.1 | 3.2 | - | 124 | −14.0 | 152 | 15.4 | <3 |

| 4 d | 63.3 | 65.6 | 5.7 | - | 124 | −15.2 | 152 | 16.9 | <3 | |

| 1 d | 51 ± 0.1 | 57.5 | 61.5 | 0.6 | - | 122 | −21 | 152 | 22 | <3 |

| 4 d | 58.2 | 62.5 | 0.9 | - | 122 | −22 | 152 | 23 | <3 | |

| 7 d | 57.7 | 62.0 | 0.8 | - | 121 | −25 | 151 | 24 | <3 | |

| 14 d | 57.1 | 63.0 | 0.7 | - | 121 | −23 | 152 | 23 | <3 | |

| 24 d | 57.5 | 62.3 | 0.8 | - | 121 | −24 | 152 | 24 | <3 | |

| 42 d | 57.2 | 62.0 | 0.8 | - | 121 | −24 | 152 | 24 | <3 | |

| 1 d | 65 ± 0.1 | 57.7 | 61.9 | 0.6 | - | 118 | −27 | 150 | 27 | <3 |

| 1 d | 75 ± 0.1 | 60.8 | - | - | - | - 2 | - 2 | 154 | 28 | 20 |

| 1 d | 80 ± 0.1 | 61.9 | - | - | - | - | 0 | 153 | 27 | 28 |

| Yield Strength | A | B | |

| 20 °C | 0.13 | 0.20 | 62.7 |

| 39 °C | 0.26 | 3.47 | 65.4 |

| Variation | 100% | 1635% | 4.7% |

| Elastic modulus | A | B | |

| 20 °C | 0.13 | 0.24 | 3.18 |

| 39 °C | 0.28 | 2.34 | 3.41 |

| Variation | 115% | 875% | 7.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orellana-Barrasa, J.; Tarancón, S.; Pastor, J.Y. Effects of Accelerating the Ageing of 1D PLA Filaments after Fused Filament Fabrication. Polymers 2023, 15, 69. https://doi.org/10.3390/polym15010069

Orellana-Barrasa J, Tarancón S, Pastor JY. Effects of Accelerating the Ageing of 1D PLA Filaments after Fused Filament Fabrication. Polymers. 2023; 15(1):69. https://doi.org/10.3390/polym15010069

Chicago/Turabian StyleOrellana-Barrasa, Jaime, Sandra Tarancón, and José Ygnacio Pastor. 2023. "Effects of Accelerating the Ageing of 1D PLA Filaments after Fused Filament Fabrication" Polymers 15, no. 1: 69. https://doi.org/10.3390/polym15010069

APA StyleOrellana-Barrasa, J., Tarancón, S., & Pastor, J. Y. (2023). Effects of Accelerating the Ageing of 1D PLA Filaments after Fused Filament Fabrication. Polymers, 15(1), 69. https://doi.org/10.3390/polym15010069