Flame Retardancy Index (FRI) for Polymer Materials Ranking

Abstract

:1. Background

2. Conceptualization

3. Visualization

, Figure 3(a3,b3,c3)), with the main action of the dilution of gas phase by releasing water, the FRI values are quite similar and the classification remains unchanged. Another example is brominated FRs (symbols

, Figure 3(a3,b3,c3)), with the main action of the dilution of gas phase by releasing water, the FRI values are quite similar and the classification remains unchanged. Another example is brominated FRs (symbols  , Figure 3(a7,b7,c7)), acting in the gas phase through free radical capture; again, the FRI values are quite similar. Aluminum diethyl phosphinate (AlPi) (symbols

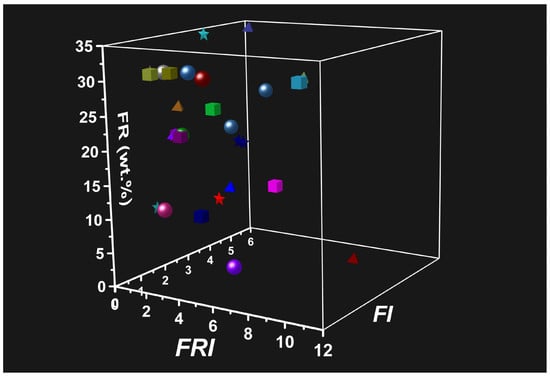

, Figure 3(a7,b7,c7)), acting in the gas phase through free radical capture; again, the FRI values are quite similar. Aluminum diethyl phosphinate (AlPi) (symbols  , Figure 3(a9,b9,c9)) can also be considered as typical phosphorus FRs acting essentially in the gas phase. However, the FRI values should be sensitive to systems in which the main flame retardancy action is contributed by the condensed phase. Even a synergistic effect could be detected by a combination of several FRs. The difference in the FRI values has more pronounced in the case of the combination/synergism between ammonium polyphosphate (APP), tripentaerythritol (TPER), and multiwall carbon nanotubes (MWCNT) acting in the condensed phase. This could be explained by the increase in the value of tp resulting from the barrier effect and the resilience of the material to liberate the combustion gases followed by apparition of the peak. Noteworthily, classification in terms of “Poor”, “Good”, or “Excellent” has remained unchanged, except for one system (PA/GF/RP). For polyamide containing glass fiber and red phosphorus (symbols

, Figure 3(a9,b9,c9)) can also be considered as typical phosphorus FRs acting essentially in the gas phase. However, the FRI values should be sensitive to systems in which the main flame retardancy action is contributed by the condensed phase. Even a synergistic effect could be detected by a combination of several FRs. The difference in the FRI values has more pronounced in the case of the combination/synergism between ammonium polyphosphate (APP), tripentaerythritol (TPER), and multiwall carbon nanotubes (MWCNT) acting in the condensed phase. This could be explained by the increase in the value of tp resulting from the barrier effect and the resilience of the material to liberate the combustion gases followed by apparition of the peak. Noteworthily, classification in terms of “Poor”, “Good”, or “Excellent” has remained unchanged, except for one system (PA/GF/RP). For polyamide containing glass fiber and red phosphorus (symbols  , Figure 3(a4,b4,c4)), the value of the FRI (ti) is 6.44, while for FRI (tp) it is 2.92. This difference can be explained by the presence of glass fiber and the special case of the “candle wick” effect during combustion with a shorter time to reach pHRR [27]. First, it can be concluded that the FRI is able to classify all types of systems whatever the action of flame retardant in the condensed or gas phase, and also regardless of the type of polymer. Second, it is difficult to reach an Excellent level of flame retardancy, such that only a hybrid FR system representing different actions of flame retardancy may be needed to reach FRI values above 10.

, Figure 3(a4,b4,c4)), the value of the FRI (ti) is 6.44, while for FRI (tp) it is 2.92. This difference can be explained by the presence of glass fiber and the special case of the “candle wick” effect during combustion with a shorter time to reach pHRR [27]. First, it can be concluded that the FRI is able to classify all types of systems whatever the action of flame retardant in the condensed or gas phase, and also regardless of the type of polymer. Second, it is difficult to reach an Excellent level of flame retardancy, such that only a hybrid FR system representing different actions of flame retardancy may be needed to reach FRI values above 10. , Figure 4c), slightly improve the flame retardancy even at a high loading percentage of 30 wt.%. In the case of phosphorus FR with well-known action in the condensed phase, however, FR percentage is a flammability-determining factor. Obviously, it is possible to obtain a high flame retardancy (symbol

