Native Potato Starch and Tara Gum as Polymeric Matrices to Obtain Iron-Loaded Microcapsules from Ovine and Bovine Erythrocytes

Abstract

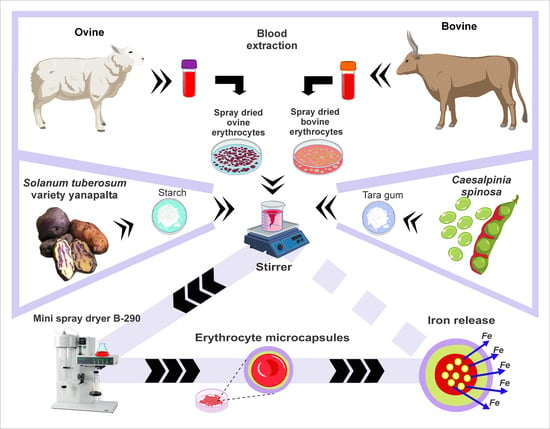

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Native Potato Starch

2.3. Tara Gum

2.4. Spray-Dried Erythrocytes

2.5. Erythrocyte Microparticles

2.6. Iron Content

2.7. Yield, Moisture, Water Activity, and Bulk Density

2.8. Color Analysis

2.9. Amylose and Amylopectin Content

2.10. Total Organic Carbon

2.11. SEM-EDS Analysis

2.12. Particle Size and ζ Potential Analysis

2.13. FTIR Analysis

2.14. Thermal Analysis

2.15. Iron Release

2.16. Statistical Analysis

3. Results and Discussions

3.1. Instrumental Characterization of Matrices and Cores

3.1.1. SEM-EDS Analysis, Particle Size, ζ Potential, Color, and Iron Content

3.1.2. Thermal Analysis

3.2. Characterization of the Microcapsules

3.2.1. Physical and Chemical Properties

3.2.2. SEM-EDS Analysis

3.2.3. FTIR Analysis

3.2.4. Thermal Analysis

3.3. Iron Release

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Halahlah, A.; Piironen, V.; Mikkonen, K.S.; Ho, T.M. Polysaccharides as wall materials in spray-dried microencapsulation of bioactive compounds: Physicochemical properties and characterization. Crit. Rev. Food Sci. Nutr. 2023, 63, 6983–7015. [Google Scholar] [CrossRef] [PubMed]

- Řepka, D.; Kurillová, A.; Murtaja, Y.; Lapčík, L. Application of Physical-Chemical Approaches for Encapsulation of Active Substances in Pharmaceutical and Food Industries. Foods 2023, 12, 2189. [Google Scholar] [CrossRef] [PubMed]

- Saldanha Coimbra, P.P.; de Souza Neves Cardoso, F.; Branco de Andrade Goncalves, E.C. Spray-drying wall materials: Relationship with bioactive compounds. Crit. Rev. Food Sci. Nutr. 2021, 61, 2809–2826. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Li, Z.; Xia, J.; Kang, Y.; Sun, P.; Xiao, Z.; Niu, Y. Research progress of starch as microencapsulated wall material. Carbohydr. Polym. 2023, 318, 121118. [Google Scholar] [CrossRef] [PubMed]

- Akbarbaglu, Z.; Peighambardoust, S.H.; Sarabandi, K.; Jafari, S.M. Spray drying encapsulation of bioactive compounds within protein-based carriers; different options and applications. Food Chem. 2021, 359, 129965. [Google Scholar] [CrossRef]

- Xu, Y.; Dong, M.; Xiao, H.; Young Quek, S.; Ogawa, Y.; Ma, G.; Zhang, C. Advances in spray-dried probiotic microcapsules for targeted delivery: A review. Crit. Rev. Food Sci. Nutr. 2023, 1–17. [Google Scholar] [CrossRef]

- Samborska, K.; Boostani, S.; Geranpour, M.; Hosseini, H.; Dima, C.; Khoshnoudi-Nia, S.; Rostamabadi, H.; Falsafi, S.R.; Shaddel, R.; Akbari-Alavijeh, S.; et al. Green biopolymers from by-products as wall materials for spray drying microencapsulation of phytochemicals. Trends Food Sci. Technol. 2021, 108, 297–325. [Google Scholar] [CrossRef]

- Otálora, M.C.; Wilches-Torres, A.; Gómez Castaño, J.A. Microencapsulation of Betaxanthin Pigments from Pitahaya (Hylocereus megalanthus) By-Products: Characterization, Food Application, Stability, and In Vitro Gastrointestinal Digestion. Foods 2023, 12, 2700. [Google Scholar] [CrossRef]

