Enhancement of Stability in n-Channel OFETs by Modulating Polymeric Dielectric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Device Fabrication

2.2. Characterization

3. Results and Discussions

3.1. Surface Morphology Analyses of Dielectric Layers

3.2. Analysis of Thin Film Microstructure

3.3. Electrical Measurements of OFETs

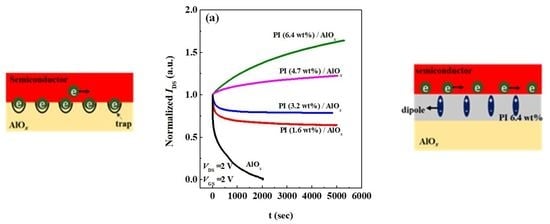

3.4. Stability Analysis of OFETs

3.5. Analyses of Memory Device Characteristics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Facchetti, A. Semiconductors for organic transistors. Mater. Today 2007, 10, 28–37. [Google Scholar] [CrossRef]

- Smith, J.; Hamilton, R.; McCulloch, I.; Stutzmann, N.S.; Heeney, M.; Bradley, D.D.C.; Anthopoulos, T.D. Solution-processed organic transistors based on semiconducting blends. J. Mater. Chem. 2010, 20, 2562–2574. [Google Scholar] [CrossRef]

- GuÈnes, S.; Neugebauer, H.; Sariciftci, N.S. Conjugated Polymer-Based Organic Solar Cells. Chem. Rev. 2007, 107, 1324–1338. [Google Scholar] [CrossRef] [PubMed]

- Peumans, P.; Yakimov, A.; Forrest, S.R. Small molecular weight organic thin photodetectors and solar cells. J. Appl. Phys. 2003, 93, 3693–3723. [Google Scholar] [CrossRef]

- Reineke, S.; Lindner, F.; Schwartz, G.; Seidler, N.; Walzer, K.; Lüssem, B.; Leo, K. White organic light-emitting diodes with fluorescent tube efficiency. Nature 2009, 459, 234–238. [Google Scholar] [CrossRef]

- Dai, X.L.; Zhang, Z.X.; Jin, Y.H.; Niu, Y.; Cao, H.J.; Liang, X.Y.; Chen, L.W.; Wang, J.P.; Peng, X.G. Solution-processed, high-performance light-emitting diodes based on quantum dots. Nature 2014, 515, 96–99. [Google Scholar] [CrossRef]

- Xia, G.D.; Wang, S.M.; Zhao, X.R.; Zhou, L.M. High-performance low-voltage organic transistor memories with room-temperature solution-processed hybrid nanolayer dielectrics. J. Mater. Chem. C 2013, 1, 3291–3296. [Google Scholar] [CrossRef]

- Baeg, K.J.; Khim, D.Y.; Kim, J.H.; Yang, B.D.; Kang, M.J.; Jung, S.W.; You, I.K.; Kim, D.Y.; Noh, Y.Y. High-Performance Top-Gated Organic Field-Effect Transistor Memory using Electrets for Monolithic Printed Flexible NAND Flash Memory. Adv. Funct. Mater. 2012, 22, 2915–2926. [Google Scholar] [CrossRef]

- Diao, Y.; Tee, B.C.K.; Giri, G.; Xu, J.; Kim, D.H.; Becerril, H.A.; Stoltenberg, R.M.; Lee, T.H.; Xue, G.; Mannsfeld, S.C.B.; et al. Solution coating of large-area organic semiconductor thin films with aligned single-crystalline domains. Nat. Mater. 2013, 12, 665–671. [Google Scholar] [CrossRef]

- Li, W.H.; Liu, Q.; Zhang, Y.; Li, C.; He, Z.F.; Choy, W.C.H.; Low, P.J.; Sonar, P.; Kyaw, A.K.K. Biodegradable Materials and Green Processing for Green Electronics. Adv. Mater. 2020, 32, 2001591. [Google Scholar] [CrossRef]

- Giri, G.; Verploegen, E.; Mannsfeld, S.C.B.; Evrenk, S.A.; Kim, D.H.; Lee, S.Y.; Becerril, H.A.; Guzik, A.A.; Toney, M.F.; Bao, Z.N. Tuning charge transport in solution-sheared organic semiconductors using lattice strain. Nature 2011, 480, 504–508. [Google Scholar] [CrossRef] [PubMed]

- Karl, N. Charge carrier transport in organic semiconductors. Synth. Met. 2003, 133–134, 649–657. [Google Scholar] [CrossRef]