, Figure 4c), slightly improve the flame retardancy even at a high loading percentage of 30 wt.%. In the case of phosphorus FR with well-known action in the condensed phase, however, FR percentage is a flammability-determining factor. Obviously, it is possible to obtain a high flame retardancy (symbol  , Figure 4c) even at a very low loading percentage., e.g., by combining LDH with graphene in EP. Based on the statistics used in this survey, the use of FRI (ti), FRI (tp), or FRI (ti&tp) does not change the category of flame retardancy performance. However, a larger pool of data would be required for analyzing the performance of FRs depending on the FRI formula. The pHRR will be weighted on the time at which the maximum heat release rate is recorded, while the THR will be weighted on the time at which the flaming phenomenon starts, which directly affects the area under the HRR curve. Thus, the FSI and FPI measures already defined by Lyon and coworkers [4] would change significantly when a flame-sensitive polymers is under measurement. Correspondingly, the FRI (ti), FRI (tp), or FRI (ti&tp) change in a manner that the classification might severely depend on the FRI formula.

, Figure 4c) even at a very low loading percentage., e.g., by combining LDH with graphene in EP. Based on the statistics used in this survey, the use of FRI (ti), FRI (tp), or FRI (ti&tp) does not change the category of flame retardancy performance. However, a larger pool of data would be required for analyzing the performance of FRs depending on the FRI formula. The pHRR will be weighted on the time at which the maximum heat release rate is recorded, while the THR will be weighted on the time at which the flaming phenomenon starts, which directly affects the area under the HRR curve. Thus, the FSI and FPI measures already defined by Lyon and coworkers [4] would change significantly when a flame-sensitive polymers is under measurement. Correspondingly, the FRI (ti), FRI (tp), or FRI (ti&tp) change in a manner that the classification might severely depend on the FRI formula.4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vahabi, H.; Laoutid, F.; Mehrpouya, M.; Saeb, M.R.; Dubois, P. Flame retardant polymer materials: An update and the future for 3D printing developments. Mater. Sci. Eng. R Rep. 2021, 144, 100604. [Google Scholar] [CrossRef]

- Bourbigot, S. Evaluation of Condensed Phase: Char/Residue Analysis. In Analysis of Flame Retardancy in Polymer Science; Elsevier: Amsterdam, The Netherlands, 2022; pp. 191–231. [Google Scholar]

- Quan, Y.; Zhang, Z.; Tanchak, R.N.; Wang, Q. A review on cone calorimeter for assessment of flame-retarded polymer composites. J. Therm. Anal. Calorim. 2022, 147, 10209–10234. [Google Scholar] [CrossRef]

- Lyon, R.E.; Balaguru, P.; Foden, A.; Sorathia, U.; Davidovits, J.; Davidovics, M. Fire-resistant aluminosilicate composites. Fire Mater. 1997, 21, 67–73. [Google Scholar] [CrossRef]

- Vahabi, H.; Kandola, B.K.; Saeb, M.R. Flame retardancy index for thermoplastic composites. Polymers 2019, 11, 407. [Google Scholar] [CrossRef]

- Seidi, F.; Movahedifar, E.; Naderi, G.; Akbari, V.; Ducos, F.; Shamsi, R.; Vahabi, H.; Saeb, M.R. Flame retardant polypropylenes: A review. Polymers 2020, 12, 1701. [Google Scholar] [CrossRef]

- Movahedifar, E.; Vahabi, H.; Saeb, M.R.; Thomas, S. Flame retardant epoxy composites on the road of innovation: An analysis with flame retardancy index for future development. Molecules 2019, 24, 3964. [Google Scholar] [CrossRef]

- Ramadan, N.; Taha, M.; La Rosa, A.D.; Elsabbagh, A. Towards selection charts for epoxy resin, unsaturated polyester resin and their fibre-fabric composites with flame retardants. Materials 2021, 14, 1181. [Google Scholar] [CrossRef]

- Lou, G.; Ma, Z.; Dai, J.; Bai, Z.; Fu, S.; Huo, S.; Li, F.; Liu, Y.-Q. Fully biobased surface-functionalized microcrystalline cellulose via green self-assembly toward fire-retardant, strong, and tough epoxy biocomposites. ACS Sustain. Chem. Eng. 2021, 9, 13595–13605. [Google Scholar] [CrossRef]