- Durán, E.; Villalobos, C.; Churio, O.; Pizarro, F.; Valenzuela, C. Encapsulación de hierro: Otra estrategia para la prevención o tratamiento de la anemia por deficiencia de hierro. Rev. Chil. De Nutr. 2017, 44, 234–243. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Moscoso-Moscoso, E.; Choque-Quispe, D.; Palomino-Rincón, H.; Martínez-Huamán, E.L.; Huamán-Carrión, M.L.; Peralta-Guevara, D.E.; Aroni-Huamán, J.; Arévalo-Quijano, J.C.; Palomino-Rincón, W.; et al. Microencapsulation of Erythrocytes Extracted from Cavia porcellus Blood in Matrices of Tara Gum and Native Potato Starch. Foods 2022, 11, 2107. [Google Scholar] [CrossRef]

- Rodríguez Cruzado, C.P.; Salcedo Robles, C.; Morán González, C.V.; Lara Sosa, I.; Sánchez Banda, L.R.; Rodríguez Mázmela, C.L.; Obregón Domínguez, J.A. Formulación de una mezcla de hierro hemínico, cacao y camu-camu en polvo instantáneo a base de quinua roja. Rev. De Innovación Y Transf. Product. 2021, 2, e004. [Google Scholar] [CrossRef]

- Gholam Jamshidi, E.; Behzad, F.; Adabi, M.; Esnaashari, S.S. Edible Iron-Pectin Nanoparticles: Preparation, Physicochemical Characterization and Release Study. Food Bioprocess Technol. 2023. [Google Scholar] [CrossRef]

- Piskin, E.; Cianciosi, D.; Gulec, S.; Tomas, M.; Capanoglu, E. Iron Absorption: Factors, Limitations, and Improvement Methods. ACS Omega 2022, 7, 20441–20456. [Google Scholar] [CrossRef] [PubMed]

- Kandasamy, S.; Naveen, R. A review on the encapsulation of bioactive components using spray-drying and freeze-drying techniques. J. Food Process Eng. 2022, 45, e14059. [Google Scholar] [CrossRef]

- Wilson, R.J.; Hui, Y.; Whittaker, A.K.; Zhao, C.-X. Facile bioinspired synthesis of iron oxide encapsulating silica nanocapsules. J. Colloid Interface Sci. 2021, 601, 78–84. [Google Scholar] [CrossRef]

- Naktinienė, M.; Eisinaitė, V.; Keršienė, M.; Jasutienė, I.; Leskauskaitė, D.J.L. Emulsification and gelation as a tool for iron encapsulation in food-grade systems. LWT 2021, 149, 111895. [Google Scholar] [CrossRef]

- Bamidele, O.P.; Emmambux, M.N. Encapsulation of bioactive compounds by “extrusion” technologies: A review. Crit. Rev. Food Sci. Nutr. 2021, 61, 3100–3118. [Google Scholar] [CrossRef]

- Wang, L.; Clardy, A.; Hui, D.; Wu, Y. Physiochemical properties of encapsulated bitter melon juice using spray drying. Bioact. Carbohydr. Diet. Fibre 2021, 26, 100278. [Google Scholar] [CrossRef]

- Barick, K.; Tripathi, A.; Dutta, B.; Shelar, S.B.; Hassan, P. Curcumin encapsulated casein nanoparticles: Enhanced bioavailability and anticancer efficacy. J. Pharm. Sci. 2021, 110, 2114–2120. [Google Scholar] [CrossRef]

- Álvarez, C.; Pando, D. Encapsulation Technologies Applied to Food Processing. In Food Formulation; Wiley Online Library: Hoboken, NJ, USA, 2021; pp. 121–145. [Google Scholar]

- Parra Huertas, R.A. Food microencapsulation: A review. Rev. Fac. Nac. De Agron. Medellín 2010, 63, 5669–5684. [Google Scholar]

- Lishchynskyi, O.; Stetsyshyn, Y.; Raczkowska, J.; Awsiuk, K.; Orzechowska, B.; Abalymov, A.; Skirtach, A.G.; Bernasik, A.; Nastyshyn, S.; Budkowski, A. Fabrication and Impact of Fouling-Reducing Temperature-Responsive POEGMA Coatings with Embedded CaCO3 Nanoparticles on Different Cell Lines. Materials 2021, 14, 1417. [Google Scholar] [CrossRef] [PubMed]

- Ali, F.; Kalva, S.N.; Koç, M. Additive Manufacturing of Polymer/Mg-Based Composites for Porous Tissue Scaffolds. Polymers 2022, 14, 5460. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, M.B.; Windhab, E.J. Encapsulation of Iron and Other Micronutrients for Food Fortification. In Encapsulation Technologies for Active Food Ingredients and Food Processing; Zuidam, N.J., Nedovic, V., Eds.; Springer New York: New York, NY, USA, 2010; pp. 187–209. [Google Scholar]