- Friederich, P.; Meded, V.; Poschlad, A.; Neumann, T.; Rodin, V.; Stehr, V.; Symalla, F.; Danilov, D.; Lüdemann, G.; Fink, R.F.; et al. Molecular Origin of the Charge Carrier Mobility in Small Molecule Organic Semiconductors. Adv. Funct. Mater. 2016, 26, 5757–5763. [Google Scholar] [CrossRef]

- Schmechel, R.; von Seggern, H. Electronic traps in organic transport layers. Phys. Status Solidi (a) 2004, 201, 1215–1235. [Google Scholar] [CrossRef]

- Jun, B.; Lee, C.H.; Lee, S.U. Strain-induced carrier mobility modulation in organic semiconductors. J. Ind. Eng. Chem. 2022, 107, 137–144. [Google Scholar] [CrossRef]

- Puntambekar, K.; Dong, J.; Haugstad, G.; Frisbie, C.D. Structural and Electrostatic Complexity at a Pentacene/Insulator Interface. Adv. Funct. Mater. 2006, 16, 879–884. [Google Scholar] [CrossRef]

- Mühlenen, A.V.; Castellani, M.; Schaer, M.; Zuppiroli, L. Controlling charge-transfer at the gate interface of organic field-effect transistors. Phys. Status Solidi (b) 2008, 245, 1170–1174. [Google Scholar] [CrossRef]

- Bürgi, L.; Richards, T.J.; Friend, R.H.; Sirringhaus, H. Close look at charge carrier injection in polymer field-effect transistors. J. Appl. Phys. 2003, 94, 6129–6137. [Google Scholar] [CrossRef]

- Lucas, B.; Amrani, A.E.; Moliton, A.; Skaiky, A.; El Hajj, A.; Aldissi, M. Charge transport properties in pentacene films: Evaluation of carrier mobility by different techniques. Solid State Electron. 2012, 69, 99–103. [Google Scholar] [CrossRef]

- Alaboson, J.M.P.; Wang, Q.H.; Emery, J.D.; Lipson, A.L.; Bedzyk, M.J.; Elam, J.W.; Pellin, M.J.; Hersam, M.C. Seeding Atomic Layer Deposition of High-k Dielectrics on Epitaxial Graphene with Organic Self-Assembled Monolayers. ACS Nano 2011, 5, 5223–5232. [Google Scholar] [CrossRef]

- Chang, J.F.; Hou, K.S.; Yang, Y.W.; Wang, C.H.; Chen, Y.X.; Ke, H.D. Enhanced mobility for increasing on-current and switching ratio of vertical organic field-effect transistors by surface modification with phosphonic acid self-assembled monolayer. Org. Electron. 2020, 81, 105689-1–105689-7. [Google Scholar] [CrossRef]

- Horii, Y.; Sakaguchi, K.; Chikamatsu, M.; Azumi, R.; Yase, K.; Kitagawa, M.; Konish, H. High-Performance Solution-Processed n-Channel Organic Thin-Film Transistors Based on a Long Chain Alkyl-Substituted C60 Derivative. Appl. Phys. Express 2010, 3, 101601. [Google Scholar] [CrossRef]

- Kim, K.; Oh, S.M.; Hong, J.; Jung, C.; Seo, J.; Jeong, Y.J.; Lee, H.S.; Kim, S.H. Electrohydrodynamic jet printing of small-molecule semiconductor crystals on chemically patterned surface for high-performance organic field-effect transistors. Mater. Chem. Phys. 2022, 285, 126165. [Google Scholar] [CrossRef]

- Volksen, W. Condensation polyimides: Synthesis, solution behavior, and imidization characteristics. Adv. Polym. Sci. 1994, 117, 111–164. [Google Scholar]

- Jiang, S.H.; Uch, B.; Agarwal, S.; Greiner, A. Ultralight, Thermally Insulating, Compressible Polyimide Fiber Assembled Sponges. ACS Appl. Mater. Interfaces 2017, 9, 32308–32315. [Google Scholar] [CrossRef]

- Ji, D.Y.; Li, T.; Hu, W.P. Harald Fuchs Recent Progress in Aromatic Polyimide Dielectrics for Organic Electronic Devices and Circuits. Adv. Mater. 2019, 31, 1806070. [Google Scholar] [CrossRef]

- Liu, Z.L.; Yu, T.P.; Wan, Z.T.; Wang, Y.R.; Li, Z.Q.; Yin, J.; Gao, X.; Xia, Y.D.; Liu, Z.G. High-Performance Pentacene-Based Field-Effect Transistor Memory Using the Electrets of Polymer Blends. Adv. Electron. Mater. 2022, 8, 2101342. [Google Scholar] [CrossRef]