- Rao, W.; Zhao, P.; Yu, C.; Zhao, H.-B.; Wang, Y.-Z. High strength, low flammability, and smoke suppression for epoxy thermoset enabled by a low-loading phosphorus-nitrogen-silicon compound. Compos. Part B Eng. 2021, 211, 108640. [Google Scholar] [CrossRef]

- Seraji, S.M.; Song, P.; Varley, R.J.; Bourbigot, S.; Voice, D.; Wang, H. Fire-retardant unsaturated polyester thermosets: The state-of-the-art, challenges and opportunities. Chem. Eng. J. 2022, 430, 132785. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiao, Z.; Shen, R.; Song, P.; Wang, Q. Accelerated Design of Flame Retardant Polymeric Nanocomposites via Machine Learning Prediction. ACS Appl. Eng. Mater. 2022, 1, 596–605. [Google Scholar] [CrossRef]

- Vahabi, H.; Naser, M.; Saeb, M. Fire protection and materials flammability control by artificial intelligence. Fire Technol. 2022, 58, 1071–1073. [Google Scholar] [CrossRef]

- Bifulco, A.; Parida, D.; Salmeia, K.A.; Lehner, S.; Stämpfli, R.; Markus, H.; Malucelli, G.; Branda, F.; Gaan, S. Improving flame retardancy of in-situ silica-epoxy nanocomposites cured with aliphatic hardener: Combined effect of DOPO-based flame-retardant and melamine. Compos. Part C Open Access 2020, 2, 100022. [Google Scholar] [CrossRef]

- Zhao, B.; Liang, W.-J.; Wang, J.-S.; Li, F.; Liu, Y.-Q. Synthesis of a novel bridged-cyclotriphosphazene flame retardant and its application in epoxy resin. Polym. Degrad. Stab. 2016, 133, 162–173. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, S.; Xing, W.; Yu, B.; Feng, X.; Song, L.; Hu, Y. Self-assembly of Ni–Fe layered double hydroxide/graphene hybrids for reducing fire hazard in epoxy composites. J. Mater. Chem. A 2013, 1, 4383–4390. [Google Scholar] [CrossRef]

- Prieur, B.; Meub, M.; Wittemann, M.; Klein, R.; Bellayer, S.; Fontaine, G.; Bourbigot, S. Phosphorylation of lignin to flame retard acrylonitrile butadiene styrene (ABS). Polym. Degrad. Stab. 2016, 127, 32–43. [Google Scholar] [CrossRef]

- Alongi, J.; Cuttica, F.; Bourbigot, S.; Malucelli, G. Thermal and flame retardant properties of ethylene vinyl acetate copolymers containing deoxyribose nucleic acid or ammonium polyphosphate. J. Therm. Anal. Calorim. 2015, 122, 705–715. [Google Scholar] [CrossRef]

- El Hage, R.; Viretto, A.; Sonnier, R.; Ferry, L.; Lopez-Cuesta, J.-M. Flame retardancy of ethylene vinyl acetate (EVA) using new aluminum-based fillers. Polym. Degrad. Stab. 2014, 108, 56–67. [Google Scholar] [CrossRef]

- Sahyoun, J.; Bounor-Legare, V.; Ferry, L.; Sonnier, R.; Da Cruz-Boisson, F.; Melis, F.; Sonnier, R. Synthesis of a new organophosphorous alkoxysilane precursor and its effect on the thermal and fire behavior of a PA66/PA6 copolymer. Eur. Polym. J. 2015, 66, 352–366. [Google Scholar] [CrossRef]

- Rabe, S.; Schartel, B. The rapid mass calorimeter: A route to high throughput fire testing. Fire Mater. 2017, 41, 834–847. [Google Scholar] [CrossRef]

- Dorez, G.; Taguet, A.; Ferry, L.; Lopez-Cuesta, J. Thermal and fire behavior of natural fibers/PBS biocomposites. Polym. Degrad. Stab. 2013, 98, 87–95. [Google Scholar] [CrossRef]

- Patel, P.; Hull, T.R.; Lyon, R.E.; Stoliarov, S.I.; Walters, R.N.; Crowley, S.; Safronava, N. Investigation of the thermal decomposition and flammability of PEEK and its carbon and glass-fibre composites. Polym. Degrad. Stab. 2011, 96, 12–22. [Google Scholar] [CrossRef]

- Lu, H.; Wilkie, C.A. Fire performance of flame retardant polypropylene and polystyrene composites screened with microscale combustion calorimetry. Polym. Adv. Technol. 2011, 22, 14–21. [Google Scholar] [CrossRef]