- Li, Y.O.; González, V.P.D.; Diosady, L.L. Chapter 31—Microencapsulation of vitamins, minerals, and nutraceuticals for food applications. In Microencapsulation in the Food Industry (Second Edition); Sobel, R., Ed.; Academic Press: Cambridge, MA, USA, 2023; pp. 507–528. [Google Scholar]

- Choque, Q.D.; Ramos, P.B.S.; Ligarda, S.C.A.; Barboza, P.G.I.; Kari, F.A.; Taipe, P.F.; Choque, Q.Y. Heavy metal removal by biopolymers-based formulations with native potato starch/nopal mucilage. Rev. Fac. De Ing. Univ. De Antioq. 2022, 103, 44–50. [Google Scholar] [CrossRef]

- Choque-Quispe, D.; Froehner, S.; Ligarda-Samanez, C.A.; Ramos-Pacheco, B.S.; Palomino-Rincón, H.; Choque-Quispe, Y.; Solano-Reynoso, A.M.; Taipe-Pardo, F.; Zamalloa-Puma, L.M.; Calla-Florez, M.; et al. Preparation and Chemical and Physical Characteristics of an Edible Film Based on Native Potato Starch and Nopal Mucilage. Polymers 2021, 13, 3719. [Google Scholar] [CrossRef] [PubMed]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Huamán-Carrión, M.L.; Ramos-Pacheco, B.S.; Peralta-Guevara, D.E.; Cruz, G.D.; Martínez-Huamán, E.L.; Arévalo-Quijano, J.C.; Muñoz-Saenz, J.C.; et al. Obtaining and Characterizing Andean Multi-Floral Propolis Nanoencapsulates in Polymeric Matrices. Foods 2022, 11, 3153. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Allende-Allende, L.F.; Ramos Pacheco, B.S.; Peralta-Guevara, D.E. Calidad sensorial y proximal en conservas de mondongo de res (Bos taurus) en salsa de ají amarillo (Capsicum baccatum). Cienc. Y Tecnol. Agropecu. 2023, 24, 13. [Google Scholar] [CrossRef]

- Choque-Quispe, D.; Ligarda-Samanez, C.A.; Huamán-Rosales, E.R.; Aguirre Landa, J.P.; Agreda Cerna, H.W.; Zamalloa-Puma, M.M.; Álvarez-López, G.J.; Barboza-Palomino, G.I.; Alzamora-Flores, H.; Gamarra-Villanueva, W. Bioactive Compounds and Sensory Analysis of Freeze-Dried Prickly Pear Fruits from an Inter-Andean Valley in Peru. Molecules 2023, 28, 3862. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Palomino-Rincón, H.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Arévalo-Quijano, J.C.; Huamán-Carrión, M.L.; Quispe-Quezada, U.R.; Muñoz-Saenz, J.C.; Gutiérrez-Gómez, E.; Cabel-Moscoso, D.J.; et al. Bioactive Compounds and Sensory Quality in Chips of Native Potato Clones (Solanum tuberosum spp. andigena) Grown in the High Andean Region of PERU. Foods 2023, 12, 2511. [Google Scholar] [CrossRef]

- Galicia, L.; Miranda, A.; Gutiérrez, M.G.; Custodio, O.; Rosales, A.; Ruíz, N.; Surles, R.; Palacios, N. Laboratorio de Calidad Nutricional de Maíz y Análisis de Tejido Vegetal: Protocolos de Laboratorio; CIMMYT: Mexico City, Mexico, 2012. [Google Scholar]

- Jimenez, M.D.; Lobo, M.; Sammán, N. 12th IFDC 2017 Special Issue—Influence of germination of quinoa (Chenopodium quinoa) and amaranth (Amaranthus) grains on nutritional and techno-functional properties of their flours. J. Food Compos. Anal. 2019, 84, 103290. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Palomino-Rincón, H.; Ramos-Pacheco, B.S.; Moscoso-Moscoso, E.; Huamán-Carrión, M.L.; Peralta-Guevara, D.E.; Obregón-Yupanqui, M.E.; Aroni-Huamán, J.; Bravo-Franco, E.Y.; et al. Modified Polymeric Biosorbents from Rumex acetosella for the Removal of Heavy Metals in Wastewater. Polymers 2022, 14, 2191. [Google Scholar] [CrossRef]