- Chou, W.Y.; Ho, T.Y.; Cheng, H.L.; Tang, F.C.; Chen, J.H.; Wang, Y.W. Gate field induced ordered electric dipoles in a polymer dielectric for low-voltage operating organic thin-film transistors. RSC Adv. 2013, 3, 20267–20272. [Google Scholar] [CrossRef]

- Baek, Y.; Lim, S.; Yoo, E.J.; Kim, L.H.; Kim, H.; Lee, S.W.; Kim, S.H.; Park, C.E. Fluorinated Polyimide Gate Dielectrics for the Advancing the Electrical Stability of Organic Field-Effect Transistors. ACS Appl. Mater. Interfaces 2014, 6, 15209–15216. [Google Scholar] [CrossRef]

- Raveendran, R.; Namboothiry, M.A.G. Bias Stress Stability and Hysteresis in Elastomeric Dielectric Based Solution Processed OFETs. Mater. Res. Bull. 2022, 146, 111596. [Google Scholar] [CrossRef]

- Kang, B.; Moon, B.; Choi, H.H.; Song, E.; Cho, K. Molecular Orientation-Dependent Bias Stress Stability in Bottom-Gate Organic Transistors Based on an n-Type Semiconducting Polymer. Adv. Electron. Mater. 2016, 2, 1500380. [Google Scholar] [CrossRef]

- Knipp, D.; Street, R.A.; Vülkel, A.; Ho, J. Pentacene thin film transistors on inorganic dielectrics: Morphology, structural properties, and electronic transport. J. Appl. Phys. 2003, 93, 347–355. [Google Scholar] [CrossRef]

- Kalb, W.L.; Batlogg, B. Calculating the trap density of states in organic field-effect transistors from experiment: A comparison of different methods. Phys. Rev. B 2010, 81, 035327. [Google Scholar] [CrossRef]

- Zaumseil, J.; Sirringhaus, H. Electron and Ambipolar Transport in Organic Field-Effect Transistors. Chem. Rev. 2007, 107, 1296–1323. [Google Scholar] [CrossRef]

- Ruzaiqi, A.A.; Okamoto, H.; Kubozono, Y.; Zschieschang, U.; Klauk, H.; Baran, P.; Gleskov, H. Low-voltage organic thin-film transistors based on [n]phenacenes. Org. Electron. 2019, 73, 286–291. [Google Scholar] [CrossRef]

- Kumar, A.; Perinot, A.; Sarkar, S.K.; Gupta, D.; Zorn, N.F.; Zaumseil, J.; Caironi, M. Low-temperature solution-processed high-capacitance AlOx dielectrics for low-voltage carbon-based transistors. Org. Electron. 2022, 110, 106636. [Google Scholar] [CrossRef]

- Kim, D.; Kim, C.; Earmme, T. Polyurethane triblock copolymer gate dielectrics for low-voltage organic thin-film transistors. J. Ind. Eng. Chem. 2019, 71, 460–464. [Google Scholar] [CrossRef]

- Zschieschang, U.; Amsharov, K.; Weitz, R.T.; Jansen, M.; Klauk, H. Low-voltage organic n-channel thin-film transistors based on a core-cyanated perylene tetracarboxylic diimide derivative. Synth. Met. 2009, 159, 2362–2364. [Google Scholar] [CrossRef]

- Unni, K.N.N.; Pandey, A.K.; Nunzi, J.M. N-channel organic field-effect transistors using N, N’-ditridecylperylene-3, 4, 9, 10-tetracarboxylic diimide and a polymeric dielectric. Chem. Phys. Lett. 2005, 407, 95–99. [Google Scholar] [CrossRef]

- Oh, J.D.; Kim, J.W.; Kim, D.K.; Choi, J.H. Low-voltage organic transistors and inverters using HfOx dielectrics. Org. Electron. 2016, 30, 131–135. [Google Scholar] [CrossRef]

- Wu, F.C.; Yeh, B.L.; Chou, T.H.; Chen, J.S.; Cheng, H.L.; Chou, W.Y. Effects of interfacial tension and molecular dipole moment on the electrical characteristics of low-voltage-driven organic electronic devices. Org. Electron. 2018, 59, 374–381. [Google Scholar] [CrossRef]