- Lu, H.; Wilkie, C.A. Study on intumescent flame retarded polystyrene composites with improved flame retardancy. Polym. Degrad. Stab. 2010, 95, 2388–2395. [Google Scholar] [CrossRef]

- Sonnier, R.; Vahabi, H.; Ferry, L.; Lopez-Cuesta, J.-M. Pyrolysis-combustion flow calorimetry: A powerful tool to evaluate the flame retardancy of polymers. Fire Polym. VI New Adv. Flame Retard. Chem. Sci. 2012, 1118, 361–390. [Google Scholar]

- Shi, X.-H.; Li, X.-L.; Li, Y.-M.; Li, Z.; Wang, D.-Y. Flame-retardant strategy and mechanism of fiber reinforced polymeric composite: A review. Compos. Part B Eng. 2022, 233, 109663. [Google Scholar] [CrossRef]

- Tan, Y.; Shao, Z.-B.; Yu, L.-X.; Long, J.-W.; Qi, M.; Chen, L.; Wang, Y.-Z. Piperazine-modified ammonium polyphosphate as monocomponent flame-retardant hardener for epoxy resin: Flame retardance, curing behavior and mechanical property. Polym. Chem. 2016, 7, 3003–3012. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, B.; Shi, Y.; Song, L.; Hu, Y. Microencapsulated ammonium polyphosphate with glycidyl methacrylate shell: Application to flame retardant epoxy resin. Ind. Eng. Chem. Res. 2013, 52, 5640–5647. [Google Scholar] [CrossRef]

- Unlu, S.M.; Dogan, S.D.; Dogan, M. Comparative study of boron compounds and aluminum trihydroxide as flame retardant additives in epoxy resin. Polym. Adv. Technol. 2014, 25, 769–776. [Google Scholar] [CrossRef]

- Rajaei, M.; Wang, D.-Y.; Bhattacharyya, D. Combined effects of ammonium polyphosphate and talc on the fire and mechanical properties of epoxy/glass fabric composites. Compos. Part B Eng. 2017, 113, 381–390. [Google Scholar] [CrossRef]

- Du, B.; Ma, H.; Fang, Z. How nano-fillers affect thermal stability and flame retardancy of intumescent flame retarded polypropylene. Polym. Adv. Technol. 2011, 22, 1139–1146. [Google Scholar] [CrossRef]

- Sonnier, R. Microscale forced combustion: Pyrolysis-combustion flow calorimetry (PCFC). In Analysis of Flame Retardancy in Polymer Science; Elsevier: Amsterdam, The Netherlands, 2022; pp. 91–116. [Google Scholar]

- Babrauskas, V. Forced combustion: Cone calorimetry. In Analysis of Flame Retardancy in Polymer Science; Elsevier: Amsterdam, The Netherlands, 2022; pp. 73–90. [Google Scholar]

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; FRI (tp) symbols are

TPES/AlPi-30 [21]; FRI (tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are

TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21].

TPES/AlPi-30 [21].

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; FRI (tp) symbols are

TPES/AlPi-30 [21]; FRI (tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are

TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21].

TPES/AlPi-30 [21].

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; FRI (tp) symbols are

TPES/AlPi-30 [21]; FRI (tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are

TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21].

TPES/AlPi-30 [21].

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; FRI (tp) symbols are

TPES/AlPi-30 [21]; FRI (tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are

TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21].

TPES/AlPi-30 [21].

EP/PAz-APP-15 [28],

EP/PAz-APP-15 [28],  EP/APP-15 [29],

EP/APP-15 [29],  EP/GMA-APP-15 [29],

EP/GMA-APP-15 [29],  EP/BO-40 [30],

EP/BO-40 [30],  EP/Mel-APP/Talc-29.7 [31],

EP/Mel-APP/Talc-29.7 [31],  PP/IFR/OTAB-MMT-28 [32],

PP/IFR/OTAB-MMT-28 [32],  PP/IFR/A-POSS-28 [32].

PP/IFR/A-POSS-28 [32].

EP/PAz-APP-15 [28],

EP/PAz-APP-15 [28],  EP/APP-15 [29],

EP/APP-15 [29],  EP/GMA-APP-15 [29],

EP/GMA-APP-15 [29],  EP/BO-40 [30],

EP/BO-40 [30],  EP/Mel-APP/Talc-29.7 [31],

EP/Mel-APP/Talc-29.7 [31],  PP/IFR/OTAB-MMT-28 [32],

PP/IFR/OTAB-MMT-28 [32],  PP/IFR/A-POSS-28 [32].