- Choque-Quispe, D.; Mojo-Quisani, A.; Ligarda-Samanez, C.A.; Calla-Florez, M.; Ramos-Pacheco, B.S.; Zamalloa-Puma, L.M.; Peralta-Guevara, D.E.; Solano-Reynoso, A.M.; Choque-Quispe, Y.; Zamalloa-Puma, A. Preliminary Characterization of a Spray-Dried Hydrocolloid from a High Andean Algae (Nostoc sphaericum). Foods 2022, 11, 1640. [Google Scholar] [CrossRef] [PubMed]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Huamán-Carrión, M.L.; Ramos-Pacheco, B.S.; De la Cruz, G.; Arévalo-Quijano, J.C.; Muñoz-Saenz, J.C.; Muñoz-Melgarejo, M.; Quispe-Quezada, U.R.; et al. Microencapsulation of Propolis and Honey Using Mixtures of Maltodextrin/Tara Gum and Modified Native Potato Starch/Tara Gum. Foods 2023, 12, 1873. [Google Scholar] [CrossRef] [PubMed]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Palomino-Rincón, H.; Taipe-Pardo, F.; Aguirre Landa, J.P.; Arévalo-Quijano, J.C.; Muñoz-Saenz, J.C.; Quispe-Quezada, U.R.; Huamán-Carrión, M.L.; et al. Nanoencapsulation of Phenolic Extracts from Native Potato Clones (Solanum tuberosum spp. andigena) by Spray Drying. Molecules 2023, 28, 4961. [Google Scholar] [CrossRef]

- Martínez, P.; Vilcarromero, D.; Pozo, D.; Peña, F.; Manuel Cervantes-Uc, J.; Uribe-Calderon, J.; Velezmoro, C. Characterization of starches obtained from several native potato varieties grown in Cusco (Peru). J. Food Sci. 2021, 86, 907–914. [Google Scholar] [CrossRef] [PubMed]

- Kaur, L.; Singh, N.; Sodhi, N.S. Some properties of potatoes and their starches II. Morphological, thermal and rheological properties of starches. Food Chem. 2002, 79, 183–192. [Google Scholar] [CrossRef]

- Diaz Barrera, Y. Determinación de las Propiedades Físicas, Químicas, Tecnofuncionales y la Estabilidad en Congelación/Descongelación del Almidón de Cuatro Variedades de Solanum tuberosum ssp. andigenum (Papa Nativa). 2015. Available online: https://repositorio.unajma.edu.pe/handle/20.500.14168/213 (accessed on 26 September 2023).

- Kurdziel, M.; Łabanowska, M.; Pietrzyk, S.; Pająk, P.; Królikowska, K.; Szwengiel, A. The effect of UV-B irradiation on structural and functional properties of corn and potato starches and their components. Carbohydr. Polym. 2022, 289, 119439. [Google Scholar] [CrossRef]

- Churio, O.; Valenzuela, C. Development and characterization of maltodextrin microparticles to encapsulate heme and non-heme iron. LWT 2018, 96, 568–575. [Google Scholar] [CrossRef]

- Pashazadeh, H.; Zannou, O.; Ghellam, M.; Koca, I.; Galanakis, C.M.; Aldawoud, T.M.S. Optimization and Encapsulation of Phenolic Compounds Extracted from Maize Waste by Freeze-Drying, Spray-Drying, and Microwave-Drying Using Maltodextrin. Foods 2021, 10, 1396. [Google Scholar] [CrossRef]

- Abe, E.; Fuwa, T.J.; Hoshi, K.; Saito, T.; Murakami, T.; Miyajima, M.; Ogawa, N.; Akatsu, H.; Hashizume, Y.; Hashimoto, Y. Expression of Transferrin Protein and Messenger RNA in Neural Cells from Mouse and Human Brain Tissue. Metabolites 2022, 12, 594. [Google Scholar] [CrossRef]

- Furuta, T.; Neoh, T.L. Microencapsulation of food bioactive components by spray drying: A review. Dry. Technol. 2021, 39, 1800–1831. [Google Scholar] [CrossRef]

- Rezvankhah, A.; Emam-Djomeh, Z.; Askari, G. Encapsulation and delivery of bioactive compounds using spray and freeze-drying techniques: A review. Dry. Technol. 2020, 38, 235–258. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, T.; Li, J.; Pan, B.; Hu, Q.; Duan, M.; Zhang, X. Study on the Effect of Spray Drying Process on the Quality of Microalgal Biomass: A Comprehensive Biocomposition Analysis of Spray-Dried S. acuminatus Biomass. BioEnergy Res. 2022, 15, 320–333. [Google Scholar] [CrossRef]

- Samborska, K.; Poozesh, S.; Barańska, A.; Sobulska, M.; Jedlińska, A.; Arpagaus, C.; Malekjani, N.; Jafari, S.M. Innovations in spray drying process for food and pharma industries. J. Food Eng. 2022, 321, 110960. [Google Scholar] [CrossRef]

- Kaul, S.; Kaur, K.; Mehta, N.; Dhaliwal, S.S.; Kennedy, J.F. Characterization and optimization of spray dried iron and zinc nanoencapsules based on potato starch and maltodextrin. Carbohydr. Polym. 2022, 282, 119107. [Google Scholar] [CrossRef] [PubMed]