- Liao, H.L.; Chen, J.X.; Lan, L.Y.; Yu, Y.P.; Zhu, G.M.; Duan, J.Y.; Zhu, X.Y.; Dai, H.J.; Xiao, M.F.; Li, Z.K.; et al. Efficient n-Type Small-Molecule Mixed Ion-Electron Conductors and Application in Hydrogen Peroxide Sensors. ACS Appl. Mater. Interfaces 2022, 14, 16477–16486. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.S.; Yeh, B.L.; Tsai, M.R.; Cheng, H.L.; Liu, S.J.; Tang, F.C.; Chou, W.Y. Initial time-dependent current growth phenomenon in n-type organic transistors induced by interfacial dipole effects. J. Appl. Phys. 2015, 117, 104507. [Google Scholar] [CrossRef]

- Wang, Y.F.; Tsai, M.R.; Wang, P.Y.; Lin, C.Y.; Cheng, H.L.; Tang, F.C.; Hsu, S.L.C.; Hsu, C.C.; Chou, W.Y. Controlling carrier trapping and relaxation with a dipole field in an organic field-effect device. RSC Adv. 2016, 6, 77735–77744. [Google Scholar] [CrossRef]

- Wang, Y.F.; Tsai, M.R.; Lin, Y.S.; Wu, F.C.; Lin, C.Y.; Cheng, H.L.; Liu, S.J.; Tang, F.C.; Chou, W.Y. High-response organic thin-film memory transistors based on dipole-functional polymer electret layers. Org. Electron. 2015, 26, 359–364. [Google Scholar] [CrossRef]

- Wang, W.V.; Zhang, Y.; Li, X.Y.; Chen, Z.Z.; Wu, Z.H.; Zhang, L.; Lin, Z.W.; Zhang, H.L. High performance nonvolatile organic field-effect transistor memory devices based on pyrene diimide derivative. Infomat 2021, 3, 814–822. [Google Scholar] [CrossRef]

| Dielectric of OFETs | Vth (V) | IOn/IOff Ratio | C | Mobility |

|---|---|---|---|---|

| PI (6.4 wt%)/AlOx | −0.67 | 7.0 × 102 | 19.67 | 3.22 × 10−3 |

| PI (4.7 wt%)/AlOx | −0.43 | 4.0 × 103 | 27.91 | 3.46 × 10−3 |

| PI (3.2 wt%)/AlOx | 0.03 | 9.2 × 103 | 72.91 | 1.52 × 10−3 |

| PI (1.6 wt%)/AlOx | 0.05 | 6.5 × 103 | 234.41 | 1.58 × 10−2 |

| AlOx | 0.09 | 4.8 × 101 | 1007.10 | 2.29 × 10−3 |

| Dielectric of OFETs | Cycle Time | C | Memory Window | Δn (×1012 cm−2) |

|---|---|---|---|---|

| PI (6.4 wt%)/AlOx | 50 | 19.67 | 0.06 | 0.007 |

| PI (4.7 wt%)/AlOx | 50 | 27.91 | 0.02 | 0.003 |

| PI (3.2 wt%)/AlOx | 50 | 72.91 | 0.42 | 0.19 |

| PI (1.6 wt%)/AlOx | 50 | 234.41 | 0.70 | 1.02 |

| AlOx | 50 | 1007.10 | −0.12 | −0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, P.-H.; Kuo, P.-L.; Wang, Y.-W.; Cheng, H.-L.; Chou, W.-Y. Enhancement of Stability in n-Channel OFETs by Modulating Polymeric Dielectric. Polymers 2023, 15, 2421. https://doi.org/10.3390/polym15112421

Fang P-H, Kuo P-L, Wang Y-W, Cheng H-L, Chou W-Y. Enhancement of Stability in n-Channel OFETs by Modulating Polymeric Dielectric. Polymers. 2023; 15(11):2421. https://doi.org/10.3390/polym15112421

Chicago/Turabian StyleFang, Po-Hsiang, Peng-Lin Kuo, Yu-Wu Wang, Horng-Long Cheng, and Wei-Yang Chou. 2023. "Enhancement of Stability in n-Channel OFETs by Modulating Polymeric Dielectric" Polymers 15, no. 11: 2421. https://doi.org/10.3390/polym15112421

APA StyleFang, P. -H., Kuo, P. -L., Wang, Y. -W., Cheng, H. -L., & Chou, W. -Y. (2023). Enhancement of Stability in n-Channel OFETs by Modulating Polymeric Dielectric. Polymers, 15(11), 2421. https://doi.org/10.3390/polym15112421