PP/IFR/A-POSS-28 [32].

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; FRI (tp) symbols are

TPES/AlPi-30 [21]; FRI (tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are

TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21].

TPES/AlPi-30 [21].

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; FRI (tp) symbols are

TPES/AlPi-30 [21]; FRI (tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are

TPES/AlPi-30 [21]; and FRI(ti&tp) symbols are  EP/DP-27.3 [14], Si-EP/DP-27.3 [14],

EP/DP-27.3 [14], Si-EP/DP-27.3 [14],  EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],

EP/DP-27.3/Mel-9.1 [14], Si-EP/DP-27.3/Mel-9.1 [14],  EP/BPA-BPP-9 [15],

EP/BPA-BPP-9 [15],  EP/GN-2 [16],

EP/GN-2 [16],  EP/Ni–Fe LDH-2 [16],

EP/Ni–Fe LDH-2 [16],  EP/NiFe-LDH&GN-2 [16],

EP/NiFe-LDH&GN-2 [16],  ABS/LIG-30 [17],

ABS/LIG-30 [17],  ABS/P-LIG-30 [17],

ABS/P-LIG-30 [17],  EVA/APP-10 [18],

EVA/APP-10 [18],  EVA/ATH-25 [19],

EVA/ATH-25 [19],  EVA/Boehm-25 [19],

EVA/Boehm-25 [19],  Cop-PA66&PA6/SiDOPO-10 [20],

Cop-PA66&PA6/SiDOPO-10 [20],  PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],

PA66/GF-35 [21], PA12/GF-30 [21], PEEK/GF-30 [23],  PA66/GF&RP-35 [21],

PA66/GF&RP-35 [21],  PBS/Cellulose-30 [22],

PBS/Cellulose-30 [22],  PBS/Bamboo-30 [22],

PBS/Bamboo-30 [22],  PEEK/CF-30 [23],

PEEK/CF-30 [23],  PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],

PP/BrFR&Sb2O3-20 [24], PP/BrFR&Sb2O3-25 [24], PS/BrFR&Sb2O3-12 [24],  PS/BrFR&Sb2O3-10/C15A-2 [24],

PS/BrFR&Sb2O3-10/C15A-2 [24],  PS/BrFR&Sb2O3-10/MWCNT-2 [24],

PS/BrFR&Sb2O3-10/MWCNT-2 [24],  PS/APP&TPER-20 [25],

PS/APP&TPER-20 [25],  PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],

PS/APP&TPER-19/C15A-1 [25], PS/APP&TPER-18//C15A-2 [25],  PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],

PS/APP&TPER-19/MWCNT-1 [25], PS/APP&TPER-18/MWCNT-2 [25],  PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],

PS/APP&TPER-19/Fe2O3-1 [25], PS/APP&TPER-18/Fe2O3-2 [25],  TPES/AlPi-30 [21].

TPES/AlPi-30 [21].

| Polymer and Incorporated FR | FR (wt.%) | Heat Flux (kW·m−2) | ti (s) | tp (s) | pHRR (kW·m−²) | THR (MJ·m−²) | FRI (ti) | FRI (tp) | FRI (ti&tp) | Tp (°C) | pHRR (W·g−1) | THR (kJ·g−1) | FI | Refs. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Epoxy (EP) | 0 | 35 | 38 | 77 | 2550 | 96 | — | — | — | 385 | 545 | 30 | — | [14] |

| EP/6H-dibenz[c,e][1,2]oxaphosphorin,6-[(1-oxido-2,6,7-trioxa-1-phosphabicyclo[2.2.2]oct-4-yl)methoxy]-, 6-oxide (DP) | 20.3 | 35 | 31 | 80 | 744 | 61 | 4.40 | 5.60 | 4.57 | 331 | 371 | 24 | 1.57 | [14] |

| EP/DP/Melamine (Mel) | 27.05 | 35 | 50 | 94 | 730 | 62 | 7.11 | 6.60 | 8.68 | 336 | 297 | 26 | 1.84 | [14] |

| Silanized epoxy with 2 wt.% silica (Si-EP) | 0 | 35 | 40 | 77 | 1964 | 79 | — | — | — | 388 | 448 | 28 | — | [14] |

| Si-EP/DP | 20.3 | 35 | 28 | 122 | 516 | 68 | 3.09 | 7.00 | 4.90 | 347 | 372 | 24 | 1.25 | [14] |

| Si-EP/DP/Mel | 27.05 | 35 | 42 | 102 | 909 | 57 | 3.14 | 3.96 | 4.16 | 340 | 270 | 26 | 1.56 | [14] |