- Premi, M.; Sharma, H. Effect of different combinations of maltodextrin, gum arabic and whey protein concentrate on the encapsulation behavior and oxidative stability of spray dried drumstick (Moringa oleifera) oil. Int. J. Biol. Macromol. 2017, 105, 1232–1240. [Google Scholar] [CrossRef] [PubMed]

- Ruengdech, A.; Siripatrawan, U. Improving encapsulating efficiency, stability, and antioxidant activity of catechin nanoemulsion using foam mat freeze-drying: The effect of wall material types and concentrations. LWT 2022, 162, 113478. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; da Silva, V.M.; Durigon, A.; Hubinger, M.D.; Laurindo, J.B. Production of mango powder by spray drying and cast-tape drying. Powder Technol. 2017, 305, 447–454. [Google Scholar] [CrossRef]

- Tuyen, C.K.; Nguyen, M.H.; Roach, P.D. Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J. Food Eng. 2010, 98, 385–392. [Google Scholar] [CrossRef]

- Ricci, A.; Mejia, J.A.A.; Versari, A.; Chiarello, E.; Bordoni, A.; Parpinello, G.P. Microencapsulation of polyphenolic compounds recovered from red wine lees: Process optimization and nutraceutical study. Food Bioprod. Process. 2022, 132, 1–12. [Google Scholar] [CrossRef]

- Chng, G.Y.V.; Chang, L.S.; Pui, L.P. Effects of maltodextrin concentration and inlet temperature on the physicochemical properties of spray-dried kuini powder. Asia Pac. J. Mol. Biol. Biotechnol. 2020, 28, 113–131. [Google Scholar] [CrossRef]

- Mahdi Jafari, S.; Masoudi, S.; Bahrami, A. A Taguchi approach production of spray-dried whey powder enriched with nanoencapsulated vitamin D3. Dry. Technol. 2019, 37, 2059–2071. [Google Scholar] [CrossRef]

- Piñón-Balderrama, C.I.; Leyva-Porras, C.; Terán-Figueroa, Y.; Espinosa-Solís, V.; Álvarez-Salas, C.; Saavedra-Leos, M.Z. Encapsulation of active ingredients in food industry by spray-drying and nano spray-drying technologies. Processes 2020, 8, 889. [Google Scholar] [CrossRef]

- Chopde, S.; Datir, R.; Deshmukh, G.; Dhotre, A.; Patil, M.; Research, F. Nanoparticle formation by nanospray drying & its application in nanoencapsulation of food bioactive ingredients. J. Agric. 2020, 2, 100085. [Google Scholar] [CrossRef]

- Baldelli, A.; Wells, S.; Pratap-Singh, A. Impact of product formulation on spray-dried microencapsulated zinc for food fortification. Food Bioprocess Technol. 2021, 14, 2286–2301. [Google Scholar] [CrossRef]

- Bordón, M.G.; Alasino, N.P.X.; Villanueva-Lazo, Á.; Carrera-Sánchez, C.; Pedroche-Jiménez, J.; del Carmen Millán-Linares, M.; Ribotta, P.D.; Martínez, M.L. Scale-up and optimization of the spray drying conditions for the development of functional microparticles based on chia oil. Food Bioprod. Process. 2021, 130, 48–67. [Google Scholar] [CrossRef]

- Caruana, R.; Montalbano, F.; Zizzo, M.G.; Puleio, R.; Caldara, G.; Cicero, L.; Cassata, G.; Licciardi, M. Enhanced anticancer effect of quercetin microparticles formulation obtained by spray drying. Int. J. Food Sci. Technol. 2022, 57, 2739–2746. [Google Scholar] [CrossRef]

- de Moura, S.C.S.R.; Schettini, G.N.; Gallina, D.A.; Dutra Alvim, I.; Hubinger, M.D. Microencapsulation of hibiscus bioactives and its application in yogurt. J. Food Process. Preserv. 2022, 46, e16468. [Google Scholar] [CrossRef]

- Arpagaus, C.; John, P.; Collenberg, A.; Rütti, D. Nanocapsules formation by nano spray drying. In Nanoencapsulation Technologies for the Food and Nutraceutical Industries; Elsevier: Amsterdam, The Netherlands, 2017; pp. 346–401. [Google Scholar]

- Moslemi, M.; Hosseini, H.; Erfan, M.; Mortazavian, A.M.; Fard, R.M.N.; Neyestani, T.R.; Komeyli, R. Characterisation of spray-dried microparticles containing iron coated by pectin/resistant starch. Int. J. Food Sci. Technol. 2014, 49, 1736–1742. [Google Scholar] [CrossRef]

- Nayak, A.K.; Pal, D. Formulation optimization and evaluation of jackfruit seed starch–alginate mucoadhesive beads of metformin HCl. Int. J. Biol. Macromol. 2013, 59, 264–272. [Google Scholar] [CrossRef]

- Roy, A.; Bajpai, J.; Bajpai, A.K. Dynamics of controlled release of chlorpyrifos from swelling and eroding biopolymeric microspheres of calcium alginate and starch. Carbohydr. Polym. 2009, 76, 222–231. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Oktiani, R.; Ragadhita, R. How to read and interpret FTIR spectroscope of organic material. Indones. J. Sci. Technol. 2019, 4, 97–118. [Google Scholar] [CrossRef]

- Santiago-Adame, R.; Medina-Torres, L.; Gallegos-Infante, J.; Calderas, F.; González-Laredo, R.; Rocha-Guzmán, N.; Ochoa-Martínez, L.; Bernad-Bernad, M. Spray drying-microencapsulation of cinnamon infusions (Cinnamomum zeylanicum) with maltodextrin. LWT-Food Sci. Technol. 2015, 64, 571–577. [Google Scholar] [CrossRef]

- Asghari-Varzaneh, E.; Shahedi, M.; Shekarchizadeh, H. Iron microencapsulation in gum tragacanth using solvent evaporation method. Int. J. Biol. Macromol. 2017, 103, 640–647. [Google Scholar] [CrossRef] [PubMed]

- Valenzuela, C.; Hernández, V.; Morales, M.S.; Neira-Carrillo, A.; Pizarro, F. Preparation and characterization of heme iron-alginate beads. LWT-Food Sci. Technol. 2014, 59, 1283–1289. [Google Scholar] [CrossRef]

- Ghayempour, S.; Montazer, M.; Rad, M.M. Tragacanth gum as a natural polymeric wall for producing antimicrobial nanocapsules loaded with plant extract. Int. J. Biol. Macromol. 2015, 81, 514–520. [Google Scholar] [CrossRef] [PubMed]

- Santos, M.B.; Isabel, I.C.A.; Garcia-Rojas, E.E. Ultrasonic depolymerization of aqueous tara gum solutions: Kinetic, thermodynamic and physicochemical properties. J. Sci. Food Agric. 2022, 102, 4640–4646. [Google Scholar] [CrossRef]

- Wardhani, D.H.; Wardana, I.N.; Ulya, H.N.; Cahyono, H.; Kumoro, A.C.; Aryanti, N. The effect of spray-drying inlet conditions on iron encapsulation using hydrolysed glucomannan as a matrix. Food Bioprod. Process. 2020, 123, 72–79. [Google Scholar] [CrossRef]

- Başyiğit, B.; Sağlam, H.; Kandemir, Ş.; Karaaslan, A.; Karaaslan, M. Microencapsulation of sour cherry oil by spray drying: Evaluation of physical morphology, thermal properties, storage stability, and antimicrobial activity. Powder Technol. 2020, 364, 654–663. [Google Scholar] [CrossRef]

- Kaur, R.; Kaur, K. Effect of processing on color, rheology and bioactive compounds of different sweet pepper purees. Plant Foods Hum. Nutr. 2020, 75, 369–375. [Google Scholar] [CrossRef]

- Singh, A.P.; Siddiqui, J.; Diosady, L.L. Characterizing the pH-dependent release kinetics of food-grade spray drying encapsulated iron microcapsules. Food Bioprocess Technol. 2018, 11, 435–446. [Google Scholar] [CrossRef]

- Pratap-Singh, A.; Leiva, A. Double fortified (iron and zinc) spray-dried microencapsulated premix for food fortification. LWT 2021, 151, 112189. [Google Scholar] [CrossRef]

- Li, Y.O. Development of Microencapsulation-Based Technologies for Micronutrient Fortification in Staple Foods for Developing Countries; University of Toronto: Toronto, ON, Canada, 2009. [Google Scholar]

| Microcapsules O | T1O | T2O | T3O | T4O | T5O | T6O | ||||||

| Properties | ± SD | * | ± SD | * | ± SD | * | ± SD | * | ± SD | * | ± SD | * |

| Iron (mg/g) | 1.99 ± 0.01 | a | 1.67 ± 0.01 | b | 1.34 ± 0.01 | c | 2.02 ± 0.01 | d | 1.87 ± 0.02 | e | 1.76 ± 0.02 | f |

| TOC (%) | 13.98 ± 0.01 | a | 14.50 ± 0.01 | b | 14.63 ± 0.05 | b | 13.78 ± 0.01 | a | 14.50 ± 0.03 | b | 14.56 ± 0.04 | b |

| EE (%) | 80.24 ± 0.21 | a | 66.03 ± 0.44 | b | 52.94 ± 0.11 | c | 78.72 ± 0.10 | d | 74.22 ± 0.73 | e | 69.86 ± 0.73 | f |