| EP | 0 | 35 | 82 | 135 | 1148 | 88.4 | — | — | — | 395.9 | 709.6 | 32.8 | — | [15] |

| EP/Bisphenol A bridged penta(anilino) cyclotriphosphazene (BPA-BPP) | 9 | 35 | 72 | 150 | 457 | 78.4 | 2.48 | 3.14 | 2.76 | 352.8 | 433.8 | 26 | 1.83 | [15] |

| EP | 0 | 35 | 68 | 130 | 1730 | 113.1 | — | — | — | 401 | 449 | 24.4 | — | [16] |

| EP/Graphene (GN) | 2 | 35 | 86 | 155.5 | 980 | 65.1 | 3.87 | 3.66 | 4.64 | 398 | 285 | 20.3 | 1.87 | [16] |

| EP/Ni–Fe layered double hydroxide (Ni–Fe LDH) | 2 | 35 | 80 | 120.2 | 1070 | 58.9 | 3.65 | 2.87 | 3.37 | 427 | 240 | 17.9 | 2.71 | [16] |

| EP/NiFe-LDH&GN | 2 | 35 | 89 | 141.2 | 678 | 44.2 | 8.54 | 7.09 | 9.28 | 440 | 189 | 16.4 | 3.87 | [16] |

| Acrylonitrile-butadiene-styrene (ABS) | 0 | 35 | 80 | 157 | 482 | 72 | — | — | — | 340 | 602.6 | 37.7 | — | [17] |

| ABS/Kraft lignin (LIG) | 30 | 35 | 49 | 153 | 275 | 63 | 1.22 | 1.95 | 1.19 | 320 | 411.7 | 29.2 | 1.77 | [17] |

| ABS/Phosphorylation of lignin (P-LIG) | 30 | 35 | 49 | 167 | 202 | 58 | 1.81 | 3.15 | 1.93 | 340 | 411 | 27.2 | 2.03 | [17] |

| Ethylene vinyl acetate copolymer (EVA) | 0 | 35 | 65 | 175 | 1588 | 108 | — | — | — | 473 | 919 | 37.8 | — | [18] |

| EVA/Ammoniumpolyphosphate (APP) | 10 | 35 | 28 | 144 | 1030 | 93 | 0.77 | 1.47 | 0.63 | 466 | 758 | 31.6 | 1.42 | [18] |

| EVA | 0 | 50 | 39 | 180 | 1366 | 135 | — | — | — | 490 | 800 | 34.8 | — | [19] |

| EVA/Aluminum trihydroxyde (ATH) | 25 | 50 | 37 | 145 | 710 | 121 | 2.03 | 1.72 | 1.64 | 490 | 572 | 27 | 1.80 | [19] |

| EVA/Precipitated boehmite (Boehm) | 25 | 50 | 54 | 180 | 612 | 122 | 3.41 | 2.46 | 3.42 | 489 | 538 | 25.5 | 2.02 | [19] |

| Polyamide 66/Polyamide 6 (90:10 wt.%) copolymer (Cop-PA66&PA6) | 0 | 50 | 77 | 250 | 886 | 140.1 | — | — | — | 458 | 618 | 26.9 | — | [20] |

| Cop-PA66&PA6/Organophosphorous alkoxysilane (SiDOPO) | 10 | 50 | 62 | 186 | 597 | 104.8 | 1.59 | 1.47 | 1.18 | 443 | 468 | 25.2 | 1.36 | [20] |

| PA66 | 0 | 50 | 51 | 149 | 1509 | 100 | — | — | — | 465 | 633 | 30 | — | [21] |

| PA66/Glass fiber (GF) | 35 | 50 | 43 | 92 | 582 | 80 | 2.73 | 2.00 | 1.68 | 455 | 354 | 18 | 2.91 | [21] |

| PA66/GF/Red phosphorus (RP) | 35 | 50 | 43 | 57 | 299 | 66 | 6.44 | 2.92 | 2.46 | 390 | 201 | 18 | 4.40 | [21] |

| Polyamide 12 (PA12) | 0 | 50 | 63 | 185 | 2205 | 164 | — | — | — | 475 | 937 | 35 | — | [21] |