| Yield (%) | 53.69 ± 1.14 | ab | 50.55 ± 1.92 | a | 50.98 ± 1.91 | a | 56.99 ± 0.31 | b | 55.60 ± 0.57 | ab | 54.04 ± 1.46 | ab |

| Moisture (%) | 6.07 ± 0.02 | a | 5.07 ± 0.06 | bc | 4.52 ± 0.24 | cd | 5.27 ± 0.22 | b | 4.64 ± 0.12 | cd | 4.31 ± 0.08 | e |

| Aw | 0.43 ± 0.003 | a | 0.41 ± 0.004 | b | 0.38 ± 0.004 | c | 0.41 ± 0.001 | b | 0.40 ± 0.004 | d | 0.38 ± 0.002 | c |

| L* | 54.06 ± 0.02 | a | 55.05 ± 0.03 | b | 59.16 ± 0.11 | c | 55.95 ± 0.28 | d | 58.11 ± 0.22 | e | 60.05 ± 0.37 | f |

| a* | 11.34 ± 0.05 | a | 11.57 ± 0.01 | a | 9.63 ± 0.06 | b | 10.62 ± 0.18 | c | 10.06 ± 0.09 | d | 8.81 ± 0.17 | e |

| b* | 19.09 ± 0.07 | a | 20.55 ± 0.08 | b | 20.06 ± 0.06 | c | 18.59 ± 0.18 | d | 20.26 ± 0.07 | bc | 19.46 ± 0.17 | e |

| ΔE*ab | 11.41 ± 0.30 | a | 12.68 ± 0.31 | b | 16.86 ± 0.18 | c | 13.30 ± 0.31 | b | 15.82 ± 0.25 | d | 17.84 ± 0.67 | e |

| Particle size (µm) | 4.26 0.13 | a | 6.23 ± 0.05 | b | 6.73 ± 0.07 | c | 5.46 ± 0.06 | d | 5.60 ± 0.12 | e | 6.28 ± 0.10 | f |

| ζ potential (mV) | −0.11 ± 0.16 | a | −0.98 ± 0.23 | b | −2.76 ± 0.91 | c | −2.90 ± 0.70 | d | −3.43 ± 0.47 | e | −3.51 ± 0.73 | f |

| Microcapsules V | T1V | T2V | T3V | T4V | T5V | T6V | ||||||

| Iron (mg/g) | 1.88 ± 0.01 | a | 1.73 ± 0.01 | b | 1.54 ± 0.02 | c | 1.93 ± 0.02 | d | 1.77 ± 0.01 | e | 1.56 ± 0.01 | f |

| TOC (%) | 13.07 ± 0.02 | a | 13.39 ± 0.14 | ab | 13.97 ± 0.04 | ab | 12.80 ± 0.13 | a | 13.65 ± 0.02 | ab | 14.88 ± 0.09 | b |

| EE (%) | 83.95 ± 0.22 | a | 78.90 ± 0.14 | b | 69.54 ± 0.15 | c | 85.88 ± 0.12 | d | 77.12 ± 0.10 | e | 68.43 ± 0.82 | f |

| Yield (%) | 60.37 ± 1.11 | a | 55.38 ± 1.46 | b | 54.93 ± 0.50 | b | 63.40 ± 0.50 | a | 62.38 ± 1.40 | a | 61.88 ± 0.81 | a |

| Moisture (%) | 7.49 ± 0.01 | a | 7.27 ± 0.08 | ab | 7.19 ± 0.08 | b | 6.22 ± 0.02 | c | 5.80 ± 0.07 | d | 5.59 ± 0.01 | d |

| Aw | 0.43 ± 0.003 | a | 0.43 ± 0.002 | a | 0.40 ± 0.003 | b | 0.42 ± 0.002 | a | 0.42 ± 0.001 | c | 0.36 ± 0.001 | d |

| L* | 52.61 ± 0.08 | a | 55.99 ± 0.14 | b | 61.61 ± 0.05 | c | 54.66 ± 0.01 | d | 58.20 ± 0.26 | e | 62.59 ± 0.08 | f |

| a* | 11.32 ± 0.08 | a | 9.87 ± 0.07 | b | 7.17 ± 0.01 | c | 10.51 ± 0.02 | d | 9.05 ± 0.11 | e | 7.00 ± 0.05 | c |

| b* | 19.51 ± 0.07 | a | 19.91 ± 0.08 | b | 18.34 ± 0.04 | c | 19.54 ± 0.02 | a | 19.49 ± 0.10 | a | 18.09 ± 0.02 | d |

| ΔE*ab | 5.25 ± 0.33 | a | 8.78 ± 0.29 | b | 15.17 ± 0.23 | c | 7.39 ± 0.24 | d | 11.17 ± 0.47 | e | 16.17 ± 0.31 | f |

| Particle size (µm) | 5.52 ± 0.03 | a | 5.54 ± 0.02 | b | 7.34 ± 0.21 | c | 5.97 ± 0.11 | d | 6.92 ± 0.09 | e | 7.59 ± 0.15 | f |

| ζ potential (mV) | −0.30 ± 0.38 | a | −0.40 ± 0.05 | b | −1.46 ± 0.61 | c | −0.51 ± 0.12 | d | −1.10 ± 0.06 | e | −1.89 ± 0.16 | f |

| Element | Weight% | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T1O | T2O | T3O | T4O | T5O | T6O | T1V | T2V | T3V | T4V | T5V | T6V | |

| C | 46.1% | 43.3% | 39.8% | 43.5% | 41.2% | 39.7% | 41.6% | 39.8% | 41.7% | 39.3% | 39.1% | 41.7% |

| O | 25.8% | 33.8% | 37.7% | 33.5% | 35.7% | 38.6% | 24.1% | 33.4% | 35.1% | 25.8% | 37.0% | 34.4% |

| N | 12.3% | 10.1% | 9.8% | 10.1% | 9.1% | 8.6% | 7.7% | 7.5% | 5.8% | 7.6% | 7.8% | 6.1% |

| Na | 8.3% | 7.0% | 6.4% | 6.2% | 7.0% | 6.7% | 15.3% | 9.6% | 8.8% | 14.5% | 7.8% | 9.4% |

| Cl | 6.7% | 4.9% | 5.4% | 6.0% | 6.1% | 5.3% | 10.4% | 8.9% | 7.8% | 11.9% | 7.5% | 7.3% |

| S | 0.5% | 0.6% | 0.6% | 0.3% | 0.4% | 0.7% | 0.4% | 0.3% | 0.3% | 0.4% | 0.3% | 0.4% |

| Fe | 0.1% | 0.1% | 0.1% | 0.2% | 0.2% | 0.2% | 0.2% | 0.2% | 0.2% | 0.3% | 0.3% | 0.3% |

| P | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% |

| K | 0.1% | 0.1% | 0.1% | 0.1% | 0.2% | 0.1% | 0.2% | 0.2% | 0.2% | 0.1% | 0.1% | 0.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ligarda-Samanez, C.A.; Moscoso-Moscoso, E.; Choque-Quispe, D.; Ramos-Pacheco, B.S.; Arévalo-Quijano, J.C.; Cruz, G.D.l.; Huamán-Carrión, M.L.; Quispe-Quezada, U.R.; Gutiérrez-Gómez, E.; Cabel-Moscoso, D.J.; et al. Native Potato Starch and Tara Gum as Polymeric Matrices to Obtain Iron-Loaded Microcapsules from Ovine and Bovine Erythrocytes. Polymers 2023, 15, 3985. https://doi.org/10.3390/polym15193985

Ligarda-Samanez CA, Moscoso-Moscoso E, Choque-Quispe D, Ramos-Pacheco BS, Arévalo-Quijano JC, Cruz GDl, Huamán-Carrión ML, Quispe-Quezada UR, Gutiérrez-Gómez E, Cabel-Moscoso DJ, et al. Native Potato Starch and Tara Gum as Polymeric Matrices to Obtain Iron-Loaded Microcapsules from Ovine and Bovine Erythrocytes. Polymers. 2023; 15(19):3985. https://doi.org/10.3390/polym15193985

Chicago/Turabian StyleLigarda-Samanez, Carlos A., Elibet Moscoso-Moscoso, David Choque-Quispe, Betsy S. Ramos-Pacheco, José C. Arévalo-Quijano, Germán De la Cruz, Mary L. Huamán-Carrión, Uriel R. Quispe-Quezada, Edgar Gutiérrez-Gómez, Domingo J. Cabel-Moscoso, and et al. 2023. "Native Potato Starch and Tara Gum as Polymeric Matrices to Obtain Iron-Loaded Microcapsules from Ovine and Bovine Erythrocytes" Polymers 15, no. 19: 3985. https://doi.org/10.3390/polym15193985

APA StyleLigarda-Samanez, C. A., Moscoso-Moscoso, E., Choque-Quispe, D., Ramos-Pacheco, B. S., Arévalo-Quijano, J. C., Cruz, G. D. l., Huamán-Carrión, M. L., Quispe-Quezada, U. R., Gutiérrez-Gómez, E., Cabel-Moscoso, D. J., Muñoz-Melgarejo, M., & Calsina Ponce, W. C. (2023). Native Potato Starch and Tara Gum as Polymeric Matrices to Obtain Iron-Loaded Microcapsules from Ovine and Bovine Erythrocytes. Polymers, 15(19), 3985. https://doi.org/10.3390/polym15193985