| PA12/GF | 30 | 50 | 36 | 155 | 1992 | 153 | 0.67 | 0.99 | 0.56 | 477 | 762 | 31 | 1.39 | [21] |

| Polybutylene succinate (PBS) | 0 | 35 | 150 | 284 | 485 | 873 | — | — | — | 410 | 394 | 18.4 | — | [22] |

| PBS/Cellulose | 30 | 35 | 96 | 298 | 385 | 984 | 0.71 | 1.17 | 0.75 | 420 | 275 | 14.9 | 1.81 | [22] |

| PBS/Bamboo | 30 | 35 | 43 | 107 | 339 | 884 | 0.40 | 0.53 | 0.15 | 413 | 293 | 15.1 | 1.65 | [22] |

| Poly(oxy-1,4-phenyleneoxy-1,4-phenylenecarbonyl-1,4-phenylene) (PEEK) | 0 | 50 | 110 | 182 | 415.2 | 36.2 | — | — | — | 619 | 303 | 10.7 | — | [23] |

| PEEK/Carbon fibre (CF) | 30 | 50 | 156 | 279 | 146.7 | 26.9 | 5.40 | 5.83 | 8.28 | 621 | 195 | 7 | 2.38 | [23] |

| PEEK/GF | 30 | 50 | 115 | 278 | 120.5 | 23.3 | 5.59 | 8.17 | 8.54 | 623 | 233 | 7.2 | 1.94 | [23] |

| Polypropylene (PP) | 0 | 35 | 47 | 168 | 1573 | 140 | — | — | — | 486 | 1228 | 41 | — | [24] |

| PP/Decabromodiphenyl oxide&Sb2O3 with 5:1 (BrFR&Sb2O3) | 20 | 35 | 57 | 135 | 1445 | 84 | 2.20 | 1.45 | 1.76 | 470 | 374 | 33 | 3.94 | [24] |

| PP/BrFR&Sb2O3 | 25 | 35 | 52 | 131 | 1177 | 61 | 3.39 | 2.39 | 2.64 | 459 | 318 | 30 | 4.98 | [24] |

| Polystyrene (PS) | 0 | 35 | 44 | 180 | 1166 | 101 | — | — | — | 441 | 1046 | 38 | — | [24] |

| PS/BrFR&Sb2O3 | 12 | 35 | 55 | 128 | 591 | 46 | 5.41 | 3.08 | 3.85 | 410 | 598 | 33 | 1.87 | [24] |

| PS/BrFR&Sb2O3/Cloisite15A (C15A) | 12 | 35 | 35 | 115 | 442 | 43 | 4.92 | 3.95 | 3.14 | 432 | 408 | 33 | 2.89 | [24] |

| PS/BrFR&Sb2O3/Multiwall carbon nanotubes (MWCNT) | 12 | 35 | 34 | 141 | 340 | 43 | 6.22 | 6.30 | 4.87 | 429 | 341 | 31 | 3.65 | [24] |

| Polystyrene (PS) | 0 | 35 | 44 | 180 | 1166 | 101 | — | — | — | 441 | 1046 | 38 | — | [25] |

| PS/Ammonium polyphosphate (APP)/Tripentaerythritol (TPER) | 20 | 35 | 34 | 67 | 601 | 73 | 2.07 | 0.99 | 0.77 | 452 | 554 | 30 | 2.45 | [25] |

| PS/APP/TPER/C15A | 20 | 35 | 34 | 201 | 333 | 72 | 3.79 | 5.48 | 4.23 | 455 | 528 | 31 | 2.50 | [25] |

| PS/APP/TPER/C15A | 20 | 35 | 34 | 225 | 320 | 77 | 3.69 | 5.97 | 4.61 | 441 | 526 | 31 | 2.43 | [25] |

| PS/APP/TPER/MWCNT | 20 | 35 | 26 | 50 | 519 | 71 | 1.88 | 0.88 | 0.52 | 451 | 581 | 30 | 2.33 | [25] |

| PS/APP/TPER/MWCNT | 20 | 35 | 32 | 41 | 457 | 69 | 2.71 | 0.85 | 0.61 | 448 | 605 | 30 | 2.22 | [25] |

| PS/APP/TPER/Nanoparticle Fe2O3 (Fe2O3) | 20 | 35 | 28 | 78 | 456 | 74 | 2.22 | 1.51 | 0.96 | 451 | 581 | 31 | 2.25 | [25] |

| PS/APP/TPER/Fe2O3 | 20 | 35 | 32 | 37 | 467 | 75 | 2.44 | 0.69 | 0.50 | 449 | 536 | 31 | 2.43 | [25] |

| Styrene Ethylene Butylene Styrene&PP (TPES) | 0 | 50 | 23 | 196 | 2346 | 215 | — | — | — | 447 | 565 | 43 | — | [21] |

| TPES/AlPi | 30 | 50 | 23 | 245 | 1048 | 160 | 3.00 | 3.76 | 3.76 | 440 | 462 | 37 | 1.39 | [21] |

| Polymer and Incorporated FR | FR (wt.%) | Heat Flux (kW·m−2) | ti (s) | tp (s) | pHRR (kW·m−²) | THR (MJ·m−²) | FRI (ti) | FRI (tp) | FRI (ti&tp) | Tp (°C) | pHRR (W·g−1) | THR (kJ·g−1) | FI | Refs. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Epoxy (EP) | 0 | 35 | 52 | 90 | 1334.3 | 58.8 | ― | ― | ― | ― | ― | ― | ― | [28] | |

| EP/Piperazine-modified ammonium polyphosphate (PAz-APP) | 15 | 35 | 33 | 55 | 246.1 | 11.3 | 17.90 | 17.24 | 10.94 | ― | ― | ― | ― | [28] |

| EP | 0 | 35 | 57 | 130 | 1730.27 | 114.16 | ― | ― | ― | ― | ― | ― | ― | [29] | |

| EP/Ammonium polyphosphate (APP) | 15 | 35 | 63 | 95 | 397.89 | 35.49 | 15.46 | 10.22 | 11.29 | ― | ― | ― | ― | [29] |

| EP/Glycidyl methacrylate microencapsulated ammonium polyphosphate (GMA-APP) | 15 | 35 | 68 | 160 | 283.09 | 44 | 18.91 | 19.51 | 23.28 | ― | ― | ― | ― | [29] |

| Epoxy (EP) | 0 | 35 | 57 | 120 | 459 | 55.2 | ― | ― | ― | ― | ― | ― | ― | [30] | |

| EP/Boric oxide (BO) | 40 | 35 | 68 | 243 | 82 | 20.6 | 17.89 | 30.37 | 36.23 | ― | ― | ― | ― | [30] |

| EP | 0 | 50 | 23 | 67 | 1910 | 61 | ― | ― | ― | ― | ― | ― | ― | [31] | |

| EP/Melamine coated ammonium polyphosphate/Talc (Mel-APP/Talc) | 29.7 | 50 | 28 | 60 | 357 | 24 | 16.55 | 12.17 | 14/82 | ― | ― | ― | ― | [31] |

| Polypropylene (PP) | 0 | 35 | 37 | 189 | 363 | 56 | ― | ― | ― | ― | ― | ― | ― | [32] | |

| PP/Nitrogen –phosphorus contained intumescent flame retardant/Octadecyl trimethyl ammonium bromide modified montmorillonite (IFR/OTAB-MMT) | 28 | 35 | 31 | 360 | 45 | 18 | 21.02 | 47.80 | 40.05 | ― | ― | ― | ― | [32] |

| PP | 0 | 35 | 37 | 189 | 363 | 56 | ― | ― | ― | ― | ― | ― | ― | [32] | |

| PP/Nitrogen–phosphorus contained intumescent flame retardant/Aminopropylisobutyl polyhedral oligosilsesquioxane (IFR/A-POSS) | 28 | 35 | 32 | 375 | 55 | 16 | 19.97 | 45.83 | 39.63 | ― | ― | ― | ― | [32] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vahabi, H.; Movahedifar, E.; Kandola, B.K.; Saeb, M.R. Flame Retardancy Index (FRI) for Polymer Materials Ranking. Polymers 2023, 15, 2422. https://doi.org/10.3390/polym15112422

Vahabi H, Movahedifar E, Kandola BK, Saeb MR. Flame Retardancy Index (FRI) for Polymer Materials Ranking. Polymers. 2023; 15(11):2422. https://doi.org/10.3390/polym15112422

Chicago/Turabian StyleVahabi, Henri, Elnaz Movahedifar, Baljinder K. Kandola, and Mohammad Reza Saeb. 2023. "Flame Retardancy Index (FRI) for Polymer Materials Ranking" Polymers 15, no. 11: 2422. https://doi.org/10.3390/polym15112422

APA StyleVahabi, H., Movahedifar, E., Kandola, B. K., & Saeb, M. R. (2023). Flame Retardancy Index (FRI) for Polymer Materials Ranking. Polymers, 15(11), 2422. https://doi.org/10.3390/polym15112422